In the rapidly growing aquaculture industry, producing high-quality, nutritionally balanced feed efficiently is critical for the success of fish farming operations. At the heart of modern feed production lies the aqua feed pellet mill, a machine designed to compress and shape feed ingredients into pellets. One of the most crucial components of this equipment is the anchorear ring die, a component that significantly affects production efficiency, pellet quality, and overall operational reliability. But what exactly is an aqua feed pellet mill anchorear ring die, and why is it so important? This article delves into its structure, working principles, applications, benefits, and challenges, providing a comprehensive guide for aquaculture feed producers.

What Is an Aqua Feed Pellet Mill Anchorear Ring Die?

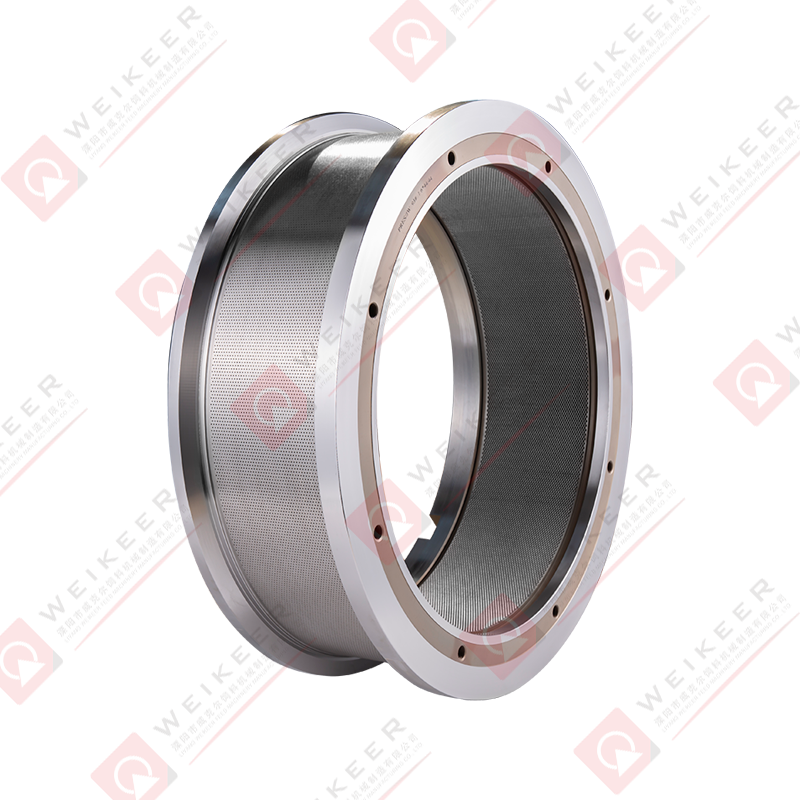

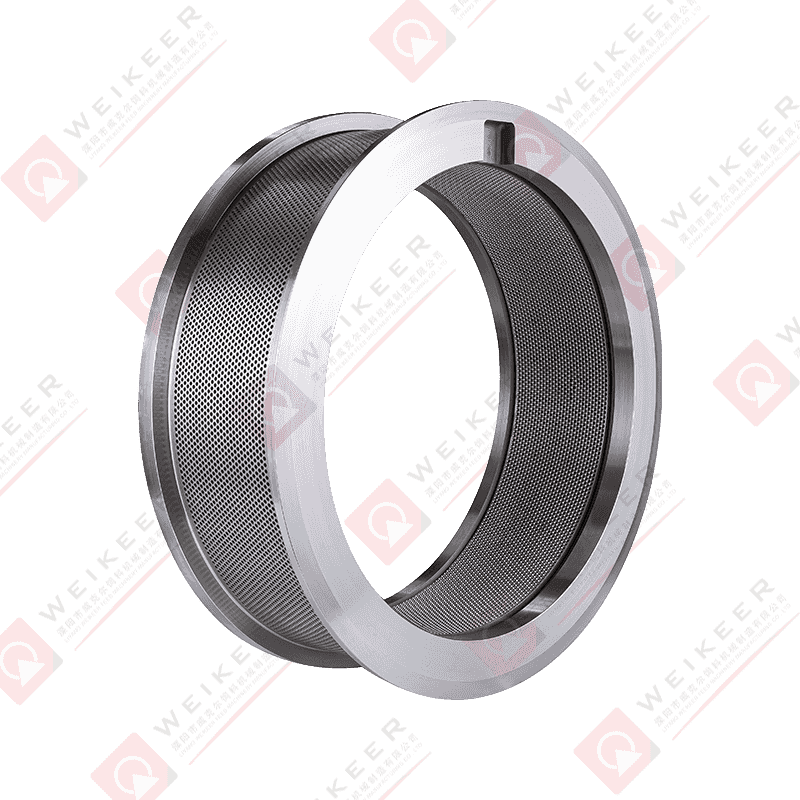

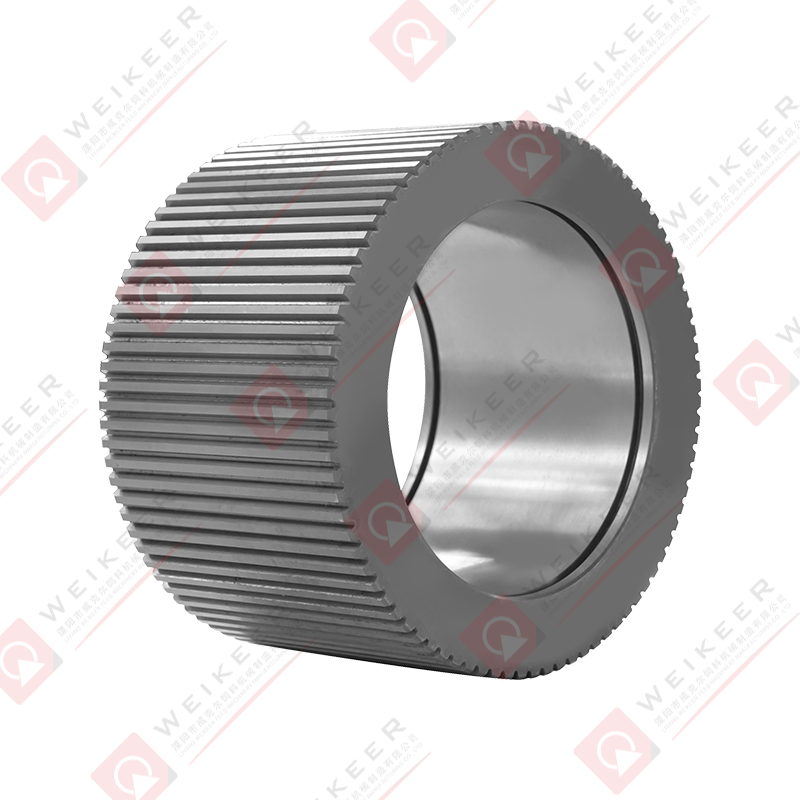

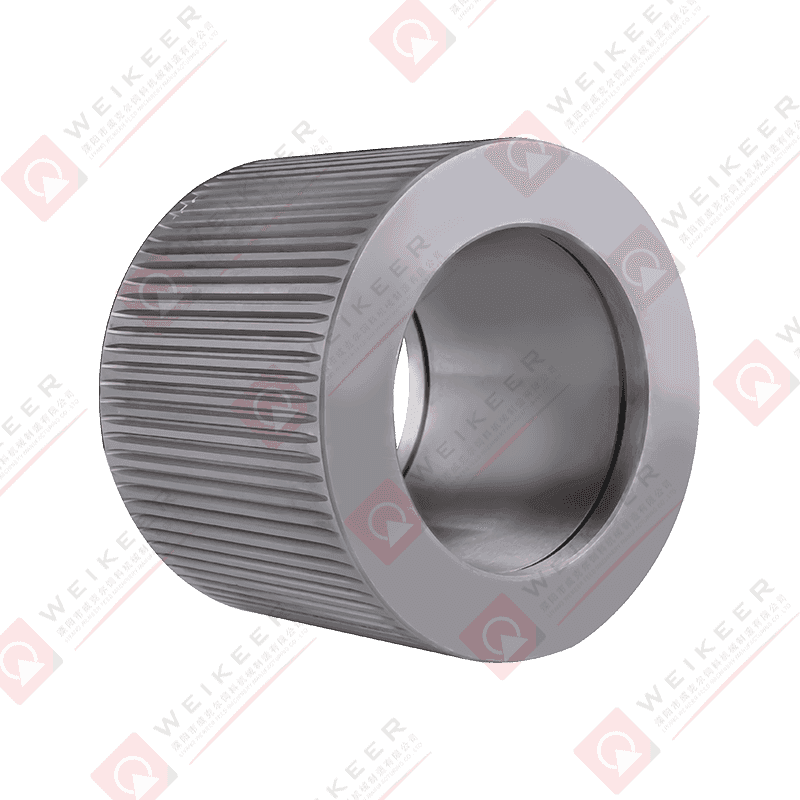

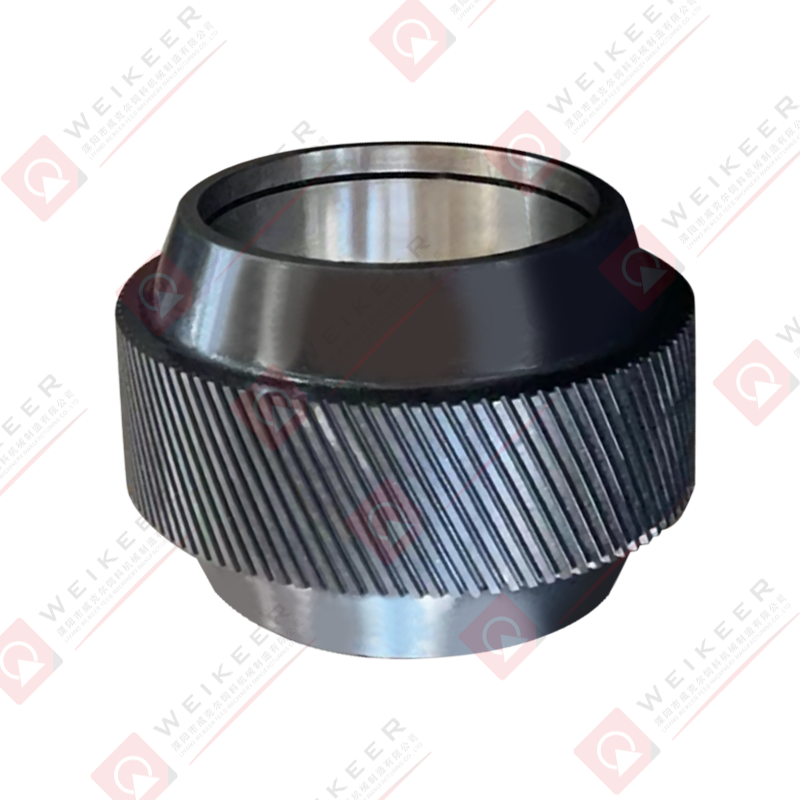

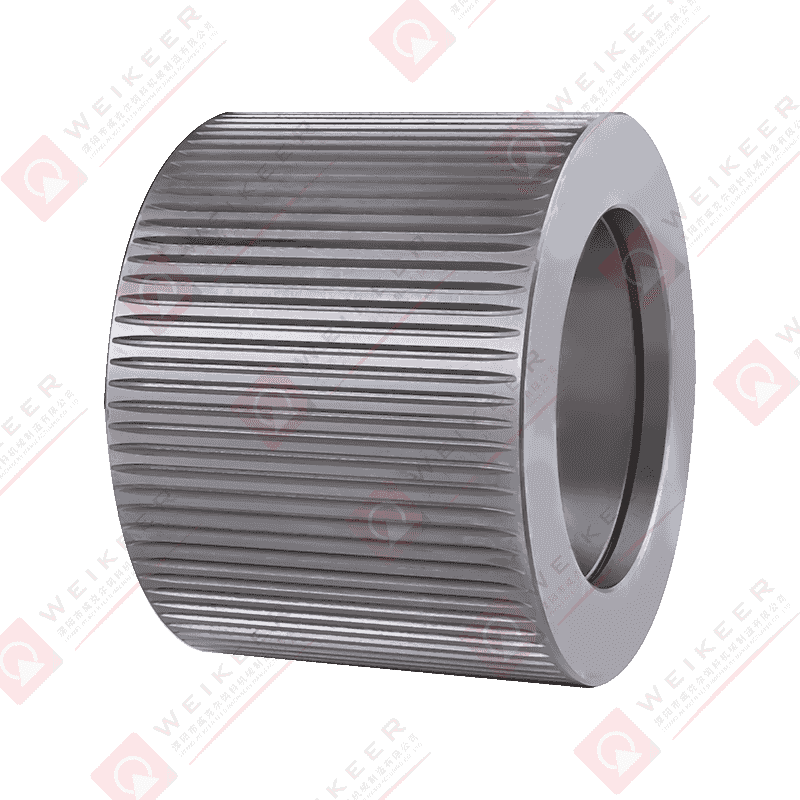

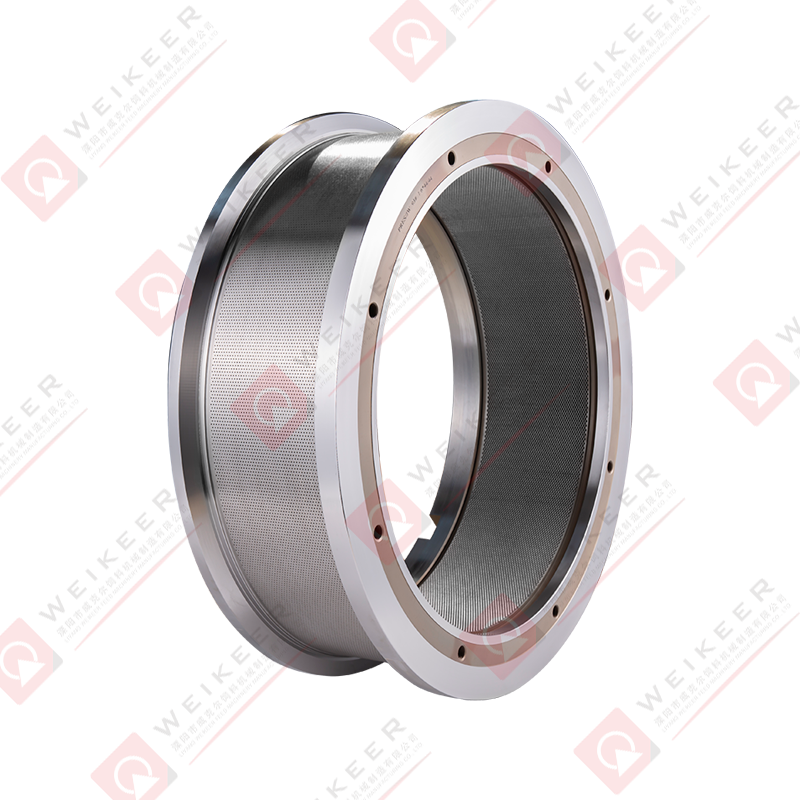

An aqua feed pellet mill anchorear ring die is a specially engineered component used in pellet mills designed for aquaculture feed production. It is a circular, perforated metal plate through which feed material is extruded under high pressure to form uniform pellets. The anchorear design refers to a reinforced and stable mounting mechanism that ensures the ring die remains securely fixed during operation, minimizing vibration, wear, and mechanical failure.

