Pellet mills are essential machines in the biomass, feed, and wood pellet industries, converting raw materials such as sawdust, straw, grass, and animal feed into compact, uniform pellets. A critical component in these machines is the ring die, which directly affects efficiency, output quality, and operational longevity. In recent years, stainless steel ring dies have gained significant popularity due to their durability, corrosion resistance, and superior performance compared to traditional materials.

This article explores the key benefits of using stainless steel ring dies in pellet mills, their role in pellet production, and why they are increasingly preferred in modern industrial applications.

1. Understanding the Role of Ring Dies in Pellet Mills

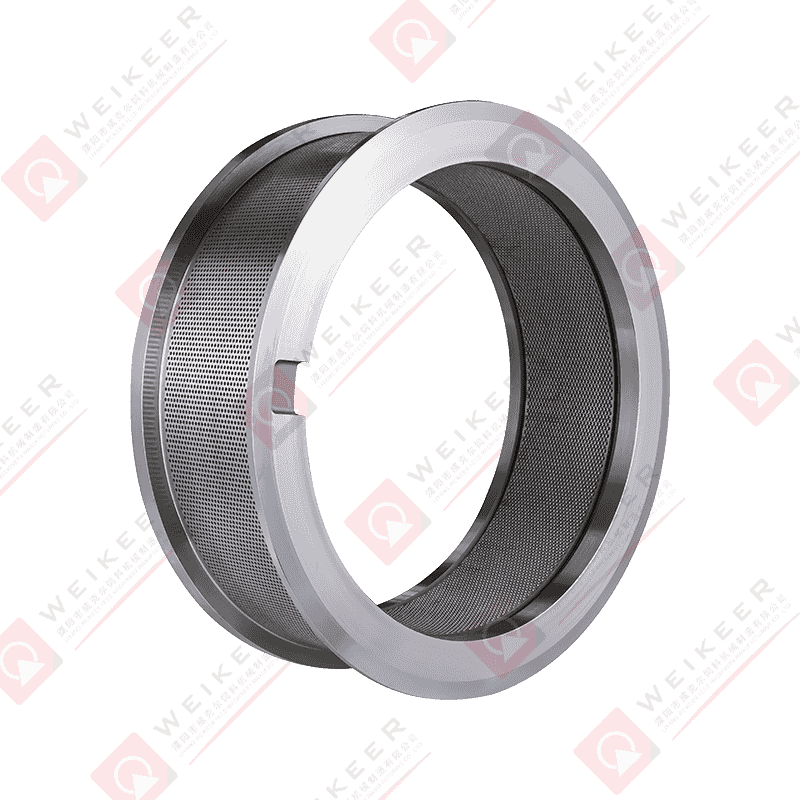

