In the pellet feed production industry, the roller shell, as one of the core components of the pelletizer, plays a decisive role in the operating efficiency, product quality and service life of the equipment. When we mention Bearing Steel Pellet Mills Roller Shells, it means higher hardness, stronger wear resistance and longer working life. So, what is a bearing steel roller shell? What are its advantages? Why is it becoming more and more popular in modern pellet production?

1. What are Bearing Steel Pellet Mills Rollers Shells?

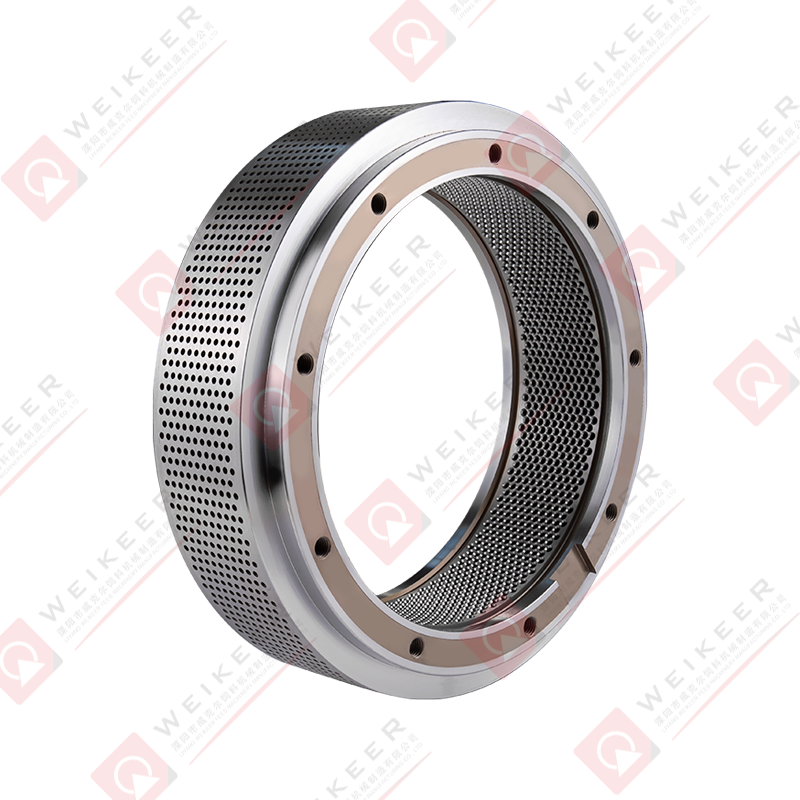

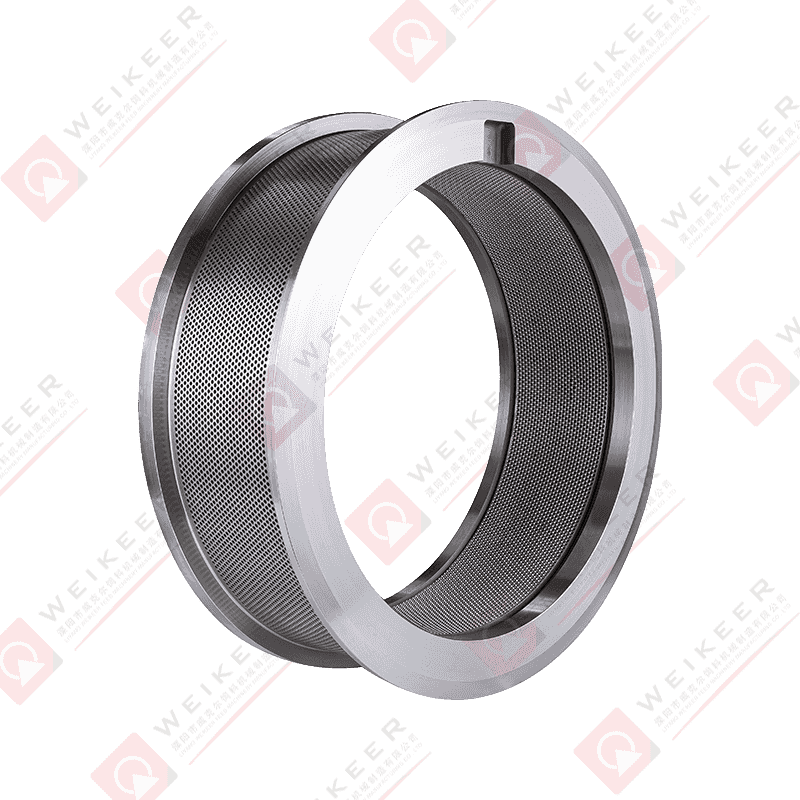

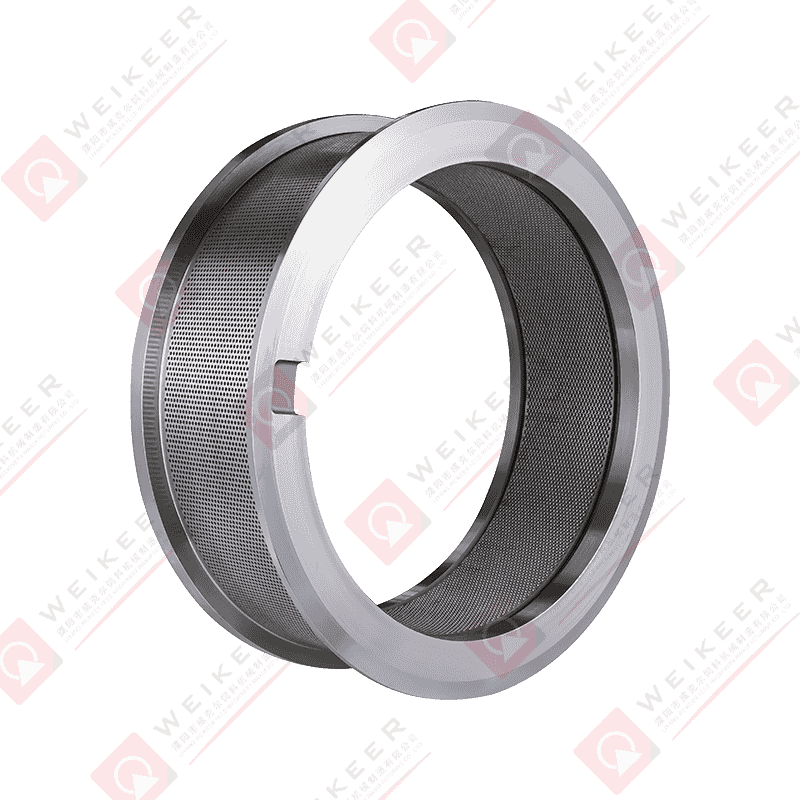

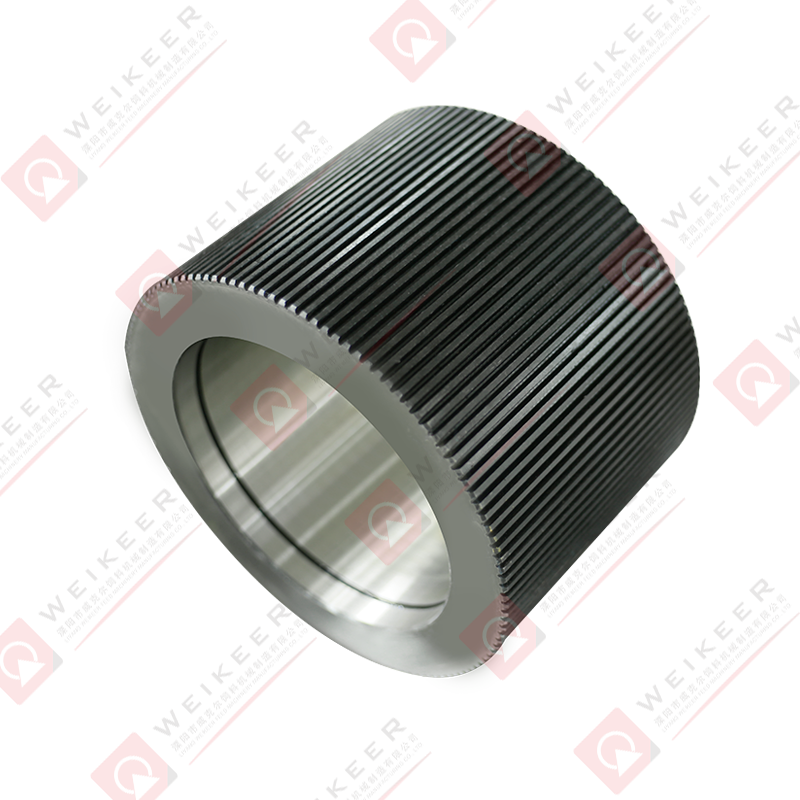

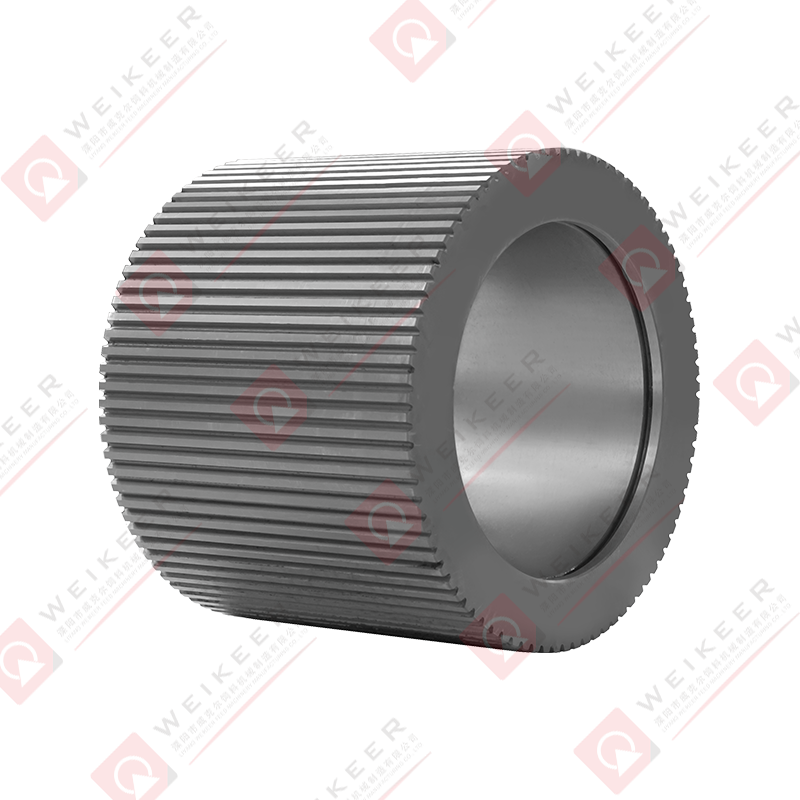

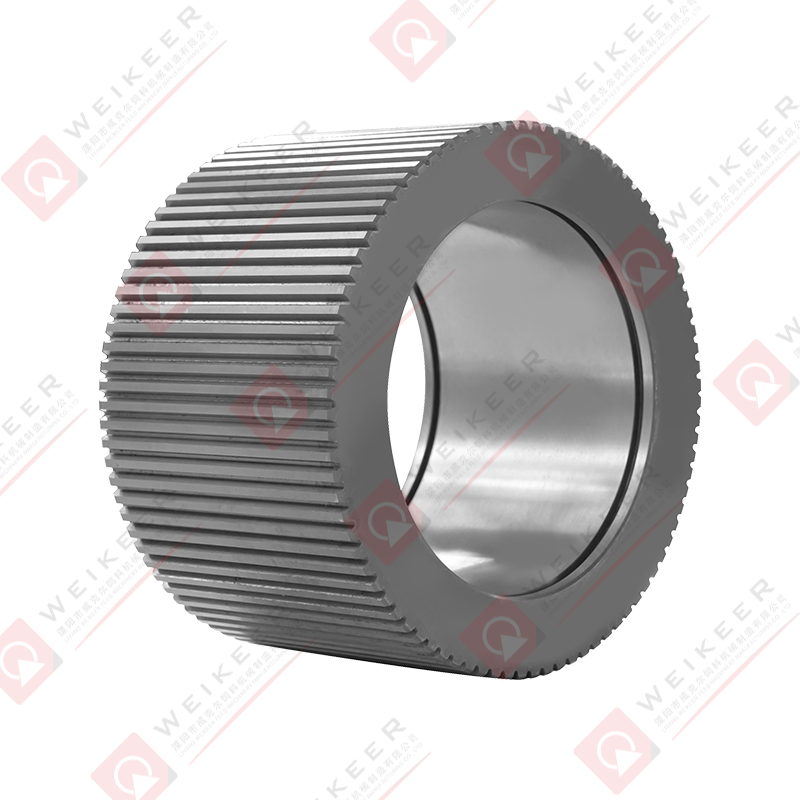

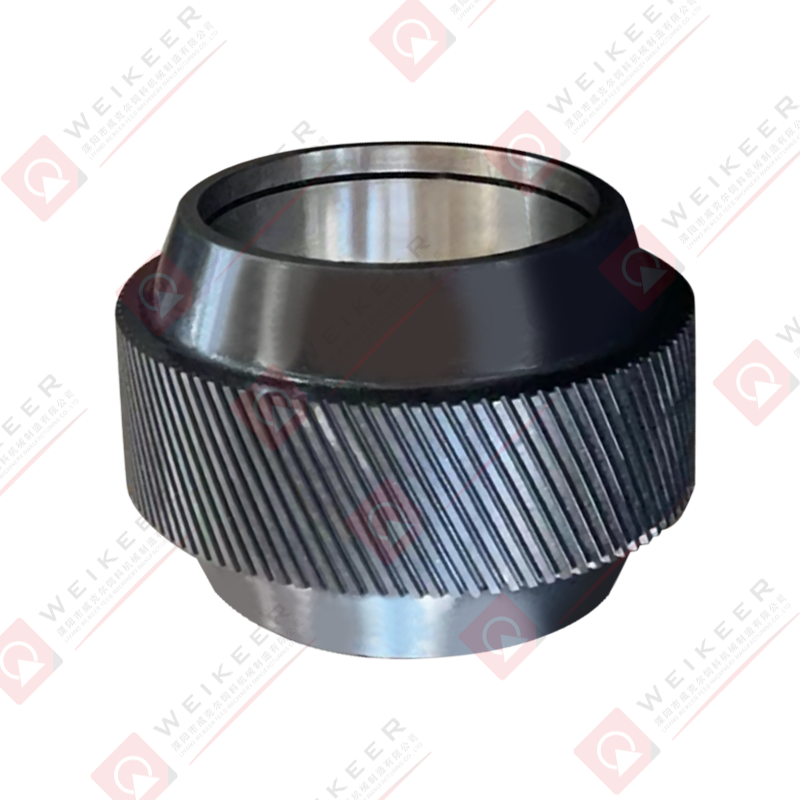

