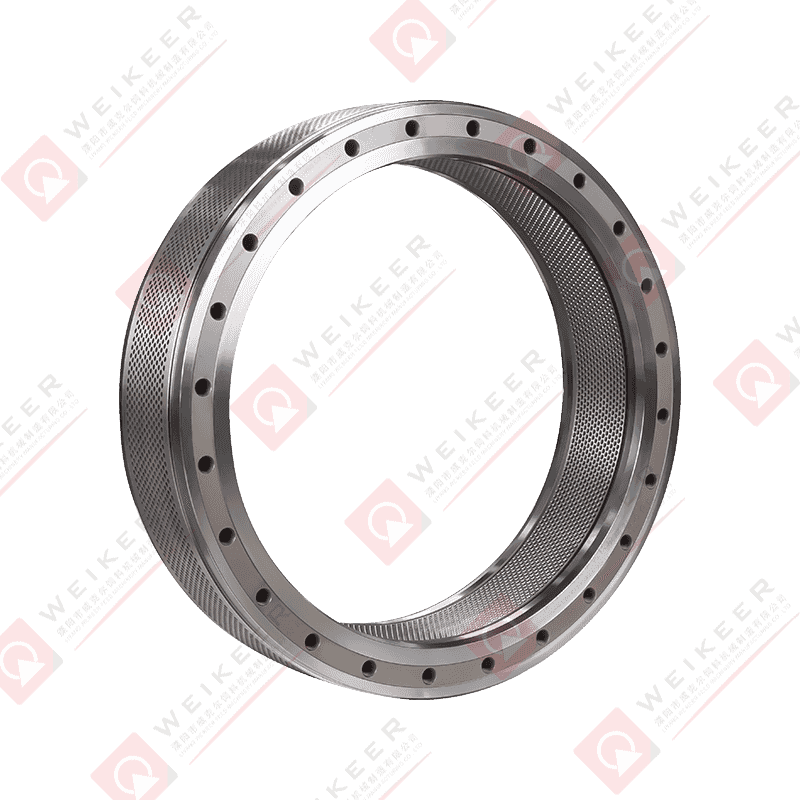

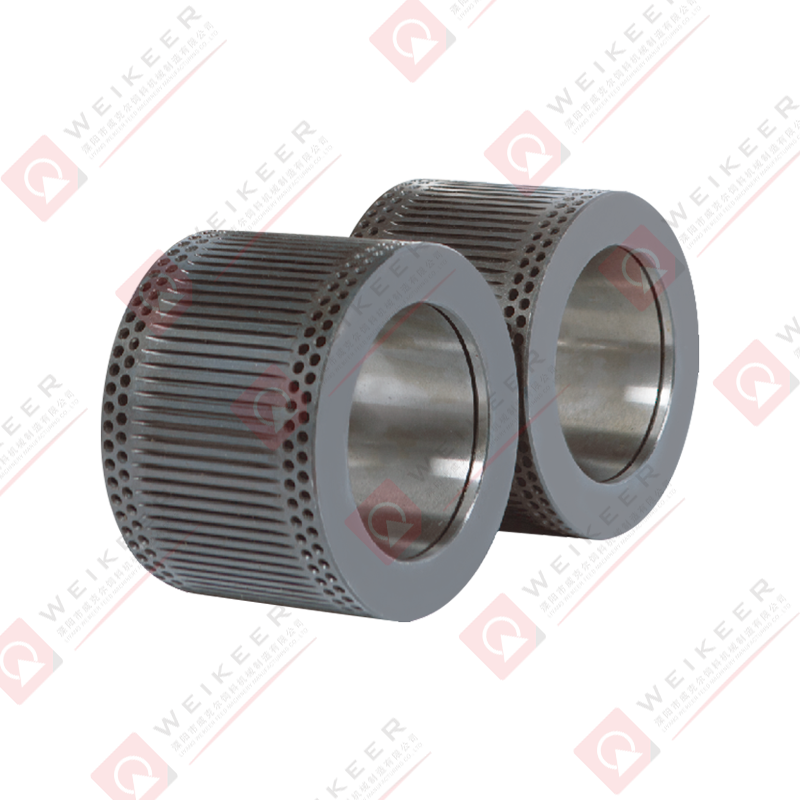

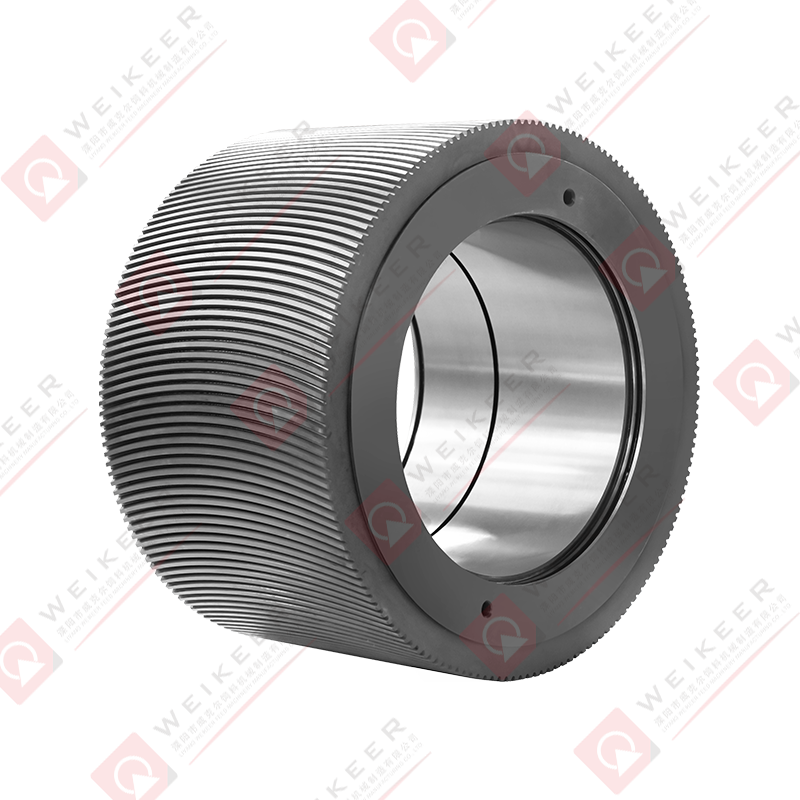

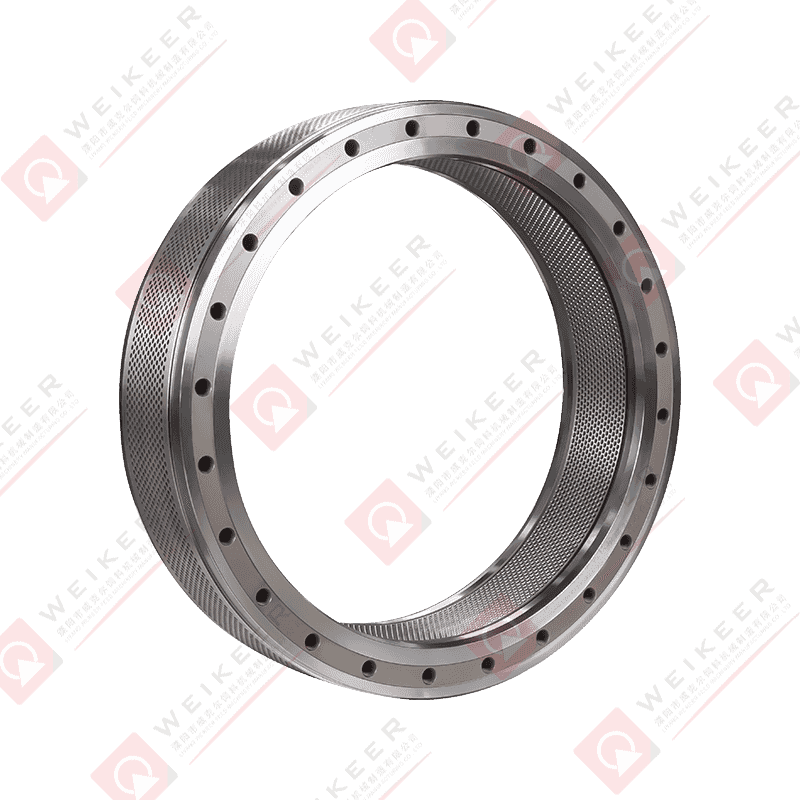

Biomass pellets mill pellet ring dies are crucial components in the production of biomass pellets. They determine the quality, density, and output of pellets by shaping raw materials into uniform forms. Ring dies are preferred over flat dies for large-scale production because of their superior efficiency and durability.

