Pellet mills are essential machines in the feed, biomass, and wood industries, where raw materials are compressed into uniform pellets for easier handling, storage, and use. At the heart of these machines lie rollers and shells, which directly impact productivity, quality, and operational longevity. When manufactured from bearing steel GCr15, these components achieve superior performance. But what makes GCr15 steel ideal for pellet mill rollers and shells, and how does it enhance the efficiency and durability of pellet production?

What Are Pellet Mill Rollers and Shells?

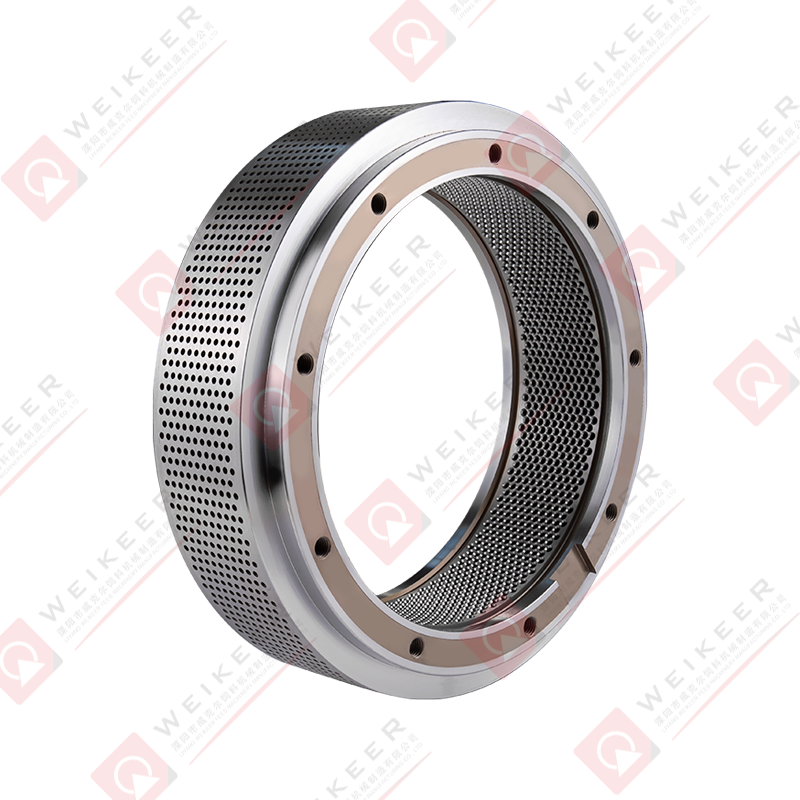

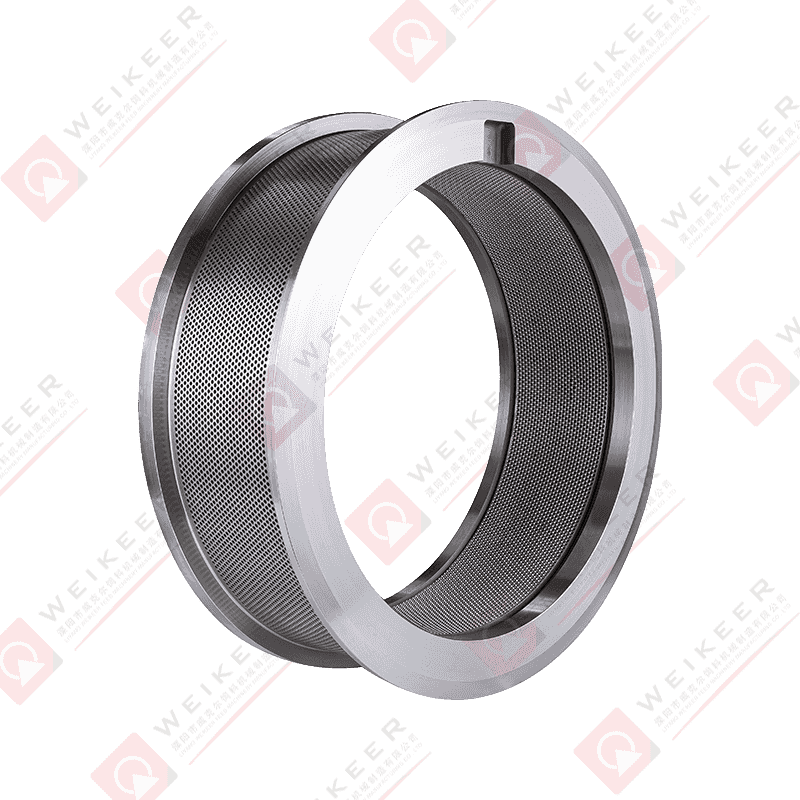

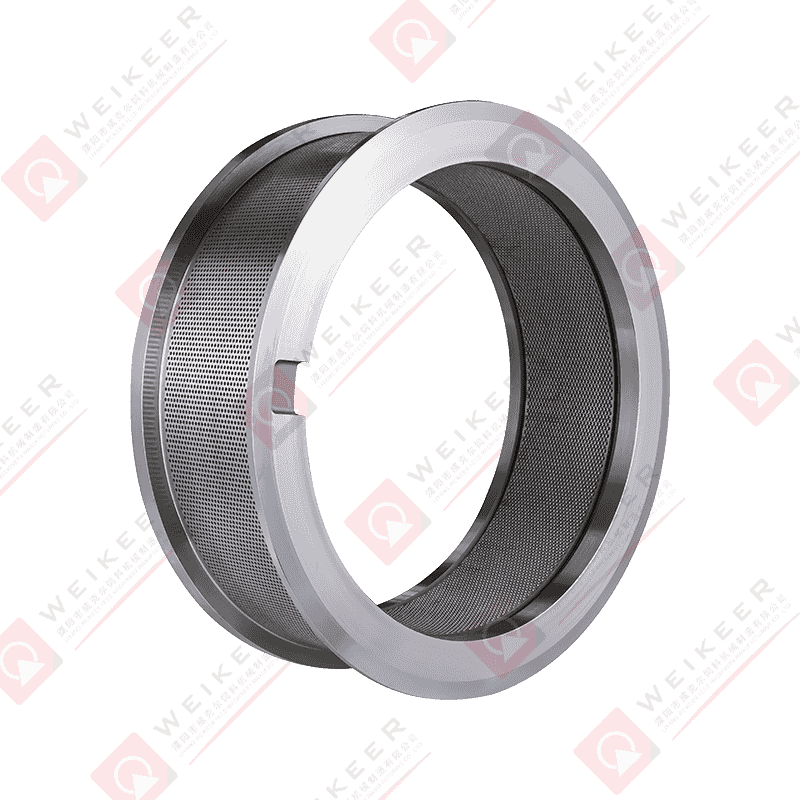

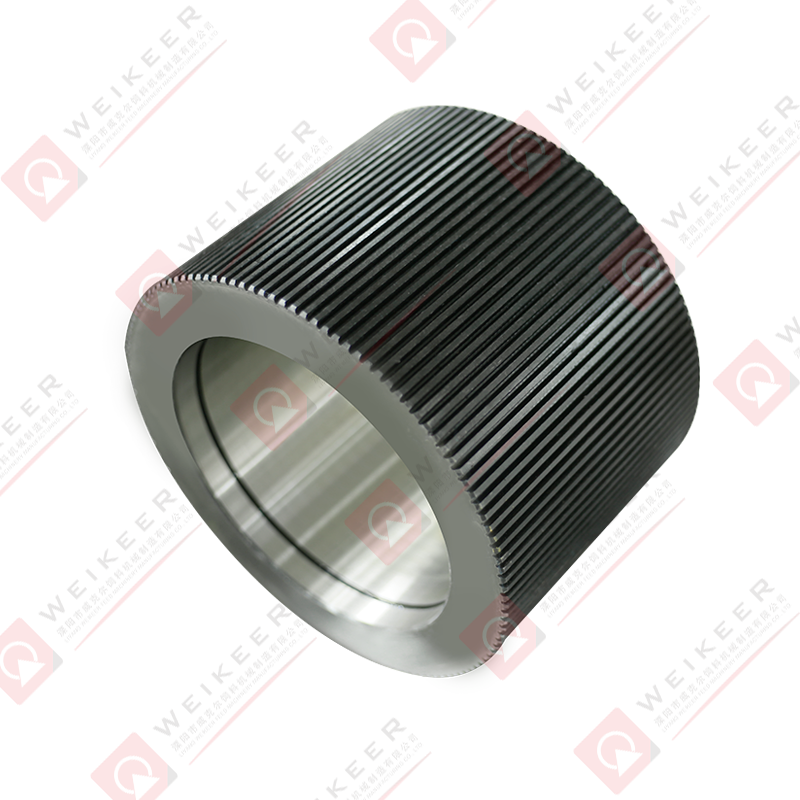

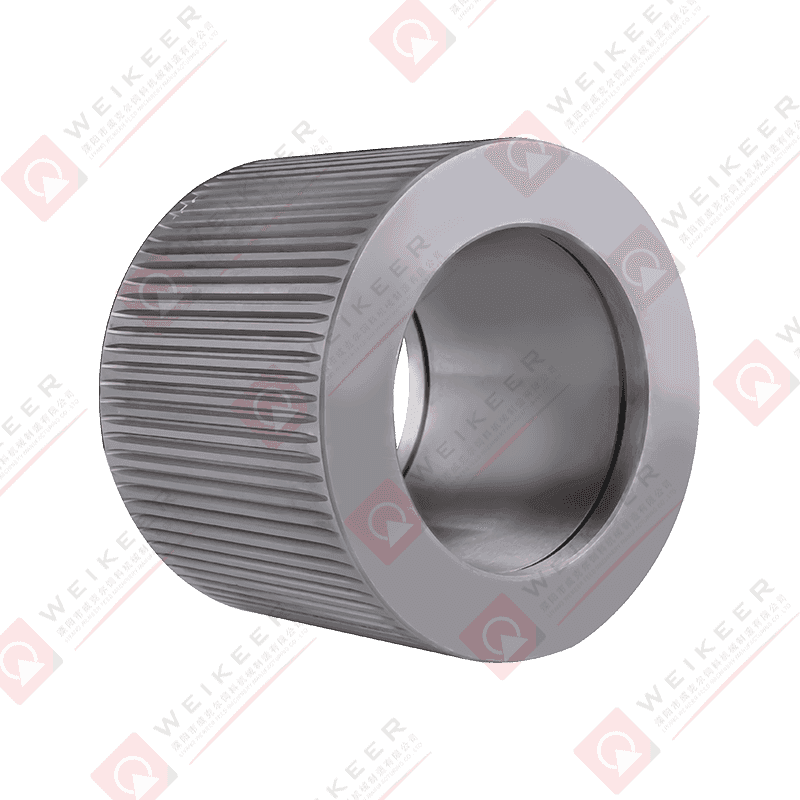

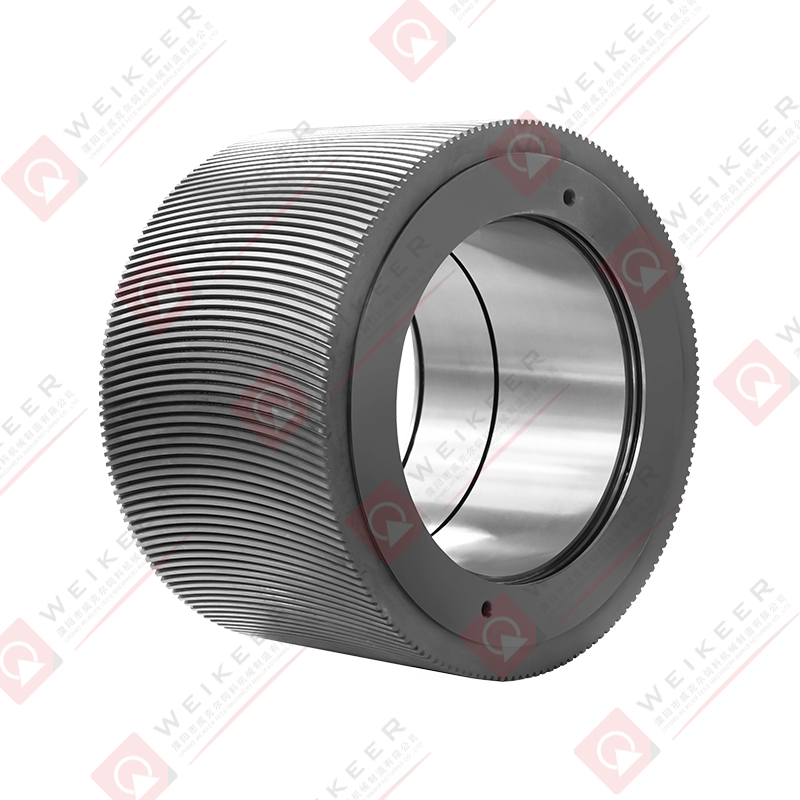

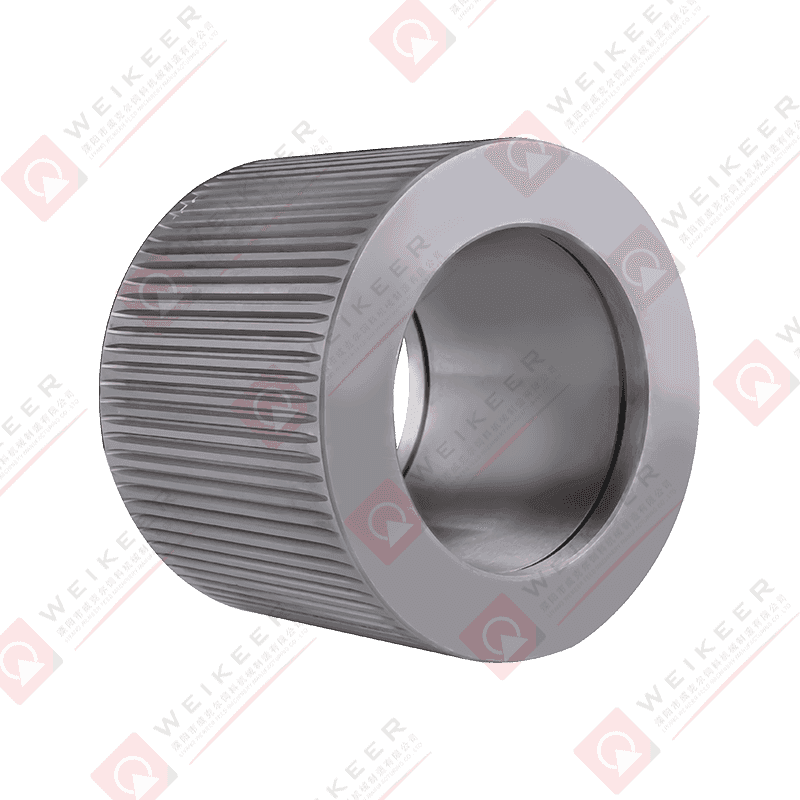

In a pellet mill, the roller is the cylindrical component that applies pressure to the raw material inside the ring or shell, also known as the die. The raw material passes between the roller and the shell under high pressure, and the result is compacted into pellets.

