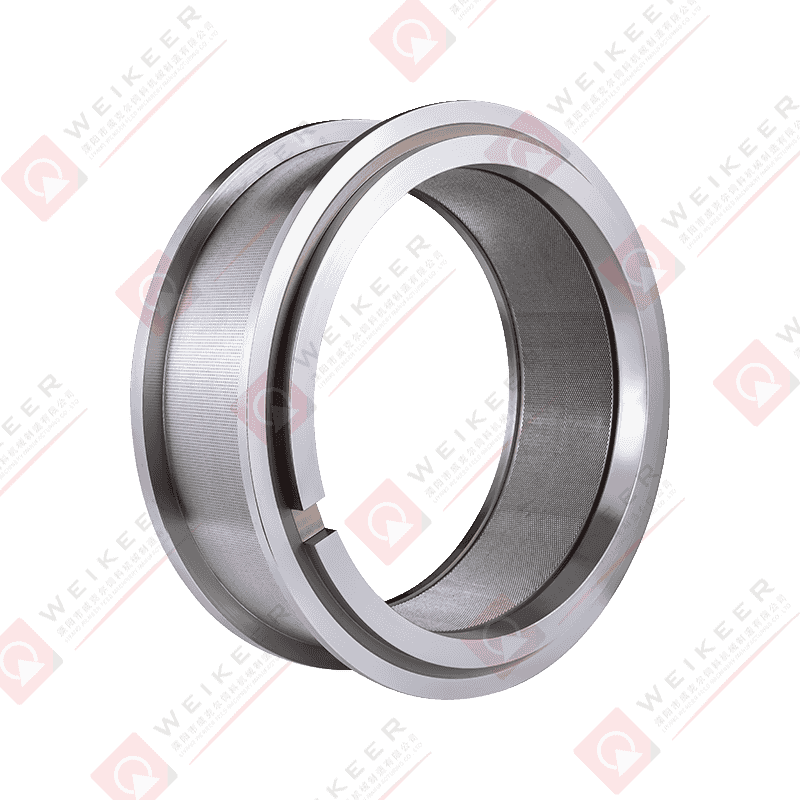

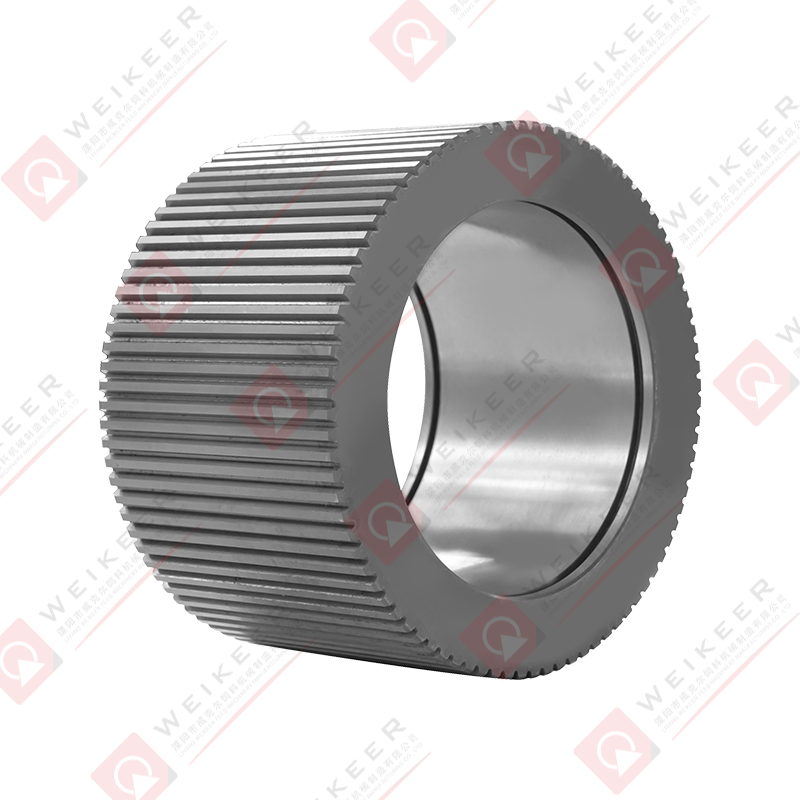

In modern aquaculture, the quality of feed is directly related to the growth rate, health status and breeding cost control of aquatic animals such as fish and shrimp. With the continuous expansion of aquaculture scale, higher requirements are placed on efficient, stable and environmentally friendly feed processing equipment. Aqua Feed Pellet Mill Anchorear Ring Die As a key component in the pellet feed production system, it is increasingly becoming the focus of feed processing companies.

Compared with traditional molds, Anchorear Ring Die performs better in terms of aperture consistency, corrosion resistance and service life, and is particularly suitable for aquatic feed production lines that have extremely high requirements for feed pellet size and quality.

Core Advantages

Made of high-quality materials, extended service life

Anchorear uses high-alloy stainless steel or high-chromium steel materials, with excellent wear and corrosion resistance, which can meet the processing needs of high-fat, high-protein and sticky raw materials in aquatic feed.