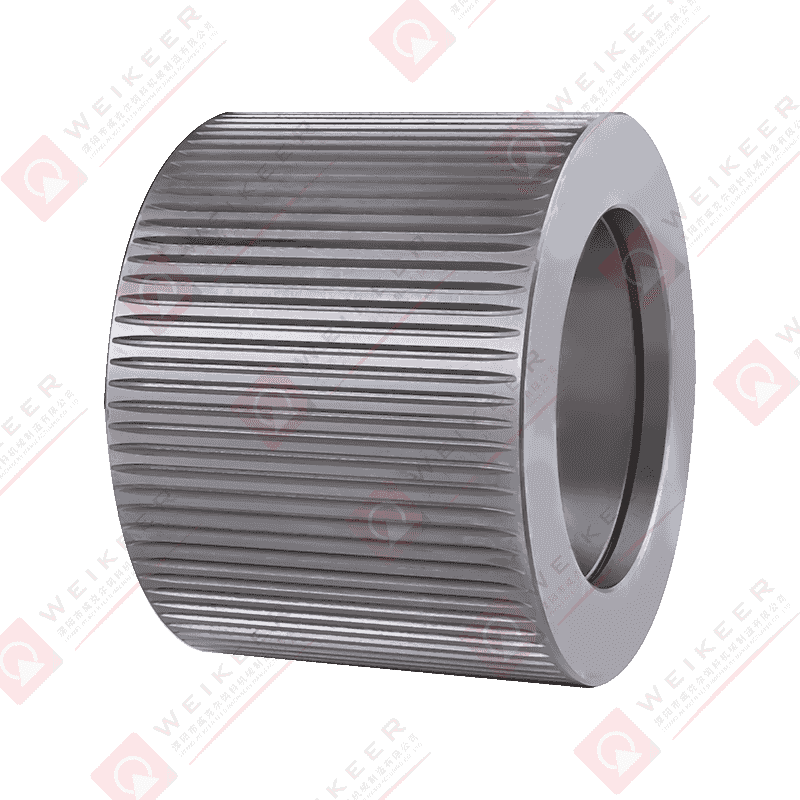

Bearing Steel Pellet Mills Roller Shells refers to the pellet machine roller shell made of high-strength bearing steel materials (such as GCr15, 100Cr6, etc.). The roller shell is an annular component installed on the outside of the pelletizer roller. Through mutual extrusion with the ring die, the powdered or fibrous raw materials are pressed into regular cylindrical particles.

Traditional roller shell materials are mostly made of alloy steel or carbon steel, but they are prone to wear, cracks and even breakage in high-strength, high-load, and continuous working environments. The roller shell made of bearing steel greatly improves wear resistance and overall strength, and is especially suitable for high-output or high-density granulation operations.

