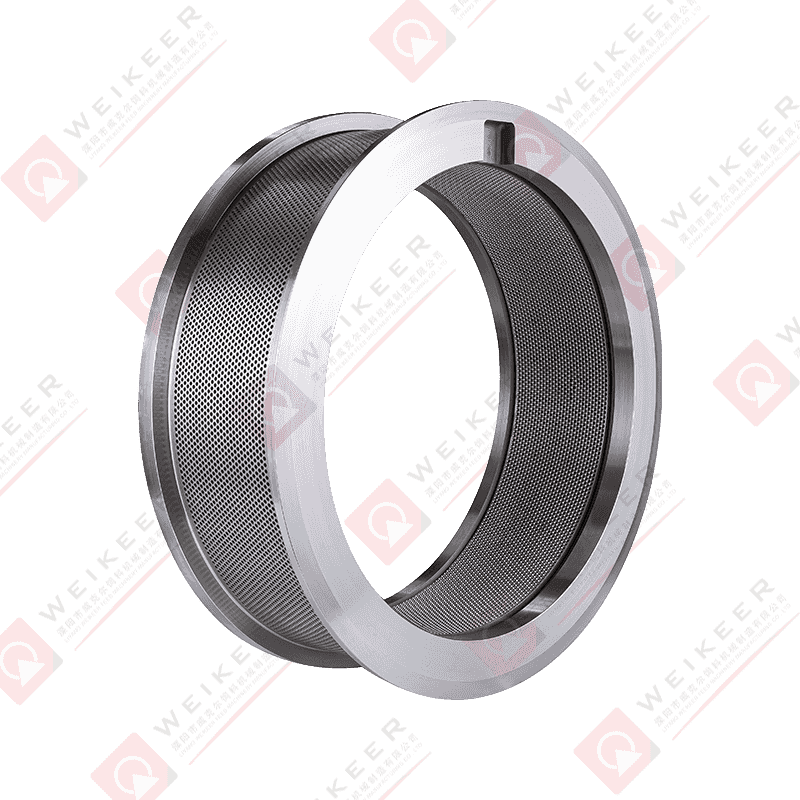

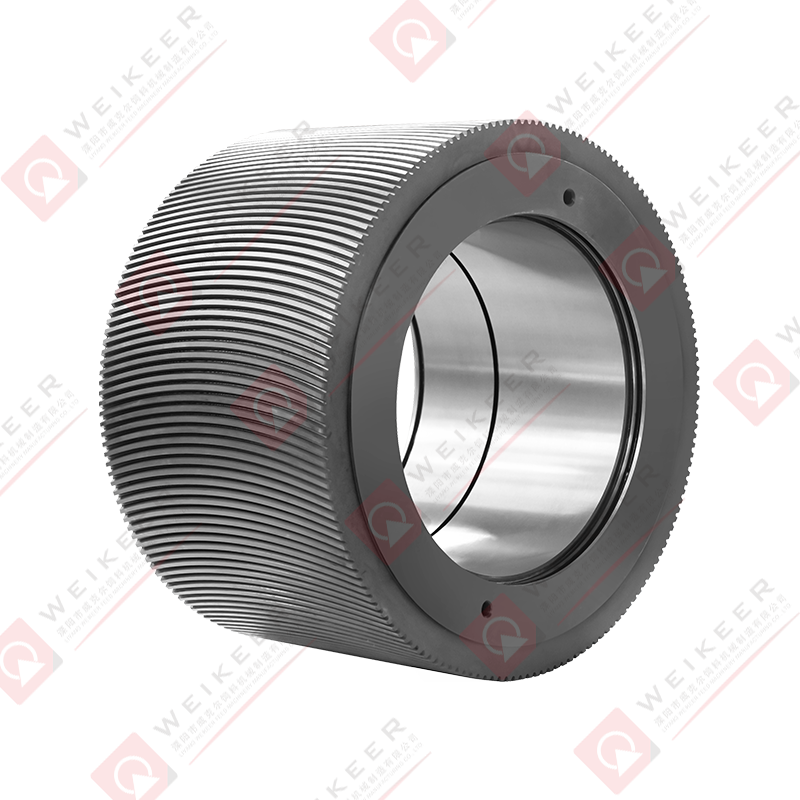

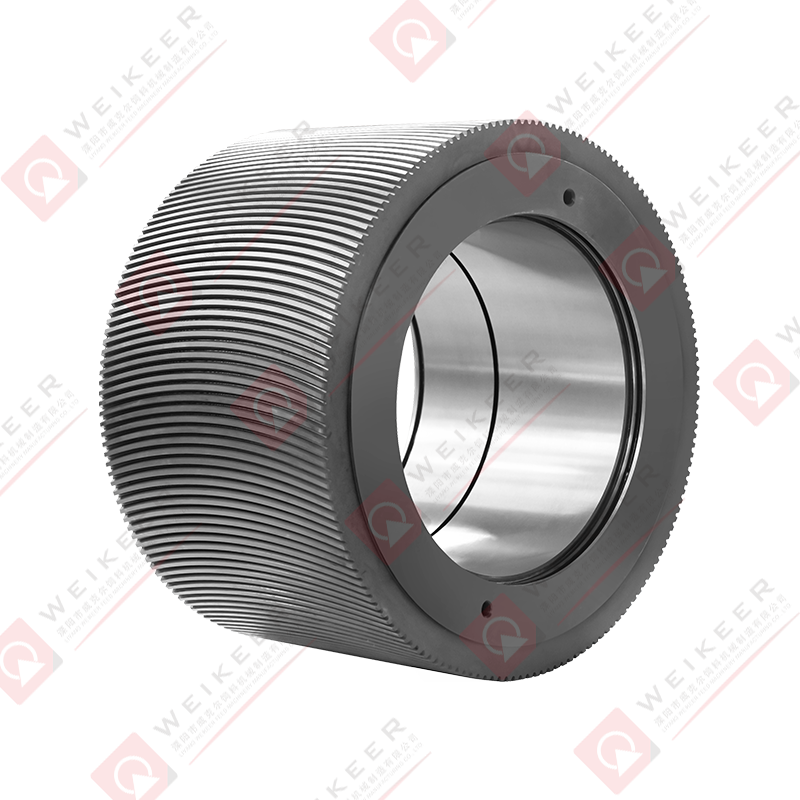

In the pellet manufacturing industry—whether producing animal feed, wood pellets, or biomass fuel—the ring die is one of the most critical components determining output efficiency, pellet quality, and energy consumption. Among various types, the screw type stainless steel ring die has become increasingly popular due to its superior mechanical strength, corrosion resistance, and easy installation. However, choosing the right ring die for a specific application requires a thorough understanding of material properties, design parameters, and operational conditions. This article explores how to properly select a screw type stainless steel ring die that matches your pellet production requirements and ensures consistent, high-quality results.

1. Understanding the Role of the Screw Type Stainless Steel Ring Die

A ring die functions as the compression chamber in a pellet mill, where raw materials are forced through small holes by rollers to form compacted pellets. The screw type design refers to a fastening method where the die is mounted onto the pellet mill’s main shaft using precision screw connections instead of bolts or clamps. This structure enhances mechanical stability, allows faster assembly and disassembly, and reduces maintenance time.

Stainless steel—typically grades such as SUS304, SUS410, or 4Cr13—is favored for its resistance to corrosion, wear, and heat deformation. These qualities are particularly beneficial in environments where high moisture content, chemical additives, or long production hours can degrade ordinary alloy steels.

2. Key Factors in Selecting the Right Ring Die

Choosing the ideal screw type stainless steel ring die involves evaluating several interconnected parameters that affect pellet quality, durability, and mill efficiency.

(1) Raw Material Type

Different raw materials have distinct fiber structures, moisture levels, and binding properties, all of which influence the compression process.

- Animal Feed Pellets: Require dies with moderate compression ratios (1:6–1:10) to ensure good pellet hardness without overheating.

- Biomass Pellets (e.g., sawdust, rice husk, straw): Need higher compression ratios (1:10–1:16) because the material is coarse and fibrous.

- Wood Pellets: Often demand high-strength stainless steel dies with smaller hole diameters to achieve smooth surface finish and high density.

Selecting a die material and design that aligns with the raw material characteristics minimizes energy loss and extends service life.

(2) Compression Ratio

The compression ratio (L/D)—the ratio of effective die length to hole diameter—is a crucial factor determining pellet density and durability.

- A higher ratio produces denser pellets but increases wear and energy consumption.

- A lower ratio reduces pressure and die wear but may lead to softer pellets.

Operators should adjust the compression ratio based on the material’s natural binding ability. For example, oily or high-protein feed materials need lower compression ratios than dry, fibrous biomass.

