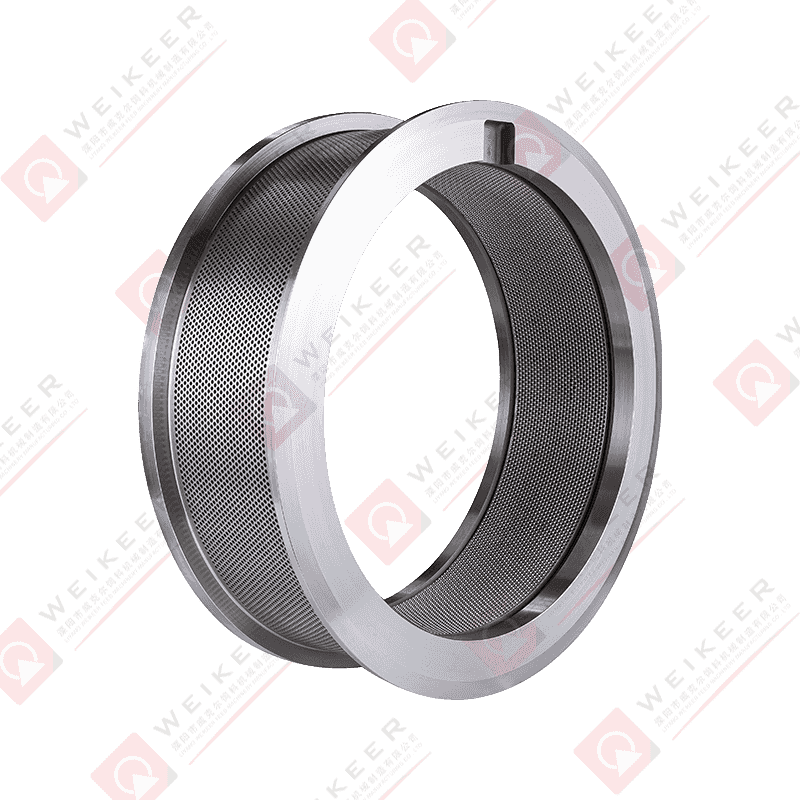

The ring die is one of the most critical components in a complex fertilizer pellet mill. It directly determines pellet density, shape consistency, production capacity, and overall operating efficiency. In complex fertilizer production, raw materials often contain corrosive elements, abrasive particles, and varying moisture levels, all of which place significant stress on the ring die. Without proper maintenance, wear accelerates, hole deformation increases, and pellet quality declines rapidly. Implementing effective maintenance practices is therefore essential to extend the service life of the fertilizer pellet mill ring die and protect long-term production stability.

Proper Raw Material Preparation to Reduce Die Wear

One of the most overlooked factors affecting ring die lifespan is raw material preparation. Poorly prepared fertilizer materials increase friction and mechanical stress on die holes, accelerating wear and fatigue. Ensuring consistent material characteristics before pelleting can significantly reduce damage to the ring die.

Controlling Particle Size and Uniformity

Oversized or irregular particles act as abrasives when forced through die holes. Crushing and screening raw materials to achieve uniform particle size helps minimize uneven pressure distribution and prevents localized wear on the ring die surface.

Maintaining Proper Moisture Content

Excessively dry materials increase friction, while overly wet materials may cause clogging and corrosion. Maintaining optimal moisture levels improves material flow through the die, reducing resistance and lowering mechanical stress on the ring die.

Correct Installation and Alignment Practices

Improper installation is a major contributor to premature ring die failure. Even high-quality complex fertilizer pellet mill ring dies can suffer rapid damage if alignment and assembly procedures are neglected.

Ensuring Accurate Die and Roller Alignment

The ring die must be precisely aligned with the press rollers to ensure even pressure distribution. Misalignment causes uneven contact, leading to accelerated wear on specific sections of the die and reduced pellet uniformity.

Proper Torque and Fastening Control

Bolts and clamping components must be tightened according to manufacturer specifications. Uneven or excessive torque can deform the die body, affecting hole geometry and shortening service life.

Optimizing Operating Parameters During Production

Operating conditions play a decisive role in determining how long a fertilizer pellet mill ring die will last. Running the pellet mill outside recommended parameters places unnecessary stress on the die and rollers.

Controlling Feed Rate and Pressure

Excessive feed rates force materials through the die too aggressively, increasing friction and temperature. Maintaining a stable and balanced feed rate allows the ring die to operate within its designed load range.

Managing Operating Temperature

High temperatures accelerate metal fatigue and corrosion, especially in fertilizer environments containing chlorides or sulfates. Monitoring temperature and adjusting cooling or lubrication systems helps protect the die structure.

Routine Cleaning and Clog Prevention

Material buildup and clogged die holes significantly reduce pellet mill efficiency and accelerate wear. Regular cleaning is essential to keep the complex fertilizer pellet mill ring die in optimal condition.

- Clean die holes after each production shift when processing sticky or corrosive materials

- Use appropriate cleaning agents that do not damage the die surface

- Avoid mechanical scraping that may enlarge or deform die holes

Lubrication and Anti-Corrosion Protection

Proper lubrication reduces friction between the die and rollers while also providing a protective barrier against corrosive fertilizer components. Selecting the right lubrication strategy is critical for extending ring die lifespan.

Using Suitable Lubricants for Fertilizer Applications

Lubricants should be compatible with fertilizer materials and resistant to chemical degradation. Inadequate or contaminated lubricants can increase wear instead of reducing it.

Applying Anti-Corrosion Treatments During Downtime

When the pellet mill is not in use, applying anti-corrosion oils or protective coatings prevents moisture and chemical residues from attacking the ring die surface.

Scheduled Inspection and Wear Monitoring

Regular inspection allows operators to detect early signs of wear before they escalate into major failures. Monitoring wear patterns helps optimize maintenance schedules and replacement planning.

| Inspection Item |

Purpose |

Recommended Frequency |

| Die Hole Diameter |

Detect enlargement or deformation |

Weekly |

| Surface Corrosion |

Identify chemical damage |

Monthly |

| Roller Contact Area |

Check pressure uniformity |

Bi-weekly |

Proper Storage of Ring Dies When Not in Use

Incorrect storage can shorten the service life of a ring die even before it is installed. Proper storage practices are essential for protecting unused or spare fertilizer pellet mill ring dies.

- Store ring dies in dry, temperature-controlled environments

- Apply rust-preventive oil before long-term storage

- Avoid stacking dies directly on hard surfaces to prevent deformation

Training Operators and Standardizing Maintenance Procedures

Human factors play a significant role in ring die longevity. Well-trained operators are more likely to identify abnormal operating conditions and apply correct maintenance practices consistently.

Establishing Standard Maintenance Protocols

Clear maintenance guidelines ensure that cleaning, inspection, and lubrication tasks are performed correctly and on schedule, reducing variability and operational risks.

Conclusion: Maximizing the Service Life of Fertilizer Pellet Mill Ring Dies

Extending the life of a complex fertilizer pellet mill ring die requires a combination of proper material preparation, correct installation, optimized operating conditions, and disciplined maintenance practices. By focusing on preventive care rather than reactive repairs, manufacturers can significantly reduce downtime, lower operating costs, and maintain consistent pellet quality. A well-maintained ring die is not only a durable component but also a key contributor to efficient and reliable fertilizer production.

русский

русский Español

Español عربى

عربى 中文简体

中文简体