Material Composition of Ring Dies

The performance of a ring die depends largely on its material composition. High-quality steel alloys are commonly used, including chromium-molybdenum and high-carbon steel. These materials provide resistance against wear, corrosion, and heat, extending the lifespan of the die.

Hardness and Durability

Optimal hardness levels allow the die to withstand high pressures while minimizing wear. Heat treatment processes enhance the mechanical strength, preventing deformation and ensuring consistent pellet quality over time.

Corrosion Resistance

Biomass materials contain moisture and chemicals that can corrode ring dies. Using corrosion-resistant alloys or applying protective coatings reduces maintenance frequency and prevents downtime.

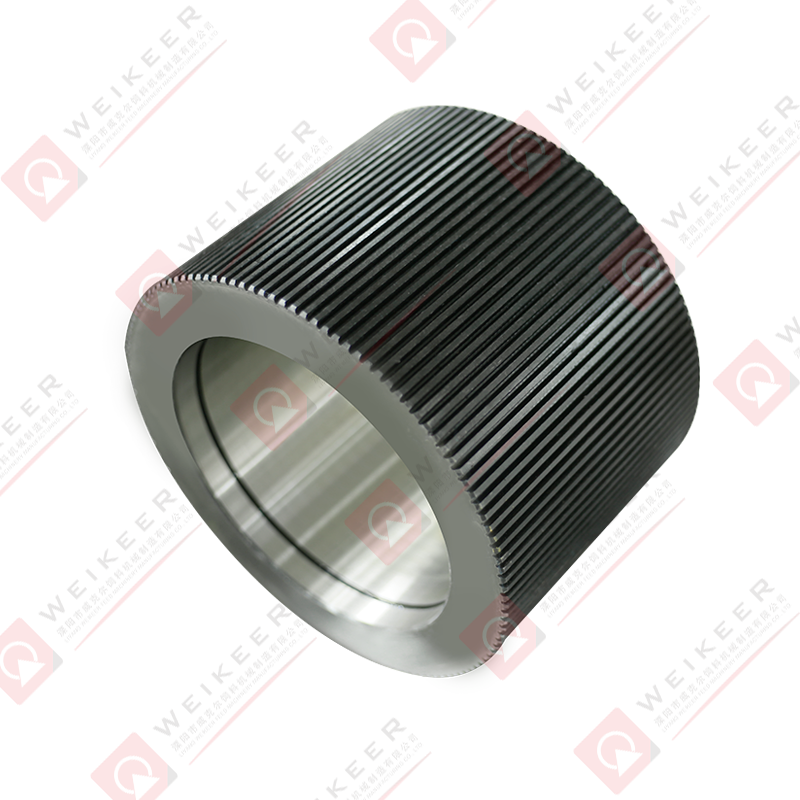

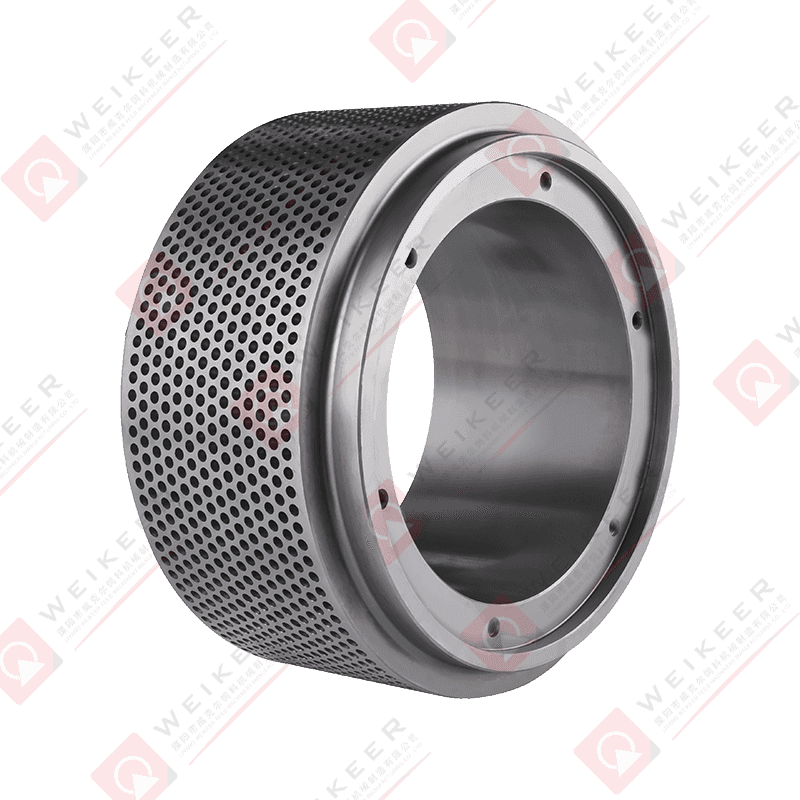

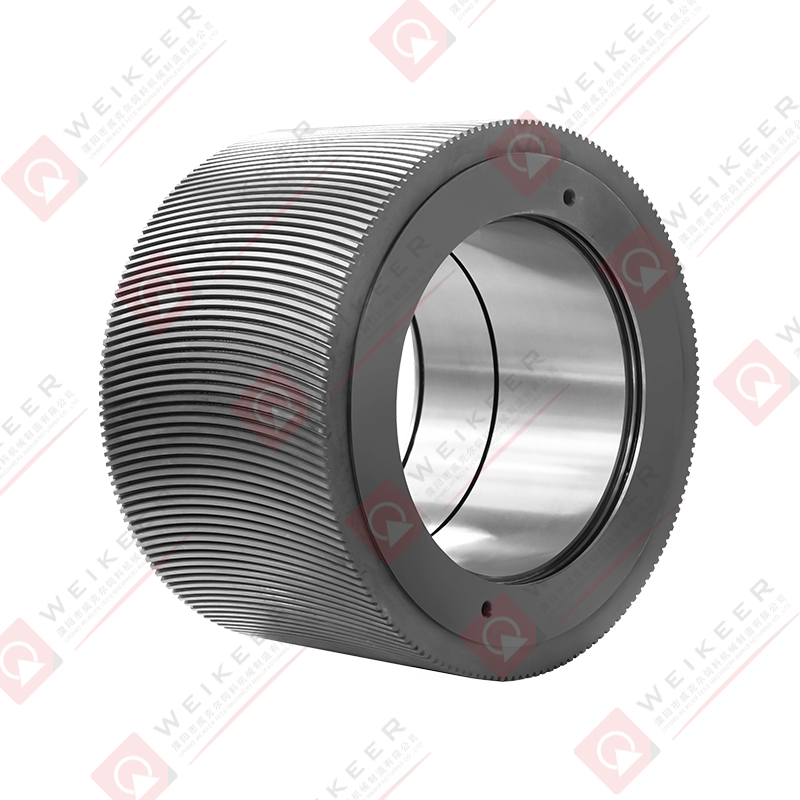

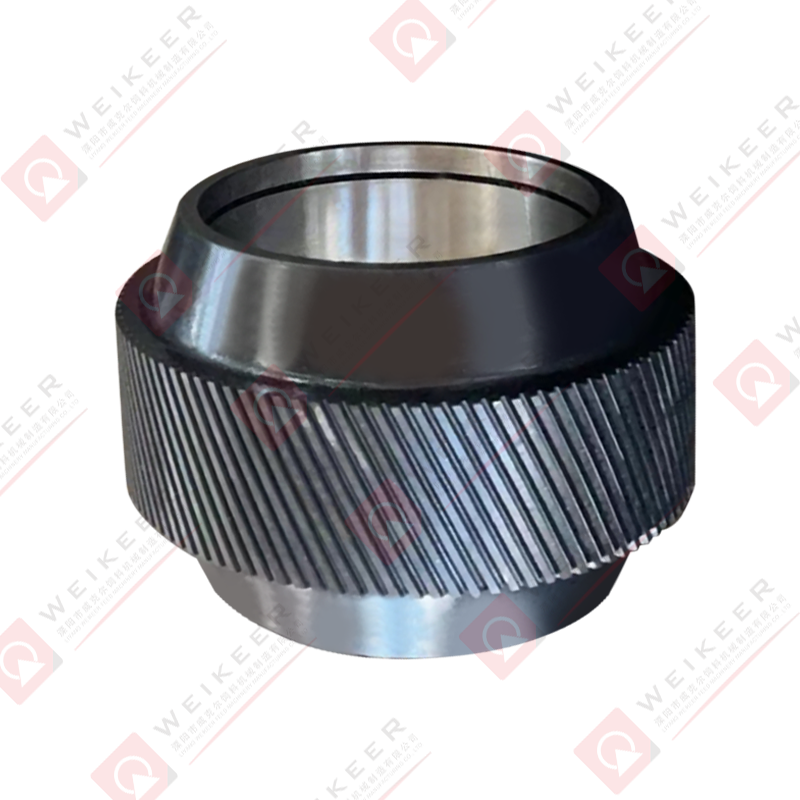

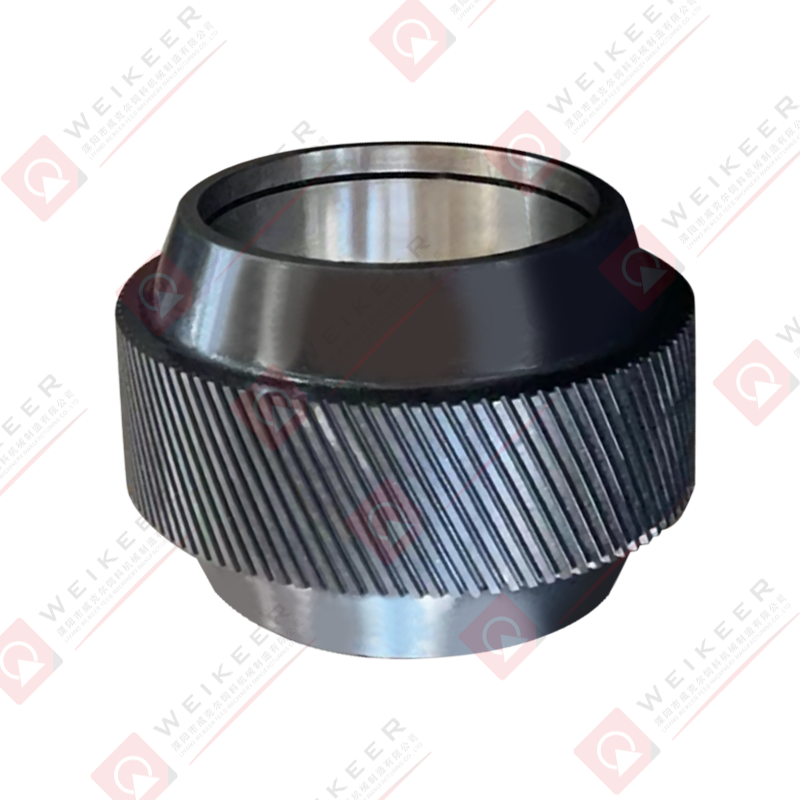

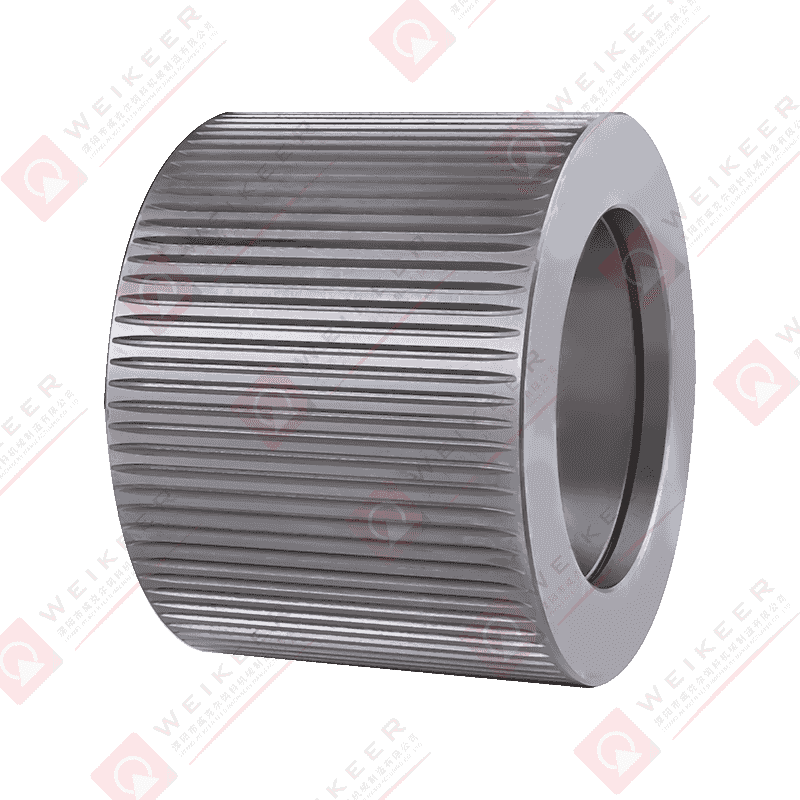

Design Features and Specifications

