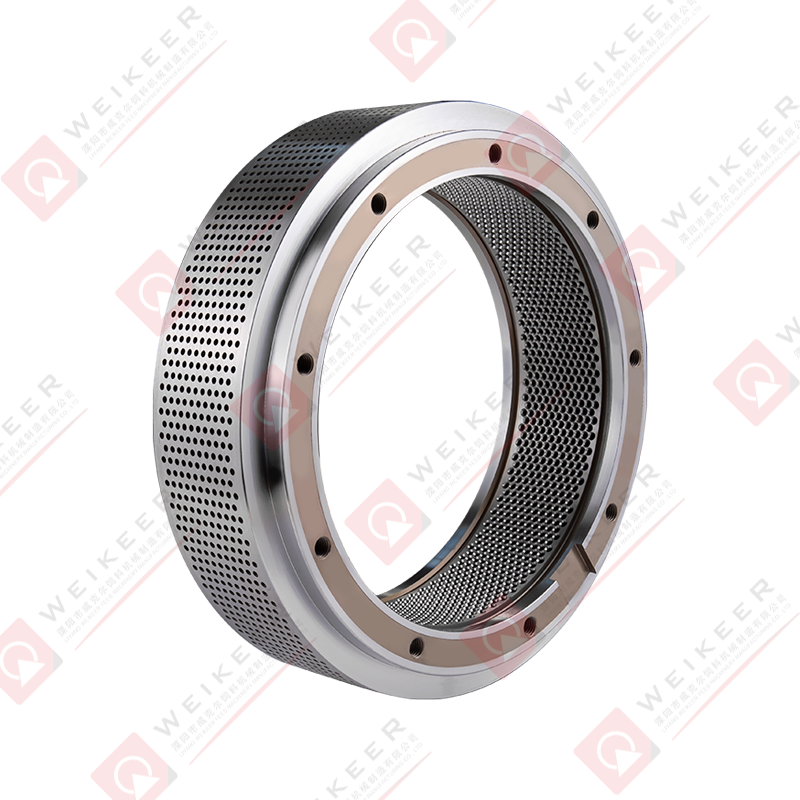

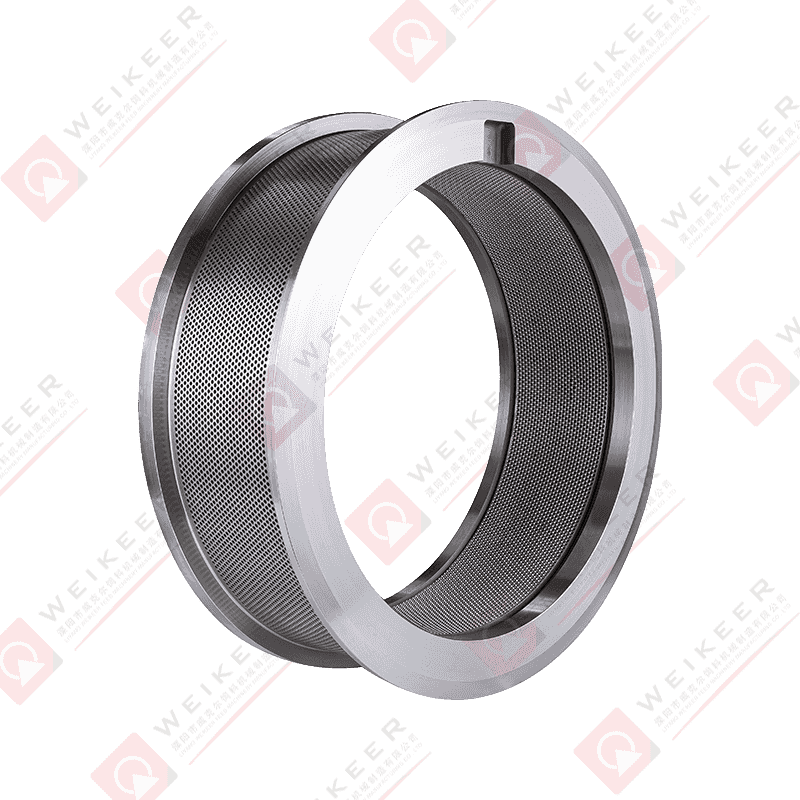

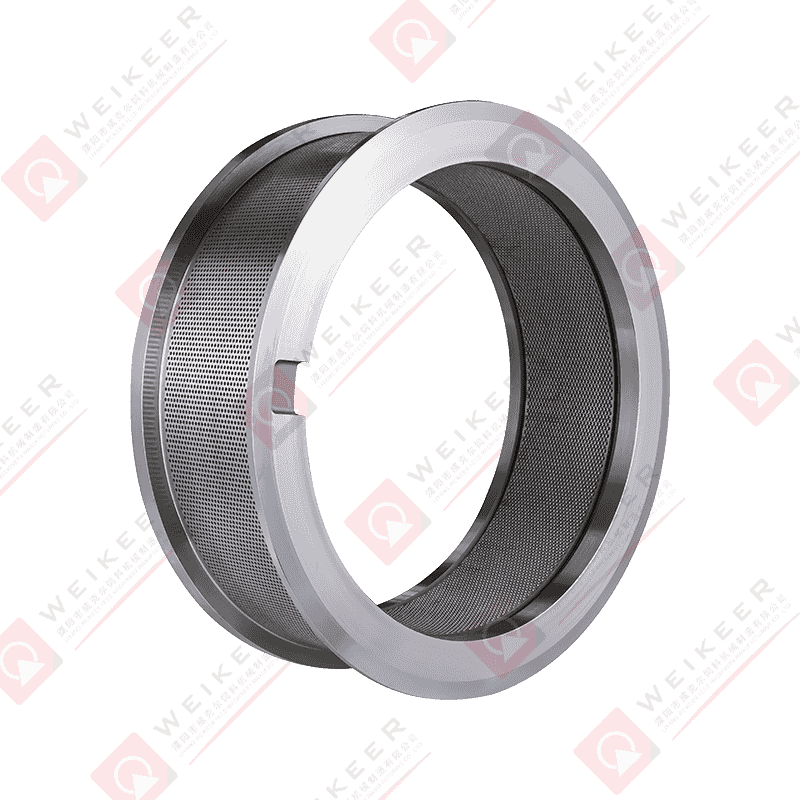

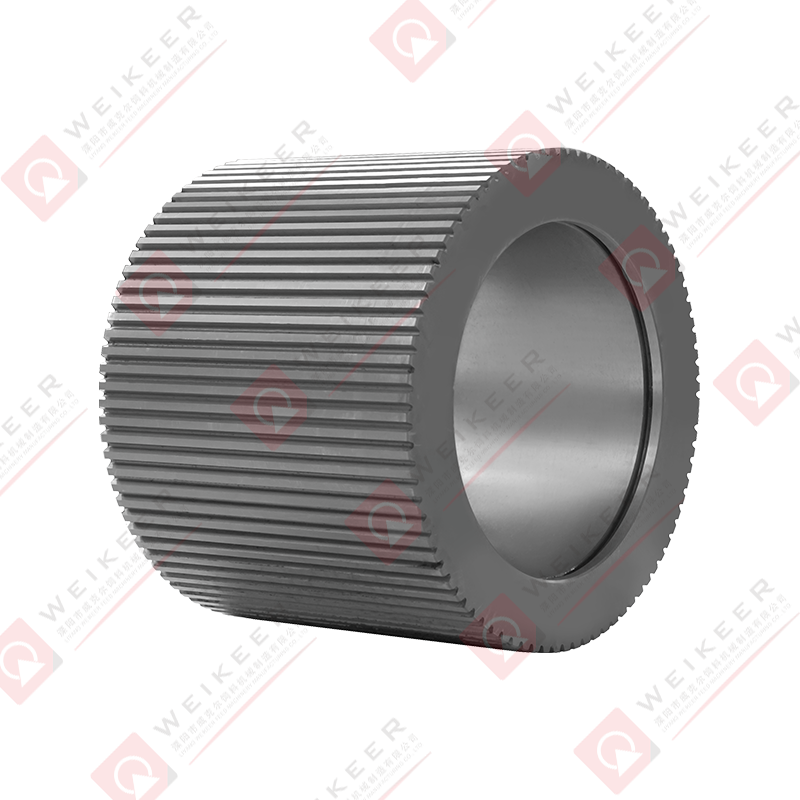

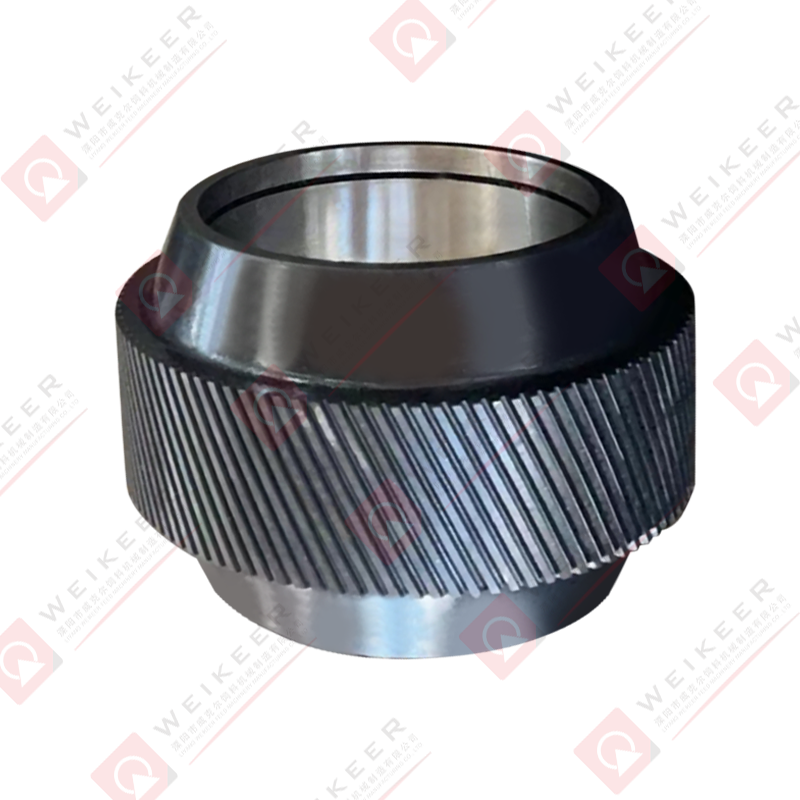

