Aquaculture has grown into one of the most significant food-producing industries worldwide, and with it, the demand for high-quality aqua feed has increased rapidly. Fish, shrimp, and other aquatic species require nutrient-dense feed that is also physically durable enough to remain stable in water until consumed. At the heart of aqua feed production lies the pellet mill, and one of its most crucial components is the pellet die. Specifically, the hole design of an aqua feed pellet die plays a decisive role in determining the size, density, water stability, and durability of the feed pellets.

Understanding how hole design works and its influence on pellet quality is essential for feed producers, as it directly affects feed efficiency, fish health, and farm profitability. This article provides a detailed examination of how pellet die hole design impacts aqua feed pellets and what factors should be considered when optimizing die selection.

The Function of Pellet Dies in Aqua Feed Production

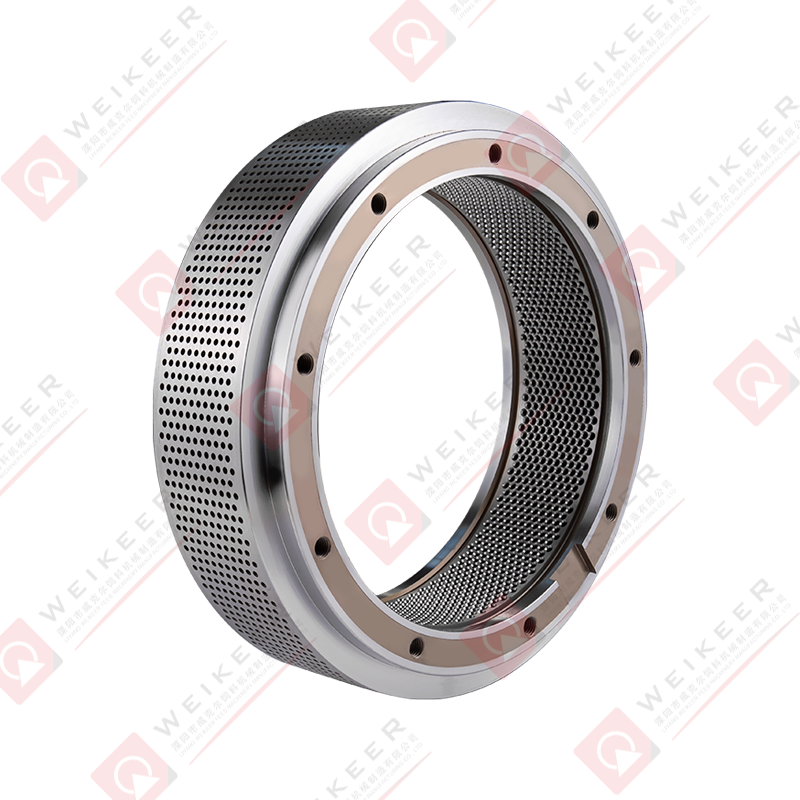

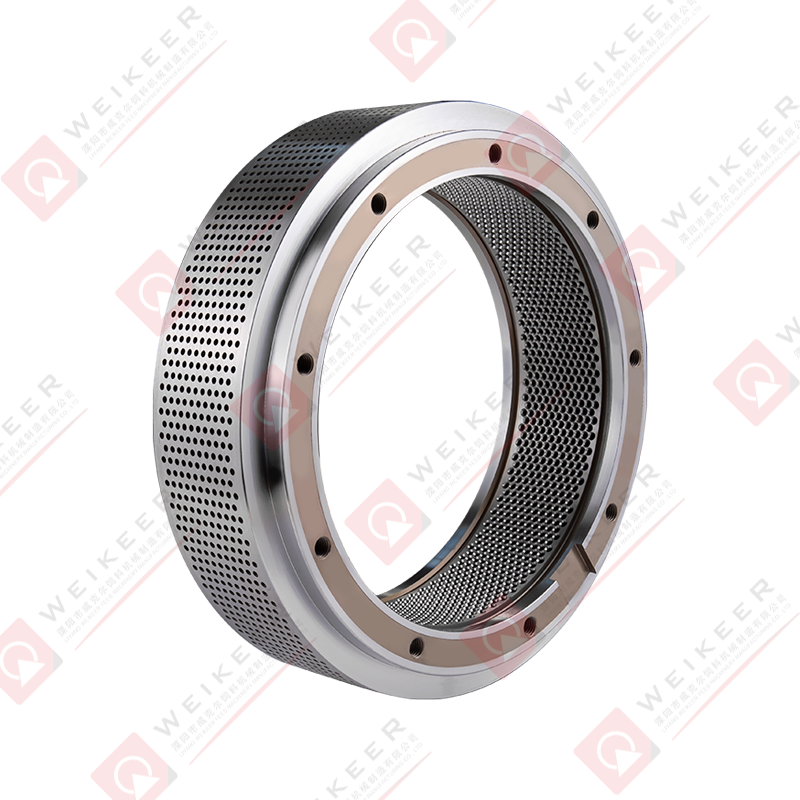

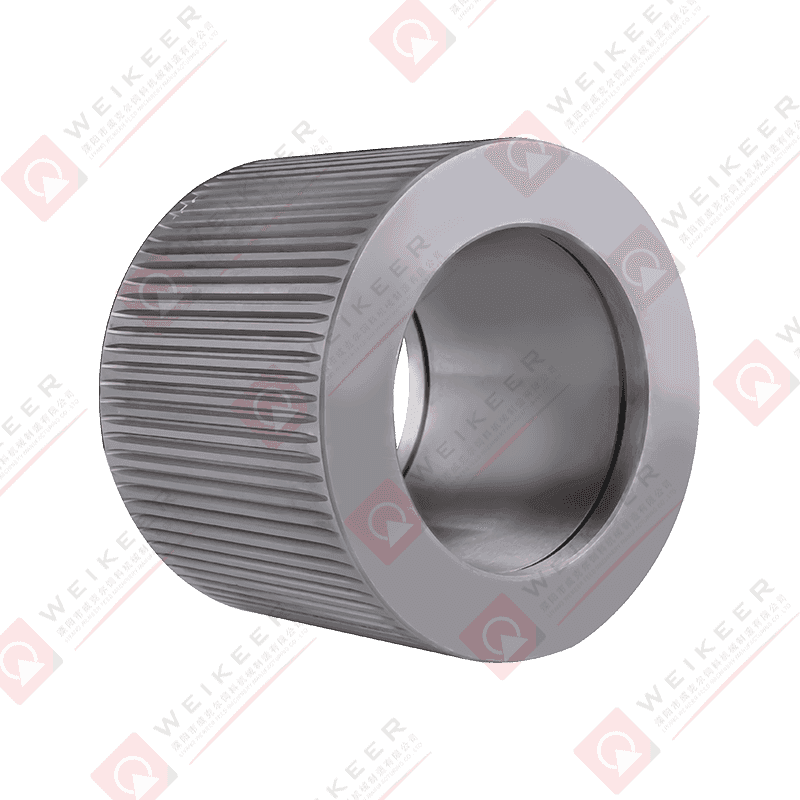

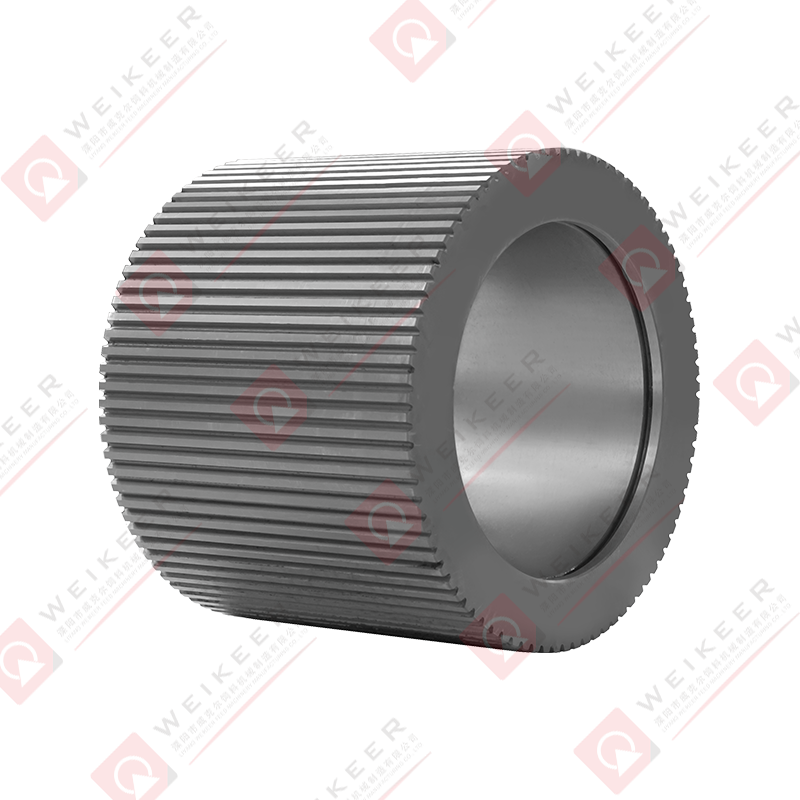

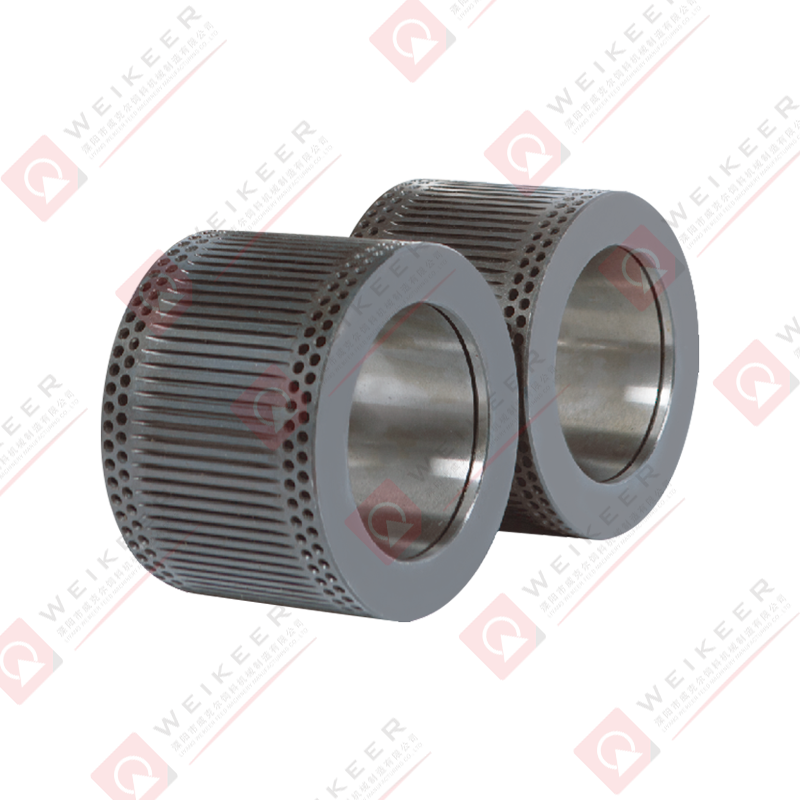

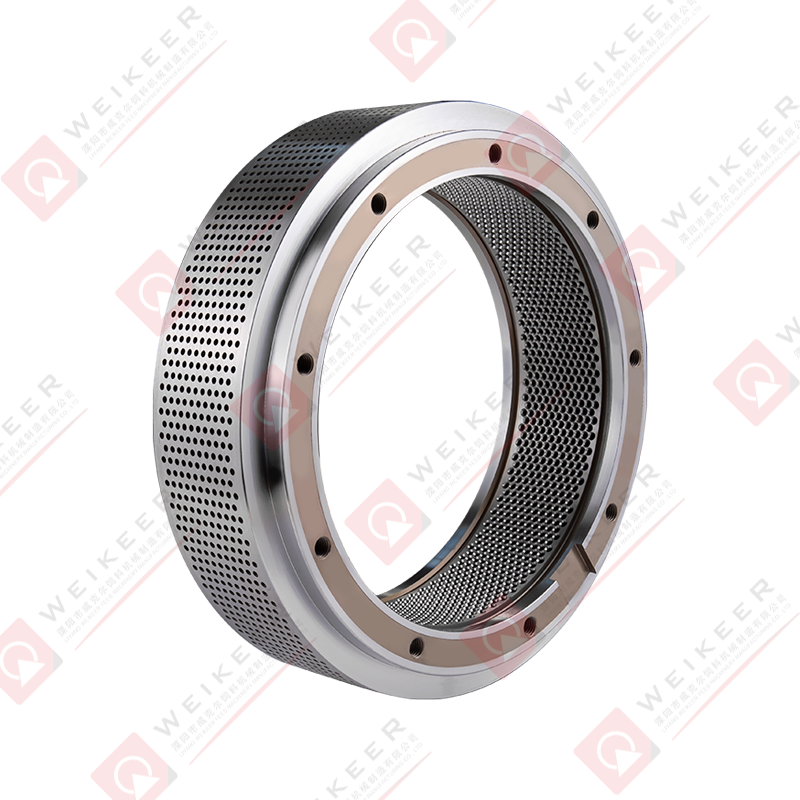

A pellet die is a precision-engineered metal plate, typically made from high-grade stainless steel or alloy steel, fitted into a pellet mill. During the pelleting process, conditioned raw materials are forced through the die holes under pressure and heat. As the feed mash is pushed through, it takes the shape of the holes, forming cylindrical pellets.

This process may seem straightforward, but the design of the die holes is far from simple. Every aspect, from the hole diameter to the compression ratio and the geometry of the inlet and outlet, influences how the feed material compacts and bonds, and ultimately how the finished pellet performs when used in aquaculture.

