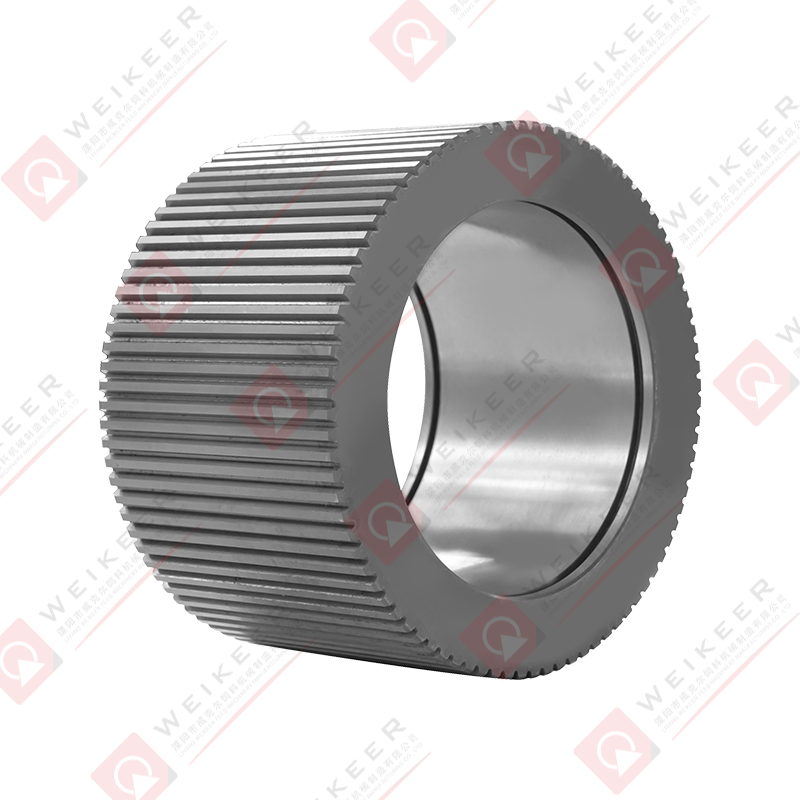

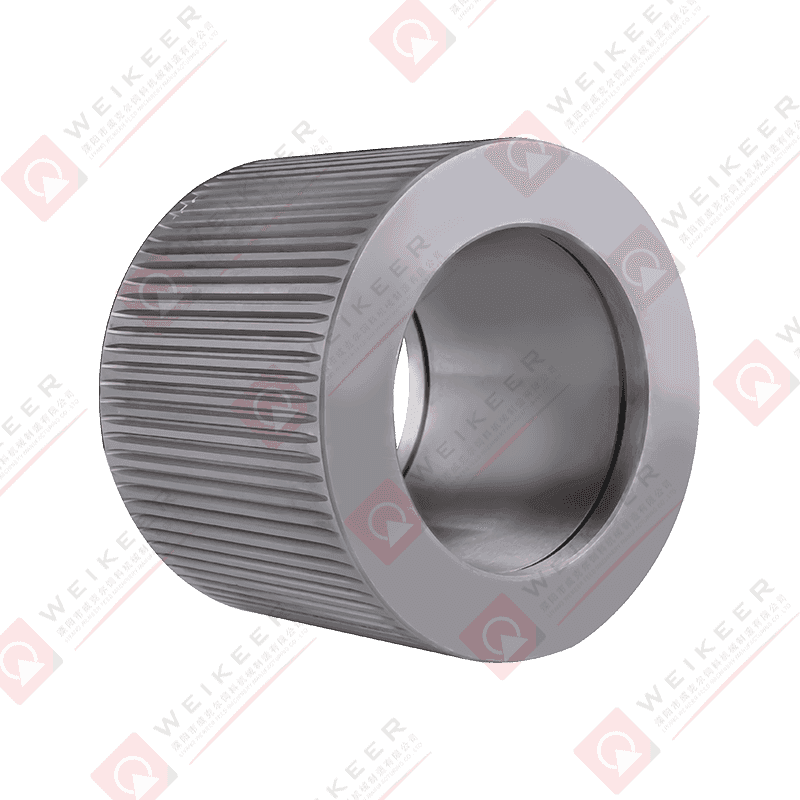

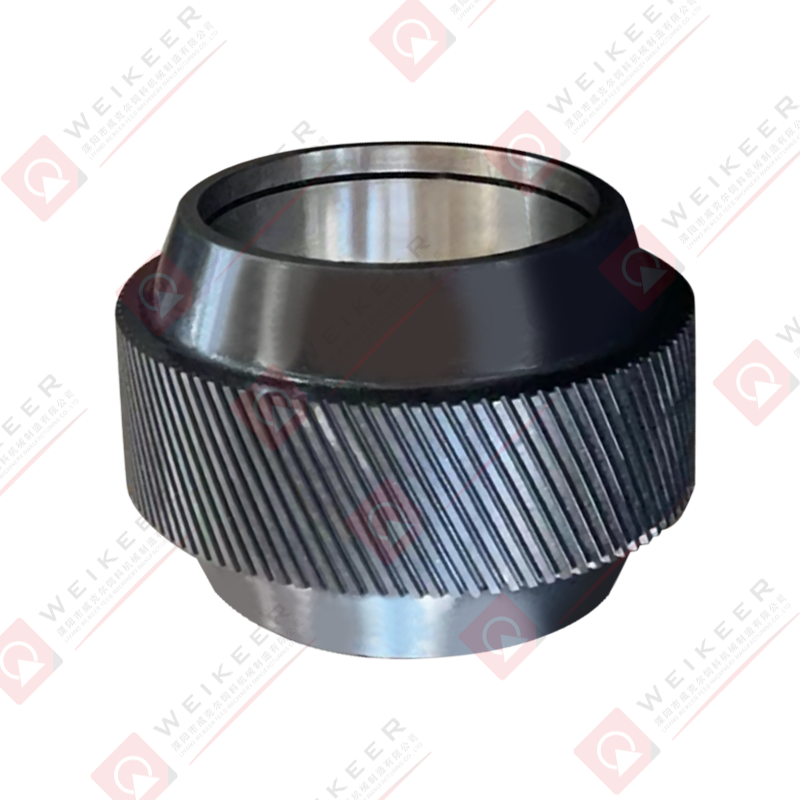

In the production of wood chips, biomass, feed and organic fertilizer pellets, the pellet mill is the core equipment. In the pellet mill, one of the most critical consumable parts is the ring die. With the increasing market demand for high-quality and high-yield pellet products, stainless steel ring dies have become the first choice for many users due to their superior wear resistance, corrosion resistance and structural stability.

