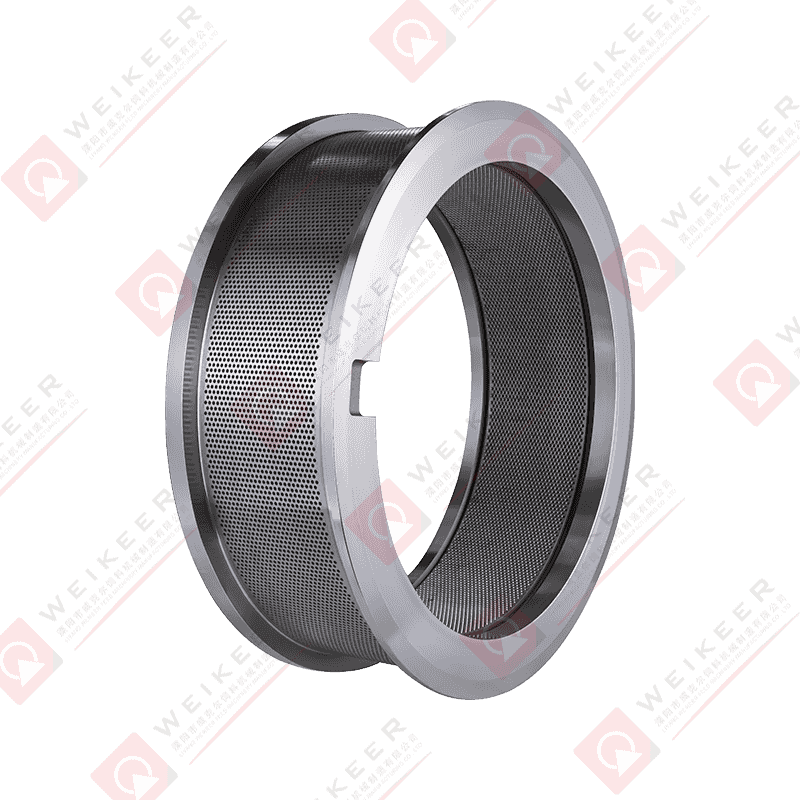

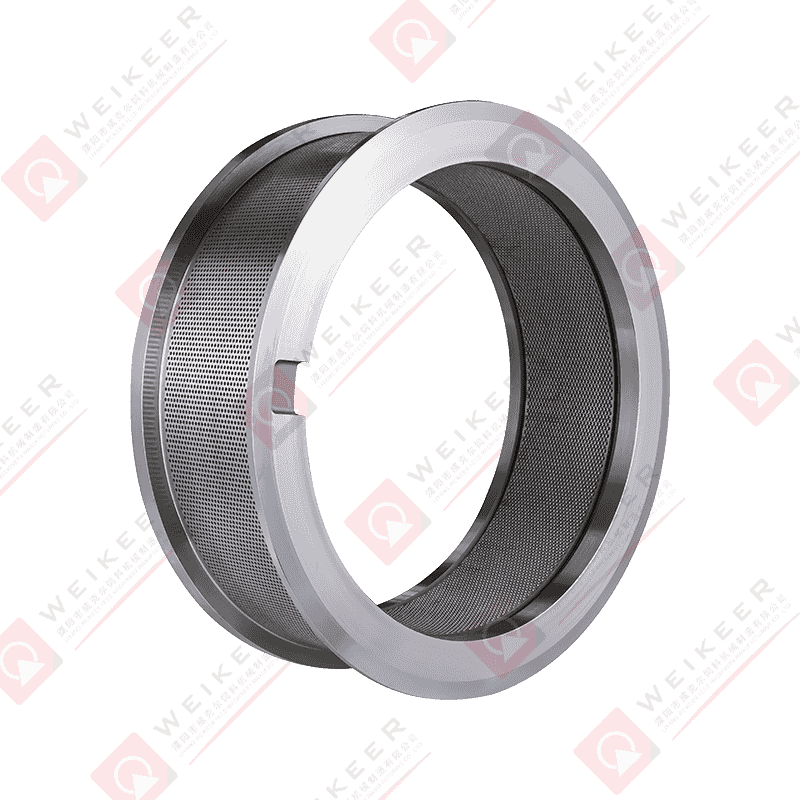

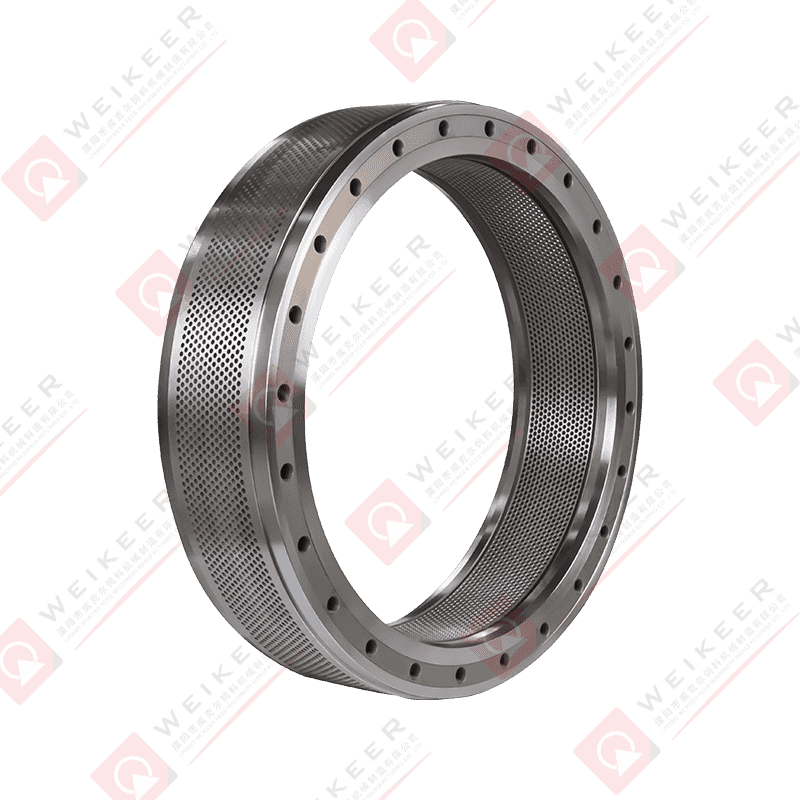

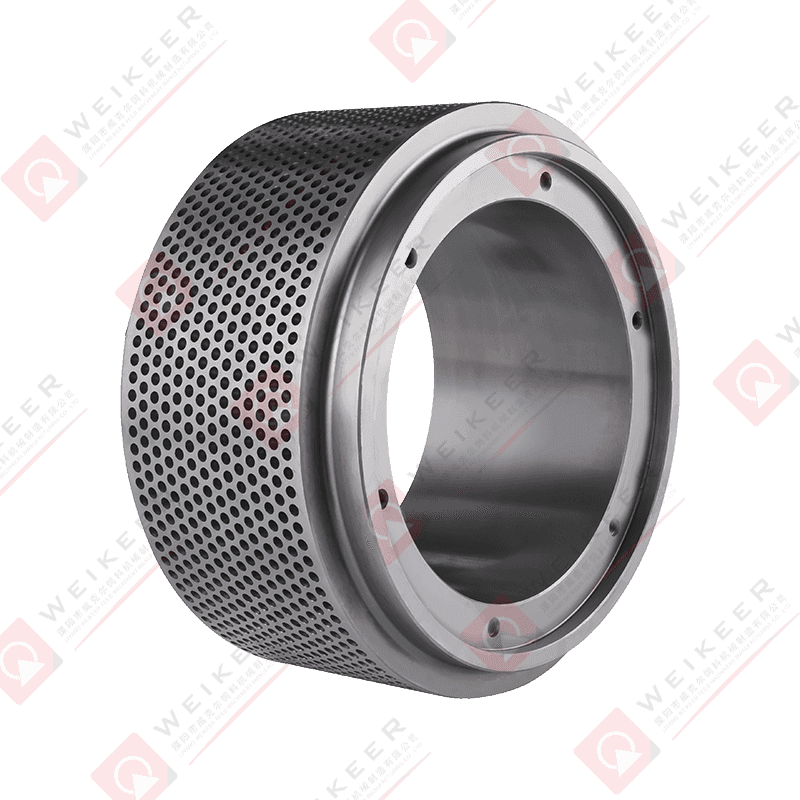

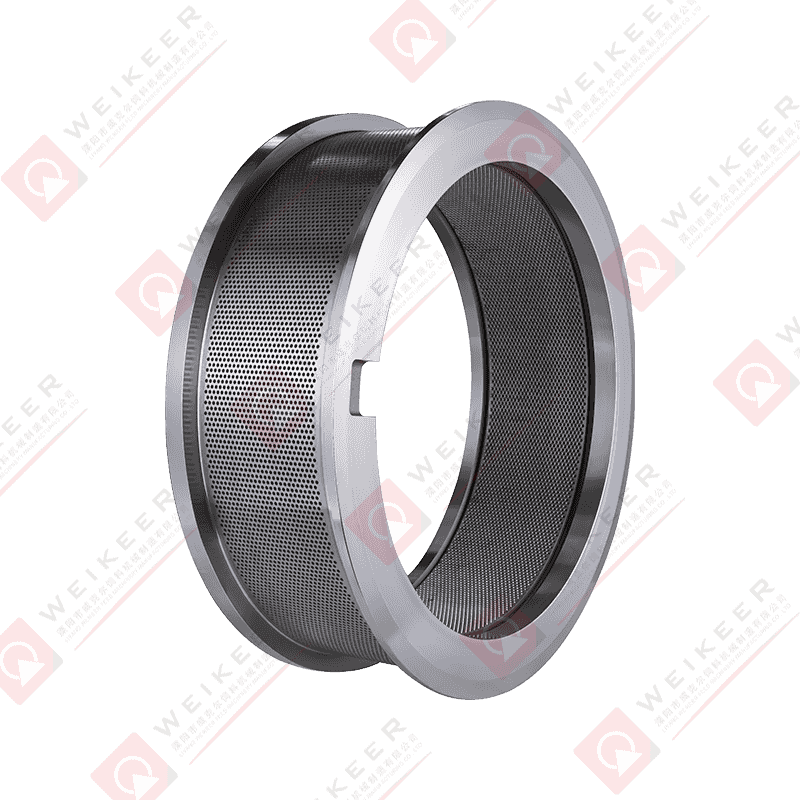

The anchor earring die of the cat litter pellet machine is one of the most critical components in the pellet machine production process, and its performance directly affects the quality of the pellets and production efficiency. However, the ring die will inevitably wear out during long-term operation. If it is not prevented and treated in time, it will not only reduce production efficiency, but also may cause equipment failure or even shutdown.

1. Common causes of wear of anchor earring die

1. High hardness of raw materials or high impurity content

When producing cat litter pellets, sand, mineral impurities or other hard particles in the raw materials will cause mechanical impact and abrasion on the surface of the ring die, accelerating the wear of the mold. Especially when the raw materials are not fully screened and pretreated, hard impurities directly act on the ring die aperture and the pressure ring part, resulting in scratches, pits and deformation on the surface of the ring die.

2. Insufficient hardness of mold material or poor heat treatment

The hardness of the ring die material and the heat treatment process are key factors affecting the wear rate. If the selected steel is not hard enough or the heat treatment process is not up to standard, the strength and wear resistance of the mold will be greatly reduced, resulting in rapid aging, deformation, cracks and wear of the mold during high-load operation.

3. Imperfect lubrication system

