With the continuous rise of the pet economy, cat litter products are a rigid consumer product with growing market demand. In order to meet the production trend of environmental protection, high efficiency and sustainable development, more and more cat litter manufacturers have begun to introduce advanced particle processing equipment.

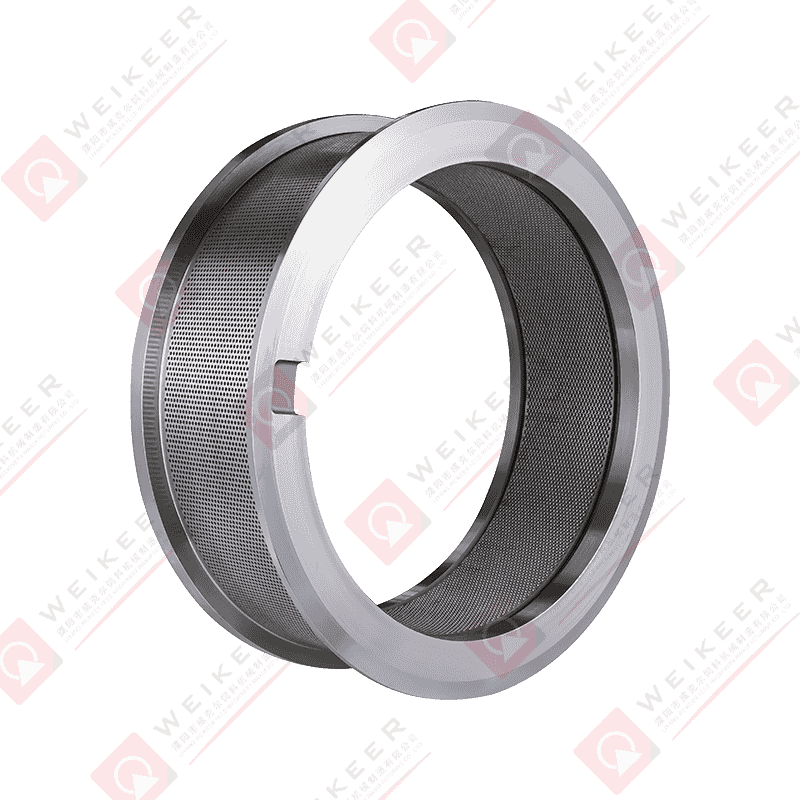

Advantages of Anchorear Ring Die

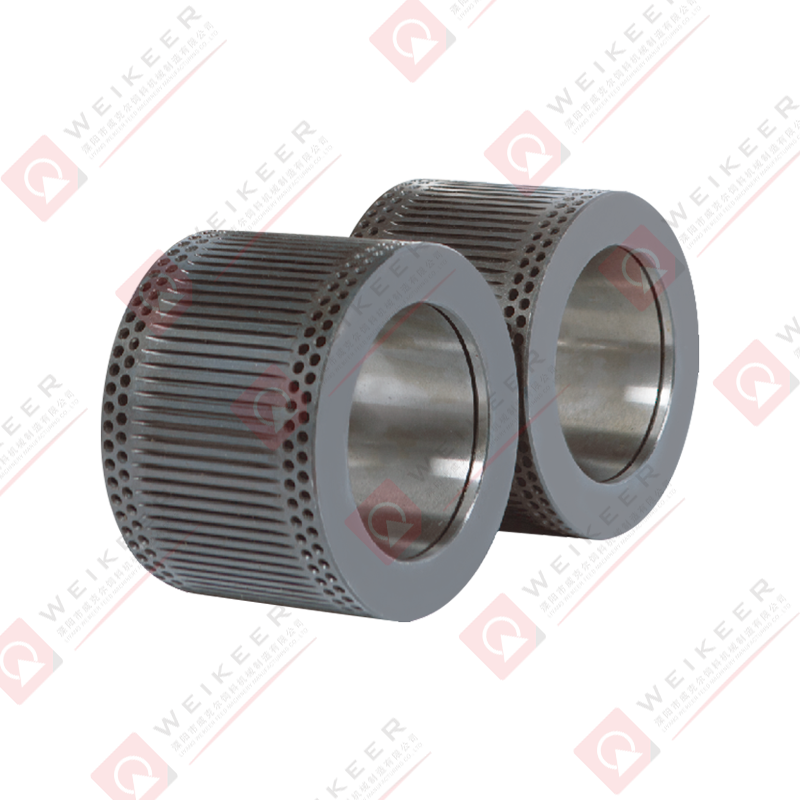