Ring dies are designed with precision holes through which biomass material is extruded. Factors such as hole diameter, compression ratio, and thickness directly affect pellet quality and production efficiency.

Hole Diameter and Shape

Smaller holes produce denser pellets, while larger holes increase throughput. The shape of the holes, typically circular or tapered, affects friction and material flow, impacting energy consumption and pellet hardness.

Compression Ratio

The compression ratio determines how tightly the biomass is compacted during pelleting. Higher ratios yield harder, longer-lasting pellets but require more energy, whereas lower ratios allow faster production at the expense of pellet density.

Maintenance and Longevity

Proper maintenance is essential to maximize the lifespan of a ring die. Regular inspection for wear, lubrication, and replacement of worn parts ensures consistent pellet quality and reduces operational costs.

Inspection and Wear Monitoring

Visual inspection can identify early signs of wear such as thinning, cracks, or hole deformation. Advanced monitoring techniques like ultrasonic testing detect internal defects before catastrophic failure occurs.

Lubrication and Cleaning

Lubricating the die rollers and cleaning residual biomass prevents material buildup, reducing friction and minimizing uneven wear. This practice also helps maintain energy efficiency during production.

Impact on Pellet Quality and Production Efficiency

The design and condition of the ring die directly influence pellet density, durability, and uniformity. A well-maintained die ensures high throughput and reduces production downtime, while poorly maintained dies increase breakage and waste.

Pellet Hardness and Durability

Uniform compression and proper die hole configuration create dense pellets resistant to breakage during storage and transportation, meeting industry standards for biomass fuel.

Energy Consumption and Efficiency

A correctly designed ring die reduces the energy required to extrude biomass, lowering operating costs. Smooth hole surfaces and optimal compression ratios decrease friction, contributing to higher efficiency.

Choosing the Right Ring Die for Your Mill

Selecting the appropriate ring die depends on biomass type, mill capacity, and desired pellet characteristics. Factors to consider include die diameter, thickness, hole size, and material composition.

Compatibility with Biomass Type

Different biomass materials like wood, straw, or agricultural waste require different die specifications. Softer materials may need larger holes and lower compression, while harder materials need smaller holes and higher compression ratios.

Mill Capacity Considerations

The ring die must match the production capacity of the pellet mill. Using an undersized die can limit output, while an oversized die may cause uneven wear and inefficiency.

Conclusion: Maximizing Productivity with the Right Ring Die

Biomass pellets mill pellet ring dies are integral to efficient and high-quality pellet production. Choosing the right material, design, and maintenance strategy ensures optimal pellet density, durability, and production efficiency while minimizing costs.

русский

русский Español

Español عربى

عربى 中文简体

中文简体