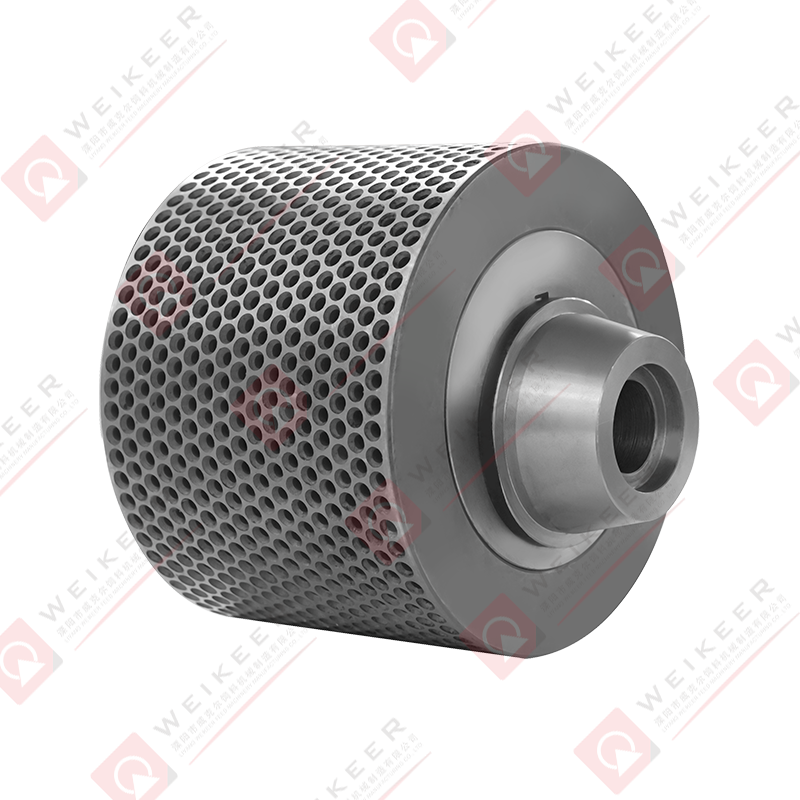

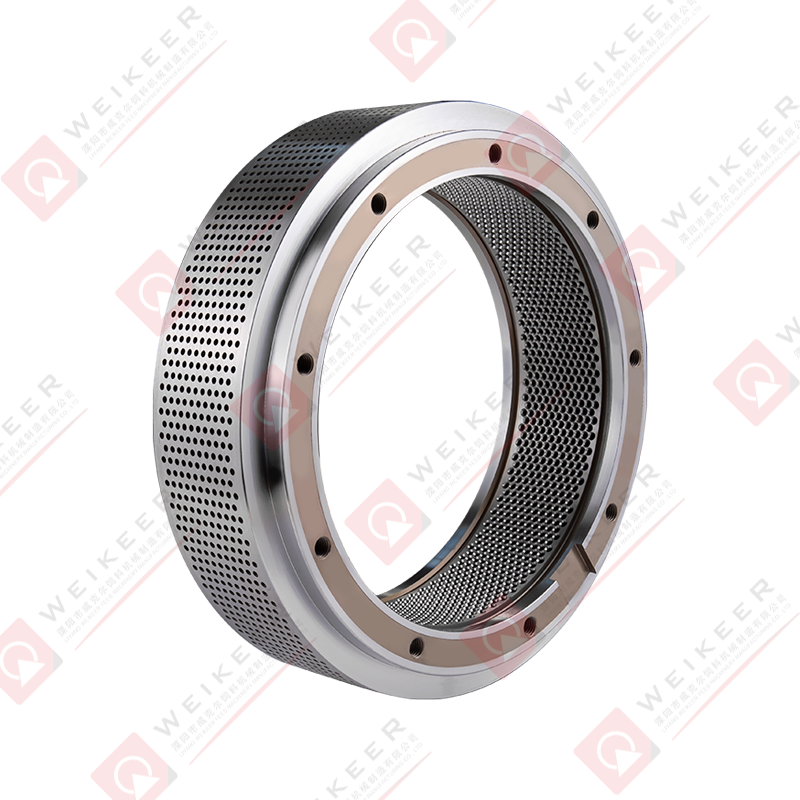

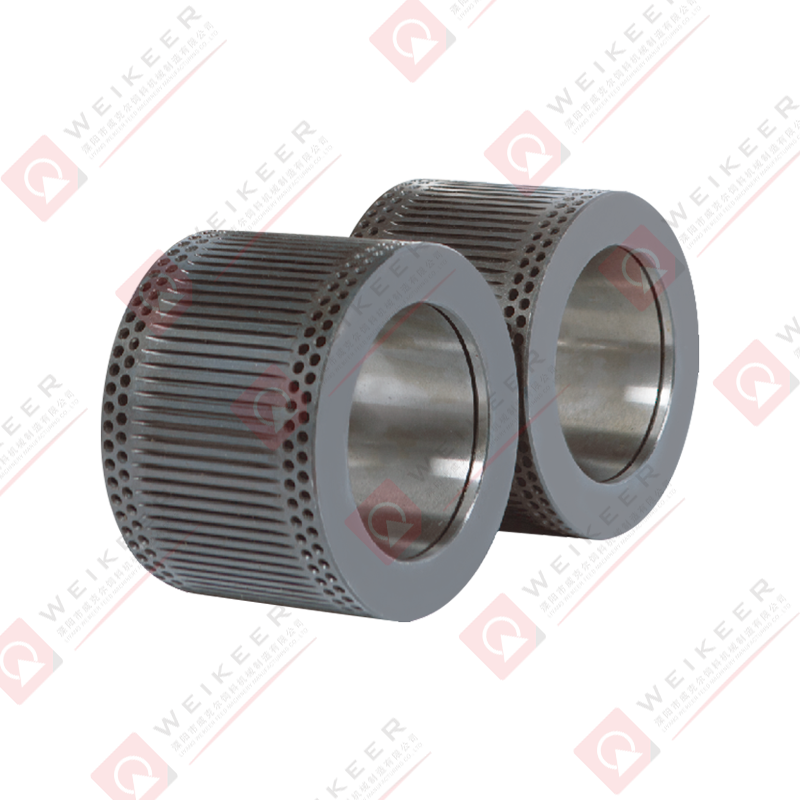

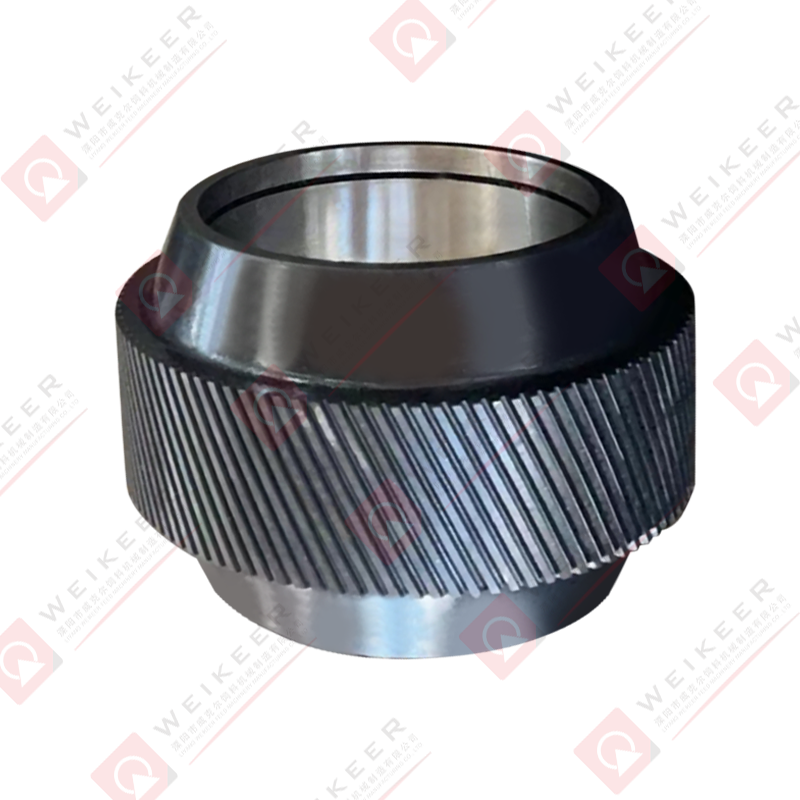

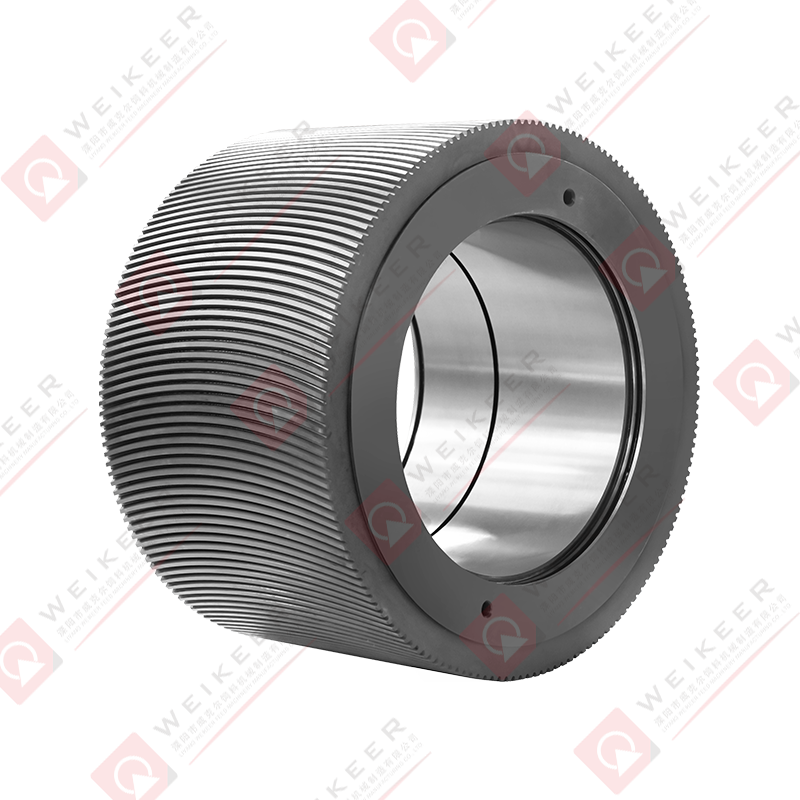