2. What are the differences between bearing steel roller shells and ordinary material roller shells?

| project |

Ordinary alloy steel roller shell |

Bearing Steel Roller Shell |

| Material Strength |

medium |

Very high |

| Hardness range |

HRC 40-50 |

HRC 58-64 |

| Wear resistance |

generally |

Very strong |

| Working life |

Relatively short |

Can be extended by 1.5~2 times or more |

| cost |

Lower |

Slightly higher but cost-effective |

| Application environment adaptability |

Suitable for small and medium loads |

Suitable for heavy-load, high-density granulation scenarios |

3. What are the specific technical advantages of bearing steel roller shells?

1. Ultra-high hardness and strength

Bearing steel can reach HRC 60 or above after quenching heat treatment, effectively resisting wear and impact during particle extrusion.

2. Excellent fatigue resistance

The roller shell is subjected to long-term rotation and repeated pressure. Bearing steel can withstand high-cycle stress with its excellent organizational structure to avoid fatigue cracks.

3. Good thermal stability

It can still maintain deformation stability under high-temperature and high-speed friction to prevent equipment misalignment caused by thermal expansion.

4. High-precision processing performance

Bearing steel is suitable for precision processing and can produce roller shells with low surface roughness and high geometric accuracy to improve particle consistency and finish.

4. Common pattern design and functional differences of bearing steel roller shells

The bearing steel roller shell is not static. Its surface knurling pattern design directly affects the granulation efficiency and particle appearance. Mainly includes:

Open Groove: Suitable for high-viscosity raw materials and reduce slippage.

Closed Groove: Improve extrusion pressure and density, suitable for high-density granulation.

Dimple Type: Improve material gripping, suitable for coarse fiber materials.

Scales Type: Improves material distribution and is suitable for general scenarios.

According to the pellet formula, raw material characteristics and target output, different grain structures can be flexibly selected to achieve the best pelletizing effect.

5. Which industries are most suitable for Bearing Steel Roller Shells?

Large feed mills: Continuous operation, high load, and extremely high wear-resistant parts are required.

Biomass pellet processing plant: Raw materials such as wood chips and straw have high hardness, and bearing steel can effectively resist wear.

Organic fertilizer granulation: In an environment with high water content and strong corrosive materials, the structure of bearing steel is more stable.

Chemical granulation system: Pellets require consistency and strength, and the roller shell needs to have high precision.

6. What are the precautions for the use and maintenance of bearing steel roller shells?

1. Ensure the press-fit accuracy before installation

The bearing steel roller shell has high precision, and forced knocking must be avoided during installation. It is recommended to use special tools for press-fitting.

2. Check the wear of the grain regularly

Severe wear will lead to a decrease in pelletizing efficiency, and it should be replaced periodically according to production volume.

3. Keep the lubrication system unobstructed

The roller shell is in close contact with the bearing, and grease should be added regularly to prevent overheating and wear.

4. Prevent foreign matter from entering the pressing system

Metallic foreign matter may cause the roller shell surface to crack or the die to be damaged, so the raw material screening needs to be strengthened.

7. How to judge the quality of the bearing steel roller shell?

To choose high-quality Bearing Steel Roller Shells, you can start from the following aspects:

Source of raw materials: Use GCr15 or equivalent high-carbon chromium bearing steel to avoid inferior steel with many impurities.

Heat treatment process: Uniform carburizing and quenching treatment can significantly improve hardness and toughness.

Grain processing accuracy: High-precision CNC milling composite processing equipment can ensure uniform and consistent patterns.

Manufacturer certification qualifications: Manufacturers with ISO, CE and other quality certifications are more reliable.

Practical word-of-mouth evaluation: Check the industry usage feedback to evaluate its actual service life and performance.

8. Industry Trends: Bearing Steel Roller Shells Intelligent Upgrade in Progress

With the development of equipment intelligence and digital manufacturing, bearing steel roller shells are also constantly upgraded:

Surface coating technology: such as nitriding, chrome plating, and spraying ceramic layers to further improve wear resistance.

Intelligent monitoring system: Linked with the host to detect temperature, vibration, and wear degree to achieve early warning maintenance.

Quick mold change structure: The modular design of the roller shell supports rapid replacement and improves production flexibility.

Environmental protection manufacturing process: low-energy consumption and low-pollution precision casting and processing methods are becoming increasingly popular.

Conclusion: Small roller shells are key components for efficient production

In the field of pellet machinery, Bearing Steel Pellet Mill Roller Shells is not just a piece of steel. It is an important cornerstone for improving production efficiency, ensuring pellet consistency, and reducing operating costs. Choosing high-quality bearing steel roller shells is the only way to efficient, safe, and sustainable production.

For every company dedicated to pellet processing, being meticulous about details, starting from the roller shell, and building core competitiveness is the real way to win in the industry.

русский

русский Español

Español عربى

عربى 中文简体

中文简体