Hole Diameter and Pellet Size

The most obvious influence of hole design is pellet size. The diameter of the die holes dictates the diameter of the final pellet. Aqua feed typically requires smaller pellets than livestock feed because fish and shrimp have smaller mouths and feeding habits vary by species and growth stage. For example:

Larval and juvenile fish may require micro-pellets less than 1 mm in diameter.

Grower feeds usually range between 2 mm and 6 mm depending on species.

Large carnivorous fish may require pellets up to 10 mm.

By carefully designing the die hole diameter, producers can tailor feed to meet the nutritional delivery and physical feeding requirements of different aquatic species. An improper hole diameter can lead to poor feed intake, feed wastage, or inefficient growth performance.

Compression Ratio and Pellet Durability

Another critical element of hole design is the compression ratio, which is defined as the effective length of the die hole divided by its diameter. In simple terms, it describes how much the material is compressed as it passes through the die.

Higher compression ratios create denser, harder pellets that are more durable and water-resistant. This is particularly important for aqua feed because pellets need to resist disintegration when exposed to water.

Lower compression ratios allow materials to pass through with less resistance, producing softer pellets. While this may reduce energy consumption and extend die life, it can compromise water stability and durability.

Choosing the right compression ratio is a balancing act. Too high, and the die may experience excessive wear or cause production bottlenecks. Too low, and the pellets may break apart before fish can consume them.

Inlet and Outlet Geometry

The shape of the die hole at both the inlet (entry) and outlet (exit) is another factor that significantly influences pellet formation.

