With the popularization of renewable energy, biomass pellets are widely used as clean fuel in industrial boilers, home heating and other fields. In the process of pellet production, mold clogging problems frequently occur, which not only affects production capacity, but may also cause equipment damage, increased energy consumption, and even shutdown. The reason is that mold clogging is not caused by a single factor, but the result of the combined effect of raw materials, moisture, mold design, operating parameters and other aspects.

1. Raw material problems are the fundamental cause of clogging

The main raw materials of biomass pellets die include plant waste such as sawdust, straw, rice husks, and palm shells. The impurity content, fiber structure and crushing particle size of the raw materials themselves will directly affect the smoothness of the pellet pressing.

Too many impurities or too large particles are easy to form blockages in the mold channel;

High sand content or mixed with metal fragments will cause abnormal wear of the mold;

Uneven fiber length makes it difficult for the raw materials to pass through the mold channel continuously during pressing.

Solution suggestions:

Use a multi-stage screening system to filter impurities;

Control the crushing particle size between 2-6mm;

Mixed use of different raw materials can improve molding stability.

2. Moisture control is the key to smooth pressing

Moisture is the "lubricant" for particle forming. Too high or too low will cause mold clogging.

When the moisture is too high (>15%), the raw materials are easy to form adhesion in the mold, cooling is slow, and the probability of pore clogging is high;

When the moisture is too low (<8%), compression molding is difficult, resulting in a lot of dust and easy cracking of particles, which in turn blocks the mold outlet.

Solution suggestions:

Control the moisture content of the raw materials between 10%-12%;

Install a pre-drying system, especially in a high humidity environment;

Real-time detection of feed moisture fluctuations, accurate adjustment of feed speed and pressure wheel pressure.

