In the animal feed and biomass processing industries, efficiency, durability, and product consistency are critical factors. One component that significantly influences these factors is the screw type stainless steel ring die used in pellet mills. But what exactly is a screw type ring die, and why is stainless steel preferred? How does it enhance pellet production, and what makes it superior to conventional designs? This article explores the structure, function, benefits, and considerations of pellet mills with screw type stainless steel ring dies.

What Is a Screw Type Stainless Steel Ring Die?

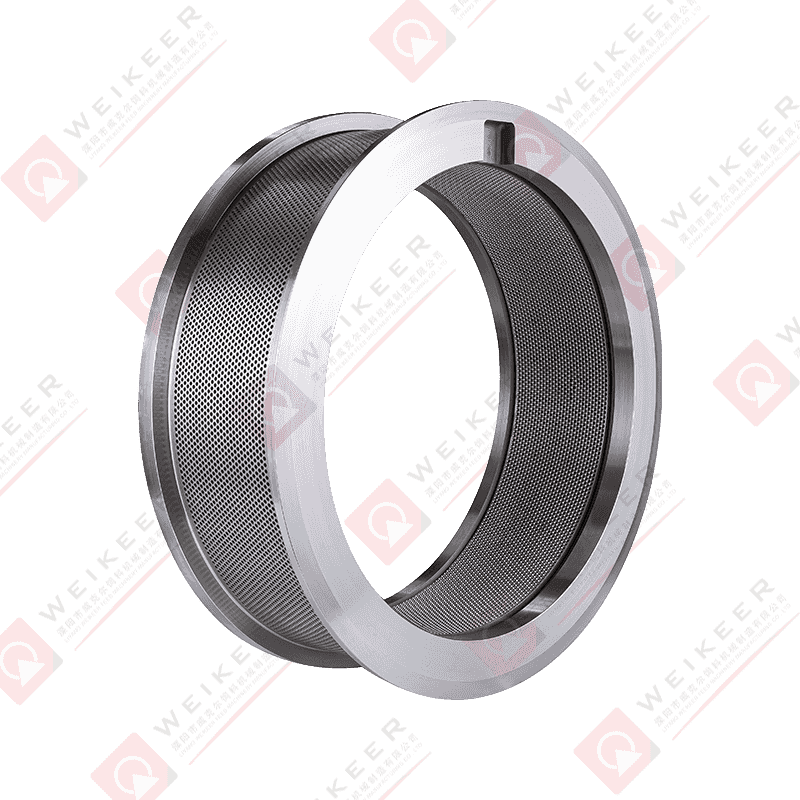

A screw type stainless steel ring die is a crucial component in pellet mills, particularly in the production of feed pellets for livestock, poultry, and aquaculture, as well as biomass pellets for energy applications. The ring die is a circular steel plate with numerous precision-engineered holes through which powdered feed or biomass is pressed to form uniform pellets.

The “screw type” designation refers to the internal design that assists in feeding and compressing the material more efficiently, reducing clogging and improving overall output. Stainless steel is used for its corrosion resistance, high hardness, and long service life, making it ideal for demanding processing environments.

How Does a Screw Type Ring Die Work in Pellet Mills?

The operation of a pellet mill with a screw type stainless steel ring die involves several coordinated actions:

Material Feeding

Powdered raw materials are fed into the mill via a screw conveyor that ensures uniform distribution.

