Livestock And Poultry Pellet Mill Anchorear Ring Die

Ring dies are primarily used in the production of feed pellets for livestock, in...

Ring dies are primarily used in the production of feed pellets for livestock, in...

Ring dies are used in pellet mills to produce feed pellets for various aquatic s...

Ring dies are used in pellet mills to form ground and mixed fertilizer ingredien...

Ring dies are used in pellet mills to form ground cat litter materials into unif...

The ring die is a critical component in the pellet production process, and its design and material can significantly impact the quality and efficiency of the feed pellets produced.

The Anchorear stainless steel die is a crucial part of pellet mills, especially in demanding industries like biomass, feed, fertilizer, and plastic pellet production. The die features multiple precision-drilled holes, which determine the size and density of the pellets. Hole diameters and lengths are customizable, allowing manufacturers to produce pellets with varying sizes and densities based on specific production needs. The tapered holes or compression channels within the die help smooth the pellet extrusion process, reducing friction and wear during production. The stainless steel die is engineered to withstand high operational temperatures generated during the pelletizing process, ensuring continuous and stable performance.

Biomass pellets mill pellet ring dies are crucial components in the production of biomass pellets. T...

View MoreLiyang Weikeer Feed Machinery Manufacturing Co., Ltd.participating in the AGRAVIA 2026 exhibition, t...

View MoreA dimpled bearing steel pellet roller is a critical component used in pelletizing and briquetting sy...

View MorePellet mills are essential equipment in feed, biomass, and industrial pellet production. At the hear...

View MoreThe ring die is one of the most critical components in a complex fertilizer pellet mill. It directly...

View MoreDimpled bearing steel pellet rollers are critical components in pelletizing processes used in indust...

View MoreLiyang Weikeer Feed Machinery Manufacturing Co.Ltd.'s Pellet Mill Anchorear Stainless steel Ring Die Performance in Thermal Stability and Oxidation Resistance

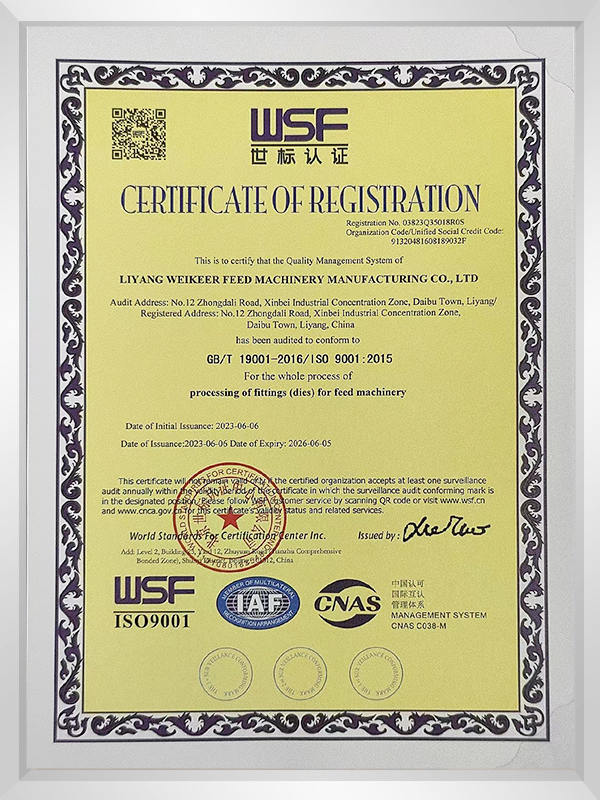

Liyang Weikeer Feed Machinery Manufacturing Co., Ltd., established in 1996, has long been a recognized leader in the production of high-quality pellet mill dies, rollers, and related accessories. Situated near the picturesque Tianmu Lake, Weikeer's new factory spans 13,000 m², with more than 7,000 m² dedicated to production workshops. Equipped with cutting-edge manufacturing technologies and a full range of advanced processing equipment, Weikeer offers specialized, high-performance solutions for the feed industry. With a focus on quality, precision, and customer satisfaction, Weikeer has firmly established itself as a trusted partner to many of the world’s leading brands in the feed machinery market, including ZCME, CPM, IDAH, Bühler, Famsun, Andritz, Van Aarsen, Yeong Ming, and Chiatung.

Among the company’s most highly regarded products are its Pellet Mill Anchorer Stainless Steel Ring Dies, which are specifically engineered to deliver outstanding thermal stability and oxidation resistance. These qualities are essential in the feed production process, where equipment is often exposed to high temperatures and aggressive operating conditions. Through strategic investments in advanced technology and expertise in material science, Weikeer has ensured that its stainless steel ring dies provide exceptional performance in the most demanding environments.