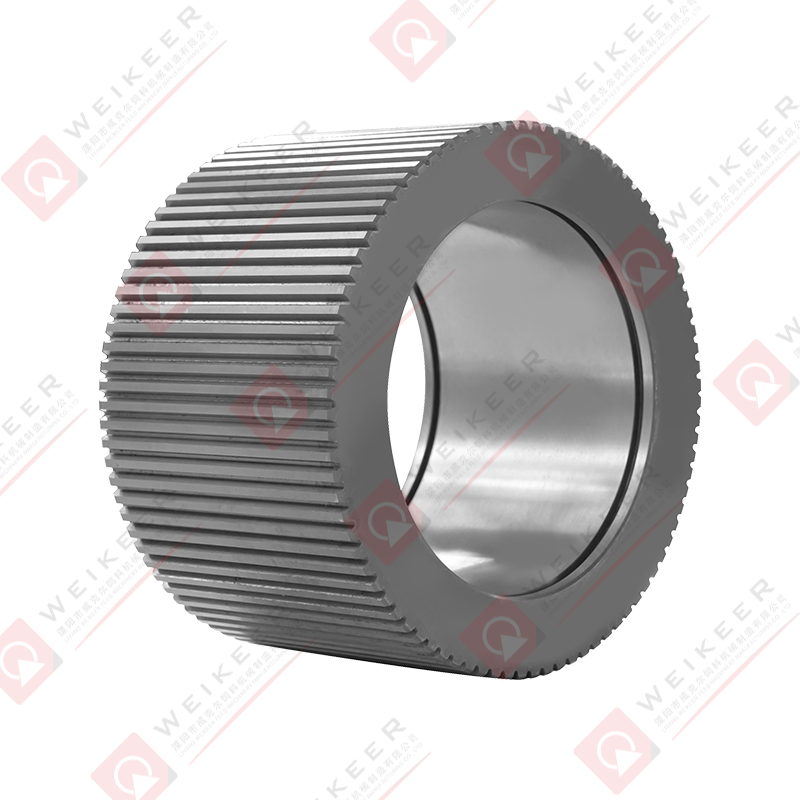

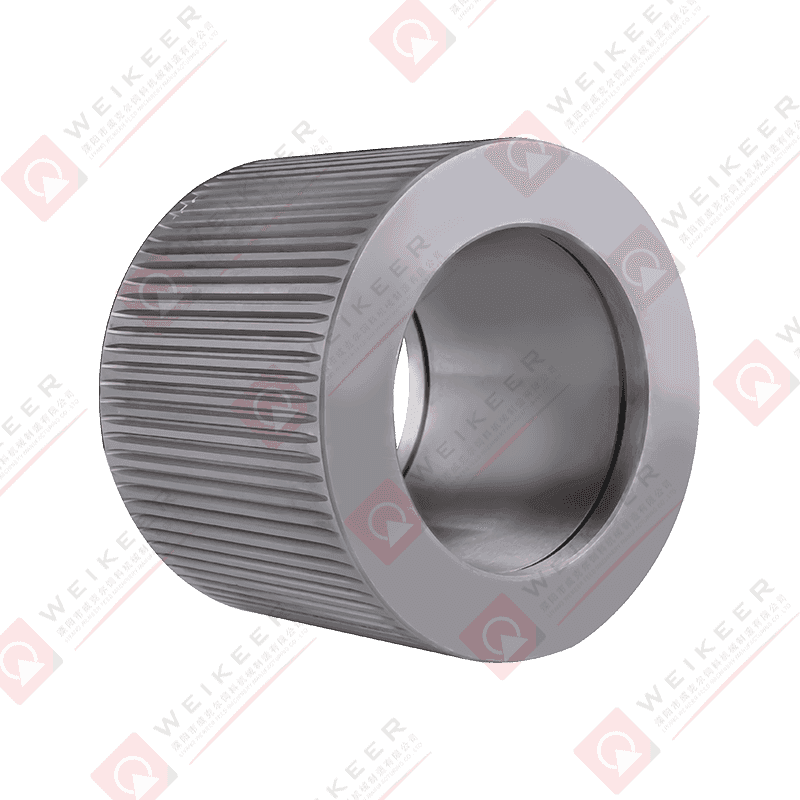

Pellet mills are essential equipment in feed, biomass, and industrial pellet production. At the heart of these mills is the ring die, which determines pellet quality, production efficiency, and machine longevity. Anchorear stainless steel ring dies have emerged as a premium solution for pellet mills, offering superior durability, corrosion resistance, and consistent performance compared to traditional materials.

This article explores the key advantages of using Anchorear stainless steel ring dies in pellet mills, highlighting their material properties, operational benefits, and maintenance considerations.