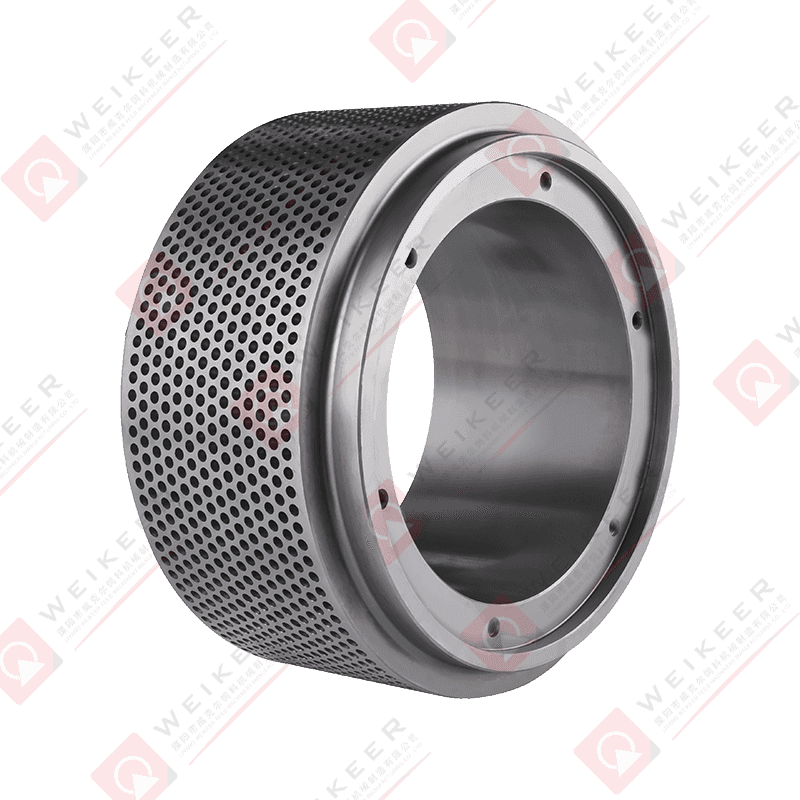

The shell (die) contains precision-engineered holes through which the compressed material is extruded. The roller moves over the inner surface of the die, providing consistent pressure for uniform pellet formation.

Together, rollers and shells are critical to:

Pellet quality

Production efficiency

Equipment lifespan

Any wear or damage to these components can result in irregular pellets, downtime, and increased maintenance costs.

Why Is Bearing Steel GCr15 Used for Rollers and Shells?

GCr15 is a high-carbon chromium bearing steel known for its exceptional hardness, wear resistance, and fatigue strength. It is widely used in applications requiring high-load and high-speed rotation, making it ideal for pellet mill rollers and shells.

Key properties of GCr15 include:

High Hardness – Typically hardened to 60–63 HRC, providing excellent wear resistance.

Wear Resistance – Maintains surface integrity under continuous friction and high pressure.