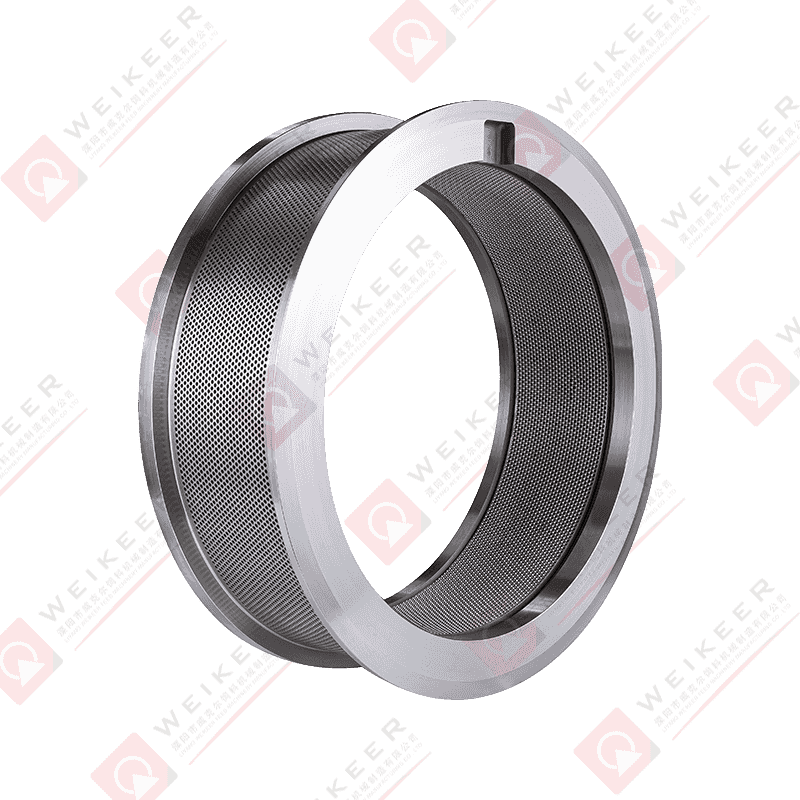

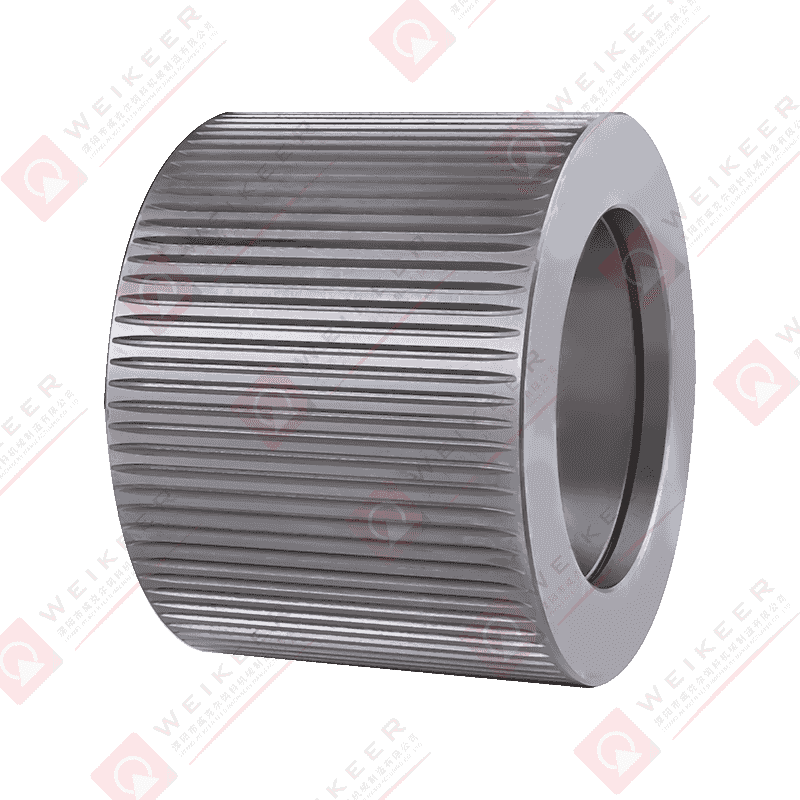

Precise die hole design to ensure feed uniformity

The die hole is processed and polished by CNC precision, and the aperture error is extremely small, ensuring that the density and size of each feed are consistent, effectively improving feed utilization and stability in water.

