Closed Corrugation And Dimpled GCr15 Pellet Roller

The GCr15 roller featuring a closed corrugation and dimpled design is a high-per...

The GCr15 roller featuring a closed corrugation and dimpled design is a high-per...

The closed-end structure enhances durability and provides better containment of ...

The bearing steel roller with an open end and corrugated design is a robust comp...

The closed-end structure enhances durability and provides better containment of ...

The GCr15 roller with a diagonal groove design is a highly engineered component ...

The GCr15 roller with a curved corrugation design is a specialized component cra...

The design and material of the roller play a crucial role in determining the quality and efficiency of the pellets produced. The choice of Bearing Steel for the roller can have a significant impact on the overall performance of the production process.

Bearing Steel GCr15 is a high-carbon chromium steel specifically designed for rolling bearings and related components. It is well-known for its performance characteristics, which make it suitable for various applications in mechanical systems. GCr15 can achieve a hardness of 58-65 HRC after heat treatment, providing wear resistance necessary for bearing applications. Despite its high hardness, GCr15 maintains a level of toughness that allows it to absorb shocks and resist fracture under dynamic loads. While GCr15 is primarily a bearing steel, it has some corrosion resistance due to its chromium content. Bearings made from GCr15 are extensively used in automotive components such as wheel hubs, transmissions, and engine applications, where reliability and longevity are crucial.

Biomass pellets mill pellet ring dies are crucial components in the production of biomass pellets. T...

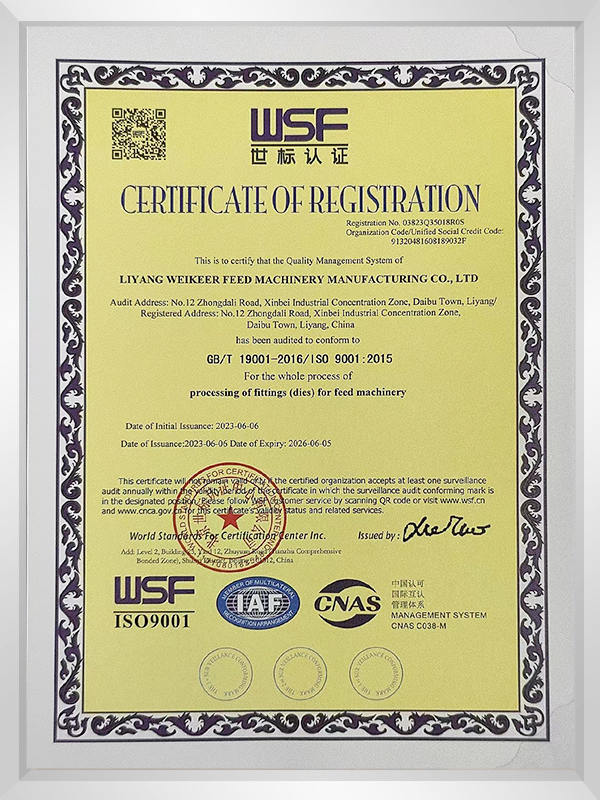

View MoreLiyang Weikeer Feed Machinery Manufacturing Co., Ltd.participating in the AGRAVIA 2026 exhibition, t...

View MoreA dimpled bearing steel pellet roller is a critical component used in pelletizing and briquetting sy...

View MorePellet mills are essential equipment in feed, biomass, and industrial pellet production. At the hear...

View MoreThe ring die is one of the most critical components in a complex fertilizer pellet mill. It directly...

View MoreDimpled bearing steel pellet rollers are critical components in pelletizing processes used in indust...

View MoreLiyang Weikeer Feed Machinery Manufacturing Co. Ltd.'s Bearing Steel GCr15 Pellet Mills Rollers Shells' wear resistance and fatigue resistance improvement method

Liyang Weikeer Feed Machinery Manufacturing Co. Ltd. has long been at the forefront of producing high-quality pellet mill dies, rollers, and related accessories. Since its establishment in 1996, Weikeer has consistently offered innovative solutions and exceptional products tailored to the needs of the feed industry. The company’s new state-of-the-art factory, located near the scenic Tianmu Lake, covers 13,000 m², with 7,000 m² of dedicated production space. Equipped with advanced machinery and a highly skilled workforce, Weikeer produces high-performance pellet mill rollers and dies that are compatible with major global brands such as ZCME, CPM, IDAH, Bühler, Famsun, Andritz, Van Aarsen, Yeong Ming, and Chiatung.

The company’s commitment to excellence is reflected in its investment in cutting-edge technology, including CNC HTT KH-4-100 for ring dies and HZQL heat treatment equipment. These advanced manufacturing technologies ensure that every product is built to meet stringent industry standards, providing maximum value to customers while maintaining high quality, low energy consumption, and high efficiency.