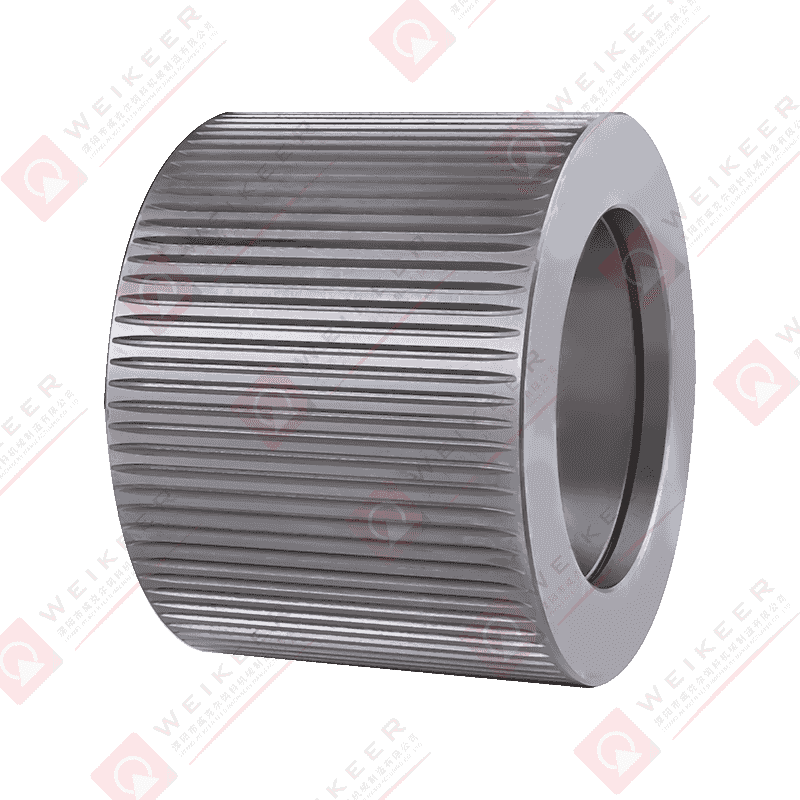

(3) Hole Size and Distribution

Hole diameter directly affects pellet size and throughput. Common sizes range from 2 mm to 12 mm depending on the product:

- Feed pellets: 2–4 mm (for poultry or aquaculture).

- Fuel pellets: 6–10 mm (for wood and biomass).

Uniform hole distribution ensures even pressure and prevents localized stress that could crack the die.

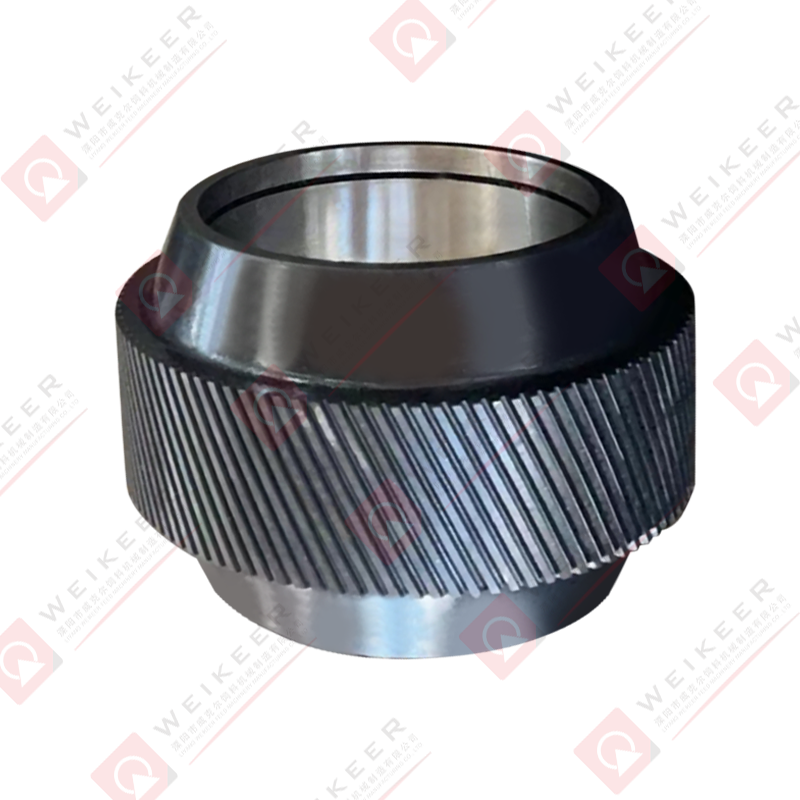

3. Importance of Stainless Steel Grade and Heat Treatment

The grade of stainless steel determines the ring die’s hardness, corrosion resistance, and fatigue strength.