The ring die plays a central role in determining pellet size, density, and durability. Its performance directly influences the efficiency of the pellet mill and the quality of feed that aquatic species receive, which in turn affects growth rates, health, and feed conversion ratios.

How Does an Anchorear Ring Die Work in an Aqua Feed Pellet Mill?

The operation of an anchorear ring die within a pellet mill involves several interconnected steps:

- Raw Material Preparation: Ingredients such as fish meal, soybean meal, corn, vitamins, and minerals are mixed and ground into a uniform powder. Moisture content is carefully controlled to optimize pellet formation.

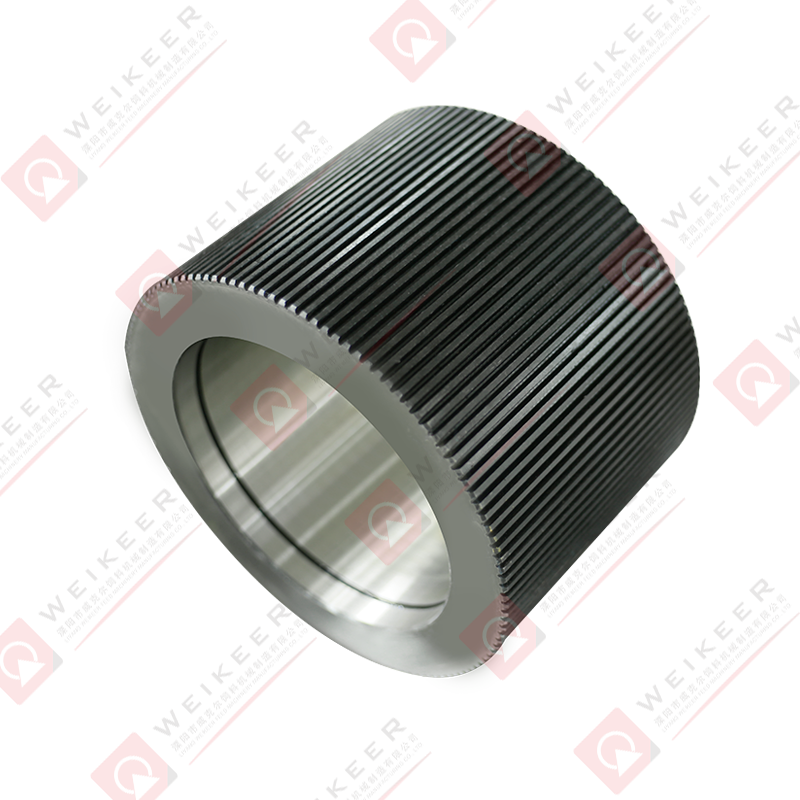

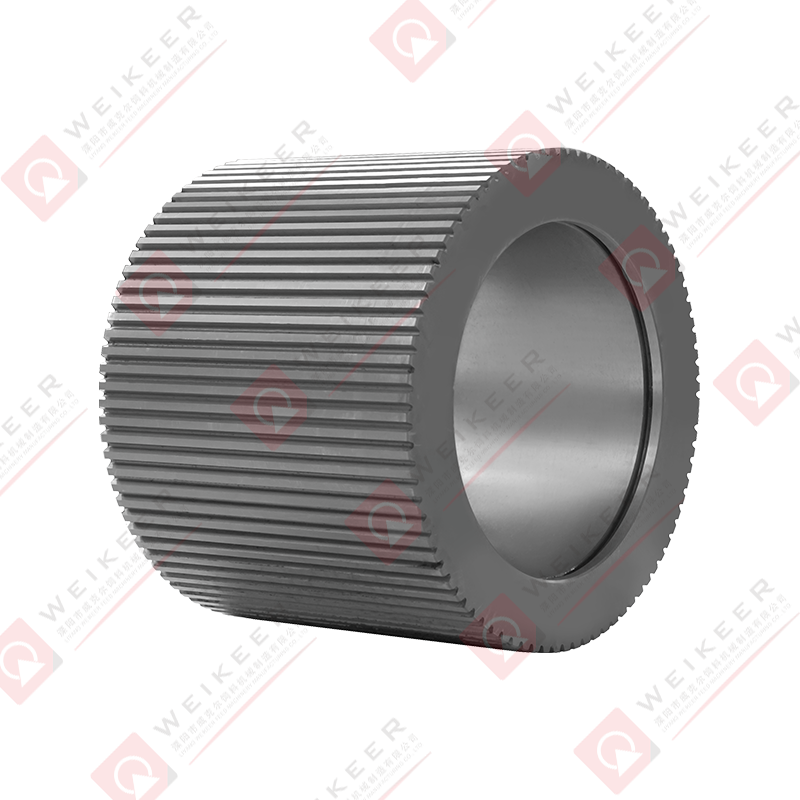

- Feed Extrusion: The prepared feed enters the pellet mill, where a rotating roller presses it against the ring die. The anchorear mechanism ensures that the die remains stable and aligned during this high-pressure process.

- Pellet Formation: Feed material is forced through the perforations of the ring die, forming cylindrical pellets. The diameter of the holes determines the pellet size, while the pressure and roller speed influence density and hardness.

- Pellet Cutting: A knife positioned at the die’s exit cuts the extruded feed into uniform pellets.

- Cooling and Drying: Newly formed pellets are hot and moist; they pass through cooling and drying systems to achieve optimal durability and shelf life.

The anchorear ring die ensures consistent extrusion pressure and alignment, reducing the risk of die wear, pellet inconsistencies, and production downtime.

Why Is the Anchorear Design Important?

The anchorear design of the ring die is critical for several reasons:

- Enhanced Stability: The anchorear system secures the die firmly, reducing vibration and movement during operation.