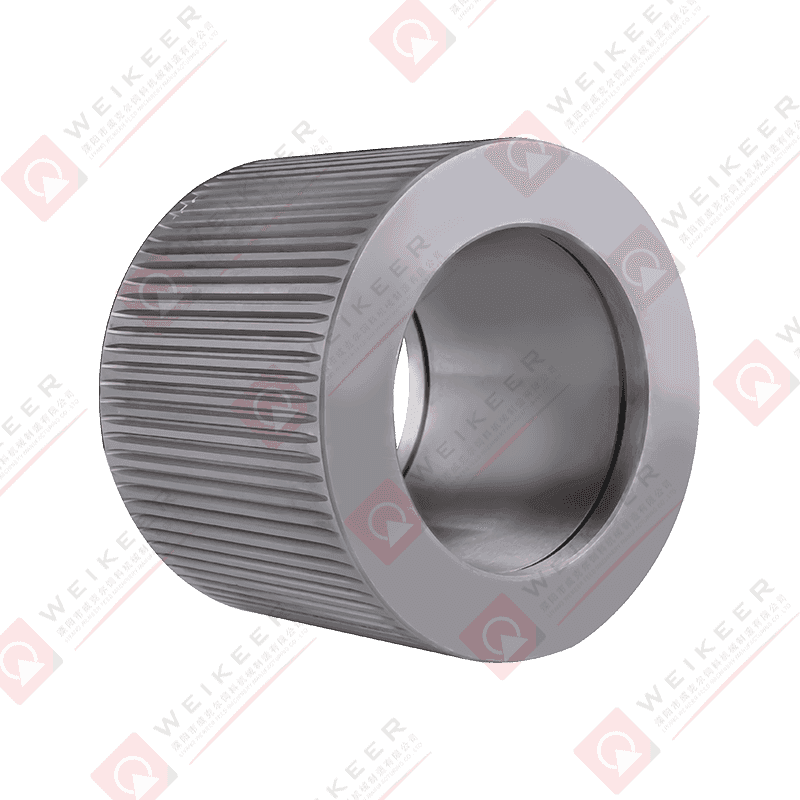

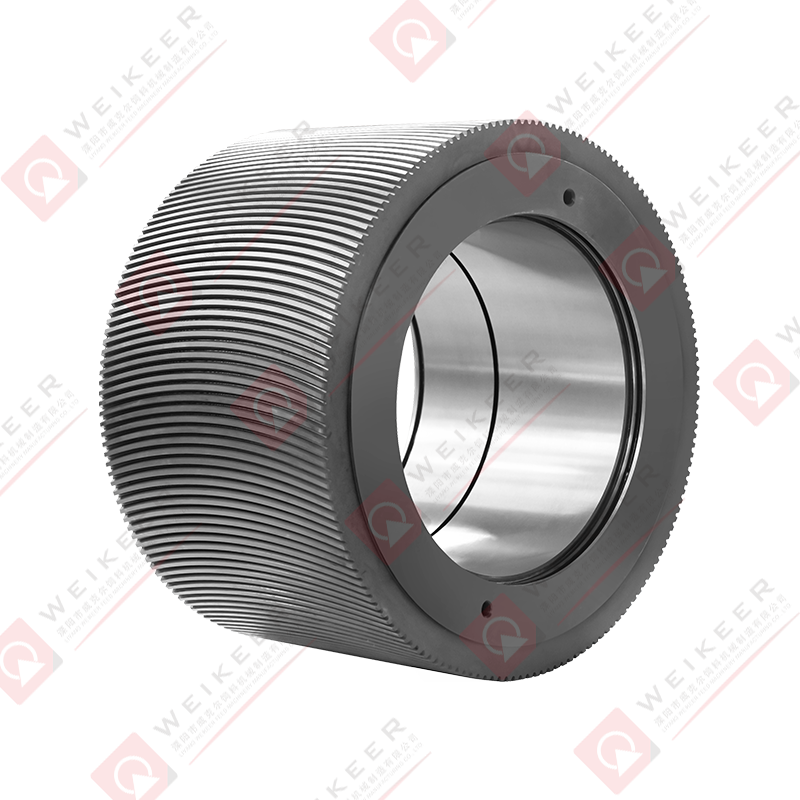

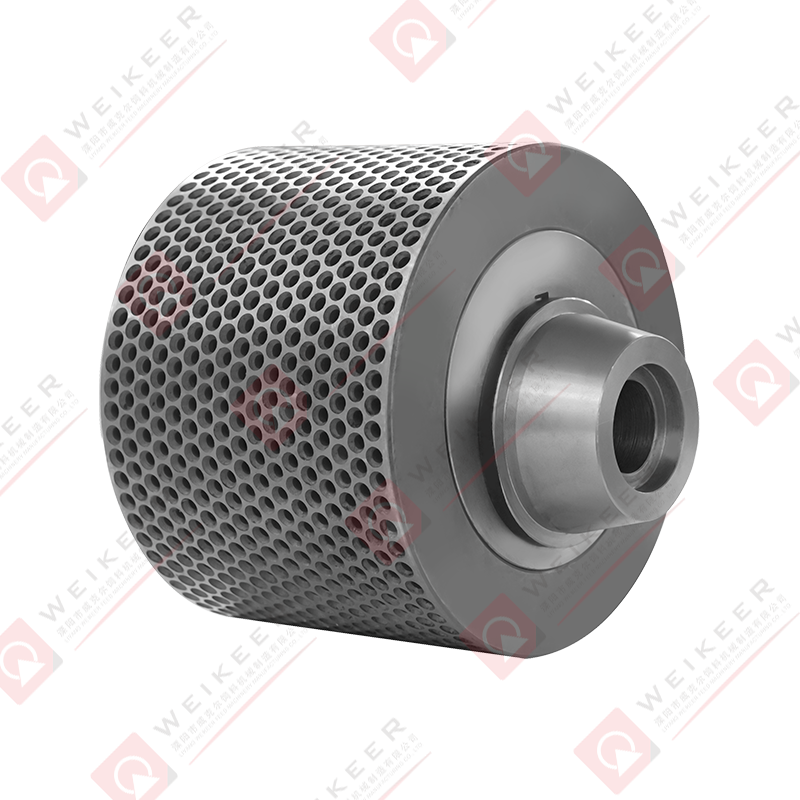

Dimpled bearing steel pellet rollers are critical components in pelletizing processes used in industries such as feed production, biomass energy, and chemical processing. These rollers feature a dimpled surface and high-strength bearing steel construction, which enhances grip, ensures uniform pellet formation, and extends operational lifespan. Their specialized design addresses common challenges in pellet production, including material slippage, inconsistent pellet size, and excessive wear on equipment.