1. Structure and working principle of stainless steel ring die

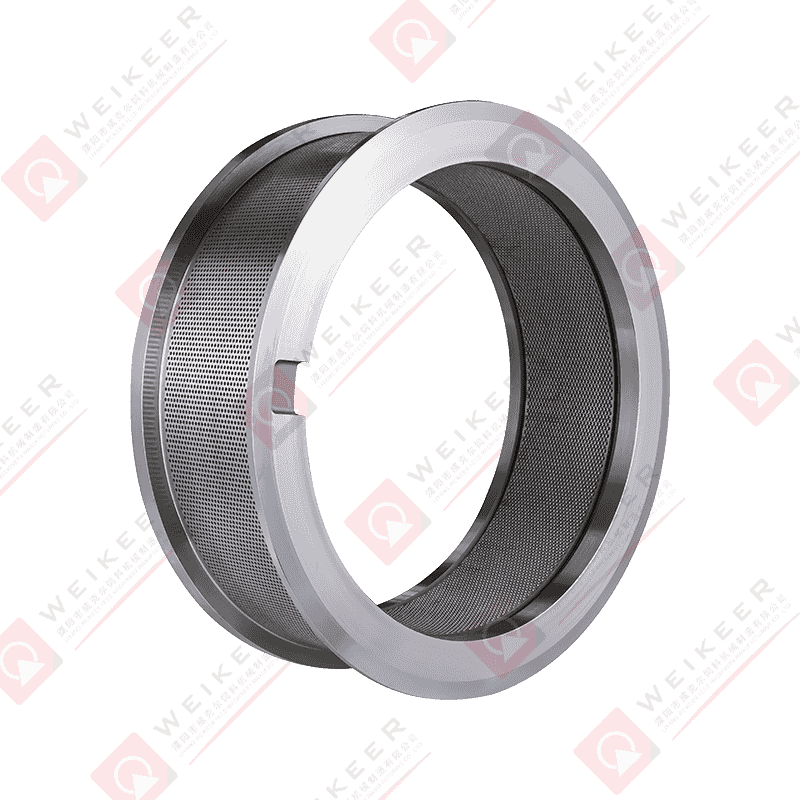

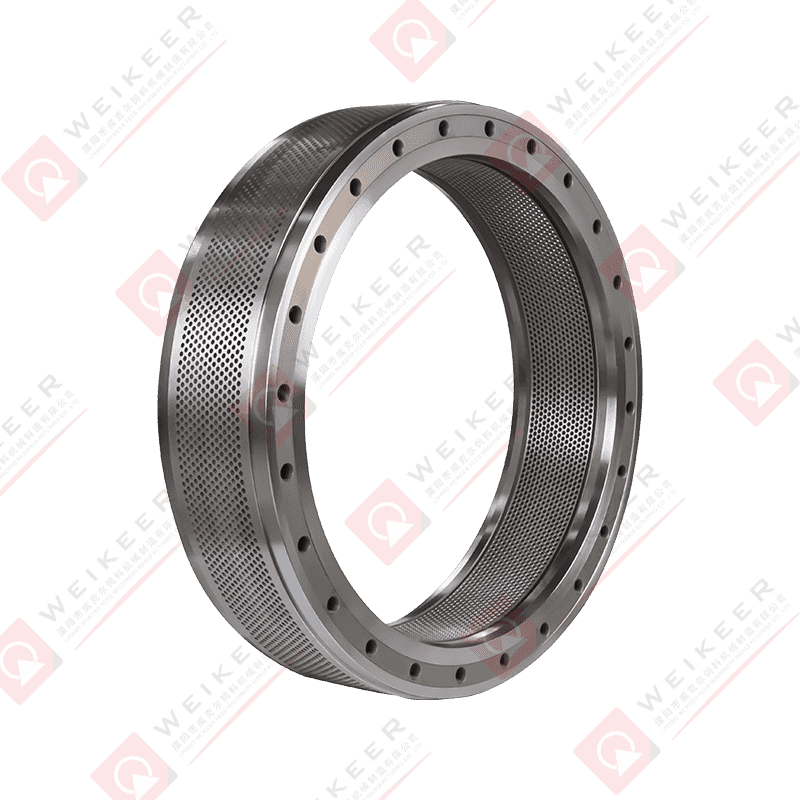

Stainless steel ring die is a cylindrical metal mold with dense holes on the ring structure. It is used to press powder or flake materials into cylindrical pellets through mechanical extrusion.