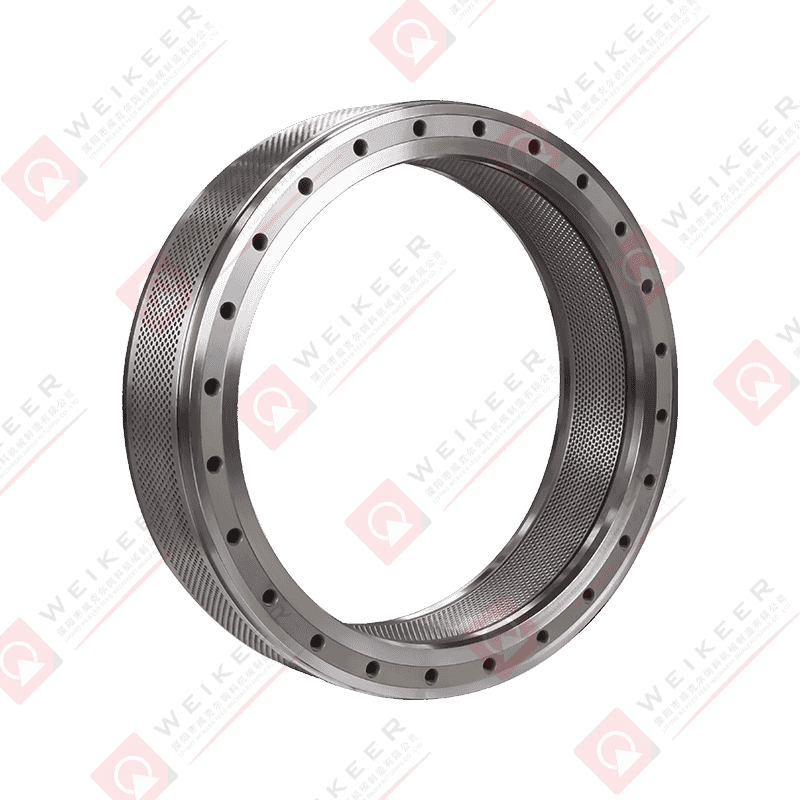

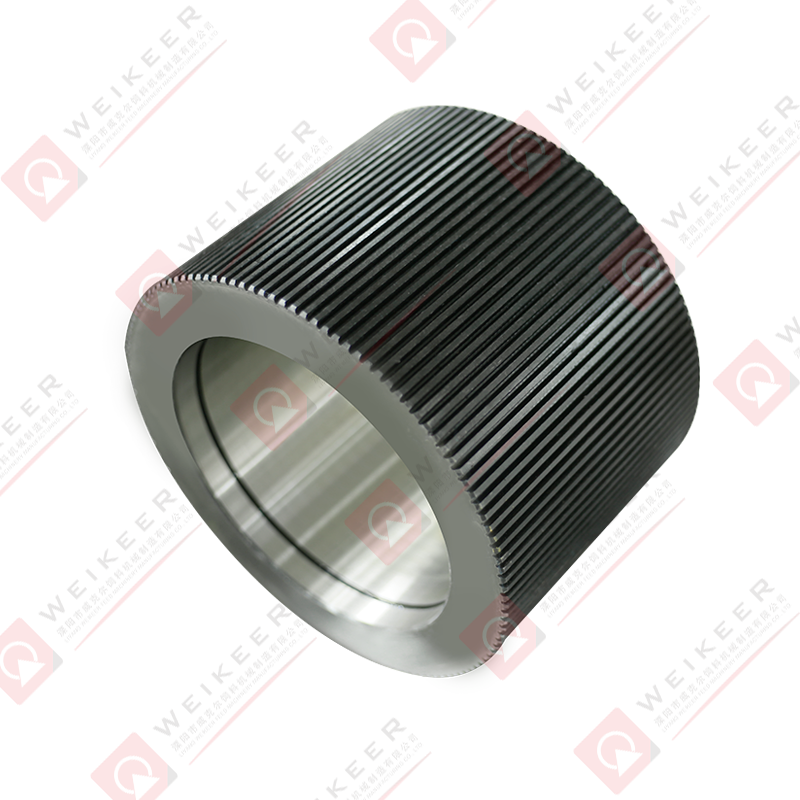

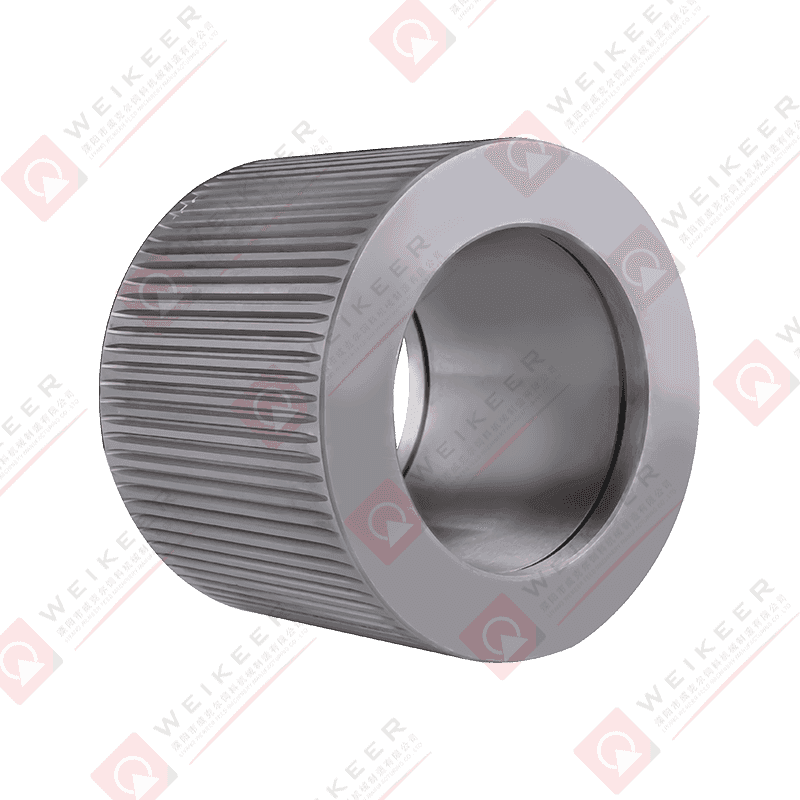

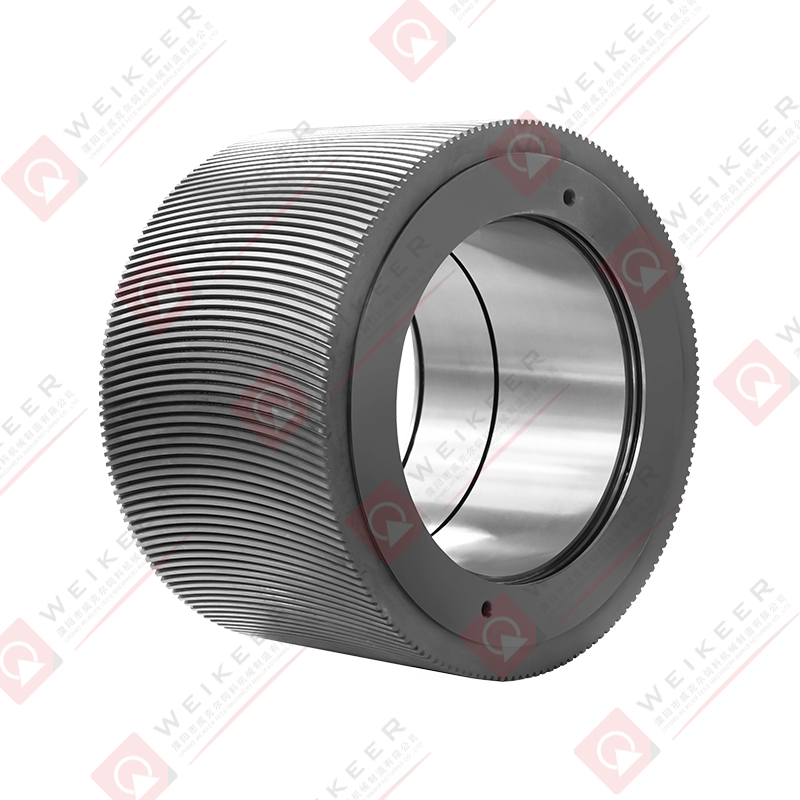

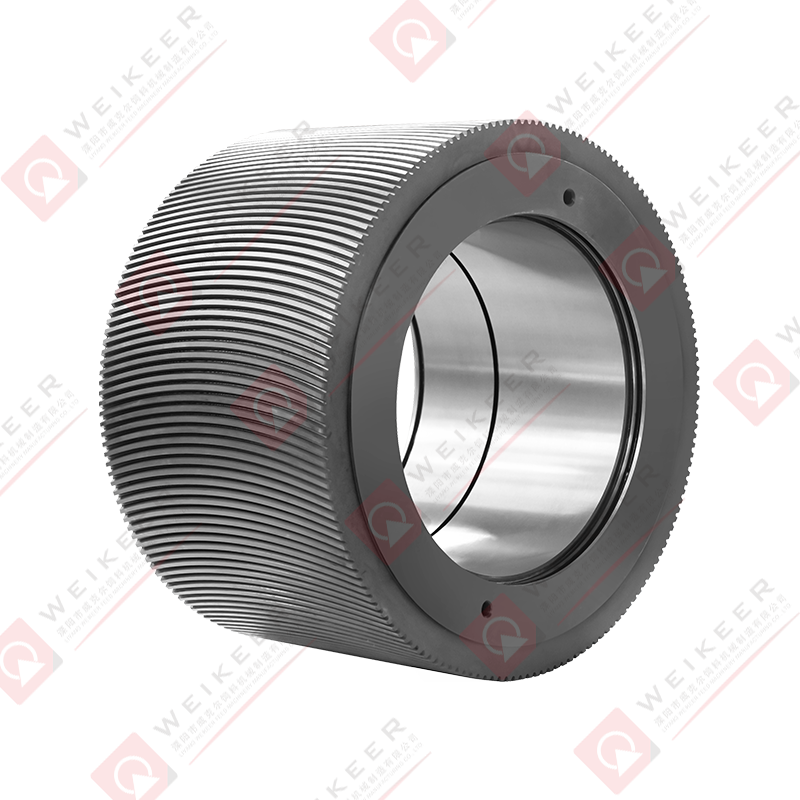

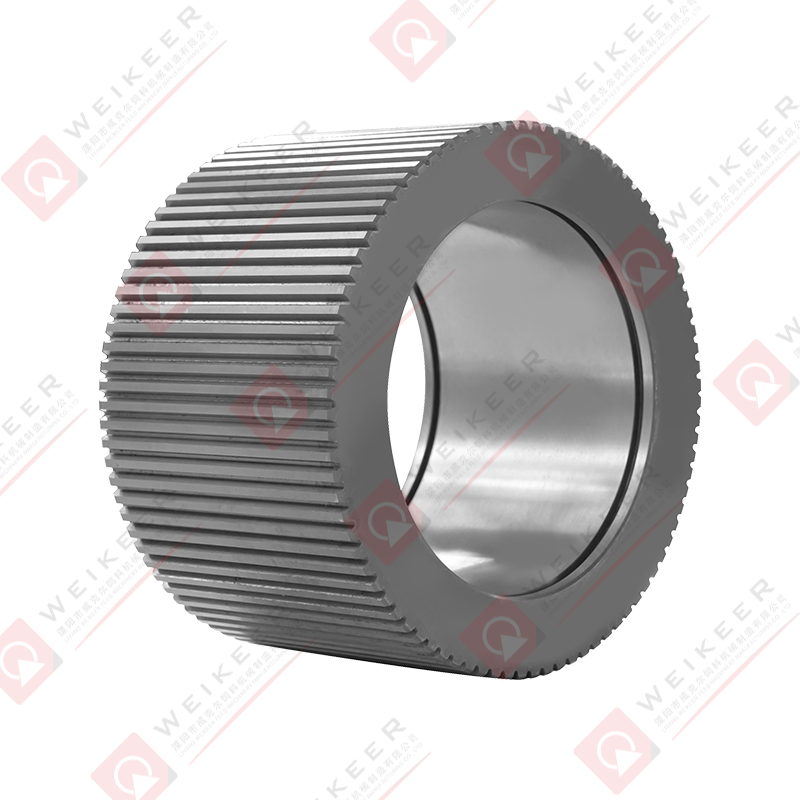

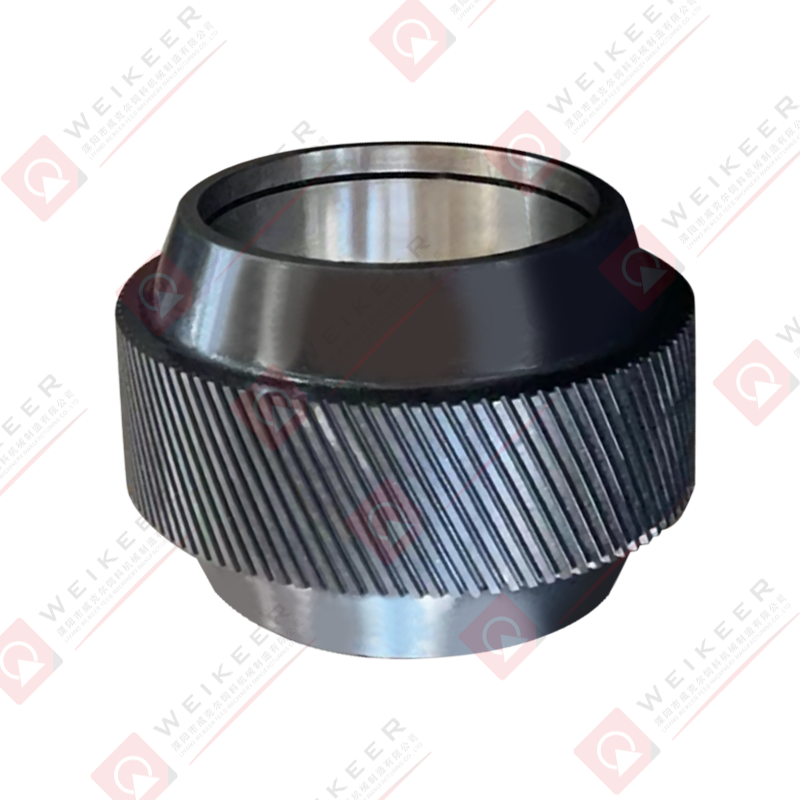

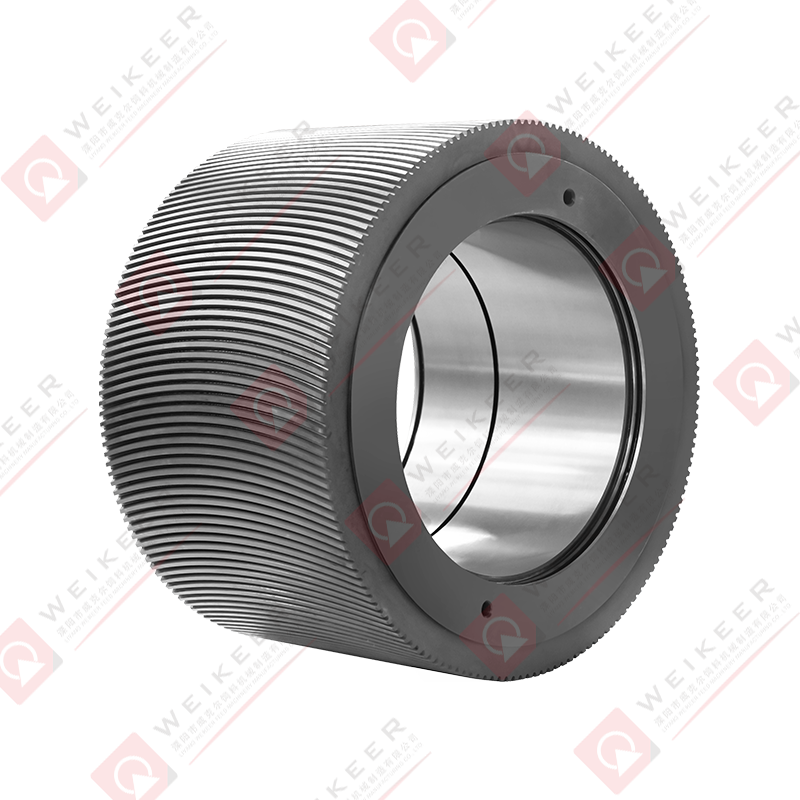

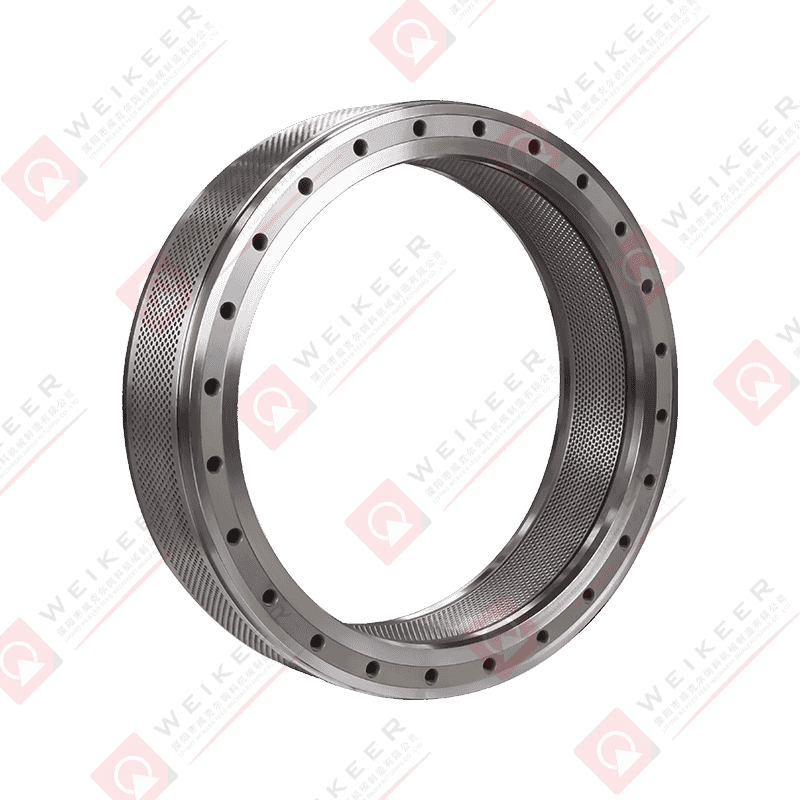

3. Mold design structure affects material discharge efficiency

Parameters such as mold aperture, compression ratio, and channel length play a decisive role in particle forming and discharge.