- SUS304: Excellent corrosion resistance; suitable for high-moisture feed production.

- SUS410 / 4Cr13: Provides higher hardness after heat treatment; ideal for wood or biomass pellets with high abrasiveness.

- Special alloyed stainless steel (custom grades): Used for applications requiring extreme wear resistance or high compression.

Heat treatment—especially vacuum hardening and tempering—enhances surface hardness (HRC 50–60) while maintaining inner toughness. This process prevents cracking and deformation under continuous high-pressure operation.

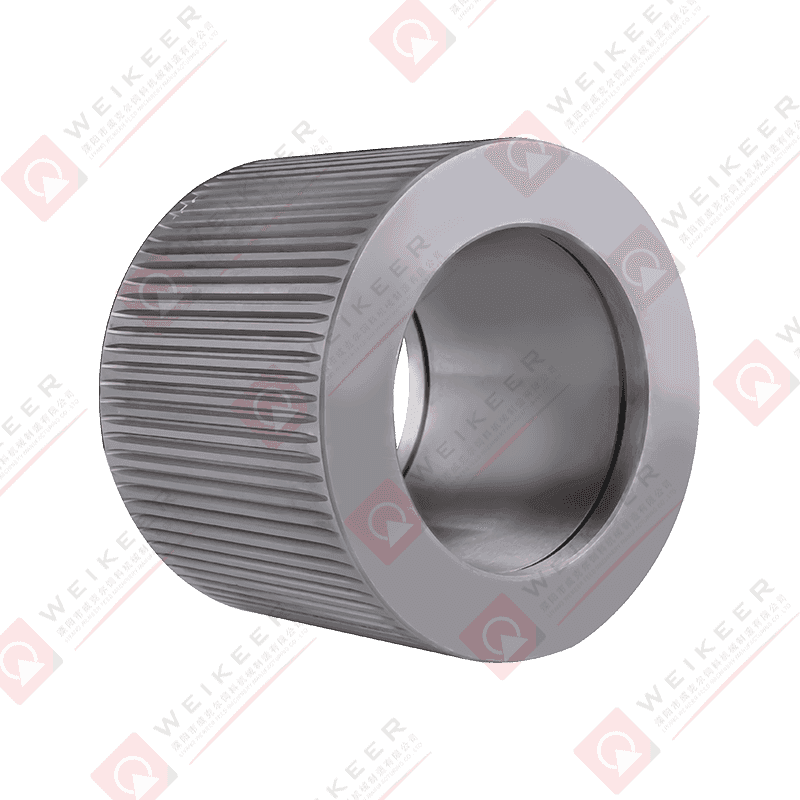

4. Screw Type Design Advantages in Industrial Operation

Compared with bolt-type dies, screw type stainless steel ring dies offer several notable operational benefits:

- Fast Installation: The screw connection system allows easy mounting and disassembly, reducing downtime during die replacement.

- Stable Operation: Uniform pressure distribution minimizes vibration and mechanical fatigue.

- Improved Concentricity: Better alignment between the die and roller ensures consistent pellet size and reduced wear.

- Enhanced Safety: The screw locking mechanism prevents loosening during high-speed operation.

For large-scale pellet plants where continuous operation is critical, these advantages translate directly into higher productivity and lower maintenance costs.

5. Matching Die Specifications to Pellet Applications

Each pellet production application requires unique ring die configurations to achieve optimal results.

| Application |

Recommended Stainless Steel Grade |

Compression Ratio |

Hole Diameter (mm) |

Key Considerations |

| Poultry Feed |

SUS304 |

1:8–1:10 |

3–4 |

Smooth inner surface, prevent feed blockage |

| Fish Feed |

SUS304 / SUS316 |

1:6–1:8 |

2–3 |

Corrosion resistance, fine surface finish |

| Biomass Fuel |

4Cr13 / SUS410 |

1:12–1:16 |

6–10 |

High wear resistance, stable heat tolerance |

| Wood Pellets |

4Cr13 |

1:14–1:18 |

6–8 |

High hardness, precise drilling |

| Fertilizer Pellets |

SUS304 |

1:8–1:12 |

3–6 |

Corrosion protection, moderate density |

Selecting a ring die with specifications tailored to your specific material ensures efficient compaction and consistent pellet dimensions.