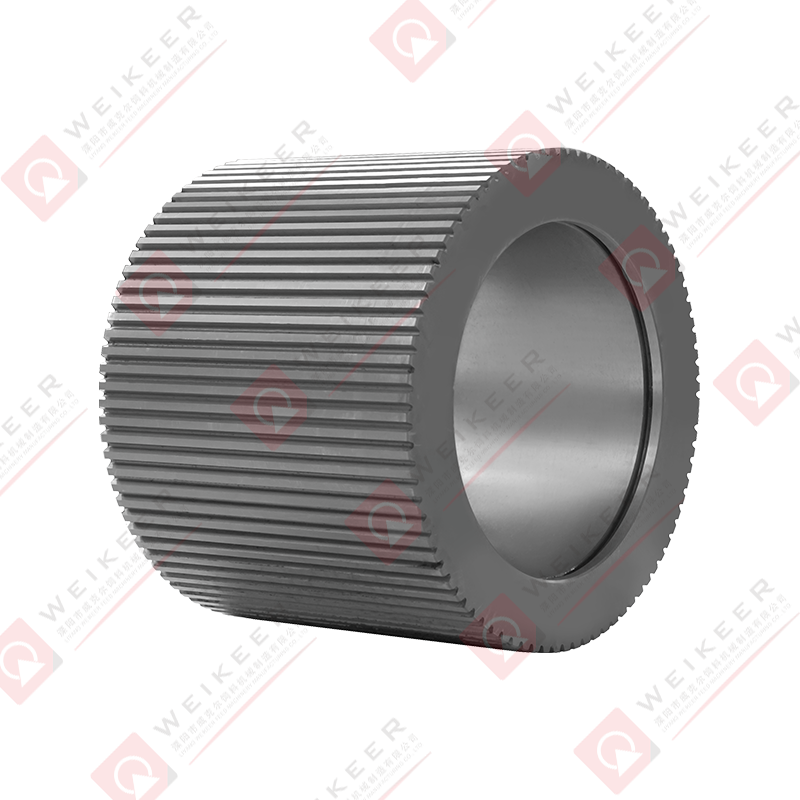

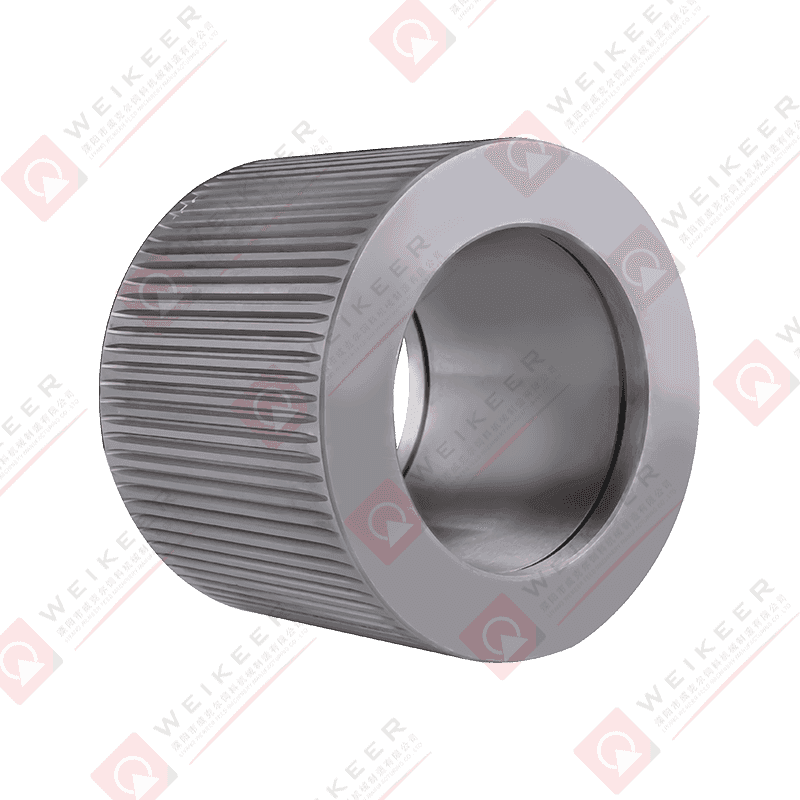

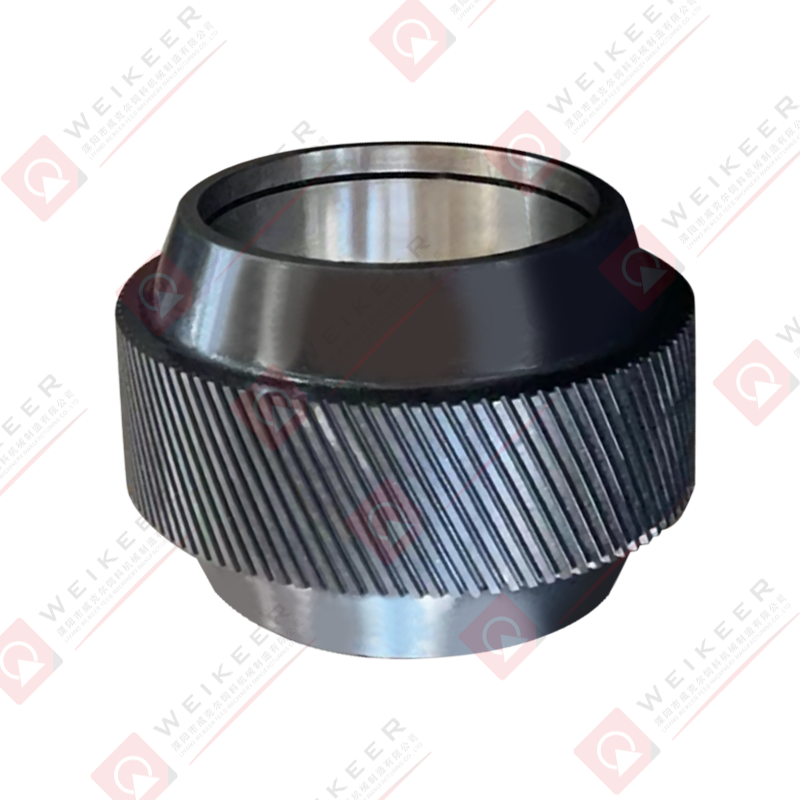

Compression and Extrusion

The screw-type mechanism pushes the material into the ring die holes, where rollers compress it under high pressure.

Pellet Formation

As the material is forced through the die, it is shaped into cylindrical pellets. The screw design helps reduce friction and prevents material from clogging the holes.

Pellet Ejection

Finished pellets are expelled from the die, cooled, and collected for packaging or further processing.

This combination of screw feeding and precision stainless steel construction ensures high efficiency, uniform pellet size, and minimal downtime.

What Are the Key Advantages of Stainless Steel Ring Dies?

Using stainless steel for ring dies in pellet mills offers numerous benefits over traditional materials such as carbon steel or cast iron:

Durability and Wear Resistance

Stainless steel withstands continuous abrasion and pressure, extending the lifespan of the die.

Corrosion Resistance

Resistant to moisture, acids, and other corrosive substances found in feed or biomass materials.

Precision and Uniformity

Machined holes ensure consistent pellet size, improving feed quality and reducing waste.

High Efficiency

Screw type design reduces clogging and friction, allowing for higher production rates.

Hygienic Material

Stainless steel prevents contamination, a critical consideration for animal feed production.

Maintenance Friendly

Easier to clean and maintain compared to other materials, reducing operational downtime.

What Types of Materials Can Be Processed Using Screw Type Stainless Steel Ring Dies?

Pellet mills with these ring dies are versatile and can handle a wide range of materials:

Animal Feed

Corn, soy, wheat, rice bran, and other powdered feed materials.

Produces uniform pellets suitable for poultry, livestock, and aquaculture.

Biomass Pellets

Wood, straw, sawdust, and other agricultural residues.

Converts low-density material into high-density fuel pellets.

Recycled Materials

Certain industrial residues can be pelletized for energy or raw material reuse.

This adaptability makes the screw type stainless steel ring die an essential component for feed mills, biomass energy plants, and recycling facilities.

