Curved Corrugation 20CrMnTi Pellet Roller

The 20CrMnTi roller with curved corrugation is a high-performance component made...

The 20CrMnTi roller with curved corrugation is a high-performance component made...

The spring steel roller with a corrugated close end is a robust component specif...

The 100Cr6 roller featuring a closed corrugation and dimpled design is a high-pe...

The 100Cr6 roller with a diagonal groove design is a specialized component craft...

Made from high-quality 100Cr6 spring steel, providing exceptional hardness and w...

The spring steel roller with a dimpled surface is a high-performance component d...

The pellet mill roller, also known as a pellet mill die, is a critical component in the pelletizing process used for making various types of pellets, including those for animal feed, biomass fuel, and even pet litter like cat litter.

Press Rollers are integral components in pelletizing machines, working in tandem with the Ring Die to compress and form materials into pellets. Made from high-quality alloy steel, stainless steel, or chrome-plated steel for wear resistance and long operational life. Press rollers ensure uniform pressure across the ring die, to consistent pellet size and quality. Their design helps distribute material evenly into the die's holes, reducing blockages and uneven wear on the die. It is used to compress feed ingredients (like corn, wheat, soy, and other grains) into compact pellets for livestock, poultry, and aquaculture. It is employed to form biomass materials (like wood chips, sawdust, straw, and grass) into fuel pellets. Press rollers handle both softwood and hardwood materials.

Biomass pellets mill pellet ring dies are crucial components in the production of biomass pellets. T...

View MoreLiyang Weikeer Feed Machinery Manufacturing Co., Ltd.participating in the AGRAVIA 2026 exhibition, t...

View MoreA dimpled bearing steel pellet roller is a critical component used in pelletizing and briquetting sy...

View MorePellet mills are essential equipment in feed, biomass, and industrial pellet production. At the hear...

View MoreThe ring die is one of the most critical components in a complex fertilizer pellet mill. It directly...

View MoreDimpled bearing steel pellet rollers are critical components in pelletizing processes used in indust...

View MoreSymmetry and balance of the Pellet Mills Press Rollers Shells of Liyang Weikeer Feed Machinery Manufacturing Co. Ltd.

In the world of pellet production, whether for animal feed, biomass fuel, or pet litter, the performance of the pellet mill's critical components directly affects the quality, efficiency, and cost-effectiveness of the entire process. Among these components, the Pellet Mills Press Rollers Shells is particularly essential for ensuring consistent pellet formation. As a specialized company that has been at the forefront of producing pellet mill dies and rollers, Liyang Weikeer Feed Machinery Manufacturing Co., Ltd. has earned a strong reputation for its high-quality, durable, and precise pelletizing components.

Pellet Mills Press Rollers Shells are a critical component in pellet mills, working in tandem with the ring die to compress and form various materials into pellets. These materials can include feed ingredients (such as corn, wheat, soybeans), biomass materials (like wood chips, sawdust, and straw), and even pet litter materials like cat litter. Pellet Mills Press Rollers Shells apply pressure to these raw materials as they move through the pellet mill, forcing them through the holes in the ring die, where they are compressed and formed into pellets of consistent size and density.

The role of the Pellet Mills Press Rollers Shells in this process is multifaceted. It must ensure that the material is distributed evenly across the ring die’s holes, applying uniform pressure to produce pellets that are of consistent size and quality. The balance and symmetry of the roller are key to ensuring that this process occurs efficiently and without obstruction or excessive wear.

The symmetry and balance of the Pellet Mills Press Rollers Shells are integral to its performance. Any imbalance in the roller’s design or wear pattern can lead to uneven pellet formation, reduced pellet quality, and faster wear on both the roller and the ring die. To address this, Weikeer has developed Pellet Mills Press Rollers Shells with a focus on achieving perfect symmetry in both design and operation.

A Pellet Mills Press Rollers Shells’s design must ensure that the pressure is applied evenly across the entire surface of the ring die. If the roller is not symmetrical, pressure may be concentrated on one part of the die, leading to uneven pellet formation, inconsistent size, and poor pellet quality. To achieve optimal symmetry, Weikeer uses precision manufacturing techniques, employing advanced CNC machines like the HTT KH-4-100, which ensure that each Pellet Mills Press Rollers Shells is made to exacting specifications. This precision ensures that the rollers operate smoothly and effectively across the entire die surface, resulting in uniform pellet quality.

Beyond the physical symmetry of the Pellet Mills Press Rollers Shells, balance in operation is equally important. Pellet Mills Press Rollers Shells must rotate smoothly and evenly as they interact with the ring die. If a roller is out of balance, it may cause vibrations or uneven contact with the ring die, leading to inconsistent pressure and potential blockages. These blockages can increase wear on the roller and die, reduce the efficiency of the pelletizing process, and ultimately affect the overall productivity of the pellet mill.