At the core of Weikeer’s ability to deliver products of exceptional quality is its state-of-the-art machinery. This includes the CNC HTT KH-4-100, which is specifically designed for producing high-precision ring dies. Alongside this, Weikeer has invested in HZQL heat treatment equipment to ensure the perfect combination of strength, durability, and resistance to wear. The company’s investment in these advanced technologies enables it to maintain a stringent quality control process throughout the production of its pellet mill dies.

The Pellet Mill Anchorer Stainless Steel Ring Die is manufactured using premium-grade stainless steel, known for its superior resistance to thermal degradation and oxidation. These dies are designed to withstand the extreme conditions commonly found in the pelletizing process, where temperatures can reach up to 85°C and pressures can exceed 30 MPa. The ring dies’ resistance to oxidation ensures that they maintain their structural integrity over prolonged use, reducing the frequency of maintenance and replacements, and thereby improving operational efficiency for feed producers.

Thermal stability is one of the most crucial properties in ensuring the longevity and reliability of pellet mill dies. Pelletizing feed often involves high temperatures, particularly when producing high-quality pellets. As the feed is subjected to intense pressure and heat, ring dies are prone to wear and degradation. Weikeer’s Pellet Mill Anchorer Stainless Steel Ring Dies are specifically engineered to resist these extreme conditions. Their superior thermal stability allows them to maintain their dimensional accuracy and shape, ensuring that the feed production process remains consistent and efficient.

In addition to thermal stability, the oxidation resistance of Weikeer’s stainless steel ring dies plays a critical role in their performance. Oxidation can lead to surface degradation, weakening the die structure and reducing its effectiveness. By using high-quality stainless steel with inherent resistance to oxidation, Weikeer ensures that its ring dies maintain optimal performance and appearance over time. This not only extends the lifespan of the dies but also minimizes the need for frequent replacements and repairs, which can significantly reduce downtime and maintenance costs for feed producers.

Weikeer’s focus on customization allows it to provide tailored solutions for each client. The company recognizes that different feed producers have unique operational requirements, and its Pellet Mill Anchorer Stainless Steel Ring Dies can be designed to meet specific production needs. Whether it is optimizing the die for a particular type of feed, increasing production capacity, or enhancing wear resistance, Weikeer works closely with its clients to deliver products that are perfectly suited to their needs.

With a team of 26 skilled technologists and over 100 employees, Weikeer has the expertise to provide comprehensive support throughout the entire process—from product selection to technical assistance and after-sales service. This collaboration ensures that every ring die is crafted to deliver maximum value, efficiency, and performance in real-world applications.

The success of Weikeer’s Pellet Mill Anchorer Stainless Steel Ring Dies can be attributed to the company’s unwavering commitment to quality and innovation. By continuously refining its manufacturin

g processes and adopting the latest technological advancements, Weikeer has built a reputation for delivering products that embody “high quality, high efficiency, and low energy consumption.” The company’s rigorous testing and quality control processes ensure that each ring die meets the highest standards for performance and durability.

Weikeer’s commitment to quality is matched by its dedication to customer satisfaction. The company’s customer service department works closely with clients to provide expert advice, guidance, and ongoing support. This ensures that customers receive the most suitable products for their needs and that they can maintain their pellet mills at peak performance.

In addition to providing high-performance products, Weikeer also focuses on sustainability. The company’s Pellet Mill Anchorer Stainless Steel Ring Dies are designed to reduce waste and energy consumption during the pelletizing process. By using high-quality materials and efficient manufacturing methods, Weikeer contributes to the overall sustainability of the feed production process, helping clients meet their environmental goals while maintaining operational excellence.

Liyang Weikeer Feed Machinery Manufacturing Co., Ltd. continues to lead the feed machinery industry with its high-performance Pellet Mill Anchorer Stainless Steel Ring Dies, which are designed to offer superior thermal stability and oxidation resistance. These advanced products enable feed producers to operate more efficiently, reduce maintenance costs, and enhance production capacity. With its unwavering focus on quality, innovation, and customer satisfaction, Weikeer remains the ideal partner for feed producers worldwide, offering tailored solutions that ensure long-term operational success. Whether you are looking for a product that withstands extreme temperatures or one that provides lasting durability, Weikeer’s Pellet Mill Anchorer Stainless Steel Ring Dies will exceed your expectations.