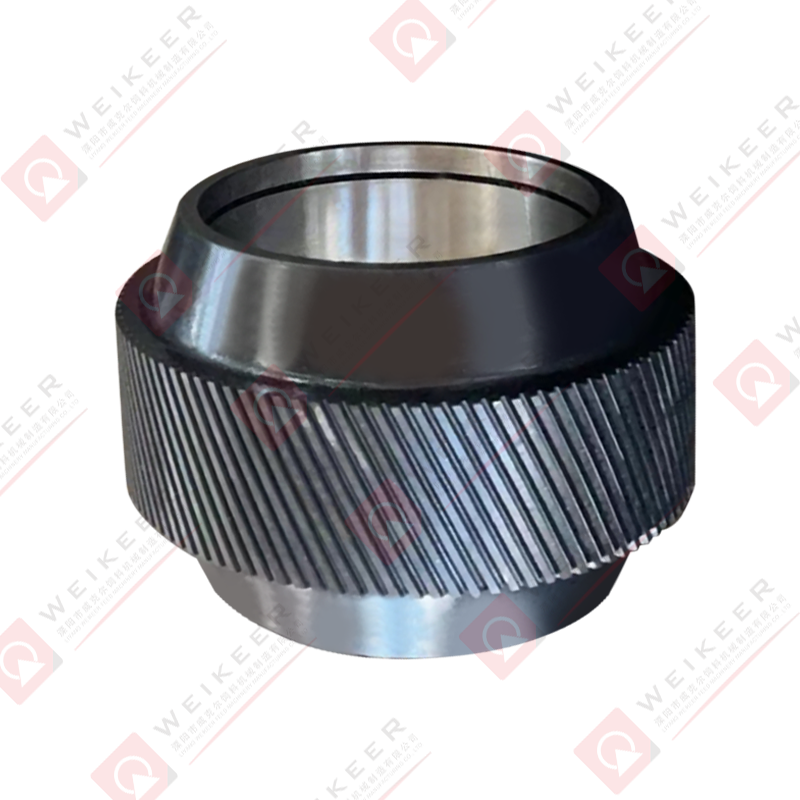

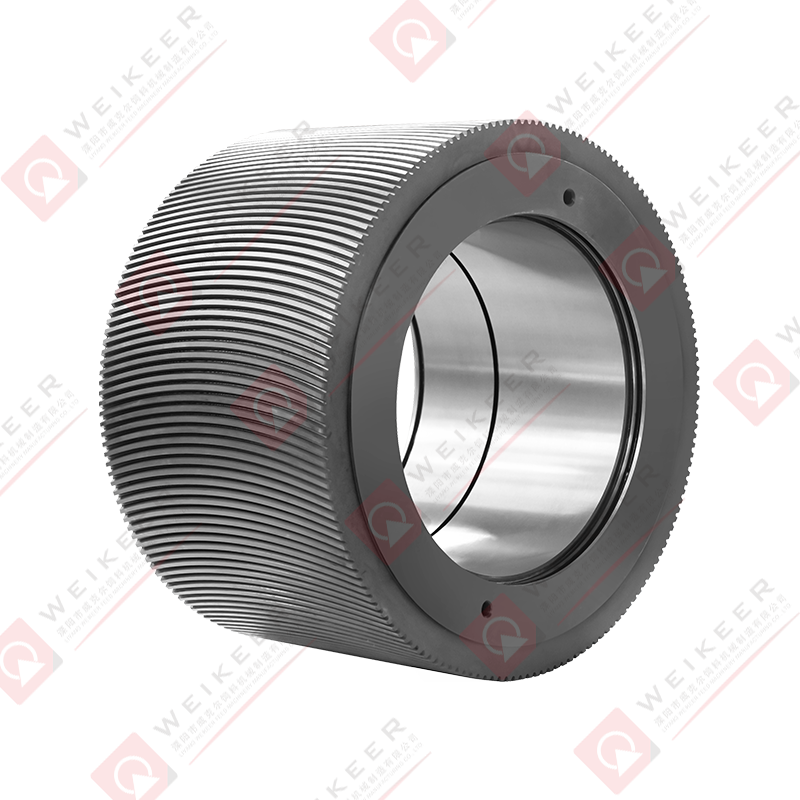

During the working process, the material is heated and softened by the conditioner and then enters the mold cavity. It is forced to pass through the hole of the ring die under the push of the pressure roller and is extruded under high pressure to form uniform and dense pellets.