To maintain this balance, Weikeer’s Pellet Mills Press Rollers Shells are designed to operate with minimal friction and smooth rotation. This balance is achieved through careful consideration of the roller’s material properties, shape, and weight distribution. High-quality alloy steel, stainless steel, and chrome-plated steel are commonly used in the construction of Weikeer’s Pellet Mills Press Rollers Shells, which enhances their strength, wear resistance, and longevity. These materials also help ensure that the rollers remain balanced over time, even with prolonged use.

Weikeer’s Pellet Mills Press Rollers Shells are manufactured using premium materials that not only contribute to the symmetry and balance of the roller but also enhance its durability. The company uses high-quality alloy steel, stainless steel, and chrome-plated steel, all of which are known for their exceptional wear resistance. These materials help the rollers maintain their shape and performance over extended periods, ensuring that the balance and symmetry are not compromised by wear or environmental factors.

In addition to material quality, the heat treatment processes employed at Weikeer ensure that the rollers maintain their strength and durability. The use of advanced heat treatment equipment, such as HZQL heat treatment technology, ensures that the rollers achieve the right balance of hardness and toughness, which is essential for maintaining the roller’s performance even under high-pressure conditions.

Symmetry and balance in the Pellet Mills Press Rollers Shells directly impact the longevity of the components. When the roller is symmetrical and well-balanced, the wear on both the roller and the ring die is even and minimized. This not only extends the life of the Pellet Mills Press Rollers Shells but also helps in prolonging the lifespan of the ring die. Additionally, this balanced operation reduces the likelihood of downtime for maintenance or repairs, which is crucial for maximizing the efficiency of the pellet mill.

When the Pellet Mills Press Rollers Shells is properly balanced, it also ensures consistent material flow into the die, reducing the chances of blockages and preventing uneven wear. This leads to fewer interruptions in the production process and allows for higher operational efficiency.

The versatility of Weikeer’s Pellet Mills Press Rollers Shells makes them ideal for use in various pelletizing applications. Whether the goal is to produce high-quality animal feed, biomass fuel pellets, or pet litter pellets, the symmetry and balance of the Pellet Mills Press Rollers Shells ensure that each type of material is processed efficiently and consistently. The rollers are designed to handle a wide range of raw materials, from softwood and hardwood biomass to grain-based animal feeds, and can even be customized to meet specific production requirements.

Weikeer’s Pellet Mills Press Rollers Shells are trusted by some of the world’s leading brands in the pellet mill industry, including ZCME, CPM, IDAH, Buhler, Famsun, Andritz, Van Aarsen, Yeong Ming, and Chiatung. These brands rely on Weikeer’s Pellet Mills Press Rollers Shells to deliver consistent, high-quality pellet production, showcasing the company’s expertise and commitment to excellence.

The symmetry and balance of the Pellet Mills Press Rollers Shells are crucial factors in ensuring the efficiency and effectiveness of the pelletizing process. At Liyang Weikeer Feed Machinery Manufacturing Co., Ltd., these factors are prioritized in every roller produced, ensuring high-quality pellets, reduced wear and tear, and increased operational efficiency. Whether for animal feed, biomass fuel, or pet litter, the company’s Pellet Mills Press Rollers Shells continue to meet the demanding requirements of pellet production, ensuring that customers can rely on Weikeer for superior performance and durability.

Liyang Weikeer Feed Machinery Manufacturing Co.Ltd.'s Pellet Mills Die Rollers are designed for high temperature and high pressure working environments to ensure continuous and efficient production capacity

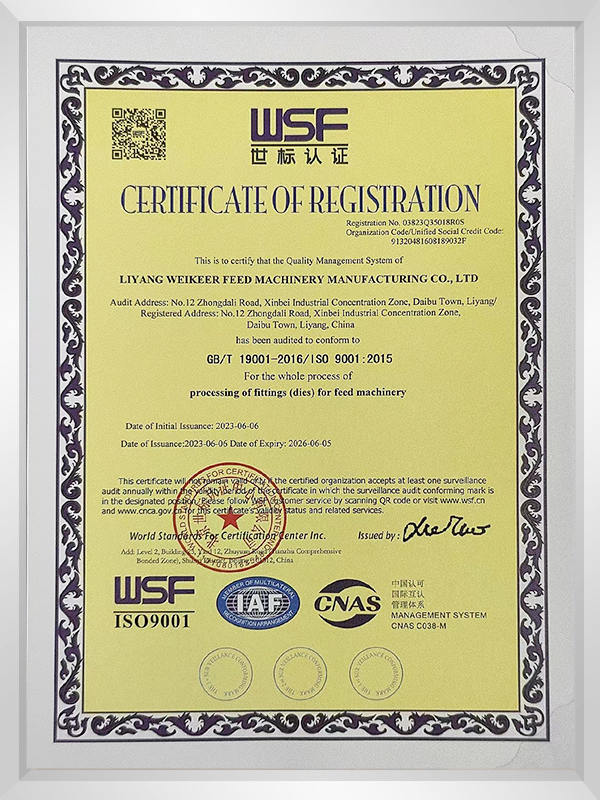

Liyang Weikeer Feed Machinery Manufacturing Co., Ltd. is a renowned manufacturer specializing in the production of high-quality pellet mill dies, rollers, and other related components. Established in 1996, Weikeer has become a trusted name in the feed machinery industry, known for its superior products and excellent customer service. With an unwavering commitment to innovation and quality, Weikeer’s pellet mill die rollers are specifically designed to withstand the challenges of high-temperature and high-pressure working environments, ensuring continuous and efficient production capacity for its customers.

