In modern industrial production and new energy development, granulation technology has become an important means to improve resource utilization and environmental benefits. Pellet Press (pellet press), as one of the core equipment, is widely used in biomass energy, feed processing, chemical metallurgy, waste recycling and other fields. It uses the principle of high-pressure molding to press powdered or finely crushed materials into compact and regular particles, greatly improving the efficiency of raw material use and product added value.

Improve raw material utilization

Through compression molding, the volume of the originally loose raw materials is significantly reduced, and the density is greatly increased, which is convenient for storage, transportation and subsequent use.

Environmental protection and energy saving

Pellet Press effectively reduces the waste and dust pollution of materials during use. Especially in the field of biomass energy, agricultural waste can be converted into combustible particles to replace traditional energy such as coal.

Compact structure and easy operation

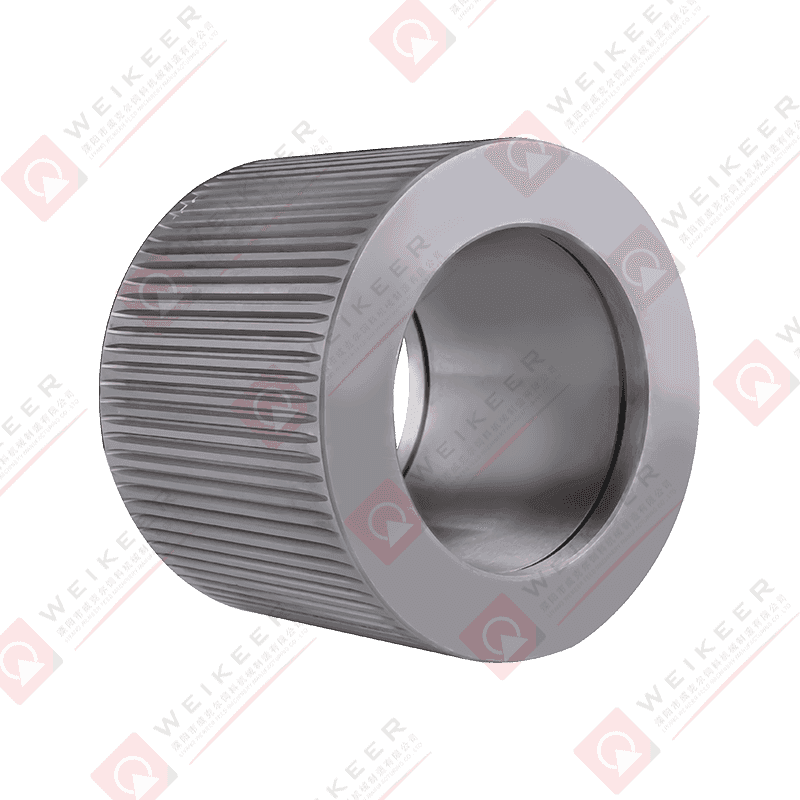

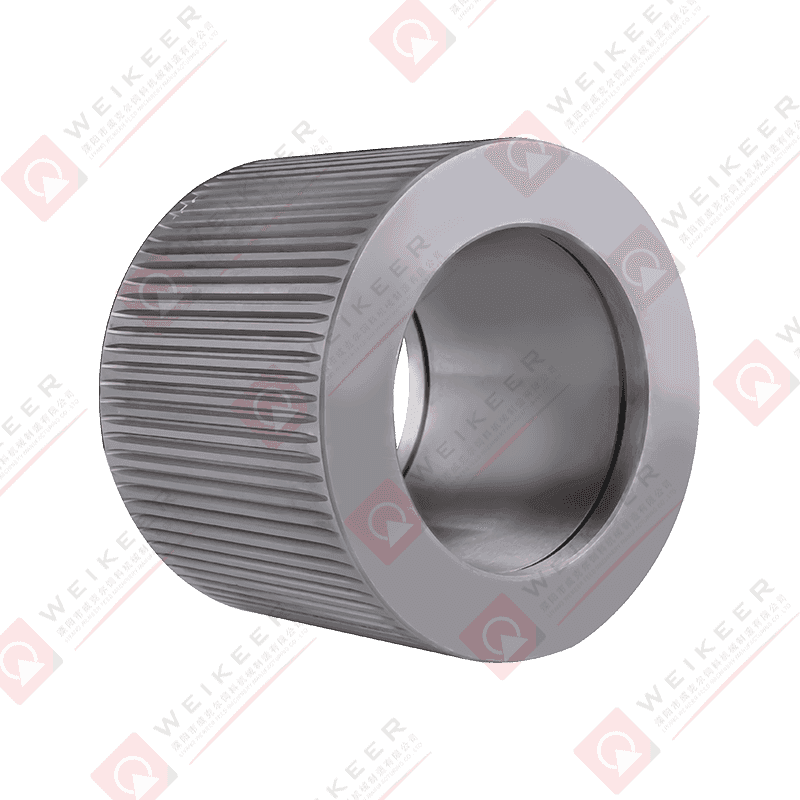

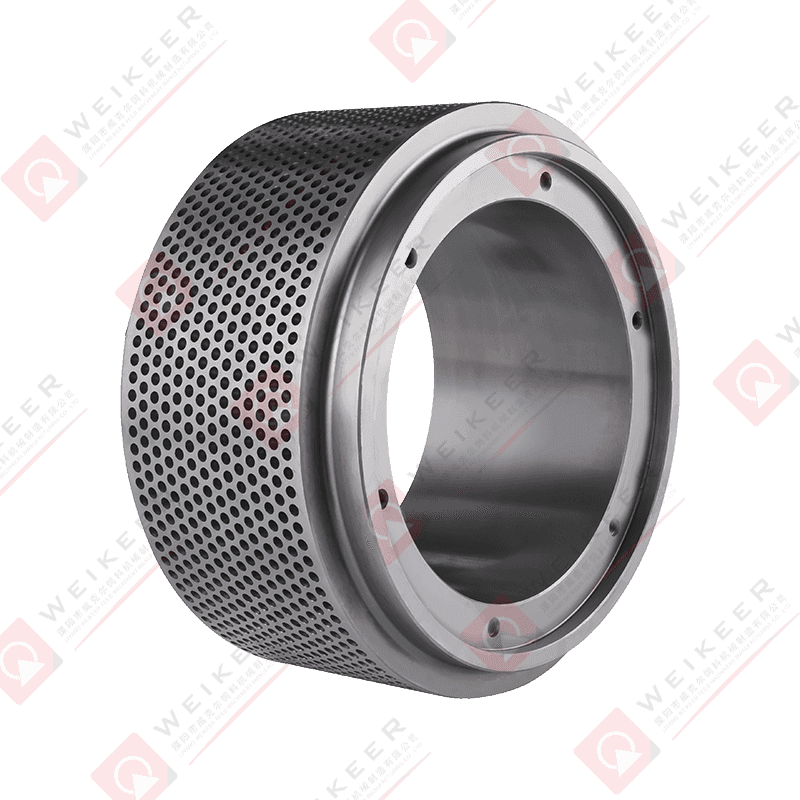

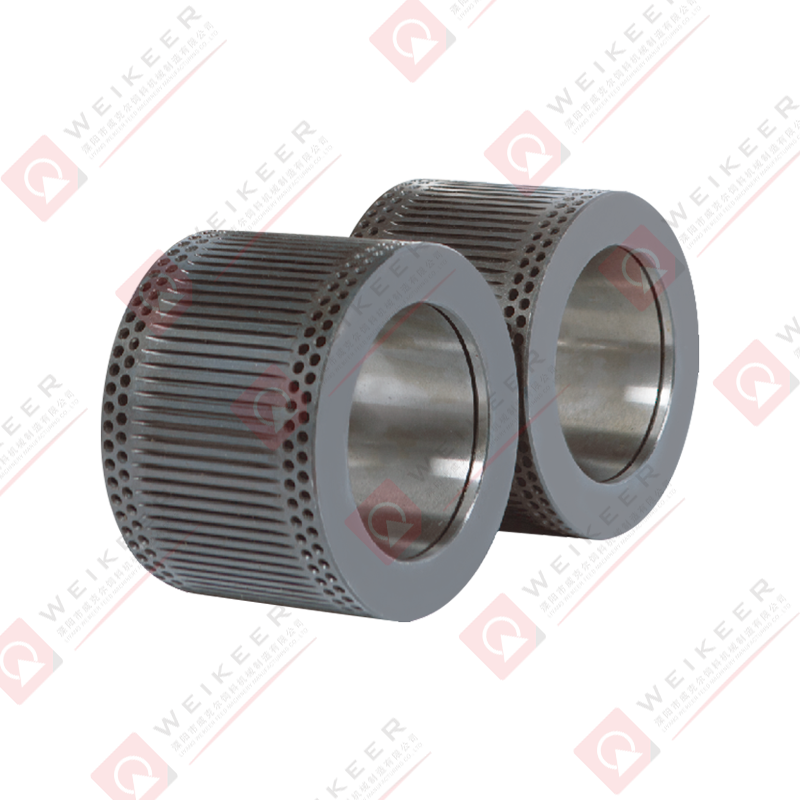

Modern Pellet Press equipment adopts modular design, which is easy to install and maintain. Users can choose corresponding molds according to different materials to achieve flexible production.

Strong product consistency

The pressed particles are uniform in size, moderate in hardness, and not easy to break. They are widely used in industrial fuel, animal feed, compound fertilizer and other purposes.

Wide range of applications

Whether it is agricultural waste, wood scraps, or chemical powders, metal oxides, etc., Pellet Press can achieve efficient pressing.

Biomass energy field

Biomass pellet fuel is an important direction for the current development of low-carbon economy. Pellet Press can convert agricultural and forestry waste into high calorific value fuel pellets, which are suitable for household boilers, industrial furnaces and other equipment, and have high alternative energy value.

Feed processing industry

In the animal husbandry industry, Pellet Press is used to press various grain powders, straw crushed materials, etc. into feed pellets that are easy for livestock to absorb, improving nutritional balance and animal intake efficiency.

Organic fertilizer and compound fertilizer production

Pressing livestock and poultry manure, crop straw, sludge, etc. into organic fertilizer pellets after processing is helpful for soil improvement and green agricultural development.

Metal powder metallurgy and chemical industry

Some high value-added materials such as metal oxides and chemical catalysts can also be precisely pressed into customized particles by Pellet Press for subsequent processing or reaction.

Capacity requirements: Select the appropriate pressing amount according to the usage scenario to meet industrial or household scale use.