2. Why choose stainless steel?

Compared with ordinary carbon steel or alloy steel, stainless steel ring molds have the following significant advantages:

1. Excellent corrosion resistance

During the pelletizing process, the material contains moisture, grease and corrosive components (such as fish meal, organic fertilizer, etc.). Stainless steel has strong corrosion resistance and can effectively resist oxidation, rust and acid and alkali erosion, extending the service life.

2. Higher strength and stability

Stainless steel can still maintain structural integrity under high temperature and high pressure, and is not easy to deform, ensuring the consistency and quality of pellet pressing.

3. Longer service life

The service life can be 30%-50% higher than that of ordinary alloy steel ring molds. Although the initial cost is slightly higher, it is more economical and durable in long-term operation.

4. Easy to clean and maintain

Stainless steel has a smooth surface, is not easy to adhere to material residues, and is easy to clean. It is particularly suitable for multiple raw material switching or food-grade application scenarios.

3. Common stainless steel materials and characteristics

| Stainless steel model |

Features |

Applicable scenarios |

| 304 |

Good corrosion resistance, moderate mechanical properties |

Feed, wood chips, general biomass |

| 316 |

Contains molybdenum, strong resistance to salt corrosion |

Aquatic feed, organic fertilizer |

| 410/420 |

Contains chromium, strong wear resistance |

High strength pressing requirements |

| Duplex stainless steel |

Combining the advantages of austenite and ferrite, corrosion resistance and high strength |

High-load industrial pellet production |

4. Ring die parameter design and selection points

Hole Diameter

Commonly 4mm~10mm, feed pellets usually use a smaller hole diameter (such as 4-6mm), and wood pellets use 6-10mm.

Compression Ratio

The ratio of hole length to hole diameter. High compression ratio is suitable for high-density materials, and low compression ratio is suitable for crushing loose raw materials.

Hardening heat treatment process

Stainless steel ring dies usually need to undergo vacuum quenching + surface carburizing/nitriding treatment to improve hardness and service life.

Drilling accuracy and polishing process

Precision CNC drilling can ensure the consistency of output and particles, and inner hole polishing can prevent blockage and increase the discharge rate.

5. Wide application field

Stainless steel ring die is suitable for the preparation of particles in various industries:

Livestock and poultry feed pellets

Pet food

Aquatic feed

Biomass fuel (wood chips, straw)

Organic fertilizer and compound fertilizer

Chemical granulation (such as ammonium chloride pellets)

It has strong adaptability and can achieve continuous long-term high-load work. It is an important component of the industrial granulation production line.

6. Usage and maintenance suggestions

Regularly check whether the ring die hole is blocked, and clean it with hot water or detergent;

Use oily materials to clean the die hole before stopping, which helps to extend the life;

Maintain uniform feeding during use to avoid eccentric wear of materials;

Reasonably replace the roller and ring die to prevent asynchronous wear of the two.

Frequently Asked Questions (FAQ)

Q1: How much more expensive is the stainless steel ring die than carbon steel? Is it worth it?

A: Generally 20%-40% higher, but the service life is more than doubled, which is more economical in the long run.

Q2: How to judge whether the ring die needs to be replaced?

A: The decrease in particle density, difficulty in discharging, frequent blockage, and incomplete particle shape indicate that it should be replaced.

Q3: Are all pellet machines compatible with stainless steel ring dies?

A: Most pellet machine manufacturers support customized stainless steel ring dies, and only need to provide models and parameters.

Conclusion

As one of the core consumables in pellet machines, stainless steel ring dies show excellent performance in wear resistance, corrosion resistance, and efficient pelletizing. It is especially suitable for pelletizing scenarios with high process requirements such as aquatic products, wood chips and organic fertilizers. By selecting high-quality materials, reasonable aperture and compression ratio design, it can not only increase production capacity, but also greatly extend service life and reduce operating costs.

If you are planning to upgrade your pelletizing equipment, stainless steel ring dies will be a key step to improve efficiency and product quality.

русский

русский Español

Español عربى

عربى 中文简体

中文简体