Weikeer’s manufacturing facility, situated near the beautiful Tianmu Lake, spans an impressive 13,000 m², with more than 7,000 m² dedicated to production workshops. The company’s extensive investment in advanced manufacturing technology is at the heart of its operations. This includes cutting-edge machinery such as the CNC HTT KH-4-100 for ring dies and the HZQL heat treatment equipment. These state-of-the-art tools allow Weikeer to produce pellet mill dies and rollers that meet stringent quality standards and exhibit exceptional performance, even under the most demanding conditions.

The company’s team of 26 highly skilled technologists and over 100 employees ensures that every product is manufactured to the highest standards. Their expertise, combined with a commitment to continuous improvement, allows Weikeer to deliver products that are both reliable and efficient. With fixed assets exceeding CNY 30 million, the company is well-equipped to meet the evolving needs of its clients in the feed industry.

One of the key features of Weikeer’s pellet mill die rollers is their ability to perform effectively in high-temperature and high-pressure working environments. Pelletizing feed is an energy-intensive process, requiring robust equipment that can endure prolonged periods of high pressure and heat. Weikeer’s die rollers are designed to withstand these extreme conditions, ensuring that customers can maintain consistent, high-volume production without compromising on quality or efficiency.

The high-temperature tolerance of Weikeer’s pellet mill die rollers is essential for producing high-quality pellets that meet the nutritional needs of livestock. These rollers are engineered to endure the heat generated during the pelletizing process, preventing warping or deformation and ensuring that the final product is uniform in size and shape. The ability to maintain consistent production capacity in such conditions is a testament to Weikeer’s focus on engineering excellence and the durability of its products.

Tailored Solutions for a Diverse Range of Clients

Weikeer understands that different customers have unique needs, and as such, the company offers tailored solutions to meet the specific requirements of each client. The company provides high-quality ring dies and rollers compatible with some of the most renowned global brands in the feed machinery industry, including ZCME, CPM, IDAH, Bühler, Famsun, Andritz, Van Aarsen, Yeong Ming, and Chiatung. This versatility in product offerings allows Weikeer to serve a wide range of customers, from small-scale operations to large-scale industrial producers.

By providing customized solutions, Weikeer ensures that its pellet mill dies and rollers integrate seamlessly with clients’ existing machinery, optimizing the performance of their production lines. Whether it’s adjusting to specific production volumes, product types, or technical specifications, Weikeer’s engineering team works closely with clients to ensure that their exact needs are met.

Weikeer’s commitment to quality is evident in every step of the production process. The company follows rigorous quality control measures to ensure that all products meet international industry standards. By utilizing advanced processing technologies and adopting best practices inspired by European standards, Weikeer guarantees that its products offer superior performance and reliability.

The company’s ongoing investment in technology and training ensures that it remains at the forefront of the feed machinery industry. Whether it's the precision of its CNC machinery, the effectiveness of its heat treatment equipment, or the expertise of its technicians, Weikeer consistently delivers products that embody "high quality, high efficiency, and low energy consumption." These principles are deeply embedded in the company’s culture, ensuring that customers receive products that not only meet but exceed their expectations.

At Weikeer, customer satisfaction is a top priority. The company’s dedicated customer service team works closely with clients to provide comprehensive support before, during, and after the sale.

From product selection and technical advice to installation and troubleshooting, Weikeer’s team is always ready to assist clients with any inquiries or challenges they may encounter.

In addition, Weikeer’s after-sales service ensures that customers receive ongoing support to maintain the performance of their pellet mills and related equipment. The company’s team of experts is available to provide guidance on maintenance practices, troubleshooting, and any necessary adjustments to optimize performance.

Over the years, Liyang Weikeer Feed Machinery Manufacturing Co., Ltd. has built a reputation as a reliable and trusted partner for businesses in the feed industry. With its advanced technology, high-quality products, and exceptional customer service, Weikeer continues to help clients achieve their production goals efficiently and effectively.

Whether you are looking to improve the performance of your existing pellet mill or invest in new, high-quality dies and rollers, Weikeer’s products are designed to deliver outstanding results. Their pellet mill die rollers, with their high-temperature and high-pressure resistance, ensure that clients can operate at maximum efficiency, minimizing downtime and maximizing production capacity.

Liyang Weikeer Feed Machinery Manufacturing Co., Ltd. offers a comprehensive solution for pelletizing feed with its high-performance pellet mill die rollers. By combining advanced technology, skilled craftsmanship, and a commitment to quality, Weikeer provides products that can withstand the most demanding working environments. For businesses in the feed industry, Weikeer remains a trusted partner, offering tailored solutions that ensure long-term operational success and efficiency.