GCr15 bearing steel is a high-carbon chromium alloy steel that is widely used in manufacturing components requiring high wear resistance, high hardness, and durability, such as bearing rings and rollers. GCr15 contains around 1.0% carbon and 1.5% chromium, offering a perfect balance between toughness and hardness. This material is highly suitable for pellet mill roller shells, which face substantial pressure, friction, and wear during the pelletizing process.

The high chromium content in GCr15 provides excellent hardness, typically reaching HRC 58-62 after heat treatment, making it highly resistant to wear and abrasion. Additionally, the steel's fatigue resistance ensures that it can withstand repetitive loading without experiencing premature cracking or failure, which is crucial in pelletizing operations where rollers endure constant pressure and mechanical stress.

Wear resistance is a critical factor in the performance of pellet mill roller shells, as these components are subjected to constant friction with the pellet die and raw materials. Over time, wear can reduce the efficiency of the pelletizing process, leading to increased downtime and higher maintenance costs. To address this, Weikeer has implemented several advanced methods to enhance the wear resistance of its Bearing Steel GCr15 Pellet Mills Rollers Shells.

Optimized Heat Treatment Process One of the most effective ways to improve the wear resistance of GCr15 steel is through advanced heat treatment. At Weikeer, the GCr15 steel is subjected to a controlled heat treatment process, which includes quenching and tempering. The quenching process involves heating the steel to a high temperature and rapidly cooling it in oil or water, which increases the hardness of the material. The tempering process follows, wherein the steel is reheated to a specific temperature and cooled slowly, which relieves internal stresses and improves toughness without compromising the material’s hardness.

Surface Hardening Techniques Weikeer utilizes various surface hardening methods, such as induction hardening and nitriding, to further enhance the surface wear resistance of GCr15 bearing steel. Induction hardening uses high-frequency electrical currents to heat the surface of the roller shells, followed by rapid cooling to form a hardened surface layer. This increases the wear resistance of the roller shells while maintaining the core’s toughness. Nitriding, on the other hand, introduces nitrogen into the surface of the steel at elevated temperatures, forming a hard nitrided layer that significantly improves resistance to abrasion.

Wear-Resistant Coatings To extend the service life of the rollers, Weikeer also applies wear-resistant coatings to the surface of the roller shells. These coatings can include chrome plating or ceramic coatings, which offer superior protection against wear and corrosion. The coatings act as a barrier, reducing the direct contact between the steel surface and the raw materials, thus minimizing friction and wear during operation.

In addition to wear resistance, fatigue resistance is another critical characteristic of pellet mill rollers, especially considering the cyclical loading and mechanical stress that rollers experience during the pelletizing process. Weikeer has implemented several methods to improve the fatigue resistance of its GCr15 bearing steel pellet mill roller shells.

Precision Manufacturing and Material Selection The first step in enhancing fatigue resistance is to ensure that the material used in the production of the roller shells is of the highest quality. Weikeer selects only high-quality GCr15 bearing steel with low levels of impurities, ensuring uniform material properties throughout the roller shells. Precision manufacturing, including CNC machining and stringent quality control procedures, ensures that the rollers are free from defects such as cracks or voids, which could serve as initiation sites for fatigue failure.

Residual Stress Control Residual stresses, which can result from manufacturing processes such as casting, welding, or machining, can negatively impact the fatigue resistance of the roller shells. At Weikeer, residual stress control is an integral part of the production process. The company uses stress-relief annealing and shot peening to mitigate the effects of residual stress. Shot peening involves bombarding the surface of the roller shells with small steel balls, creating compressive stress on the surface, which improves fatigue resistance by preventing the initiation of cracks under cyclic loading.

Microstructural Optimization Weikeer also optimizes the microstructure of GCr15 steel to improve fatigue resistance. The company achieves this by refining the grain structure during heat treatment and ensuring a consistent distribution of carbide particles within the material. A finer, more uniform microstructure enhances the material's ability to withstand repetitive stress cycles without cracking or breaking.

Liyang Weikeer Feed Machinery Manufacturing Co. Ltd. is committed to producing high-quality pellet mill rollers that meet the demanding needs of the feed industry. Through the use of Bearing Steel GCr15 Pellet Mills Rollers Shells, the company has successfully enhanced the wear resistance and fatigue resistance of its roller shells, ensuring that they deliver long-lasting, high-performance operation in pellet mills.

By employing advanced heat treatment, surface hardening, wear-resistant coatings, precision manufacturing, residual stress control, and microstructural optimization, Weikeer guarantees that its rollers are up to the task of withstanding the harsh conditions of feed production. These innovations not only improve the durability of the rollers but also reduce downtime, maintenance costs, and improve overall productivity.

With a continued commitment to excellence, Weikeer remains a trusted partner for customers in the feed machinery sector, providing high-quality solutions that deliver exceptional value and performance. Whether you are looking for durable, high-performance pellet mill rollers or tailored solutions for your feed production needs, Liyang Weikeer is your ideal choice.