- Uniform Pellet Quality: Stability ensures even pressure distribution across the die surface, resulting in pellets with consistent size and density.

- Reduced Wear and Tear: Secure anchoring minimizes mechanical stress on the die and rollers, extending their service life.

- Energy Efficiency: Less vibration and friction mean lower energy consumption during operation.

- Operational Safety: The robust design reduces the risk of mechanical failures, protecting operators and equipment.

Without a properly anchored ring die, pellet mills may experience frequent breakdowns, uneven feed quality, and increased maintenance costs.

What Materials Are Used for Aqua Feed Pellet Mill Ring Dies?

The performance and longevity of a ring die depend heavily on its material composition. Common materials include:

- Alloy Steel: Provides a balance of hardness, wear resistance, and corrosion resistance. Ideal for general feed production.

- Stainless Steel: Offers superior corrosion resistance, especially important for feed containing fish meal or other moisture-sensitive ingredients.

- Tool Steel with Surface Coating: Enhances wear resistance and reduces friction, extending the die’s lifespan.

Material selection depends on feed formulation, production scale, and operational demands. For aquaculture feeds, corrosion resistance and durability are often prioritized due to the presence of fats, oils, and moisture in fish feed.

How Does an Anchorear Ring Die Affect Pellet Quality?

The ring die has a direct impact on several key pellet characteristics:

- Pellet Density: Adequate compression ensures pellets are compact, reducing breakage during transportation and storage.

- Durability: Proper die design prevents crumbling and fines, maintaining feed integrity.

- Size Uniformity: Hole diameter consistency ensures all pellets are the same size, which is crucial for uniform feeding and growth rates in fish.