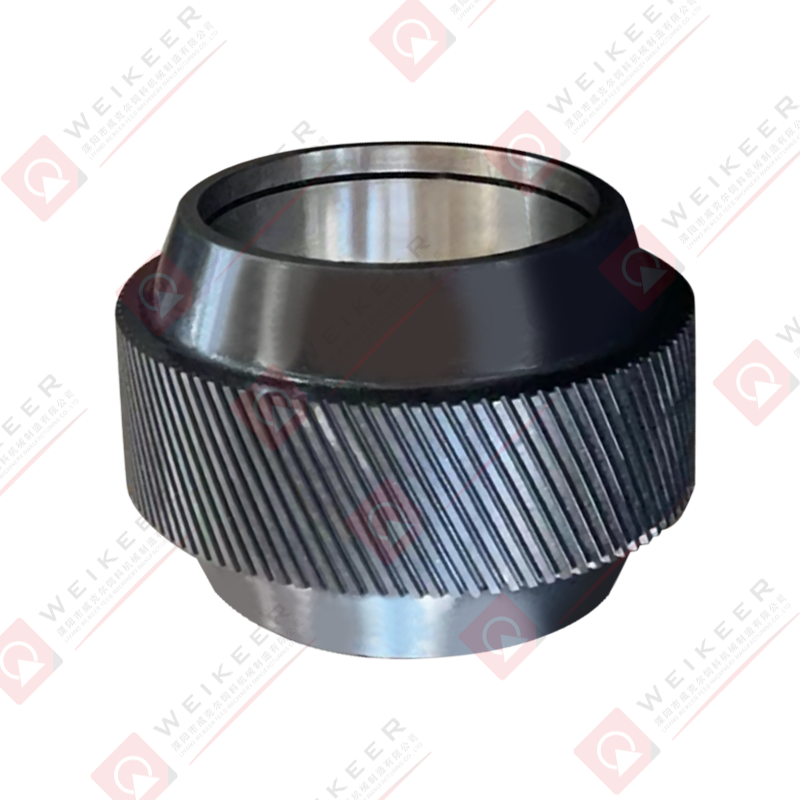

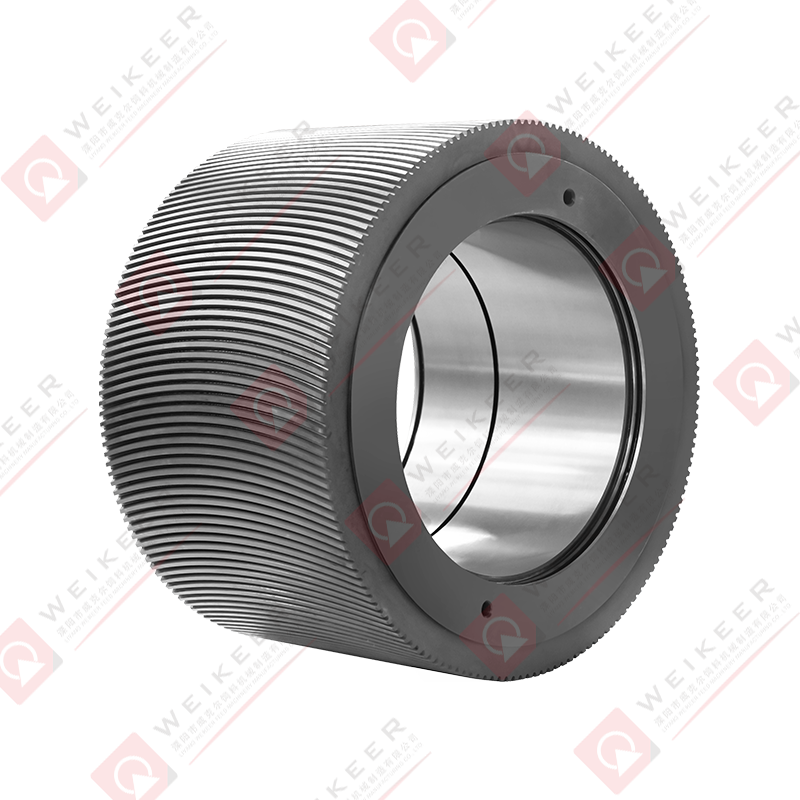

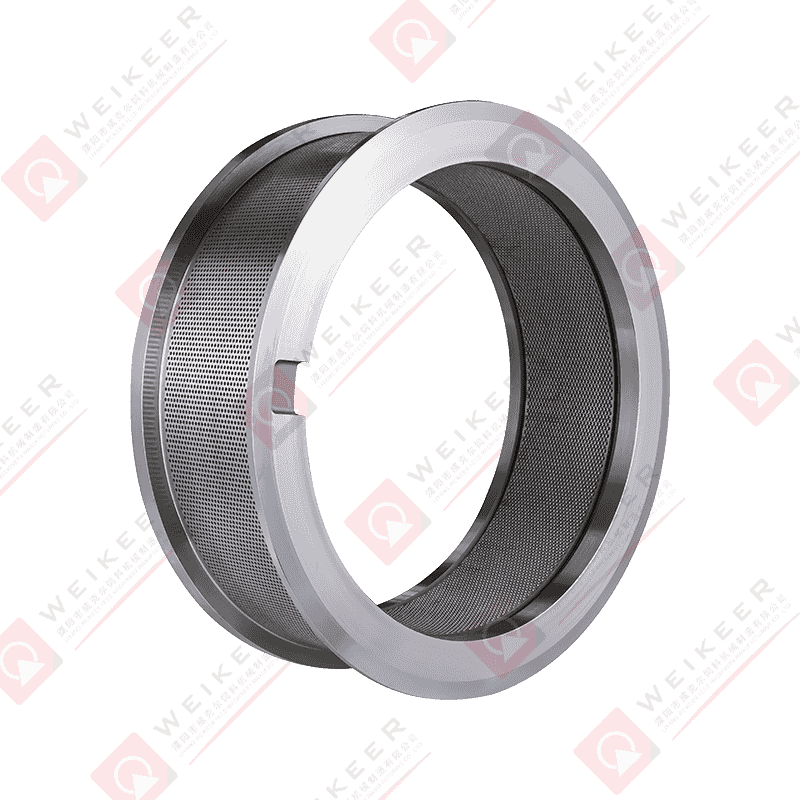

Made of high-strength materials: Anchorear's ring die is mostly made of high-chromium stainless steel (such as 4Cr13) or alloy steel. After precision machining and vacuum heat treatment, it has excellent hardness and wear resistance, and can cope with the common fiber and mineral components in cat litter raw materials.

High-precision manufacturing technology: CNC machining equipment is used to ensure the consistency of aperture size, more uniform discharge, stable particle formation, and effectively avoid particle breakage or blockage caused by size deviation.

Long service life and low replacement frequency: It shows lower wear rate in continuous operation environment, significantly reduces maintenance costs, and improves the operation efficiency of the whole machine.