By integrating dimpled bearing rollers, manufacturers can improve production efficiency, reduce downtime, and maintain consistent product quality across high-volume operations.

Enhanced Grip and Material Handling

The dimpled surface of these steel rollers provides superior traction on raw materials during the pelletizing process. Each dimple acts as a micro-grip point, reducing slippage and ensuring materials are properly compressed into uniform pellets. This design is particularly effective for materials that are sticky, fibrous, or prone to uneven flow.

Compared to smooth rollers, dimpled rollers minimize material wastage and allow for consistent feedstock processing, resulting in higher overall pellet yield.

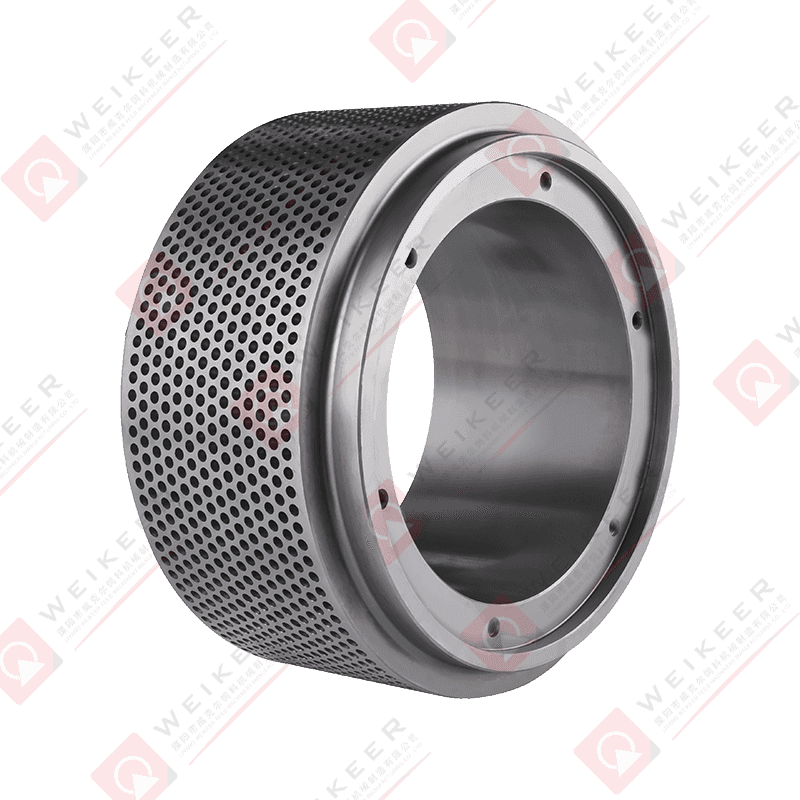

Durability and Long Service Life

Constructed from high-grade bearing steel, these rollers offer excellent hardness, wear resistance, and fatigue strength. Bearing steel allows the roller to withstand high pressures, friction, and repetitive stress typical in pellet mills without deforming or developing surface cracks.

The combination of dimpled design and durable steel extends the lifespan of the roller, reducing the frequency of replacements and maintenance interventions, which lowers operational costs for manufacturers.

