Livestock And Poultry Pellet Mill Screw Type Ring Die

The Screw Type Pellet Ring Die for livestock and poultry feed production is a cr...

The Screw Type Pellet Ring Die for livestock and poultry feed production is a cr...

The Screw Type Pellet Ring Die for aqua feed production is a vital component in ...

Biomass pellet ring dies play a critical role in the production of biomass pelle...

These ring dies are made from high-quality stainless steel, such as X46Cr13, which are martensitic stainless steels known for their strength and corrosion resistance. This ensures the ring die can withstand the continuous pressure and friction from the pelletizing process.

The Pellet Mill Screw Type Stainless Steel Die is designed to handle the intense pressure and friction involved in the pelletizing process. The die is constructed from high-grade stainless steel, which is heat-treated to achieve hardness. This ensures it can endure the intense compression forces generated during pelletizing. It also has high tensile strength, making it resistant to deformation even under continuous heavy-duty operation. Stainless steel is highly resistant to rust and corrosion, particularly when exposed to moisture-rich environments or corrosive materials like those in biomass and fertilizer. The screw-type stainless steel die is designed with wear-resistant properties, preventing premature wear from the constant grinding action of the material.

Biomass pellets mill pellet ring dies are crucial components in the production of biomass pellets. T...

View MoreLiyang Weikeer Feed Machinery Manufacturing Co., Ltd.participating in the AGRAVIA 2026 exhibition, t...

View MoreA dimpled bearing steel pellet roller is a critical component used in pelletizing and briquetting sy...

View MorePellet mills are essential equipment in feed, biomass, and industrial pellet production. At the hear...

View MoreThe ring die is one of the most critical components in a complex fertilizer pellet mill. It directly...

View MoreDimpled bearing steel pellet rollers are critical components in pelletizing processes used in indust...

View MoreImportance of Maintenance and Optimization Measures for Pellet Mill Screw Type Stainless Steel Ring Die at Liyang Weikeer Feed Machinery Manufacturing Co.Ltd.

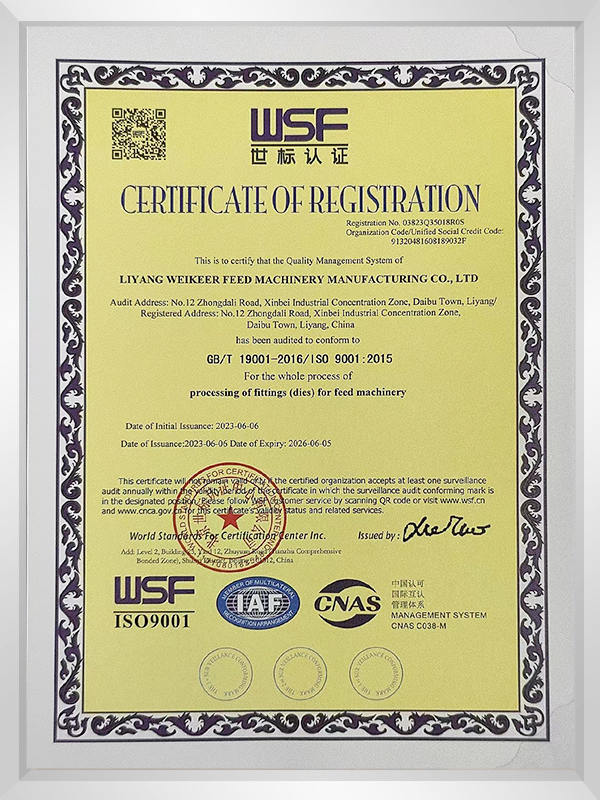

Liyang Weikeer Feed Machinery Manufacturing Co., Ltd., established in 1996, has become a leader in the production of high-quality pellet mill dies, rollers, and related components. Located near the scenic Tianmu Lake, the company operates a modern factory covering an area of 13,000 m², with more than 7,000 m² dedicated to the production workshop. Weikeer’s commitment to delivering superior products is supported by advanced manufacturing technologies, including CNC machines (HTT KH-4-100) and HZQL heat treatment equipment. In this article, we will explore the importance of maintenance and optimization measures for the pellet mill screw type stainless steel ring dies, which are a key part of Weikeer’s product line.

pellet mill screw type stainless steel ring dies are integral to the feed production process, shaping the feed into high-quality pellets. These dies are essential for determining the quality, size, and consistency of the pellets, which in turn affects the efficiency of the entire pelletizing process. At Liyang Weikeer, the company’s advanced manufacturing technologies ensure that these dies are durable and reliable, meeting the demanding needs of global brands like ZCME, CPM, IDAH, Buhler, Famsun, Andritz, Van Aarsen, Yeong Ming, and Chiatung. As the demand for high-quality animal feed increases, maintaining and optimizing these dies is critical for ensuring operational efficiency and minimizing downtime.

