Corrugated Open End Spring Steel Pellet Roller

The spring steel roller with a corrugated open end is a high-performance compone...

The spring steel roller with a corrugated open end is a high-performance compone...

The spring steel roller with a corrugated close end is a robust component specif...

The 100Cr6 roller featuring a closed corrugation and dimpled design is a high-pe...

The 100Cr6 roller with a diagonal groove design is a specialized component craft...

Made from high-quality 100Cr6 spring steel, providing exceptional hardness and w...

The spring steel roller with a dimpled surface is a high-performance component d...

Our Spring Steel roller shells are essential components of pellet mills, playing a crucial role in the extrusion of feed. These roller shells are designed to work seamlessly with dies to ensure top-quality production tailored to specific needs. Trust in our technical specifications to deliver customized parts that meet industry standards and exceed expectations.

Spring steel 100Cr6 is a high-carbon chromium alloy steel primarily used for bearings and other applications requiring high wear resistance, hardness, and toughness. 100Cr6 exhibits resistance to fatigue, making it highly suitable for cyclic loading applications, such as springs and bearings, where the material undergoes repeated stress over its lifespan. The high carbon and chromium content make 100Cr6 extremely resistant to wear, making it ideal for components subjected to friction, such as ball bearings, roller bearings, and other high-wear mechanical parts.100Cr6 can be used in both bearing and spring applications, offering a wide range of uses across different industries. The combination of wear resistance, toughness, and fatigue strength makes it suitable for cams, shafts, and rollers used in various types of machinery, including those in manufacturing and heavy industry.

Biomass pellets mill pellet ring dies are crucial components in the production of biomass pellets. T...

View MoreLiyang Weikeer Feed Machinery Manufacturing Co., Ltd.participating in the AGRAVIA 2026 exhibition, t...

View MoreA dimpled bearing steel pellet roller is a critical component used in pelletizing and briquetting sy...

View MorePellet mills are essential equipment in feed, biomass, and industrial pellet production. At the hear...

View MoreThe ring die is one of the most critical components in a complex fertilizer pellet mill. It directly...

View MoreDimpled bearing steel pellet rollers are critical components in pelletizing processes used in indust...

View MoreAdvantages of Spring Steel 100Cr6 Pellet Mills Rollers from Liyang Weikeer Feed Machinery Manufacturing Co.Ltd. in practical applications

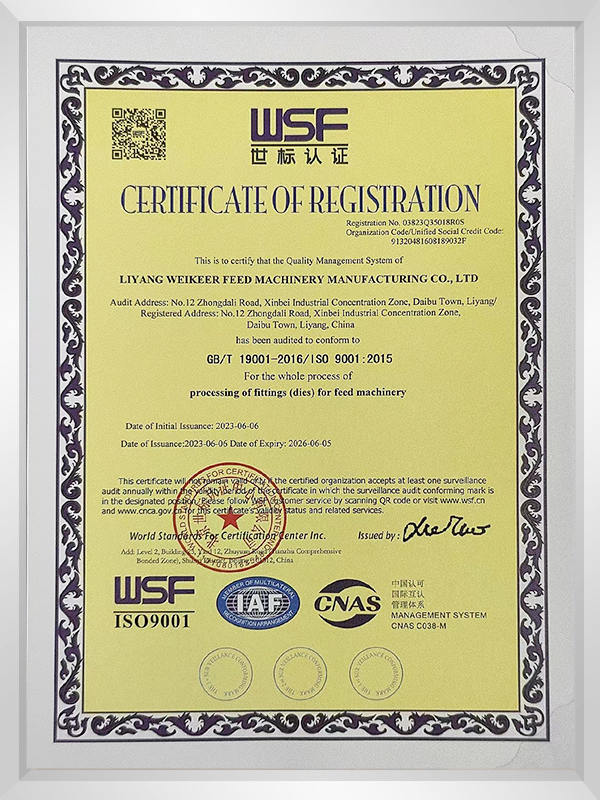

Liyang Weikeer Feed Machinery Manufacturing Co. Ltd. has built a reputation as a leading manufacturer of pellet mill dies, rollers, and related accessories. Established in 1996, the company’s modern factory, strategically located near the picturesque Tianmu Lake, spans 13,000 m², with over 7,000 m² dedicated to production workshops. Equipped with state-of-the-art technology and processing equipment, Weikeer has become a trusted supplier for customers worldwide. With investments in advanced machinery, including CNC HTT KH-4-100 for ring dies and HZQL heat treatment equipment, Weikeer ensures the production of high-quality, durable products. Weikeer’s commitment to quality is reflected in its wide-ranging client base, including industry giants like ZCME, CPM, IDAH, Bühler, Famsun, Andritz, Van Aarsen, Yeong Ming, and Chiatung.

At the heart of Weikeer’s product lineup are high-performance pellet mill rollers, made using premium materials such as Spring Steel 100Cr6. These rollers are integral components in the feed production process, as they are exposed to extreme pressure, high temperatures, and wear. Weikeer’s Spring Steel 100Cr6 rollers are designed for outstanding performance and longevity. This article will highlight the advantages of using Spring Steel 100Cr6 in pellet mill rollers and explore how these benefits translate into practical applications within the feed production industry.