The ring die and roller generate a lot of friction and heat during high-speed operation. Poor lubrication will increase the surface temperature of the mold, causing metal softening, premature wear and even local ablation. In addition, lubricating oil pollution or lack of timely replacement will also affect the lubrication effect and accelerate mold wear.

4. Improper equipment commissioning and installation

Anchor earring die installation position deviation, equipment bearing wear, uneven roller pressure and other problems will cause uneven force on the ring die, local stress concentration, abnormal wear and even cracks. Long-term vibration or instability of the equipment will also aggravate the mechanical fatigue of the mold.

5. Unreasonable operation process

For example, too fast production speed, improper control of raw material moisture content, unreasonable particle formula design, etc. will increase the load on the ring die and lead to faster wear. Excessive particle pressure or uneven pressure distribution causes the ring die to be overloaded, prone to deformation and wear.

2. Preventive measures for wear of anchor ear ring die

1. Strictly control the quality of raw materials

Ensure that the impurity content in the raw materials is as low as possible, especially to avoid hard impurities from entering the production system. If necessary, use screening, magnetic separation and other processes to pre-treat the raw materials to reduce the mechanical impact on the ring die and extend the life of the die.

2. Select high-quality materials and reasonable heat treatment processes

Select high-wear-resistant alloy steel or powder high-speed steel to manufacture the ring die, and perform scientific heat treatment processes to improve the surface hardness and toughness of the die. Advanced surface treatment technologies (such as nitriding, ceramic coating, etc.) can also significantly improve the wear resistance of the ring die.

