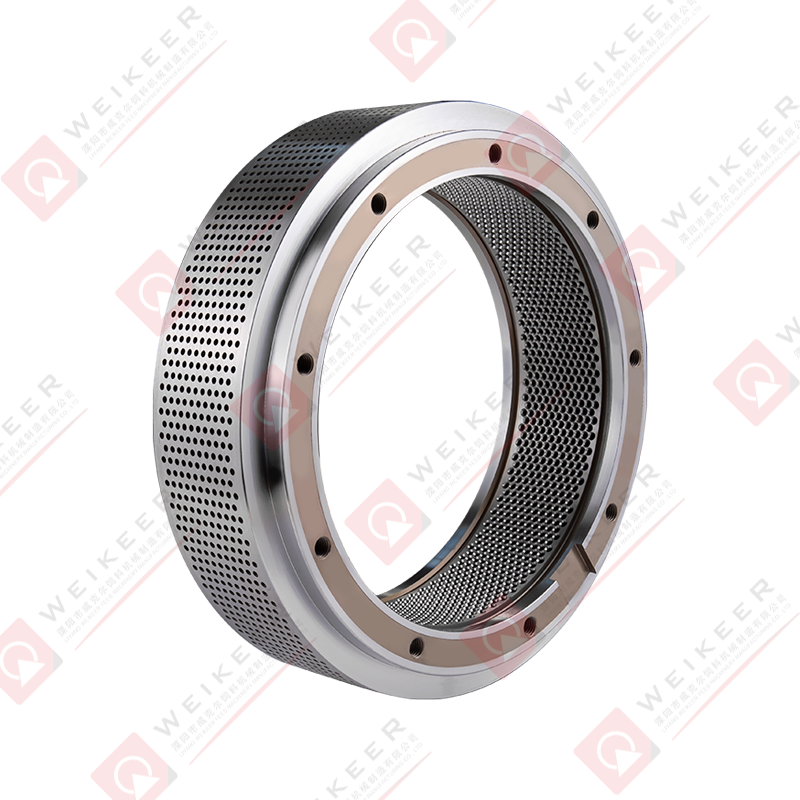

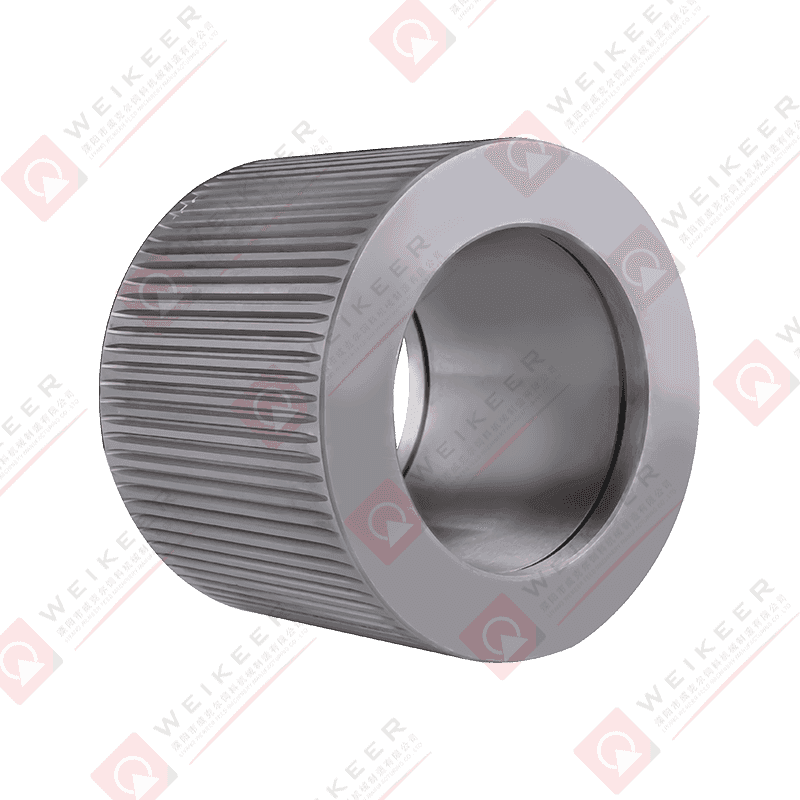

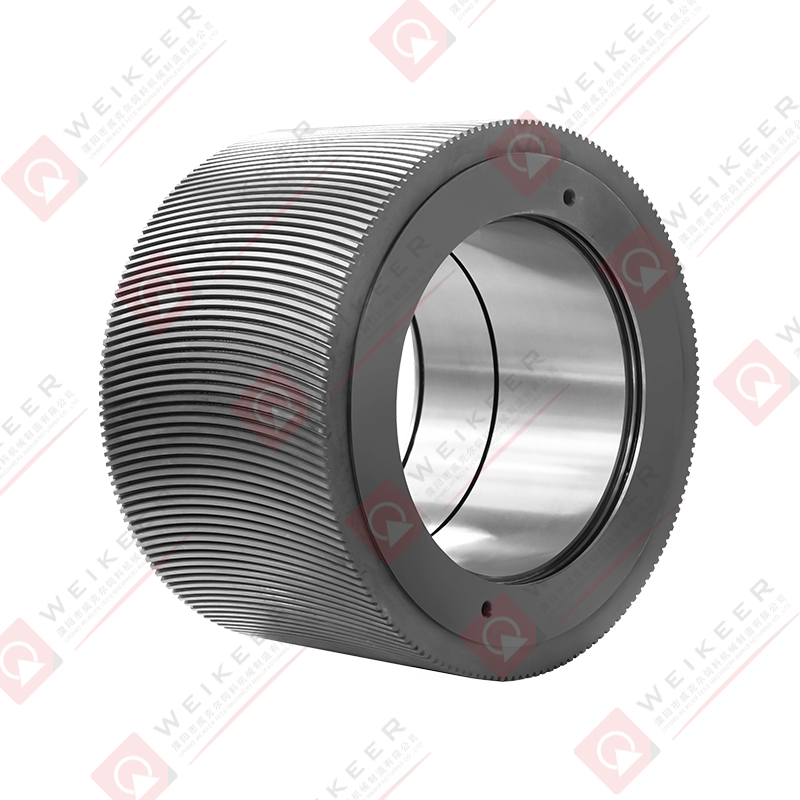

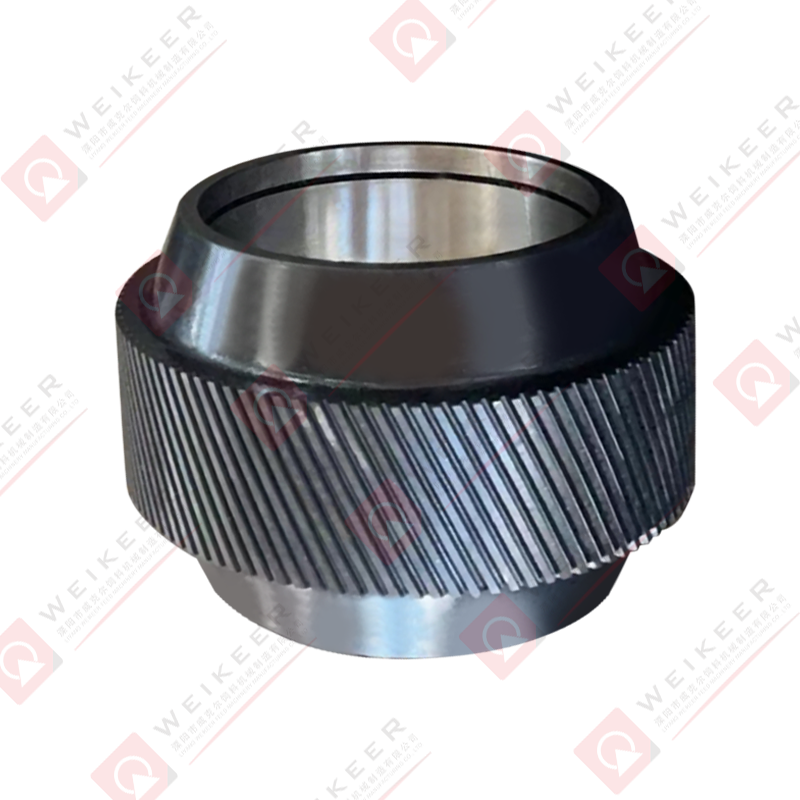

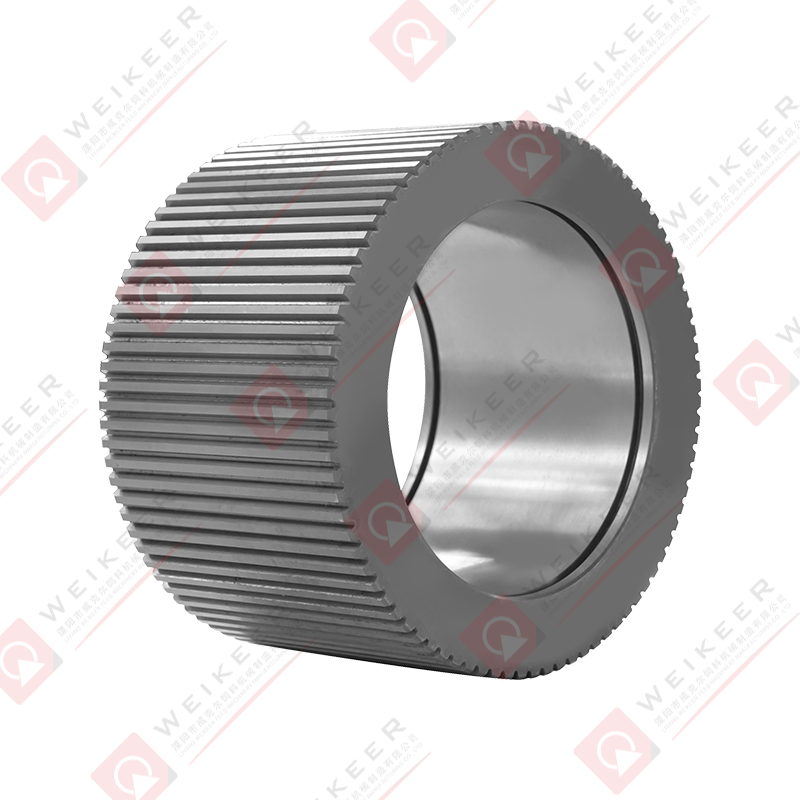

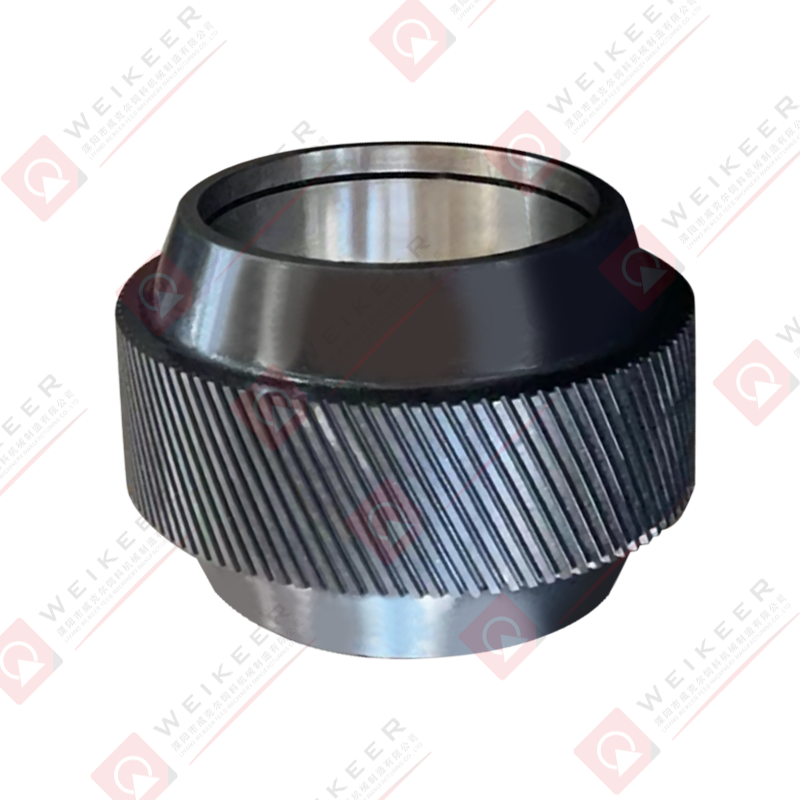

In the feed, wood chip, biomass fuel, chemical and organic fertilizer industries, the efficiency of pellet production and the quality of finished products often depend on the "heart" component of the pelleting equipment - Pellet Mills Ring Die. It not only affects the output and energy consumption, but also directly determines the stability, density and appearance of pellet forming. Choosing high-quality ring dies is the key for enterprises to improve pelleting efficiency, reduce maintenance costs and extend equipment life.

As a professional brand in the field of ring die manufacturing, we adhere to high standards of material selection and precision processing to produce high-performance ring die products suitable for various pellet mill models, with the following outstanding advantages:

1. High-quality materials, wear-resistant and pressure-resistant

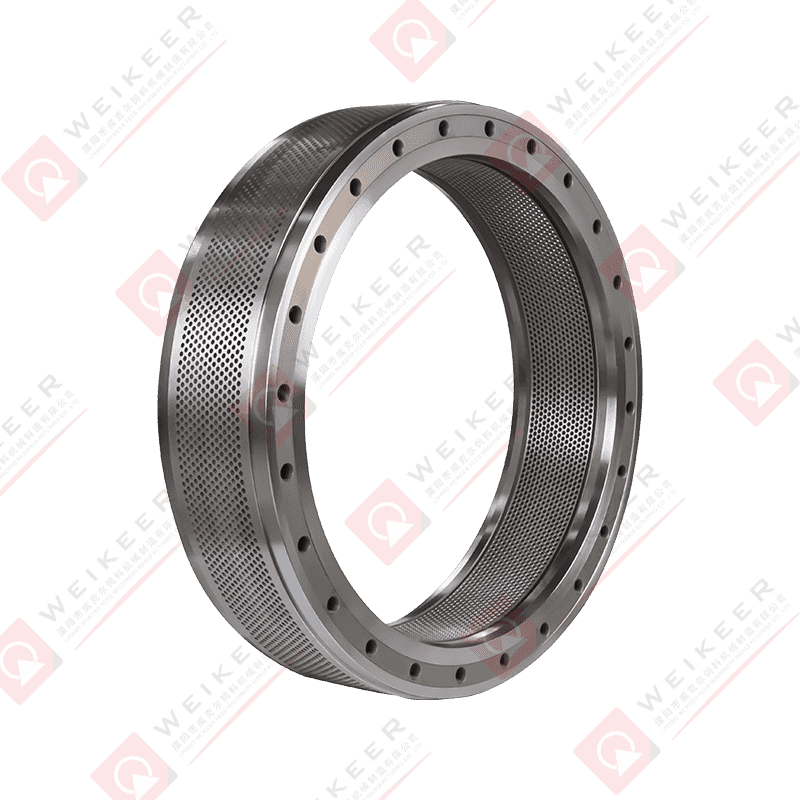

We use high-quality alloy steel (such as 4Cr13, X46Cr13, 304 stainless steel) or customized alloys, and after precision heat treatment, the mold has extremely high hardness and wear resistance. It can also maintain stable performance under high-intensity pressing, greatly extending the service life.

2. Precision machining to improve pelletizing efficiency

Through the German CNC machining center and vacuum heat treatment process, each die hole is strictly ground and polished to ensure smooth pellet forming, reduce hole clogging and energy consumption, and improve the yield and particle density.

3. Diversified aperture design to adapt to different raw materials

We provide die hole options ranging from φ2mm to φ12mm, which can meet the needs of raw materials with different densities and viscosities such as feed, wood chips, biomass, and organic fertilizer. At the same time, we support customized die hole angles and compression ratios to adapt to special materials.

4. High yield and low consumption, significant economic benefits

Thanks to high-precision porosity and excellent material guide design, our ring die can achieve higher output under the same energy consumption conditions, while reducing raw material waste and replacement frequency of wear parts, and comprehensively reducing operating costs.

5. Strict quality inspection, consistent quality

Every ring die shipped out of the factory undergoes multiple process controls such as dynamic balance test, hardness test, and microscopic pore structure test to ensure that every product received by the user meets high standards of industrial use requirements.

Widely used in various industries

Pellet Mills Ring Die is suitable for the following pelleting industries:

Feed processing: pelleting of animal feed such as pigs, chickens, ducks, and aquatic products;

Wood pellets: wood chips, wood shavings, and bamboo powder are pressed into biomass pellet fuel;

Straw pelleting: pressing rice husks, corn stalks, wheat straw, etc.;

Organic fertilizer pelleting: livestock and poultry manure and compost raw materials are converted into fertilizer pellets;

Chemical industry: pellet forming and processing of powdered chemical raw materials.

More than 10 years of manufacturing experience, serving more than 100 pellet machine manufacturers worldwide;

Complete models, support customization, compatible with all kinds of mainstream pelleting equipment (such as CPM, ANDRITZ, BUHLER, etc.);

Fast delivery and global distribution to ensure no production interruption and no work delay;

Technical support and after-sales guarantee, providing installation guidance, compression ratio recommendations and mold maintenance knowledge.

Maintenance and life extension suggestions

In order to maximize the use effect and life of the ring die, we recommend that customers pay attention to the following points:

Clean the die hole regularly to prevent blockage and uneven compression;

Reasonably adjust the gap between the roller and the ring die to avoid unnecessary wear;

Select the correct compression ratio as needed, and different raw materials require different designs;

Avoid long-term dry running or empty machine operation to prevent mold damage;

Use appropriate lubricants and clean particles to extend the smoothness of the mold surface.

Pellet Mills Ring Die is not only an important component in pelletizing equipment, but also a guarantee for the company's product quality and capacity improvement. Choosing a high-quality ring die means choosing more efficient production, more stable operation, and longer-term return on investment.

русский

русский Español

Español عربى

عربى 中文简体

中文简体