High Durability and Wear Resistance

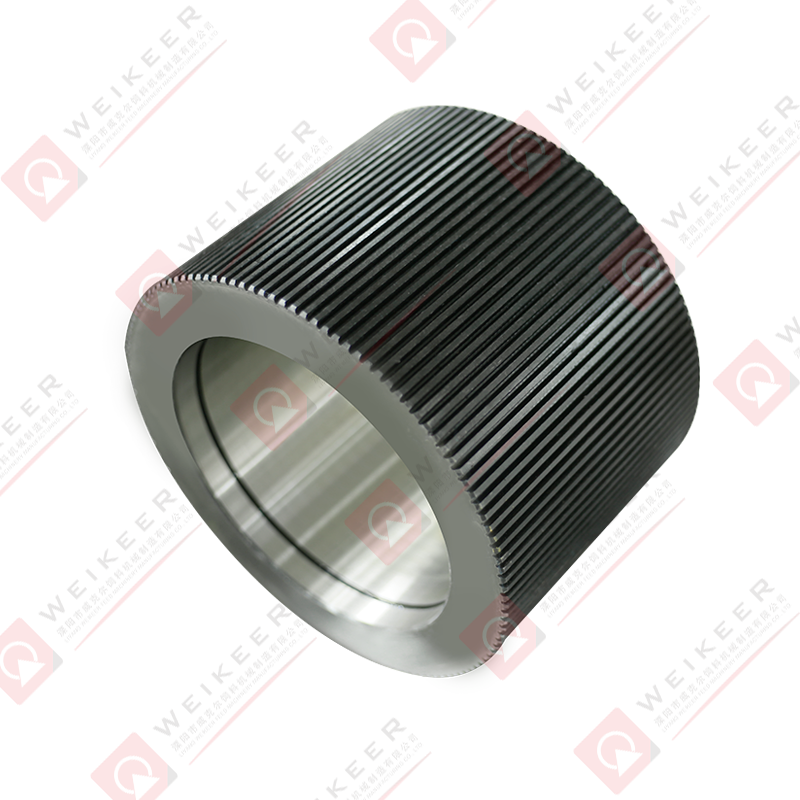

One of the primary benefits of Anchorear stainless steel ring dies is their exceptional durability. Pellet production involves high pressure and friction as raw materials are compressed through die holes. Conventional dies made from low-grade steel can wear quickly, leading to uneven pellet sizes and frequent replacements.

Anchorear stainless steel is engineered to resist abrasion, maintaining its structural integrity even under continuous high-pressure operation. This wear resistance reduces downtime and replacement costs while ensuring consistent pellet output.

Corrosion and Chemical Resistance

Many pellet feedstocks, such as those containing minerals, salts, or high moisture, can cause corrosion over time. Anchorear stainless steel ring dies offer excellent resistance to oxidation and chemical attack, which extends the die’s service life.

This corrosion resistance is particularly valuable in biomass pellet production, where acidic or chemically active materials are common. By using Anchorear stainless steel dies, operators can maintain consistent pellet quality and avoid contamination caused by corroded surfaces.

Improved Pellet Quality and Consistency

The precision engineering of Anchorear ring dies allows for uniform die hole diameters and surface finishes. Consistency in die hole size ensures that each pellet has a uniform density, shape, and weight, which is critical for feed processing and biomass applications.

Uniform pellet size also improves storage and transport efficiency and reduces breakage during handling. This results in higher product quality and customer satisfaction.

Enhanced Production Efficiency

Anchorear stainless steel ring dies can withstand high-speed operation without deforming or overheating. Their excellent thermal conductivity and strength allow pellet mills to operate at optimal speeds, increasing throughput while maintaining consistent pellet quality.

The durability and low wear rate of these dies also minimize downtime for maintenance or replacement, further enhancing overall production efficiency and cost-effectiveness.

Low Maintenance Requirements

Maintenance is a significant factor in pellet mill operation costs. Anchorear stainless steel ring dies require less frequent replacement and surface conditioning than conventional dies, thanks to their wear and corrosion resistance.

Routine maintenance, such as cleaning and lubrication of the die and rollers, is simpler and more predictable, reducing labor requirements and downtime while ensuring optimal machine performance.

Versatility in Pellet Mill Applications

Anchorear ring dies are suitable for a wide range of pellet mill applications, including animal feed, biomass, and industrial material processing. Their chemical and thermal resistance allows them to handle various raw materials, from high-moisture feedstocks to abrasive biomass fibers.

This versatility reduces the need for multiple die types for different materials, simplifying inventory management and operational planning.

Cost Savings Over Time

While Anchorear stainless steel ring dies may have a higher initial cost compared to traditional dies, their longevity and reduced maintenance requirements lead to significant cost savings over time. Longer service life means fewer replacements, lower labor costs, and reduced production interruptions.

Additionally, consistent pellet quality minimizes waste and improves customer satisfaction, further enhancing the return on investment.

Installation and Operational Considerations

Proper installation and alignment are crucial to maximizing the benefits of Anchorear stainless steel ring dies. Ensuring correct roller-to-die clearance and routine inspection of die surfaces helps maintain optimal performance. Operators should also follow manufacturer guidelines for lubrication, speed, and material feed to prevent premature wear.

Conclusion

Anchorear stainless steel ring dies provide numerous advantages for pellet mill operations, including high durability, corrosion resistance, consistent pellet quality, enhanced efficiency, low maintenance, and versatility across materials. Investing in these high-quality dies ensures reliable performance, reduces operational costs, and maximizes productivity over the long term. For pellet mill operators seeking to optimize performance and product quality, Anchorear stainless steel ring dies represent a smart and cost-effective choice.

русский

русский Español

Español عربى

عربى 中文简体

中文简体