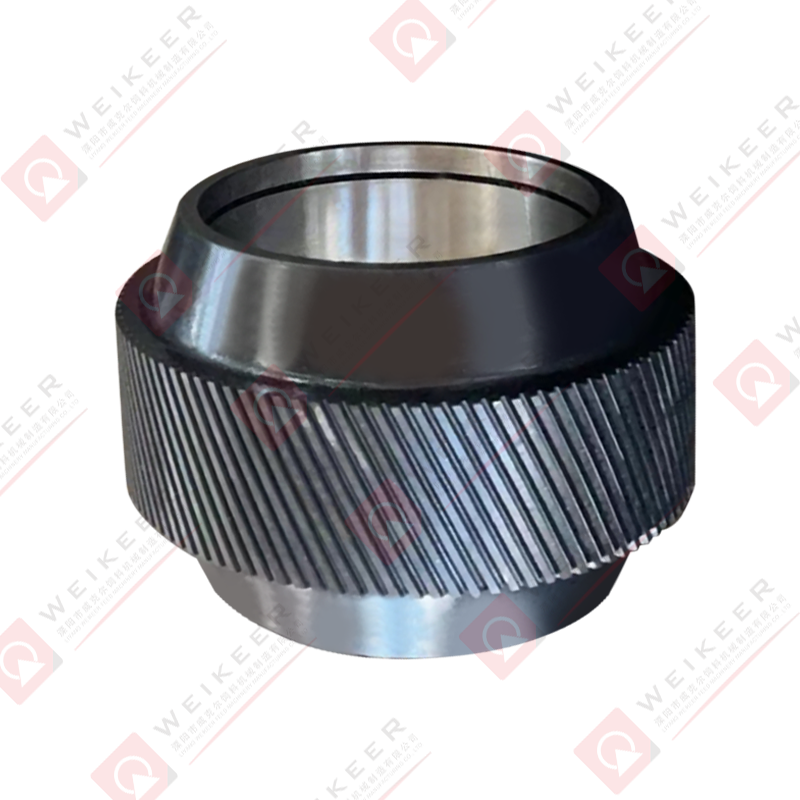

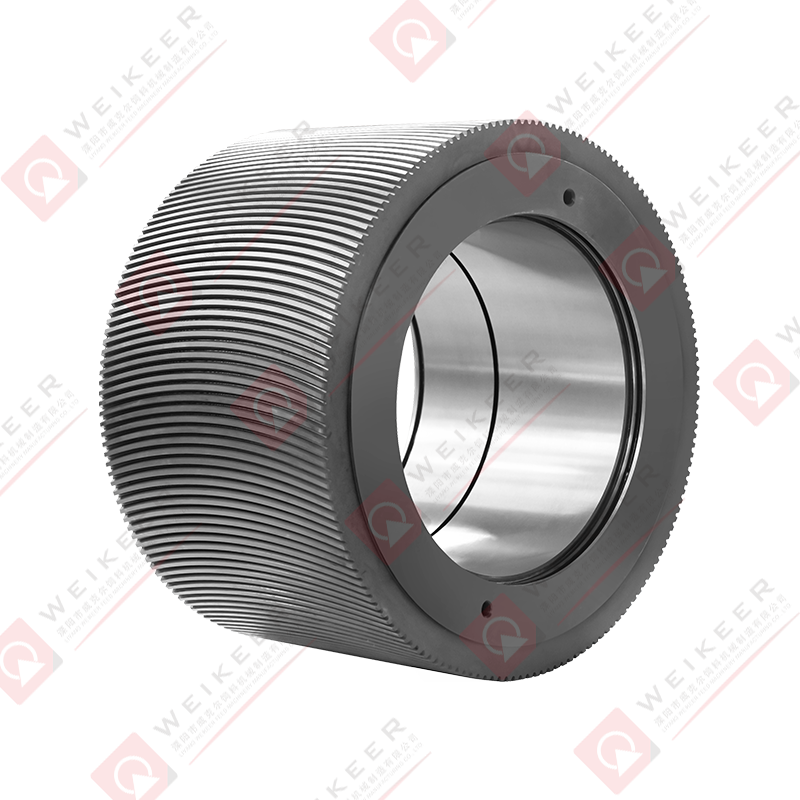

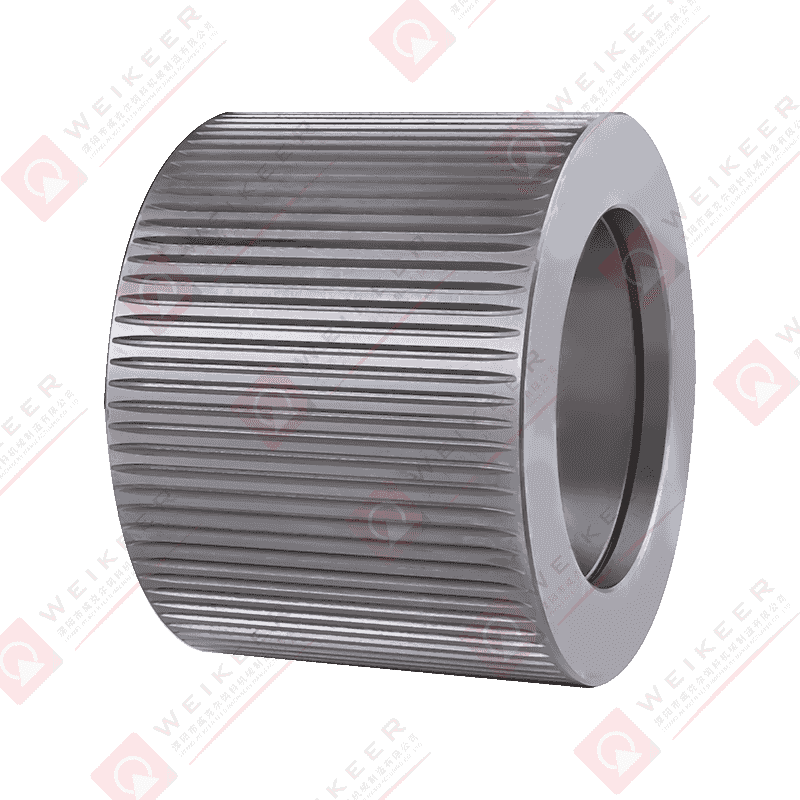

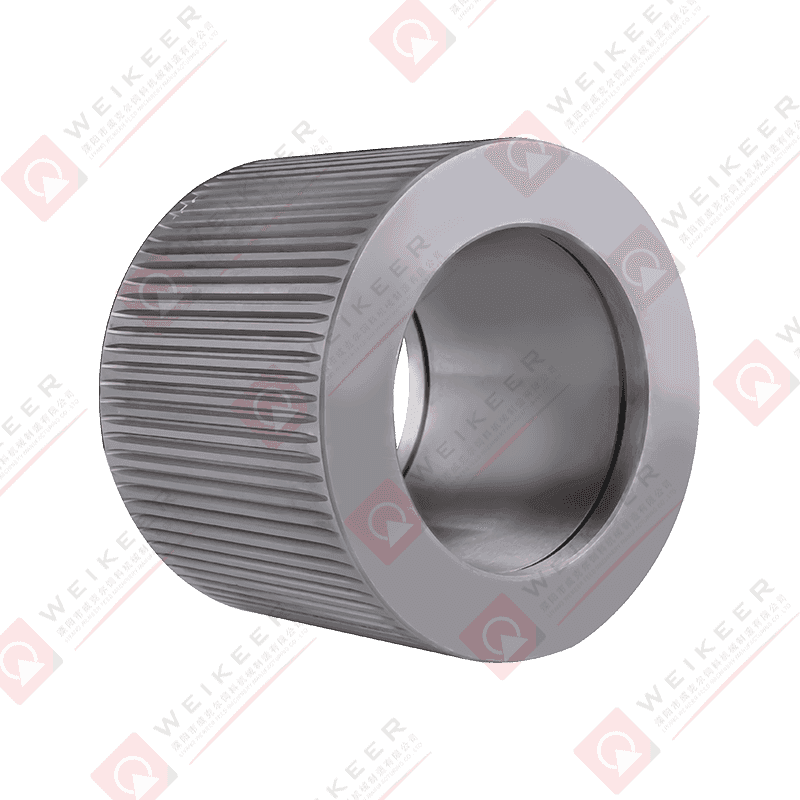

Mold specifications: Different particle diameters and densities need to match different molds.

Raw material adaptability: Ensure that the equipment can adapt to a variety of raw materials and improve versatility.

Energy efficiency: Choosing energy-saving designs helps reduce operating costs.

After-sales service and maintenance: A high-quality service system can ensure the long-term and stable operation of the equipment.

With the rapid development of green energy and resource recycling, Pellet Press is becoming a key equipment to promote industrial upgrading and sustainable development. It not only improves material utilization, but also brings significant economic and environmental benefits to multiple industries. In the future, with the continuous innovation of technology, Pellet Press will be more intelligent and modular, help the green transformation of industry, and contribute more to the construction of an energy-saving and environmentally friendly modern society.

русский

русский Español

Español عربى

عربى 中文简体

中文简体