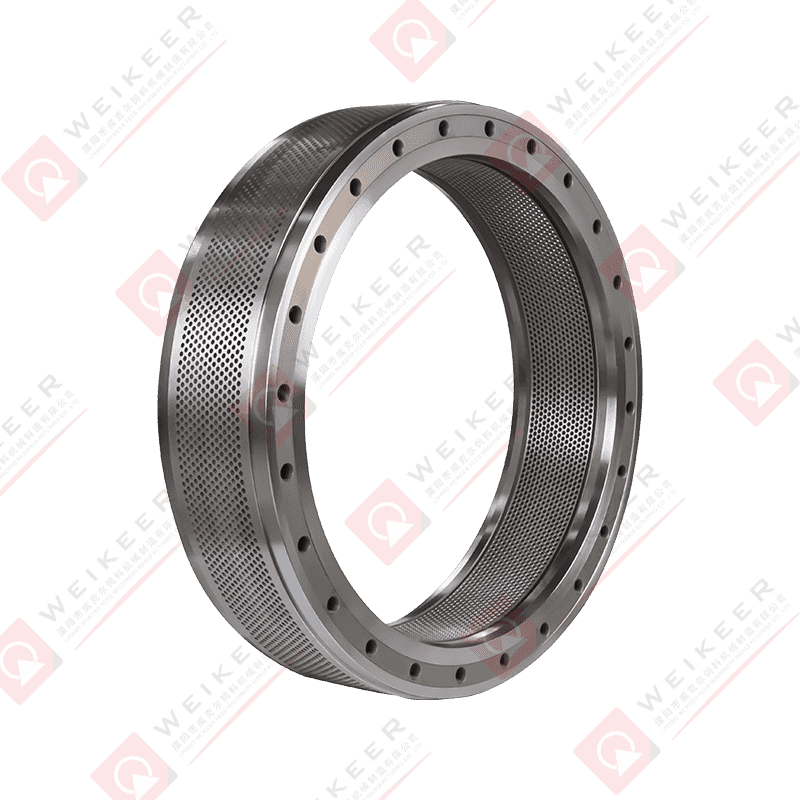

Adaptable to a variety of raw materials

Cat Litter Pellet Mill Anchorear Ring Die is suitable for pressing a variety of cat litter raw materials, including tofu cat litter, wood chip cat litter, mineral cat litter, corn cat litter, etc., with wide applicability and flexible mold switching capabilities.

High molding efficiency

By optimizing the aperture design and compression ratio parameters, Anchorear Ring Die can achieve higher compression density, making cat litter particles less fragile and absorbent, with better overall product texture and improved user experience.