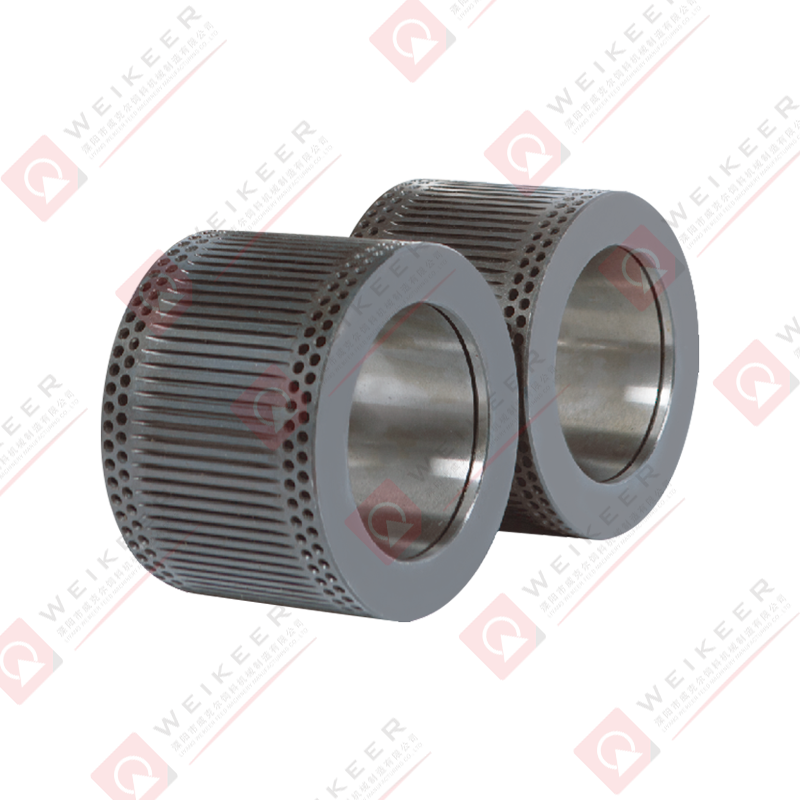

6. Evaluating Die Quality and Manufacturing Precision

High-precision manufacturing is essential for consistent pellet output and die longevity. When purchasing a screw type stainless steel ring die, consider:

- Surface Finish: Smooth inner walls reduce friction and material buildup.

- Hole Drilling Accuracy: Laser or gun drilling provides consistent hole geometry and prevents uneven wear.

- Roundness and Concentricity: Ensures balanced rotation during operation.

- Heat Treatment Uniformity: Prevents warping or cracking from uneven hardness.

It’s advisable to choose ring dies from reputable manufacturers with CNC machining and advanced heat treatment capabilities to guarantee performance consistency.

7. Maintenance and Replacement Guidelines

Even the best ring die will wear out over time. Proper maintenance extends its service life significantly.

- Regular Cleaning: Remove material residues after each production shift to prevent clogging.

- Check for Wear Patterns: Uneven wear may indicate misalignment or improper roller pressure.

- Monitor Output and Pellet Quality: A sudden drop in output or increase in fines often signals die wear.

- Scheduled Replacement: Replace dies before hole walls become excessively smooth or enlarged.

By maintaining the die properly and following a replacement schedule based on production hours, operators can minimize downtime and avoid costly breakdowns.

8. Common Mistakes to Avoid in Ring Die Selection

- Choosing Incorrect Compression Ratio: Overly high ratios may increase pellet hardness but shorten die life.

- Ignoring Raw Material Differences: Using the same die for all materials can cause inefficiency or damage.

- Overlooking Heat Treatment Quality: Poorly treated dies lose hardness quickly and wear unevenly.

- Neglecting Compatibility: Ensure the screw type ring die matches the model and torque specifications of your pellet mill.

Avoiding these pitfalls ensures consistent production and optimal return on investment.

9. Conclusion

Selecting the right screw type stainless steel ring die is a crucial step toward achieving efficient, durable, and cost-effective pellet production. The choice should be guided by raw material characteristics, desired pellet quality, compression ratio, and operating environment.

By considering stainless steel grade, die hole configuration, and screw connection design, manufacturers can optimize productivity while minimizing wear and maintenance costs. Ultimately, a well-chosen and properly maintained screw type stainless steel ring die not only improves pellet quality but also enhances the overall sustainability and profitability of your production line.

русский

русский Español

Español عربى

عربى 中文简体

中文简体