Inlet angle and shape determine how easily feed mash enters the die. A well-designed inlet minimizes friction, reduces die wear, and ensures smooth material flow. Poor inlet design can lead to uneven pellet density or even blockages.

Outlet design influences the release of pellets. A sharp outlet may cause pellets to crack or fracture, while a tapered or well-finished outlet helps pellets exit smoothly with consistent shape and durability.

Surface Finish of Die Holes

The smoothness of the die hole’s internal surface also affects pellet quality. A polished hole surface reduces friction and ensures consistent flow, leading to more uniform pellets. Conversely, rough or worn-out holes increase resistance, cause irregular pellet surfaces, and shorten die life.

Uniform, smooth pellets are more desirable not only for appearance but also because they reduce dust and fines, which can pollute aquaculture water systems and reduce feeding efficiency.

Influence on Water Stability

Unlike livestock feed, aqua feed must maintain integrity in water until it is consumed. Poorly designed die holes that produce pellets with low density or weak bonding lead to disintegration within minutes. This not only results in wasted feed but also deteriorates water quality by increasing organic load.

By controlling hole design—especially compression ratio and diameter—manufacturers can produce pellets that remain stable in water for several hours, giving fish enough time to consume the feed without excessive nutrient leaching.

Energy Consumption and Die Life

Hole design also has a direct impact on energy efficiency and die wear. Narrower diameters and higher compression ratios demand more energy to push feed through, which increases production costs. Similarly, poorly designed or excessively tight die holes can accelerate wear and reduce die lifespan.

Producers must therefore strike a balance between achieving durable pellets and keeping energy and maintenance costs within acceptable limits.

Customization for Different Species

Different aquatic species have unique feeding behaviors that influence the optimal pellet properties. For example:

Shrimp feed requires pellets with high water stability but softer texture so shrimp can nibble. Dies with smaller diameters and moderate compression ratios are preferred.

Tilapia feed demands floating pellets, achieved by optimizing hole design in combination with feed formulation and processing conditions.

Salmon feed requires denser pellets with higher oil content, which influences both the hole diameter and surface finish needed for efficient extrusion.

This species-specific customization underscores the importance of selecting die hole designs tailored to the target market.

Innovations in Die Hole Technology

Advances in pellet die manufacturing have introduced new possibilities in hole design. Computer-aided engineering (CAE) and precision drilling technologies now allow for highly accurate and consistent hole geometries. Additionally, surface treatments such as chrome plating or wear-resistant coatings extend die life and maintain smoother hole surfaces for longer periods.

Some manufacturers are experimenting with variable hole patterns within the same die, enabling multi-size pellet production in a single batch. Such innovations reflect the industry’s growing focus on efficiency, flexibility, and feed quality.

Best Practices for Optimizing Hole Design

To maximize pellet quality and production efficiency, feed producers should consider the following best practices:

Match hole diameter to species and life stage – ensuring feed size is appropriate for consumption.

Select compression ratios carefully – balancing pellet durability with energy consumption.

Monitor die wear regularly – as hole surfaces roughen over time, pellet quality declines.

Invest in precision-engineered dies – high-quality dies produce more consistent pellets and last longer.

Collaborate with die manufacturers – custom designs tailored to specific feed formulations and aquaculture needs deliver the best results.

Conclusion

The hole design of an aqua feed pellet die is far more than a technical detail; it is a key factor that determines pellet size, durability, and water stability. From diameter and compression ratio to inlet geometry and surface finish, each element influences how well pellets perform in aquaculture environments. Well-designed dies produce feed that is not only more palatable and digestible for aquatic species but also reduces waste, improves farm profitability, and minimizes environmental impact.

As aquaculture continues to expand globally, the importance of precision-engineered pellet dies and optimized hole design will only grow. Feed producers who understand and apply these principles will be better positioned to deliver superior feed solutions for a sustainable future.

русский

русский Español

Español عربى

عربى 中文简体

中文简体