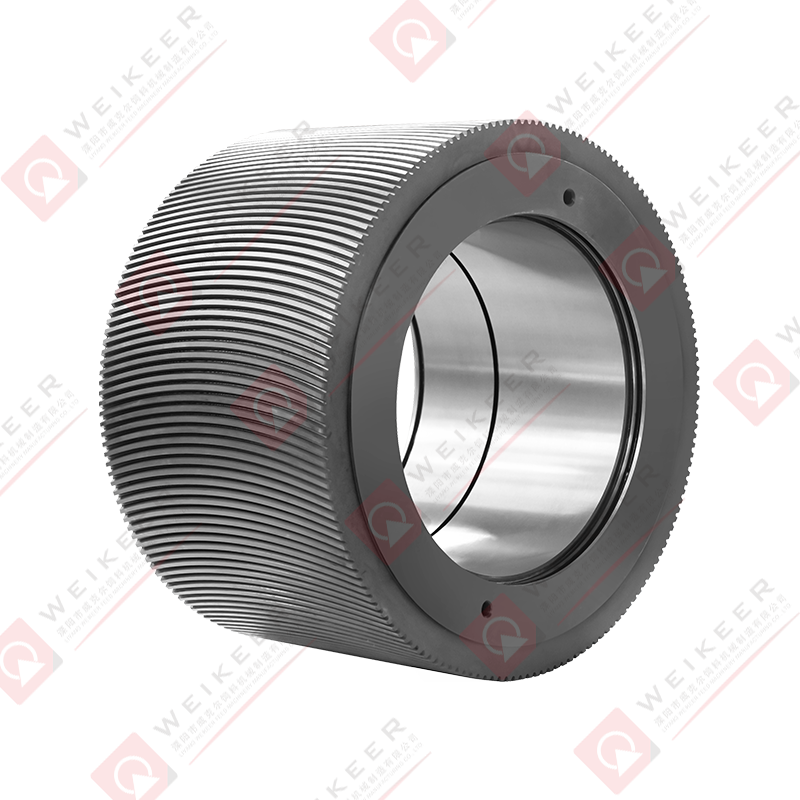

Advanced heat treatment process to improve fatigue resistance

Anchorear uses vacuum heat treatment and multi-stage quenching technology to make the ring die have excellent hardness and crack resistance, and can maintain long-term operation even under high-pressure continuous operation.