Irrational compression ratio design (such as too high) will increase material resistance and cause clogging;

The number density of mold holes is too high, heat is not easy to dissipate, and the raw materials are easy to heat and stick to the orifice;

The mold material is not hard enough, and the wear and deformation of the channel will also affect the smoothness of discharge.

Solution suggestions:

Choose a suitable compression ratio according to the characteristics of the raw materials (generally between 1:4 and 1:6);

Optimize the cooling system to keep the working temperature of the mold within the normal range;

Regularly check whether the mold hole is deformed or carbonized, and replace or clean it in time.

IV. Operation parameters and maintenance mechanisms cannot be ignored

In addition to the above technical factors, the operator's commissioning and daily maintenance of the equipment also play a decisive role.

Operation suggestions:

Maintain a suitable gap between the pressing wheel and the mold to avoid "crushing";

Stop the machine in time when encountering blockage to avoid greater damage caused by forced operation;

Clean the mold surface every shift, and regularly perform maintenance operations such as decarbonization and lubrication on the equipment.

Blocking of biomass pellet molds is a comprehensive problem that cannot be simply attributed to a single factor. Only by starting from multiple aspects such as raw material screening, moisture control, mold design and operation and maintenance, and forming a systematic production management process, can we effectively reduce mold blockage and improve the stability and economy of pellet production.

русский

русский Español

Español عربى

عربى 中文简体

中文简体