To maintain the high performance of pellet mill screw type stainless steel ring dies, regular maintenance is essential. Liyang Weikeer’s focus on precision and quality manufacturing means that our dies are built to last. However, even the most robust dies can experience wear over time due to the intense pressures and high temperatures associated with pelletizing. Therefore, routine inspection and maintenance are crucial to extend the lifespan of the dies and ensure optimal performance.

Weikeer’s advanced production capabilities, including the use of state-of-the-art CNC machines, enable the production of dies that are precisely engineered to withstand wear. Regular cleaning and lubrication help prevent the buildup of residue and reduce friction, ensuring that the die continues to function efficiently. Additionally, inspections of the rollers and die components are essential to identify any signs of wear or damage early, preventing further issues and reducing the risk of costly repairs or unplanned downtime.

In addition to regular maintenance, optimization measures are key to enhancing the performance of pellet mill screw type stainless steel ring dies. Liyang Weikeer continuously invests in technology to improve product performance. This includes the implementation of advanced heat treatment equipment, such as the HZQL heat treatment system, which increases the durability and wear resistance of the dies. This technological investment allows Weikeer to offer pellet mill dies that can endure higher operational pressures, increasing both their lifespan and the efficiency of the entire pelletizing system.

By fine-tuning the design of the dies, such as optimizing hole diameter and pattern, Weikeer ensures that the dies perform efficiently, producing pellets with the correct density and consistency. Customization of the die design based on the specific needs of different feed formulations is an example of how Weikeer helps its customers optimize their production processes. Optimizing these parameters reduces energy consumption and minimizes wear on the dies, which can ultimately reduce operational costs.

Liyang Weikeer’s ongoing investment in advanced CNC machines and heat treatment technologies plays a significant role in ensuring the highest quality and durability of its pellet mill dies. The CNC (HTT KH-4-100) machines used by Weikeer allow for precise manufacturing of ring dies and other components, ensuring that they meet the most stringent standards for performance and reliability. This technology not only ensures the production of high-quality dies but also contributes to faster turnaround times and greater production flexibility.

The use of HZQL heat treatment equipment further enhances the performance of the dies. This heat treatment process ensures that the stainless steel used in the dies is hardened and made more resistant to wear, even under the intense conditions of continuous pellet production. As a result, customers benefit from dies that offer increased durability, reduced wear, and enhanced efficiency.

For feed manufacturers, the maintenance and optimization of pellet mill screw type stainless steel ring dies translate into significant cost savings. By reducing the frequency of repairs and replacements through proactive maintenance, companies can avoid unplanned downtime and the associated costs. Weikeer’s investment in high-quality manufacturing equipment ensures that the dies are long-lasting and require less frequent replacement, thus lowering the overall operating costs for customers.

Furthermore, optimized dies help reduce energy consumption during the pelletizing process. By fine-tuning the design and adjusting operational parameters, feed producers can improve efficiency, leading to lower energy bills and improved overall profitability. This approach aligns with Weikeer’s goal of maximizing the benefit to its customers, ensuring that they achieve optimal performance while minimizing operational costs.

Pellet quality is a critical factor in the feed industry, directly affecting the nutritional value and digestibility of the pellets for livestock and poultry. Well-maintained and optimized pellet mill screw type stainless steel ring dies produce pellets that are more uniform in size and density, which is essential for ensuring consistent feed quality. Weikeer’s commitment to quality is reflected in the advanced manufacturing technologies that allow for the precise production of these dies, ensuring that customers receive products that meet the highest standards.

In addition to improving pellet quality, optimized dies also contribute to greater operational efficiency. With the reduced need for maintenance and the extended lifespan of the dies, feed manufacturers can focus on increasing their production output rather than dealing with frequent repairs or replacements. This results in higher productivity and less downtime, contributing to an overall improvement in the profitability of the feed production process.

At Liyang Weikeer Feed Machinery Manufacturing Co., Ltd., the importance of regular maintenance and optimization measures for pellet mill screw type stainless steel ring dies cannot be overstated. Through a combination of advanced manufacturing technologies, such as CNC machining and heat treatment, and a commitment to providing high-quality products, Weikeer ensures that its pellet mill dies are built for performance and durability. By prioritizing maintenance and optimization, feed producers can enhance operational efficiency, reduce costs, and improve pellet quality. As Weikeer continues to invest in state-of-the-art technologies and offer customized solutions, it remains a trusted partner for feed manufacturers worldwide, helping them maximize the benefits of their feed production systems.