Fatigue Strength – Endures repetitive stress without cracking.

Dimensional Stability – Retains shape under high temperatures and mechanical load.

Corrosion Resistance – Resists minor oxidation, prolonging component life.

These characteristics ensure that pellet mill rollers and shells perform efficiently under the demanding conditions of industrial pellet production.

How Do GCr15 Rollers and Shells Improve Pellet Quality?

The quality of pellets depends heavily on the precision and consistency of rollers and shells. GCr15 steel contributes in several ways:

Uniform Pressure Distribution – Hard and smooth rollers apply consistent pressure across the raw material, producing dense, uniform pellets.

Accurate Pellet Size – High-quality shells maintain precise die hole dimensions, ensuring pellets are of uniform diameter.

Surface Smoothness – Reduces friction and prevents material from sticking, minimizing pellet defects.

Longer Service Life – Consistent performance over time ensures that pellet quality remains high without frequent replacement.

In summary, GCr15 steel allows pellet mills to produce high-quality pellets efficiently and reliably.

What Types of Pellet Mills Use GCr15 Rollers and Shells?

GCr15 rollers and shells are suitable for a variety of pellet mills:

Flat Die Pellet Mills – Rollers press material against a stationary die.

Ring Die Pellet Mills – Rollers rotate inside a cylindrical die, suitable for large-scale industrial production.

Biomass Pellet Mills – Used for wood, straw, and other biofuels.

Feed Pellet Mills – Produces animal feed pellets from grains and other feed materials.

The use of high-quality GCr15 steel ensures efficiency and durability across all these types.

How Does GCr15 Steel Extend Component Life?

Pellet mills operate under high pressure, heat, and friction, which can quickly wear down ordinary steel components. GCr15 steel extends component life by:

Reducing Wear Rate – The high hardness minimizes surface abrasion from raw materials.

Preventing Deformation – Strong fatigue resistance prevents rollers and shells from warping under stress.

Maintaining Dimensional Accuracy – Essential for uniform pellet formation and high-quality production.

Minimizing Maintenance Downtime – Longer-lasting components reduce the frequency of replacements and maintenance interventions.

Investing in GCr15 rollers and shells is cost-effective over the long term because downtime and replacement costs are significantly reduced.

How Are Rollers and Shells Manufactured from GCr15 Steel?

The manufacturing process ensures the strength, hardness, and precision of rollers and shells:

Material Selection – High-quality GCr15 bearing steel is chosen.

Forging or Machining – Rolled or machined to precise dimensions.

Heat Treatment – Hardened and tempered to achieve the required hardness and toughness.

Grinding and Polishing – Ensures smooth surfaces for low-friction operation.

Quality Inspection – Checked for dimensional accuracy, surface finish, and hardness.

This meticulous process guarantees long-lasting, high-performance rollers and shells.

What Are the Benefits of Using GCr15 Rollers and Shells in Pellet Mills?

High Durability – Resistant to wear, reducing frequent replacements.

Improved Pellet Quality – Consistent pressure and precision lead to uniform, dense pellets.

Energy Efficiency – Smooth, hard surfaces reduce friction, lowering energy consumption.

Cost Savings – Longer service life and fewer maintenance requirements reduce operating costs.

Operational Reliability – Less downtime and smoother operation improve production efficiency.

These advantages make GCr15 rollers and shells indispensable for modern pellet production facilities.

How to Maintain GCr15 Pellet Mill Components?

Even with high-quality GCr15 steel, proper maintenance is essential:

Regular Cleaning – Remove material residues to prevent sticking.

Lubrication – Ensure smooth rotation of rollers to reduce friction.

Inspection – Check for cracks, wear, and alignment issues.

Replacement – Replace worn or damaged components promptly to avoid damage to other machine parts.

Routine maintenance ensures maximum performance and extended lifespan of rollers and shells.

Are GCr15 Rollers and Shells Cost-Effective?

While the initial investment in GCr15 steel components may be higher than ordinary steel, the long-term benefits outweigh the upfront costs:

Reduced replacement frequency

Lower maintenance expenses

Improved pellet quality and production efficiency

Energy savings due to reduced friction

For industrial pellet producers, these advantages result in significant overall cost savings.

Final Thoughts: Why Choose Bearing Steel GCr15 Rollers and Shells?

Bearing steel GCr15 rollers and shells are the cornerstone of efficient and durable pellet mills. Their exceptional hardness, wear resistance, and fatigue strength ensure consistent pellet quality, reduced downtime, and long-term operational reliability.

русский

русский Español

Español عربى

عربى 中文简体

中文简体