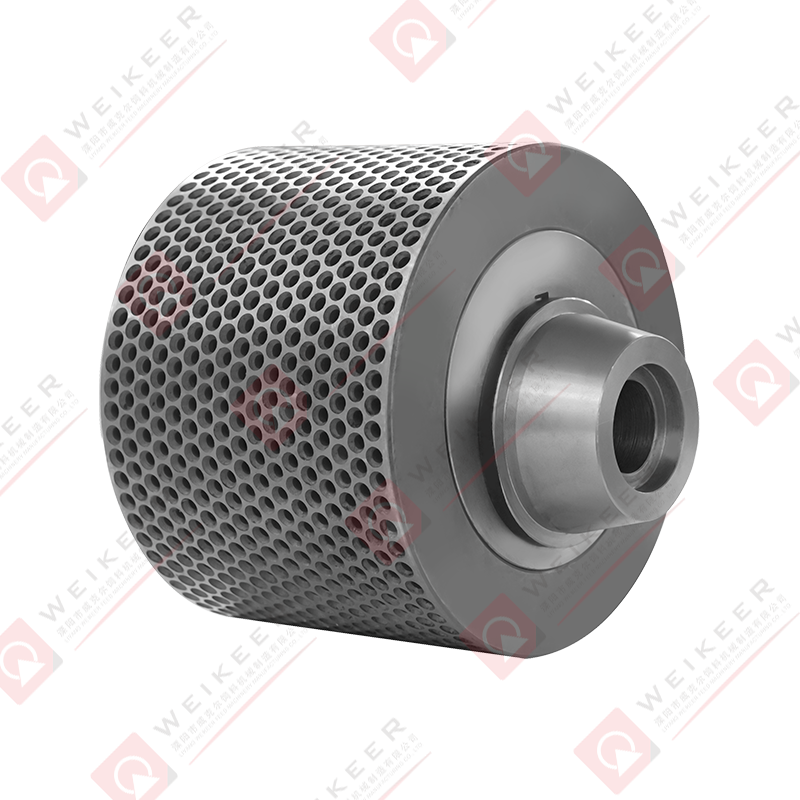

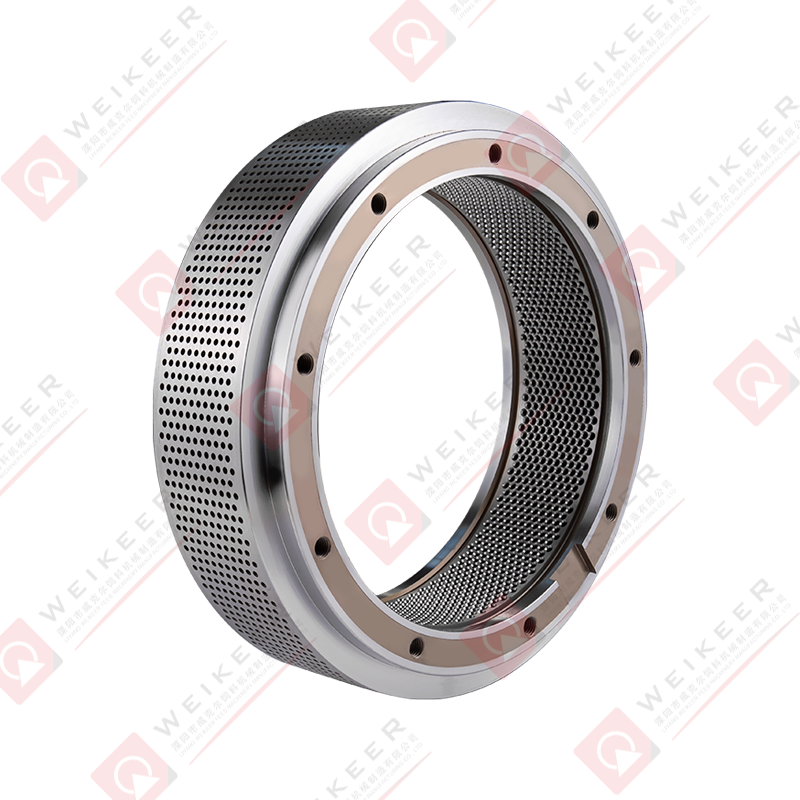

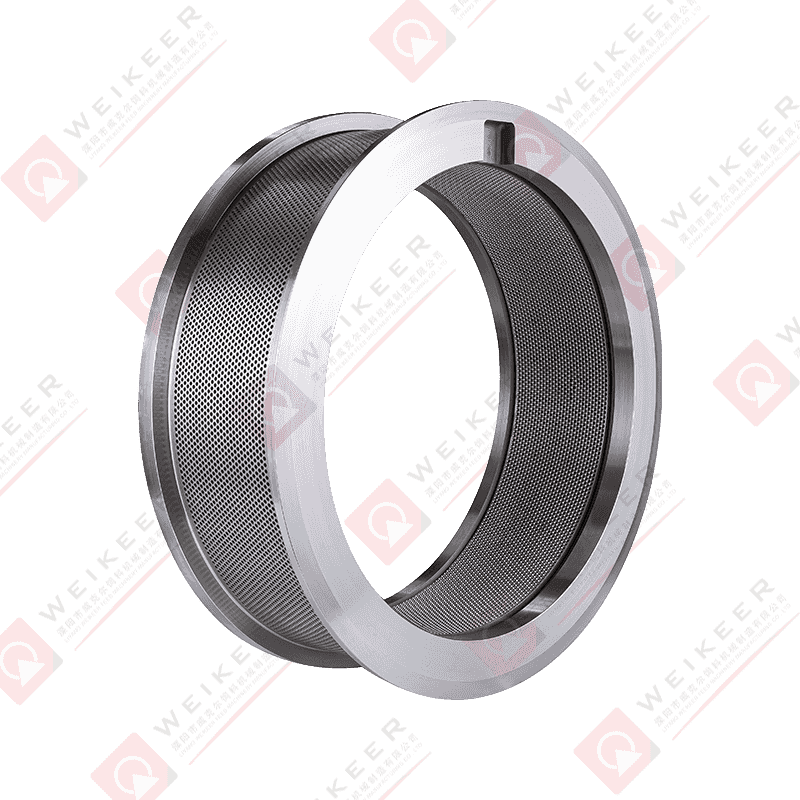

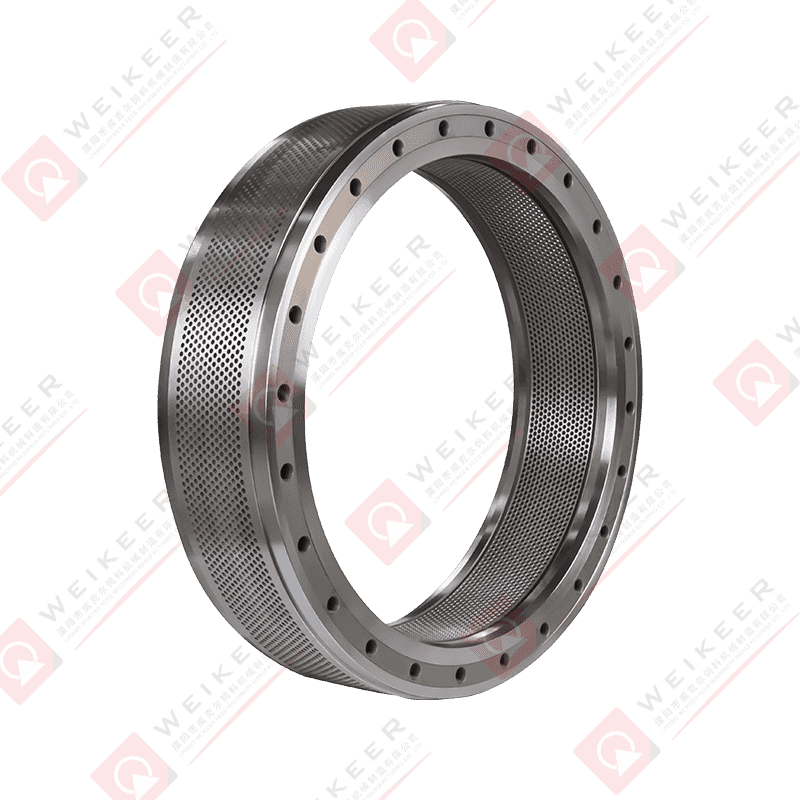

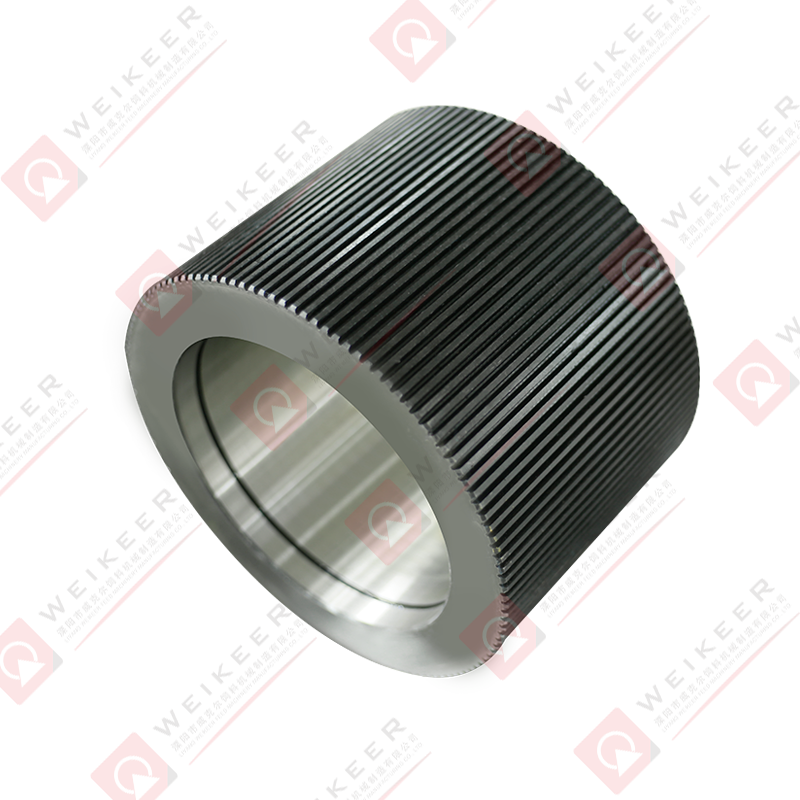

