Dimpled Alloy Steel Pellet Roller

Alloy steel roller dimpled rollers have unique advantages and specific applicati...

Alloy steel roller dimpled rollers have unique advantages and specific applicati...

Alloy steel roller corrugated close ends are specialized components with distinc...

The 20CrMnTi roller with a diagonal groove design is a specialized component cra...

The 20CrMnTi alloy steel provides tensile strength and toughness, making the rol...

Alloy steel roller corrugated open ends are designed for specific applications w...

The 20CrMnTi roller with curved corrugation is a high-performance component made...

Alloy steel rollers are crafted from top-quality materials such as 20CrMnTi, renowned for their exceptional strength and durability. This ensures that the rollers can endure the continuous pressure and friction encountered during the pelletizing process.

Alloy steel 20CrMnTi is a high-quality, low-alloy carburizing steel known for its strength, hardness, wear resistance, and toughness after heat treatment. It is primarily used in applications where components require a hardened surface and a tough core, making it a popular choice for high-stress, high-load parts like gears and shafts.20CrMnTi achieves surface hardness after carburizing and quenching. The surface hardness can reach 58-62 HRC, providing exceptional resistance to wear and surface fatigue. The core of the material retains toughness and ductility after heat treatment, allowing it to absorb shocks and impacts without cracking or breaking.20CrMnTi is particularly well-suited for carburizing. This process increases the carbon content at the surface, allowing for a hard, wear-resistant outer layer while maintaining a softer, tough core.

Biomass pellets mill pellet ring dies are crucial components in the production of biomass pellets. T...

View MoreLiyang Weikeer Feed Machinery Manufacturing Co., Ltd.participating in the AGRAVIA 2026 exhibition, t...

View MoreA dimpled bearing steel pellet roller is a critical component used in pelletizing and briquetting sy...

View MorePellet mills are essential equipment in feed, biomass, and industrial pellet production. At the hear...

View MoreThe ring die is one of the most critical components in a complex fertilizer pellet mill. It directly...

View MoreDimpled bearing steel pellet rollers are critical components in pelletizing processes used in indust...

View MoreMechanical properties of Alloy steel 20CrMnTi Pellet Mills Die Rollers from Liyang Weikeer Feed Machinery Manufacturing Co.Ltd.

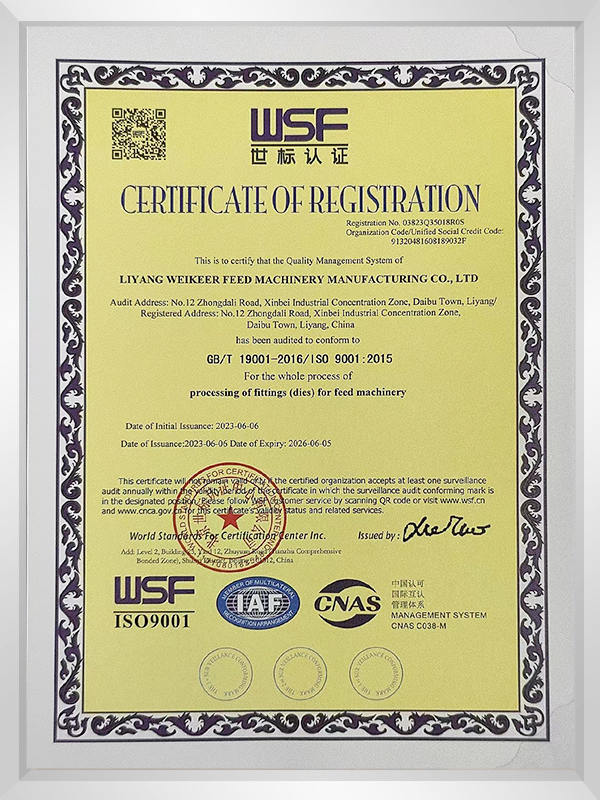

Liyang Weikeer Feed Machinery Manufacturing Co., Ltd., a prominent manufacturer of pellet mill dies, rollers, and related accessories, has built a strong reputation for providing reliable and high-performance products to the feed industry. Established in 1996 and located near the picturesque Tianmu Lake, Weikeer has grown into a leading name in the industry. With over 7,000 m² of production workshops within a factory spanning 13,000 m², the company is equipped with cutting-edge technology, advanced machinery, and a team of skilled professionals.

In recent years, Weikeer has made substantial investments in state-of-the-art equipment, such as the CNC HTT KH-4-100 for ring dies and HZQL heat treatment systems. These investments reflect the company’s commitment to quality and efficiency, ensuring that its products meet the highest industry standards. Weikeer manufactures high-quality, precision-engineered products compatible with leading brands in the feed machinery sector, including ZCME, CPM, IDAH, Bühler, Famsun, Andritz, Van Aarsen, Yeong Ming, and Chiatung. The company’s focus on innovation, advanced manufacturing, and customer satisfaction has positioned it as a trusted partner in the feed industry.