3. Ensure the effective operation of the lubrication system

Regularly check the quality of the lubricating oil and the unobstructed oil circuit to ensure timely replacement of the lubricating oil and avoid aging and contamination of the lubricant. Use an automatic lubrication device to ensure continuous and uniform lubrication between the die and the pressure roller to reduce friction and temperature rise.

4. Accurate equipment commissioning and maintenance

Ensure that the anchor earring mold is installed accurately, adjust the pressure of the pressure roller to meet the design requirements, and avoid uneven pressure causing local excessive wear. Regularly maintain equipment bearings, guide rails and other components to reduce vibration and abnormal operation and ensure the overall stability of the equipment.

5. Optimize production process parameters

Reasonably control the production speed, maintain an appropriate moisture content of raw materials, and avoid increasing the mold load due to abnormal process parameters. Reduce the content of hard particles through formula optimization, make the particle molding pressure uniform, and reduce the force on the ring mold.

As an important core component of the cat litter pellet machine, the anchor earring mold is inevitably worn, but through reasonable material selection, strict raw material control, effective lubrication maintenance, precise equipment commissioning and scientific process management, the wear rate can be significantly slowed down, the mold service life can be extended, and production efficiency and product quality can be improved. Enterprises should establish a complete ring mold maintenance and monitoring system to promptly discover and solve wear hazards and maximize economic benefits.

русский

русский Español

Español عربى

عربى 中文简体

中文简体