Energy saving and high yield, improve equipment efficiency

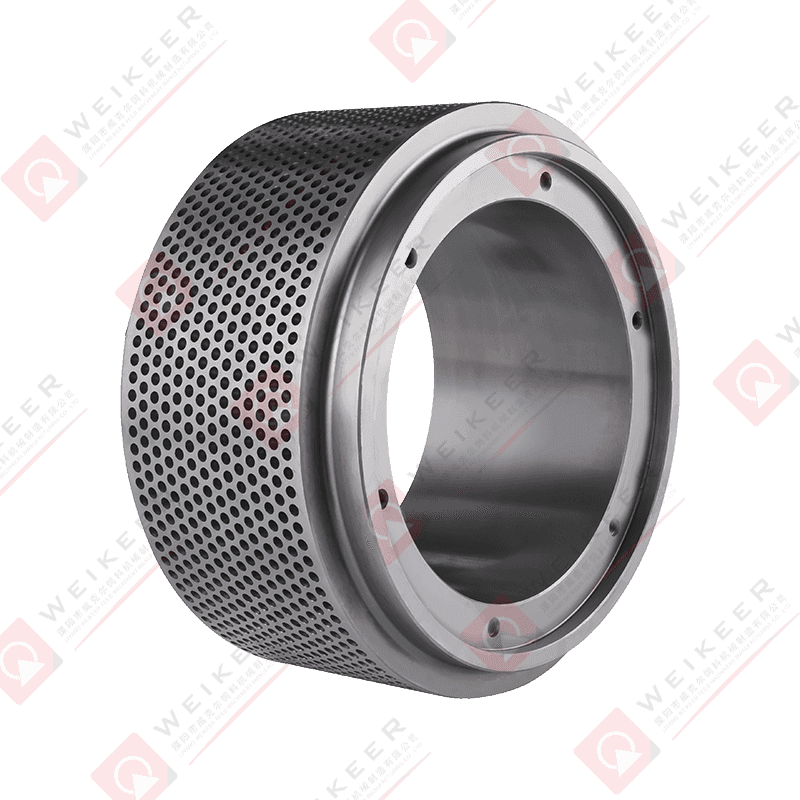

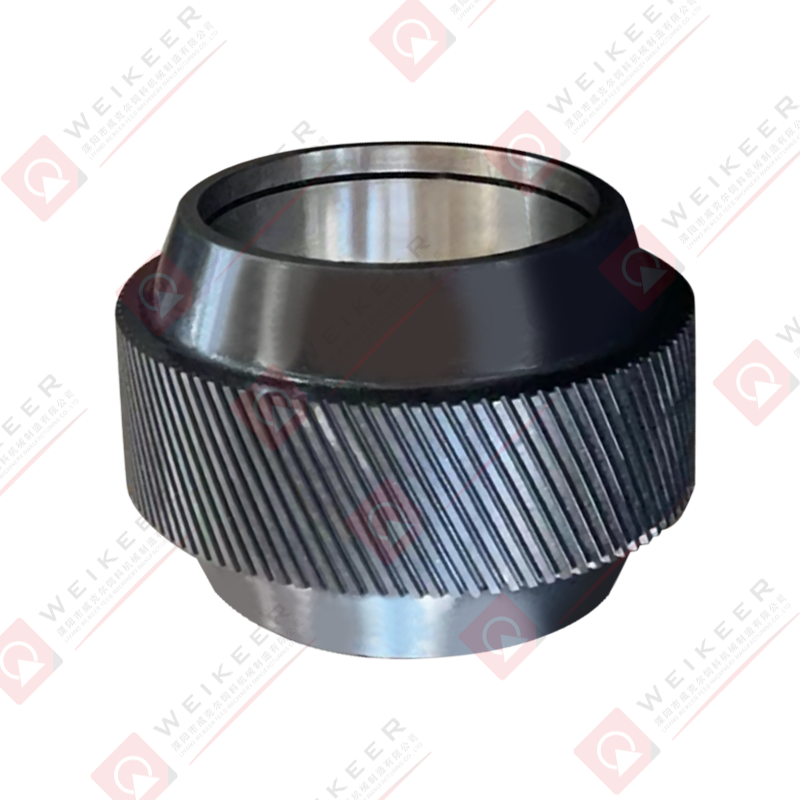

The high porosity and reasonable pore distribution structure design effectively reduce energy consumption, increase discharging speed, suitable for mass production environment, and reduce operating costs.