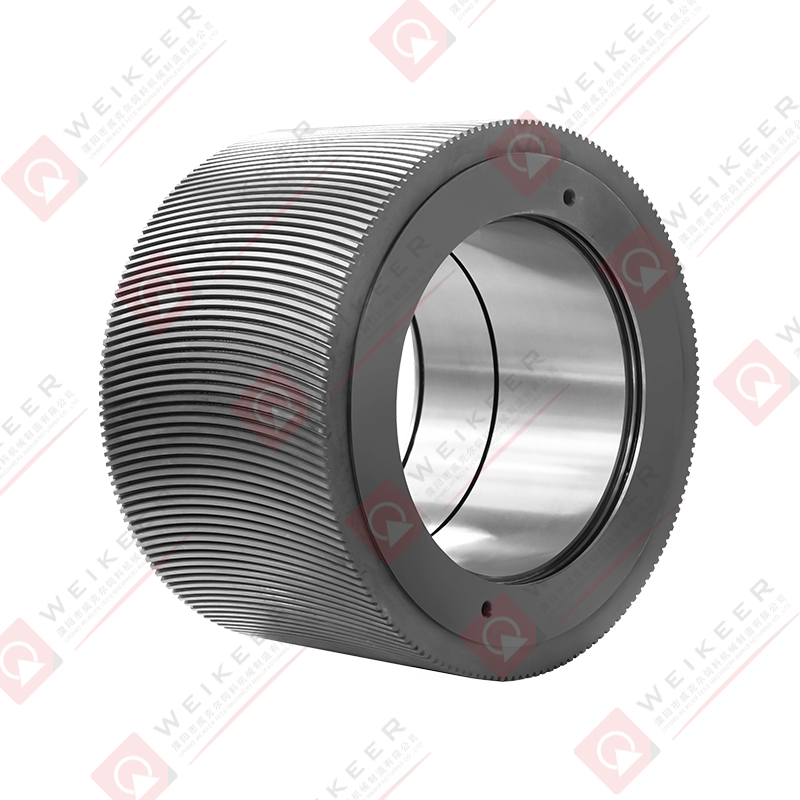

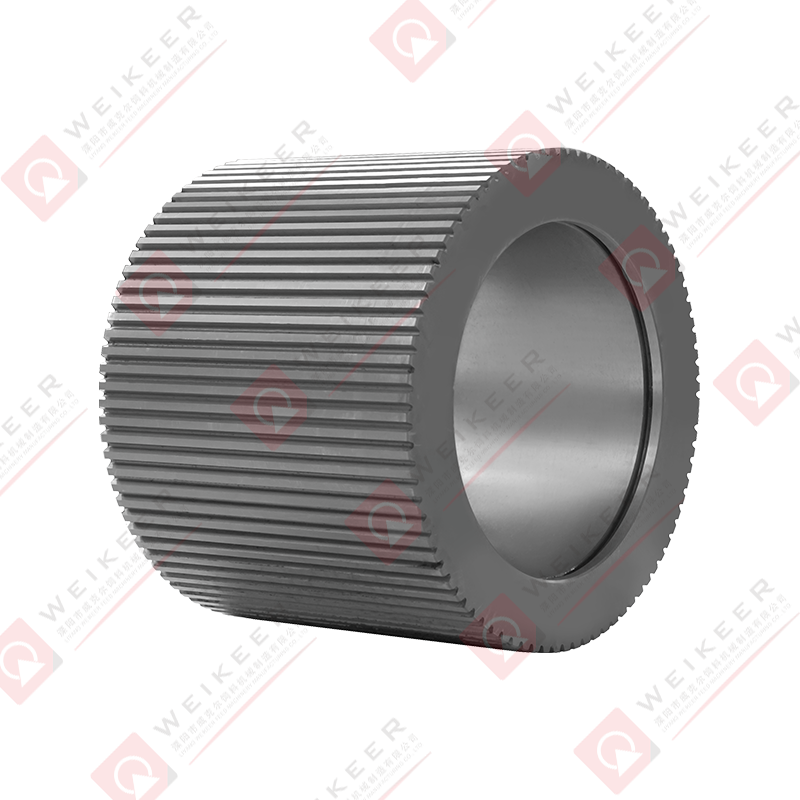

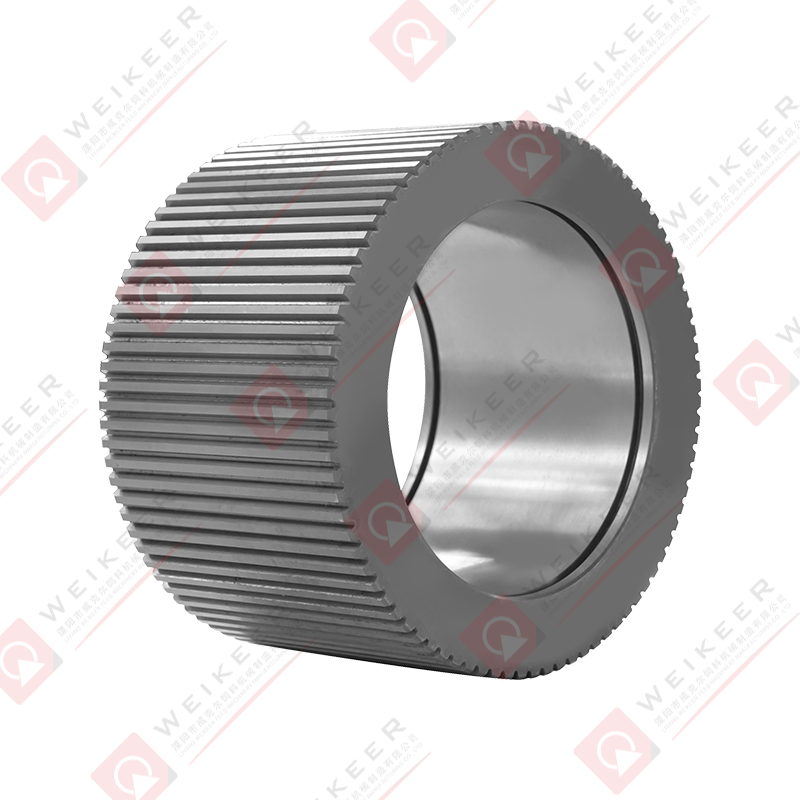

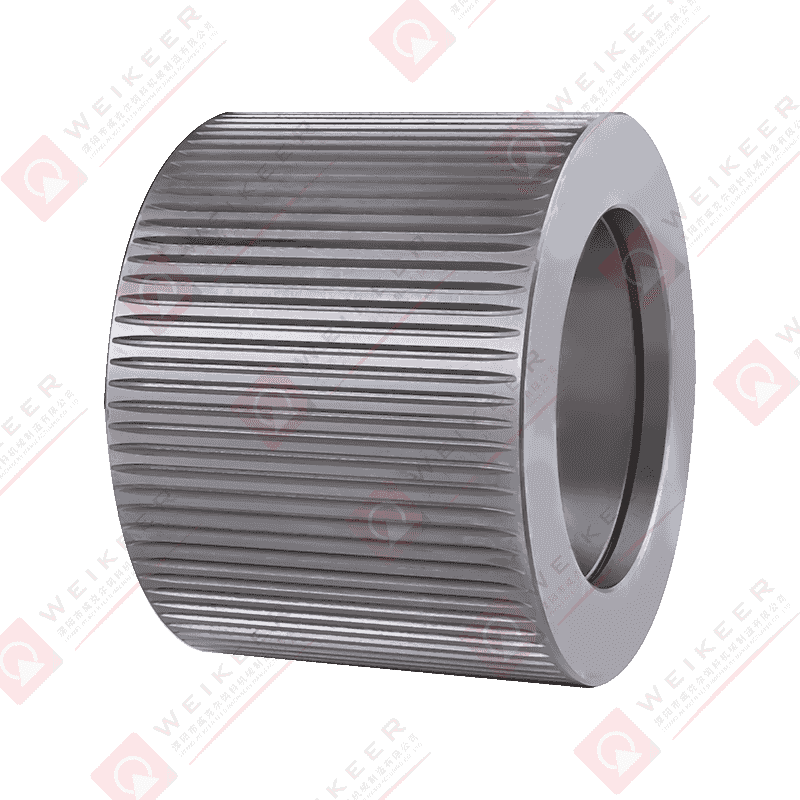

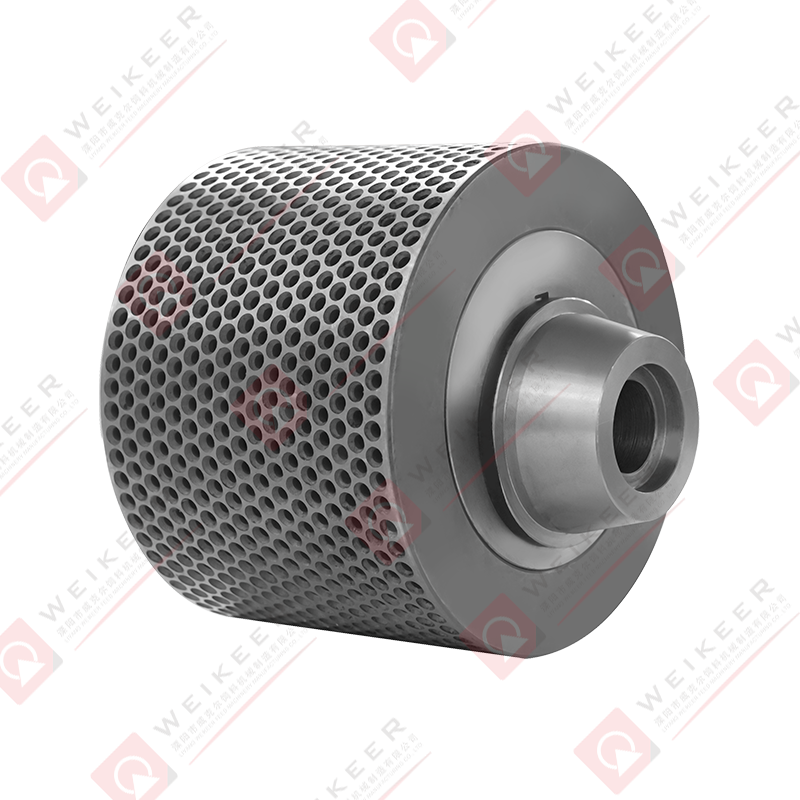

Introduction to Dimpled Bearing Steel Pellet Rollers

Dimpled bearing steel pellet rollers are specialized components used in pellet mills to compress raw feed materials into uniform pellets. Unlike smooth rollers, dimpled rollers feature small indentations across the surface, enhancing the gripping and shearing action during pellet formation. Their unique design provides multiple advantages for pellet production, including increased efficiency, reduced downtime, and improved product quality. In this article, we explore these advantages in detail and highlight practical considerations for their use.