Spring Steel 100Cr6 is a high-carbon chromium steel known for its excellent hardness, wear resistance, and fatigue strength. Typically used in applications where high stress, abrasion, and continuous use are factors, Spring Steel 100Cr6 possesses the ideal mechanical properties for pellet mill rollers. The material contains carbon (approximately 0.95-1.05%) and chromium (1.3-1.6%), which contribute to its toughness and wear resistance. These properties make it an optimal choice for producing rollers that endure high pressure and friction during the pelletizing process.

The high carbon content ensures that the steel can be hardened to high levels, typically achieving hardness in the range of HRC 58-62. The addition of chromium helps to further improve resistance to wear and corrosion, extending the lifespan of the rollers and maintaining their efficiency over time. These advantages are critical in feed production, where pellet mills must operate efficiently and continuously under heavy loads.

One of the primary advantages of Spring Steel 100Cr6 Pellet Mills Rollers in pellet mill rollers is its superior wear resistance. During the pelletizing process, rollers are subjected to intense friction and pressure as they compress raw materials to form pellets. Over time, this results in significant wear on the rollers. By using 100Cr6, Weikeer ensures that the rollers retain their shape and functionality even under harsh conditions.

The high hardness of 100Cr6 steel, achieved through heat treatment processes such as quenching and tempering, contributes to its outstanding wear resistance. This makes the rollers more resistant to surface degradation, reducing the frequency of maintenance and replacement. For feed manufacturers, this translates into reduced downtime and lower operational costs.

Pellet mill rollers are not only exposed to wear but also undergo constant loading and unloading during their operation. The cyclic stress exerted on the rollers can lead to fatigue failure if the material does not possess sufficient fatigue resistance. Spring Steel 100Cr6 excels in this regard, as it is specifically designed to withstand repeated stress cycles without cracking or breaking.

Weikeer’s use of advanced heat treatment technologies ensures that the 100Cr6 steel maintains optimal hardness and fatigue resistance, even after prolonged use. The roller shells retain their structural integrity, reducing the likelihood of failure and ensuring that pellet mills operate smoothly and efficiently for longer periods. This is especially important for high-volume feed production facilities that require continuous, reliable operation.

Another key benefit of 100Cr6 steel is its toughness. Toughness refers to a material’s ability to absorb energy without fracturing. In pellet mill rollers, toughness is vital because it prevents cracks and breakages that can occur under sudden impacts or stress. Weikeer’s 100Cr6 pellet mill rollers have been engineered to provide excellent toughness, even under the most demanding conditions.

The heat treatment processes employed by Weikeer enhance the toughness of the rollers, making them capable of withstanding extreme pressure without fracturing. This ability to absorb impact and resist cracking extends the lifespan of the rollers, further reducing operational costs for feed producers.

Given the operating environment in feed mills, where humidity and the presence of dust can contribute to corrosion, corrosion resistance is a crucial factor in material selection for pellet mill rollers. The chromium content in Spring Steel 100Cr6 Pellet Mills Rollers enhance its resistance to corrosion, helping to maintain the integrity of the rollers even when exposed to challenging environmental conditions.

Weikeer’s 100Cr6 rollers, therefore, offer not only high wear and fatigue resistance but also ensure that corrosion does not compromise their performance. This makes the rollers ideal for long-term use in humid and abrasive environments, ensuring that feed mills remain efficient and productive.

While Spring Steel 100Cr6 may involve higher initial material costs compared to lower-grade steels, its superior performance and durability lead to significant cost savings over time. The enhanced wear resistance, fatigue resistance, and corrosion resistance translate into fewer roller replacements, reduced maintenance costs, and less downtime.

Feed manufacturers using Weikeer’s 100Cr6 pellet mill rollers can expect to enjoy long-term operational efficiency. These rollers maintain optimal performance for extended periods, ensuring that the pellet mills continue to operate at peak capacity without the need for frequent repairs or replacements.

In feed production, 100Cr6 pellet mill rollers are indispensable for ensuring the continuous production of high-quality pellets. The material’s wear resistance allows for consistent pellet output, while its fatigue resistance ensures that rollers can withstand the cyclical loading and unloading during operation. This is particularly important for facilities with high production volumes that require reliable machinery capable of handling large quantities of raw materials.

Furthermore, the corrosion resistance of 100Cr6 steel ensures that the rollers can maintain their integrity even in moist, abrasive environments typical of feed mills. This results in greater durability and longer service life, making these rollers a smart investment for feed manufacturers seeking to improve productivity and reduce operational costs.

Liyang Weikeer Feed Machinery Manufacturing Co. Ltd. has established itself as a leading supplier of high-quality pellet mill dies, rollers, and related accessories. Through its commitment to innovation and customer satisfaction, Weikeer continues to provide cutting-edge solutions for the feed industry. The use of Spring Steel 100Cr6 in pellet mill rollers is one of the company’s most significant advancements, offering outstanding benefits such as superior wear resistance, enhanced fatigue resistance, improved toughness, and corrosion resistance.

By using 100Cr6 steel, Weikeer ensures that its pellet mill rollers provide superior performance, reliability, and longevity in demanding feed production environments. These rollers are an essential part of any feed production line, delivering consistent, high-quality pellets while reducing maintenance costs and downtime. With a reputation for producing high-performance machinery and an unwavering commitment to quality, Liyang Weikeer is the ideal partner for feed manufacturers worldwide.