Application value in the aquatic feed industry

Aquatic feed pellets are required to have good stability in water, not easy to dissolve, and moderate density, which puts high demands on the design and manufacture of ring dies. Anchorear Ring Die can customize the die hole diameter and compression ratio according to the feed formula and needs of different species (such as tilapia, grass carp, white shrimp, etc.), helping companies to flexibly adjust feed hardness and particle size.

Floating feed: requires larger die holes and moderate compression ratio to make the feed have sufficient expansion capacity.

Sinking feed: requires higher compression ratio and dense structure so that the feed sinks quickly.

Anchorear's professional customization capabilities make its ring die products widely used in a variety of aquatic feed production lines and trusted by large feed companies.

Technological innovation and future trends

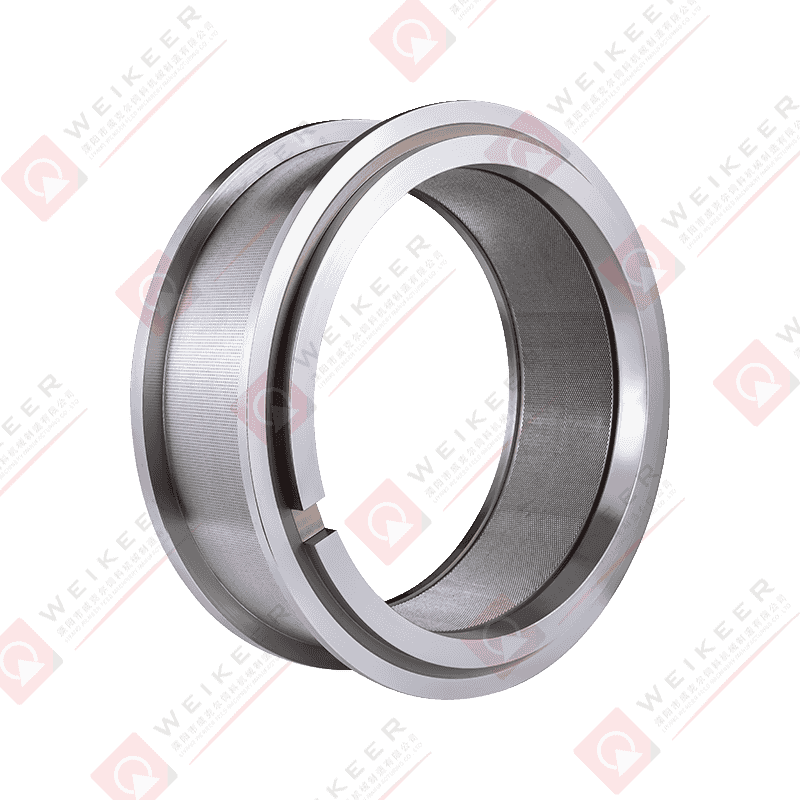

With the tightening of environmental protection regulations and the development of refined feed management, the technological innovation of ring die is also continuously advancing:

Introducing laser drilling and cold pressing molding technology to further improve the accuracy of die holes;

Developing anti-clogging surface treatment coatings to reduce the residue of high-protein raw materials;

Applying digital mold management system to monitor mold wear status and realize intelligent maintenance;

Promoting modular ring die structure to reduce replacement and maintenance time and improve the efficiency of the whole machine.

Aqua Feed Pellet Mill Anchorear Ring Die is an inconspicuous but crucial component in aquatic feed production equipment. It not only determines the molding quality and nutritional stability of the feed, but also affects the energy efficiency, maintenance cost and final benefits of aquaculture of the entire production line. As the demand for high-quality feed continues to rise, choosing a high-performance Anchorear ring die is undoubtedly a wise choice for aquatic feed companies to achieve sustainable development.

русский

русский Español

Español عربى

عربى 中文简体

中文简体