Enhanced Pellet Formation and Consistency

One of the primary benefits of dimpled bearing steel pellet rollers is their ability to create uniform pellets with consistent density and size. The dimples help guide the raw material through the die evenly, preventing over-compression in some areas and under-compression in others. This results in pellets that are more durable, have a better surface finish, and meet strict size specifications.

Improved Material Grip

The dimpled surface significantly increases friction between the roller and feed material. This enhanced grip reduces slippage during the pelletizing process, ensuring that the material moves smoothly through the die. As a result, the roller requires less adjustment and delivers a more stable operation, which is particularly beneficial when processing high-moisture or fibrous feed materials.

Increased Production Efficiency

Efficiency is a critical factor in pellet production. Dimpled bearing steel rollers reduce the energy required to compress feed materials, allowing the mill to operate at higher throughput rates without compromising pellet quality. The improved grip and controlled material flow minimize bottlenecks, resulting in a smoother production process and reduced downtime for maintenance or adjustments.

Lower Energy Consumption

By reducing material slippage and ensuring more uniform compression, dimpled rollers require less mechanical force to pelletize feed. This translates into lower energy consumption per ton of pellets produced. In large-scale operations, the cumulative energy savings can be significant, contributing to both operational cost reduction and environmental sustainability.

Durability and Longevity

Dimpled bearing steel rollers are made from high-quality bearing steel, which is known for its hardness, wear resistance, and toughness. These properties allow the rollers to withstand the high pressure and friction involved in pellet production over extended periods. The dimpled design also helps distribute stress more evenly across the roller surface, reducing the risk of premature wear or cracking.

Resistance to Corrosion and Abrasion

The steel used in dimpled rollers is typically heat-treated and coated to resist corrosion and abrasion. This is especially important when processing feed materials containing moisture, salts, or other corrosive elements. The combination of hardness and protective coatings ensures that the roller maintains its performance and appearance for a longer service life.

Maintenance and Operational Benefits

Dimpled bearing steel rollers are easier to maintain compared to traditional smooth rollers. The dimples prevent material build-up on the surface, reducing the frequency of cleaning. Additionally, the improved grip and consistent pellet formation reduce wear on other machine components, such as the die and bearings, extending the overall lifespan of the pellet mill.

Simplified Adjustment and Calibration

Because the dimples enhance material control and reduce slippage, operators can achieve optimal pellet quality with fewer adjustments. This minimizes downtime for recalibration and allows the mill to run continuously for longer periods, improving overall productivity.

Application Across Different Industries

Dimpled bearing steel pellet rollers are widely used in industries that require pelletized products. Their applications include:

- Animal feed production: Ensuring uniform pellet size and quality for poultry, cattle, and aquaculture feed.

- Biomass and wood pellet production: Enhancing efficiency and consistency in fuel pellets for energy generation.

- Fertilizer pelletization: Producing high-density pellets for efficient transport and application.

- Recycling and waste management: Converting organic waste into manageable pelletized forms.

Comparative Advantages Over Smooth Rollers

Compared to smooth rollers, dimpled bearing steel rollers offer several distinct advantages:

- Higher friction and improved material flow control

- Reduced roller slippage and energy consumption

- Longer service life due to even stress distribution

- Lower maintenance requirements and less cleaning frequency

- Improved pellet quality and density uniformity

Factors to Consider When Selecting Dimpled Rollers

Selecting the right dimpled bearing steel pellet roller involves considering several factors:

- Roller diameter and length: To match the pellet mill specifications and desired throughput

- Dimple pattern and depth: To optimize gripping for the specific feed material

- Material hardness: To ensure wear resistance and longevity under high-pressure conditions

- Coating or surface treatment: For corrosion and abrasion protection

- Compatibility with existing pellet mill components: Ensuring smooth integration without excessive modification

Conclusion

Dimpled bearing steel pellet rollers provide significant advantages in pellet mill operations, including enhanced pellet quality, increased production efficiency, and extended durability. Their unique dimpled design improves material grip, reduces energy consumption, and minimizes maintenance requirements, making them an ideal choice for feed, biomass, fertilizer, and recycling industries. By carefully selecting the right roller specifications, operators can maximize both performance and longevity, ensuring consistent high-quality pellet production.

русский

русский Español

Español عربى

عربى 中文简体

中文简体