Among Weikeer's standout products are its Alloy Steel 20CrMnTi Pellet Mills Die Rollers, which offer superior mechanical properties, making them an ideal choice for high-demand, high-performance applications in the feed production process. These die rollers are carefully engineered for optimal durability, strength, and resistance to wear and deformation, ensuring maximum efficiency in pelletizing operations.

Alloy steel 20CrMnTi is a high-strength, wear-resistant steel widely used in the production of components subjected to high levels of mechanical stress and harsh operating environments. The key elements of this alloy—chromium (Cr), manganese (Mn), and titanium (Ti)—contribute to its exceptional hardness, tensile strength, and resistance to wear, making it particularly well-suited for pellet mill die rollers, which endure extreme pressure and temperature during feed production.

The combination of these elements in 20CrMnTi alloy steel provides an excellent balance of hardness and toughness, ensuring that the die rollers can withstand the mechanical stresses encountered during the pelletizing process without cracking, warping, or losing their structural integrity. This makes them particularly effective in applications where longevity, durability, and performance are critical.

The mechanical properties of 20CrMnTi alloy steel make it a top choice for pellet mill die rollers. These include:

The hardness of 20CrMnTi steel is one of its most defining features, typically reaching values of 58-63 HRC (Rockwell Hardness). This high hardness ensures the die rollers are resistant to wear, making them ideal for the high-speed operation of pellet mills, where constant friction and pressure are exerted on the rollers.

The tensile strength of 20CrMnTi is generally in the range of 900-1,200 MPa. This high tensile strength allows the die rollers to withstand the intense forces involved in the pelletizing process, ensuring that they do not fracture or deform under pressure.

Pellet mill die rollers are subject to repetitive mechanical stresses, which can lead to fatigue failure over time. However, 20CrMnTi steel exhibits excellent fatigue resistance, ensuring that the rollers retain their strength and performance over an extended service life.

The wear resistance of 20CrMnTi alloy steel is another critical factor in the performance of die rollers. This property ensures that the rollers maintain their surface integrity even after prolonged use, reducing the need for frequent maintenance and replacement. The wear resistance of 20CrMnTi alloy is enhanced through heat treatment processes, which further improve the material's performance under stress.

Pelletizing operations often involve high temperatures, and the ability of the die rollers to maintain their mechanical properties at elevated temperatures is essential for consistent performance. Alloy steel 20CrMnTi has excellent heat resistance, ensuring that the rollers retain their hardness and strength even under high thermal loads.

20CrMnTi is known for its outstanding impact toughness, which enables the die rollers to absorb shock and prevent sudden failures under high-pressure conditions. This property makes it ideal for the harsh conditions in pellet mills, where mechanical shocks and vibrations are common.

In feed production, pellet mills play a vital role in converting raw ingredients into uniform, compact pellets that are easy to handle, store, and distribute. Pellet mill die rollers are essential components of these mills, responsible for applying pressure to the raw material to form pellets. The mechanical properties of the die rollers directly influence the efficiency and effectiveness of the pelletizing process.

Weikeer’s Alloy steel 20CrMnTi Pellet Mills Die Rollers are designed to endure the high pressures and temperatures encountered during feed production. The superior mechanical properties of these rollers ensure consistent production quality, reduced downtime, and improved throughput. The ability of the rollers to maintain their structural integrity over time reduces the frequency of maintenance, ultimately lowering the cost of ownership and increasing the operational efficiency of feed mills.

Liyang Weikeer’s investment in advanced CNC machines and heat treatment equipment ensures that each Pellet Mill Die Roller is manufactured with precision and high-quality standards. The company’s experienced technicians carefully control the production process, from material selection to heat treatment, to guarantee that every die roller meets the exact specifications required for optimal performance.

The use of heat treatment techniques such as carburizing and quenching ensures that the 20CrMnTi alloy steel achieves the desired hardness and wear resistance. This process also enhances the toughness of the material, ensuring that the rollers can withstand the extreme conditions of the pelletizing process without cracking or breaking.

Liyang Weikeer Feed Machinery Manufacturing Co., Ltd. continues to lead the feed machinery industry with its high-quality, high-performance Pellet Mill Die Rollers made from Alloy Steel 20CrMnTi. With superior mechanical properties including hardness, tensile strength, wear resistance, and heat resistance, these die rollers ensure consistent and efficient pelletizing performance, even under the most demanding conditions. Through continuous investment in advanced manufacturing technologies and a commitment to quality, Weikeer has established itself as a trusted partner for feed producers worldwide. Whether you are looking for durable, high-performance pellet mill die rollers or tailored solutions for your feed production needs, Weikeer remains your ideal partner for success.