- Nutrient Preservation: The extrusion process can generate heat; a well-designed die helps control temperature, preventing nutrient degradation.

Ultimately, the ring die is a determining factor in achieving high-quality aquaculture feed that promotes healthy fish growth and maximizes feed conversion efficiency.

Which Industries and Applications Use Anchorear Ring Dies?

The primary application is aquaculture feed production, but its use extends to:

- Fish Farms: Producing feed for freshwater and marine species, including tilapia, salmon, catfish, and shrimp.

- Shrimp and Prawn Hatcheries: Small-particle pellet feed suitable for juvenile stages.

- Commercial Feed Mills: Manufacturing large-scale aquafeed for distributors and exporters.

- Specialty Aquatic Species: Formulating feeds for ornamental fish, crustaceans, and other niche species.

In all these cases, pellet quality, durability, and nutrient preservation are paramount, making the anchorear ring die an essential component.

What Are the Benefits of Using an Anchorear Ring Die?

Investing in a high-quality anchorear ring die offers multiple advantages:

- Improved Production Efficiency: Stable die operation reduces downtime and maintenance.

- Consistent Feed Quality: Uniform pellets support optimal fish growth and reduce feed waste.

- Longevity of Equipment: Reduced mechanical stress increases the lifespan of rollers, shafts, and the die itself.

- Cost Savings: Fewer replacements and energy-efficient operation reduce operational costs over time.

- Adaptability: Dies can be customized for different pellet sizes and feed formulations.

These benefits are particularly valuable for large-scale commercial feed producers and fish farmers aiming for high productivity and quality standards.

Are There Any Challenges Associated with Anchorear Ring Dies?

Despite their advantages, certain challenges exist:

- High Initial Cost: Premium dies with anchorear designs can be more expensive than standard dies.

- Maintenance Requirements: Regular cleaning and inspection are necessary to prevent wear and corrosion.

- Precision Manufacturing: High-quality dies require precise engineering, which can be a limiting factor for small-scale producers.

- Material Compatibility: Selection of die material must match feed composition to prevent chemical or abrasive damage.

Addressing these challenges involves proper selection, preventive maintenance, and operator training.

What Are the Future Trends in Aqua Feed Pellet Mill Ring Dies?

As aquaculture expands globally, ring die technology continues to evolve:

- Advanced Materials: Development of corrosion-resistant and wear-resistant alloys or composites.

- Customizable Die Designs: Variable hole sizes, shapes, and patterns to produce specialized feed pellets.

- Automation and Monitoring: Integration with smart pellet mills for real-time pressure, temperature, and wear monitoring.

- Energy Optimization: Dies designed to minimize friction and energy consumption during extrusion.

- Sustainability: Materials and coatings that reduce the environmental footprint and extend service life.

These trends indicate that anchorear ring dies will remain a cornerstone of efficient, high-quality aquafeed production in the future.

Conclusion: Why Is the Anchorear Ring Die Essential for Aquaculture Feed Production?

So, why is the aqua feed pellet mill anchorear ring die indispensable in aquaculture feed production? The answer lies in its direct influence on feed quality, production efficiency, and equipment reliability. By providing a stable and durable extrusion surface, the anchorear ring die ensures uniform, dense, and nutrient-rich pellets that promote healthy fish growth while reducing waste and operational costs.

For aquaculture feed producers, investing in high-quality anchorear ring dies is not just a matter of operational necessity—it is a strategic decision that enhances productivity, ensures consistent feed quality, and supports sustainable fish farming practices.

In summary, the anchorear ring die is more than a simple component; it is a critical enabler of efficient, high-quality, and sustainable aquaculture feed production. For industries seeking to optimize feed production and maximize returns, understanding the importance of the ring die and choosing the right design is essential.

русский

русский Español

Español عربى

عربى 中文简体

中文简体