How Does the Screw Type Design Improve Pellet Production?

The screw type design in the ring die addresses several challenges commonly encountered in pellet production:

Prevents Clogging: The spiral design ensures material flows continuously into the die holes.

Reduces Friction: Minimizes wear on the die and rollers, extending operational life.

Enhances Compression: Produces denser, uniform pellets that are less prone to breakage.

Improves Efficiency: Increases throughput and reduces energy consumption.

By improving material flow and pellet consistency, the screw type die enhances both production quality and operational efficiency.

What Should Be Considered When Choosing a Stainless Steel Ring Die?

Die Thickness and Hole Diameter

Select based on desired pellet size, material type, and production volume.

Material Hardness

High-grade stainless steel offers better wear resistance and longevity.

Screw Type Configuration

Ensure compatibility with the specific pellet mill model and feed type.

Maintenance and Replacement

Evaluate ease of cleaning and replacement to minimize downtime.

Production Capacity

Match the die specifications with the mill’s intended output to optimize efficiency.

Careful selection guarantees maximum performance, durability, and consistent pellet quality.

Final Thoughts: Are Pellet Mills with Screw Type Stainless Steel Ring Dies Worth the Investment?

The answer is a clear yes for businesses focused on feed production or biomass processing. The combination of stainless steel durability, corrosion resistance, and precision engineering, along with the screw type feeding design, ensures high-efficiency operation, uniform pellet quality, and reduced maintenance costs.

Whether producing animal feed for commercial farms, biomass pellets for energy, or other pelletized materials, investing in a pellet mill with a screw type stainless steel ring die provides long-term operational benefits, improved productivity, and superior product quality. For industries that rely on pellet production, this technology is not just beneficial—it is essential for competitive, reliable, and sustainable operations.

русский

русский Español

Español عربى

عربى 中文简体

中文简体