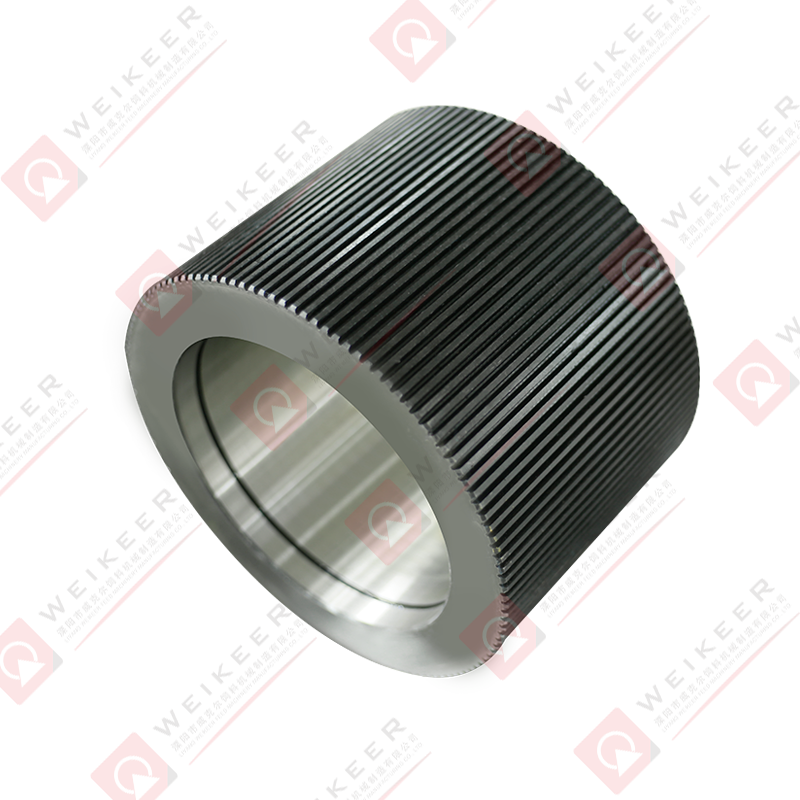

Environmental protection and energy saving

The advanced pressing system reduces energy consumption and reduces the waste of raw materials. The high wear resistance of the ring die also means fewer maintenance times, further reducing the consumption of energy and material resources.

High degree of automation, convenient for industrial scale production

The pellet machine with modern control system can realize one-button operation and intelligent monitoring, which is suitable for large cat litter production plants to achieve standardized and batch operations.

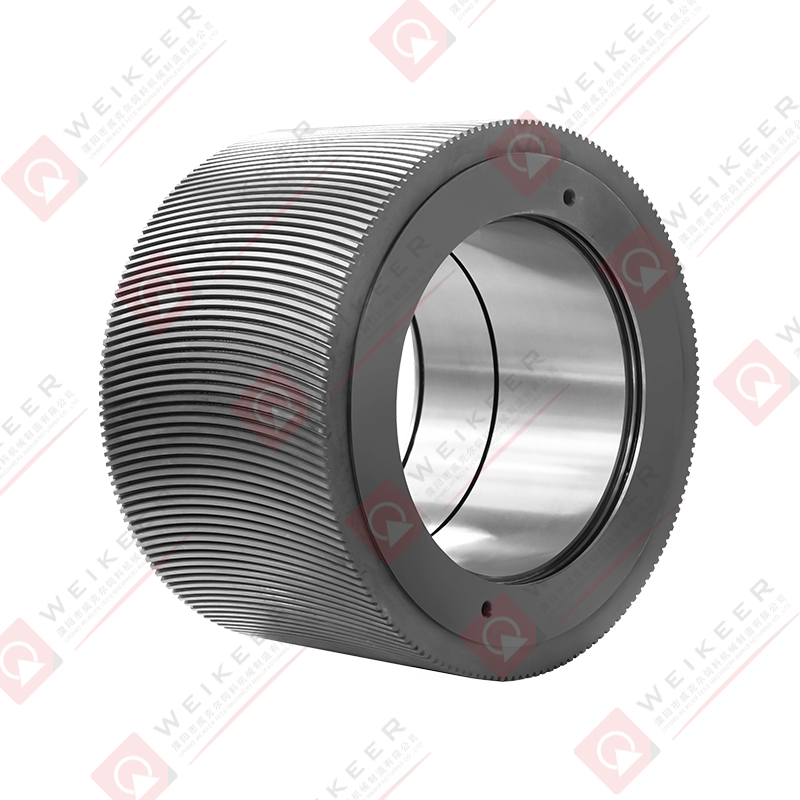

As consumers' demand for environmental protection and functionality of pet products continues to increase, cat litter manufacturers face higher production standards and market competition. Introducing high-performance, high-durability pellet pressing equipment like the Cat Litter Pellet Mill Anchorear Ring Die not only improves product quality, but also helps companies achieve green and sustainable development strategies.

Cat Litter Pellet Mill Anchorear Ring Die provides a more efficient, economical and sustainable solution for cat litter manufacturing. It is not only a reflection of the progress of mechanical technology, but also an important support for the cat litter industry to move towards high-quality development. For companies that want to improve productivity and build brand competitiveness, this is undoubtedly a key technical equipment worth investing in.

русский

русский Español

Español عربى

عربى 中文简体

中文简体