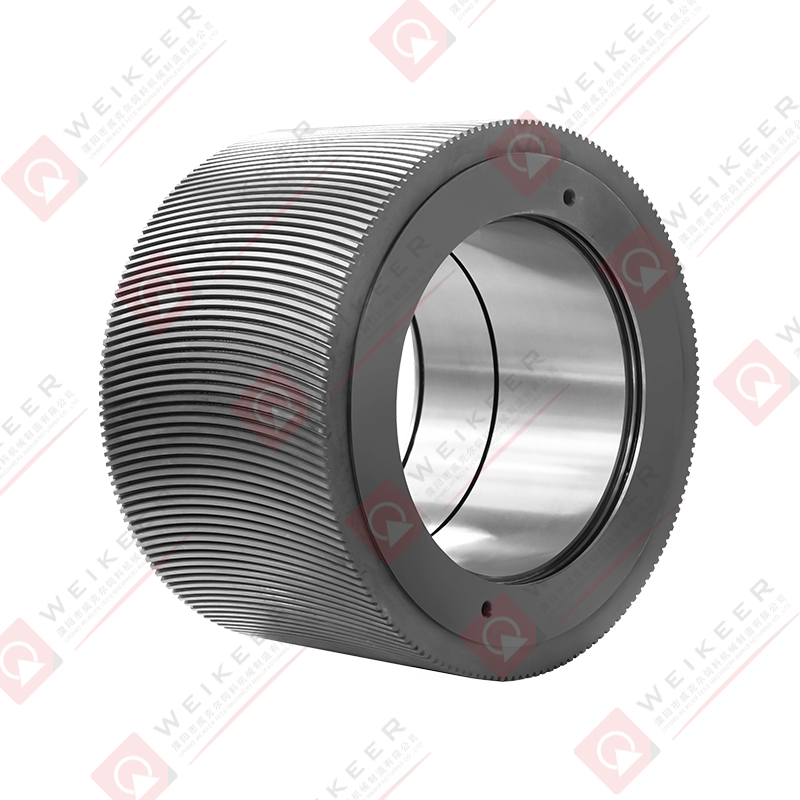

Improved Pellet Quality

Uniform compression achieved by dimpled rollers ensures consistent pellet density and size. This consistency is crucial in feed and biomass industries, where pellet quality directly affects product performance, storage stability, and combustion efficiency.

By reducing irregularities such as cracked or uneven pellets, these rollers help manufacturers meet stringent quality standards, improve end-user satisfaction, and minimize product rejection.

Reduced Maintenance and Downtime

Dimpled bearing steel rollers are designed for minimal maintenance. Their robust construction resists wear from abrasive materials, while the bearing steel composition prevents premature fatigue or surface degradation.

- Less frequent replacement due to superior wear resistance

- Reduced risk of unexpected operational failure

- Easy cleaning and maintenance due to hardened surface

These advantages translate into reduced machine downtime, more continuous production, and lower labor costs associated with maintenance tasks.

Adaptability to Various Pelletizing Materials

Dimpled bearing steel rollers are suitable for a wide range of materials, including wood, feed grains, biomass, and chemical powders. The dimple pattern can be optimized to match specific material properties, ensuring efficient compression without excessive wear or energy consumption.

This adaptability allows manufacturers to use the same roller design across multiple production lines or switch feedstock without compromising pellet quality or equipment performance.

Energy Efficiency in Pellet Production

Dimpled rollers reduce the force required to compress materials into pellets by increasing grip and improving material flow. This efficiency reduces the load on pellet mill motors, lowers energy consumption, and decreases operational costs over time.

Efficient energy usage is especially important in large-scale operations where energy costs can be a significant portion of total production expenses.

Comparison with Standard Rollers

| Feature |

Dimpled Bearing Steel Roller |

Standard Smooth Roller |

| Material |

High-grade bearing steel |

Standard steel or alloy |

| Surface Grip |

High (dimpled) |

Low (smooth) |

| Pellet Consistency |

High |

Moderate |

| Maintenance Frequency |

Low |

High |

| Service Life |

Long |

Moderate |

Conclusion

Dimpled bearing steel pellet rollers offer significant advantages in pelletizing processes, including enhanced grip, durability, consistent pellet quality, reduced maintenance, adaptability, and energy efficiency. Their design addresses common challenges faced in industrial pellet production and ensures high operational reliability.

By investing in dimpled bearing rollers, manufacturers can achieve improved production efficiency, lower operational costs, and superior product quality, making them a preferred choice over standard smooth rollers in demanding pelletizing applications.

русский

русский Español

Español عربى

عربى 中文简体

中文简体