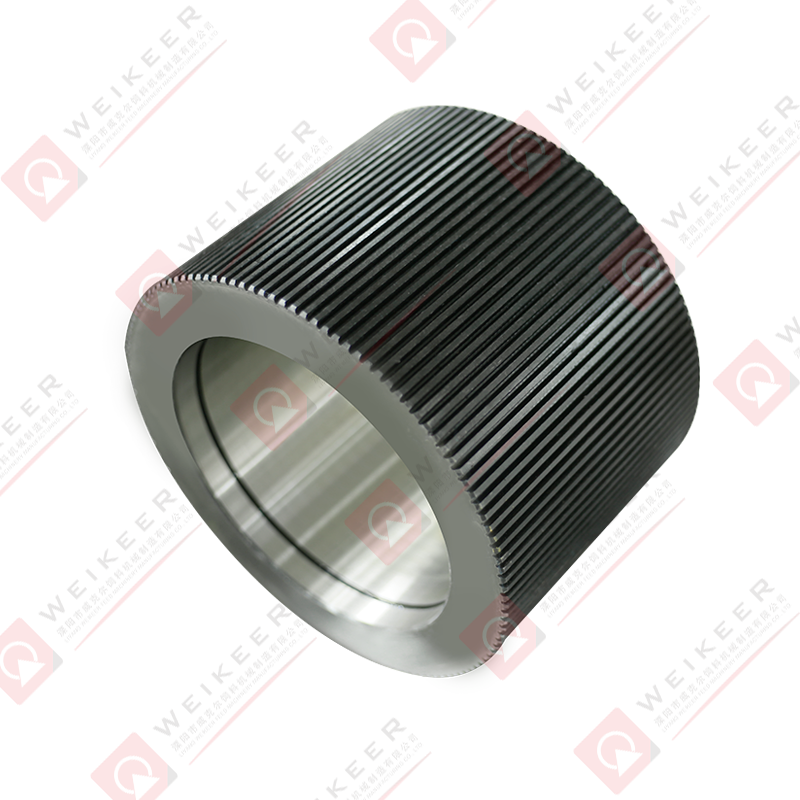

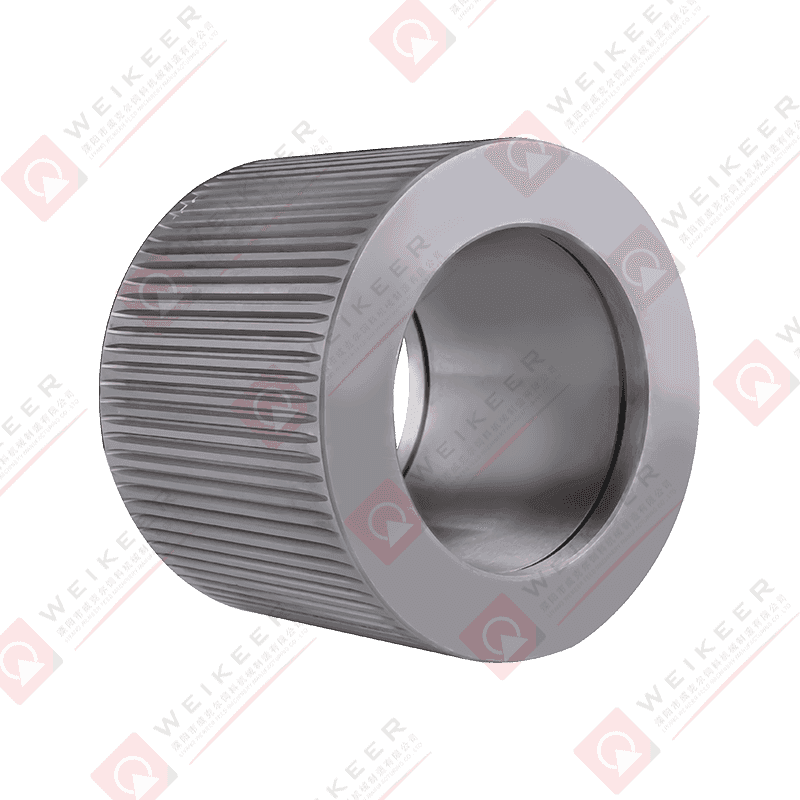

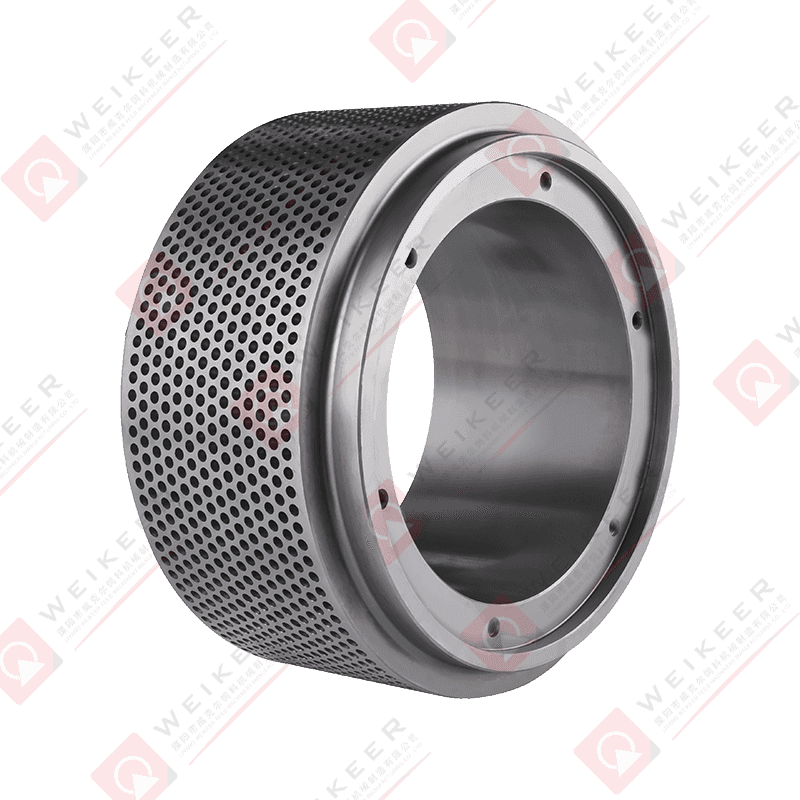

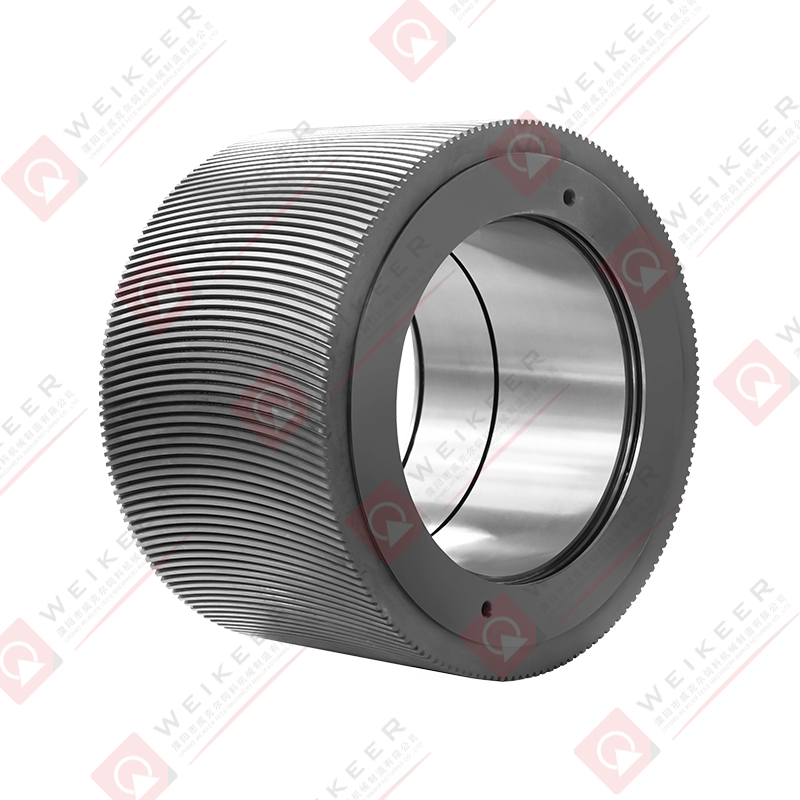

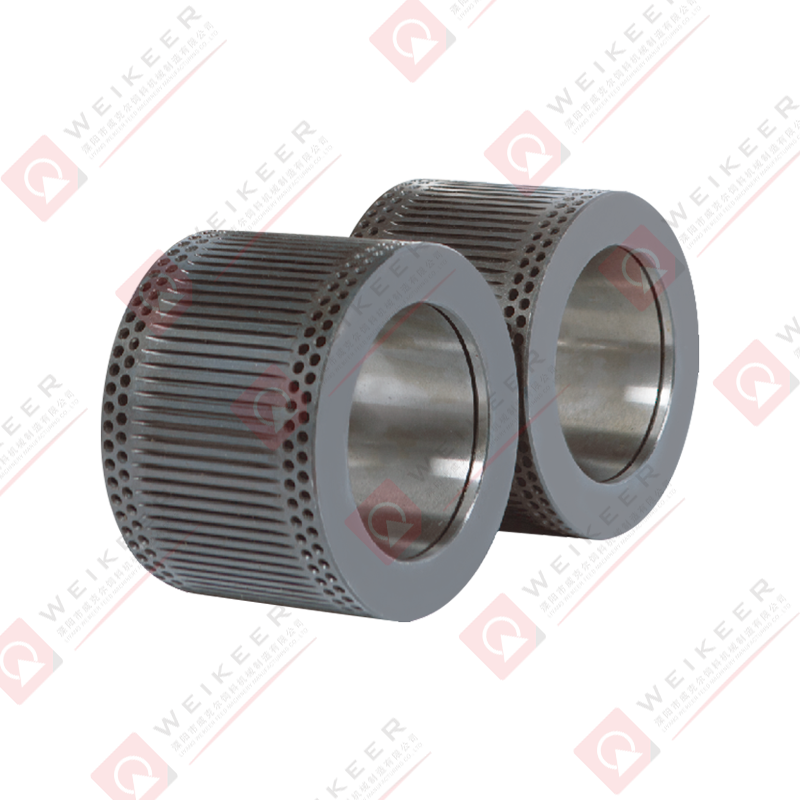

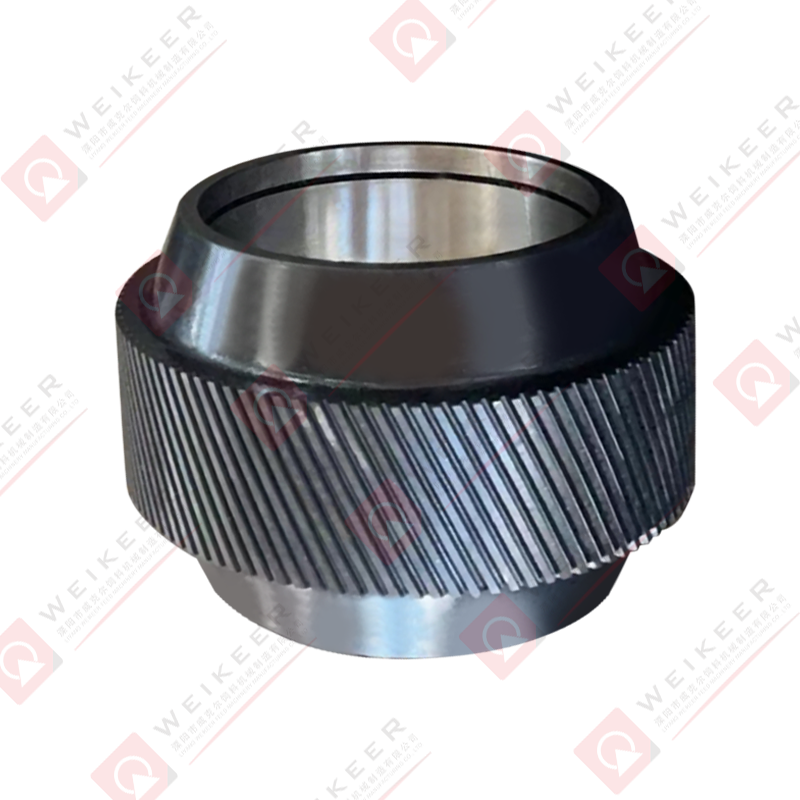

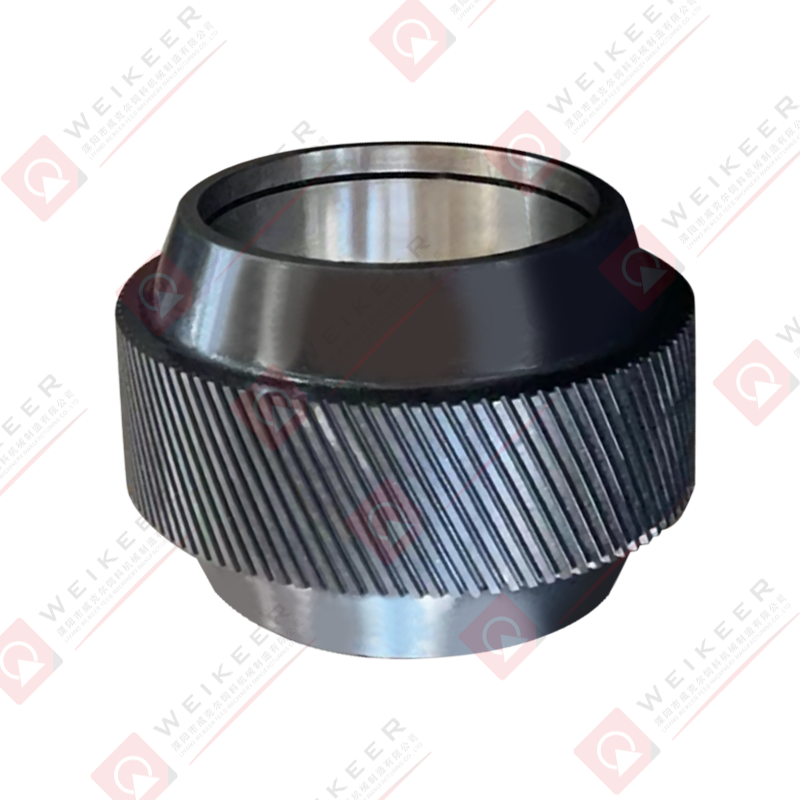

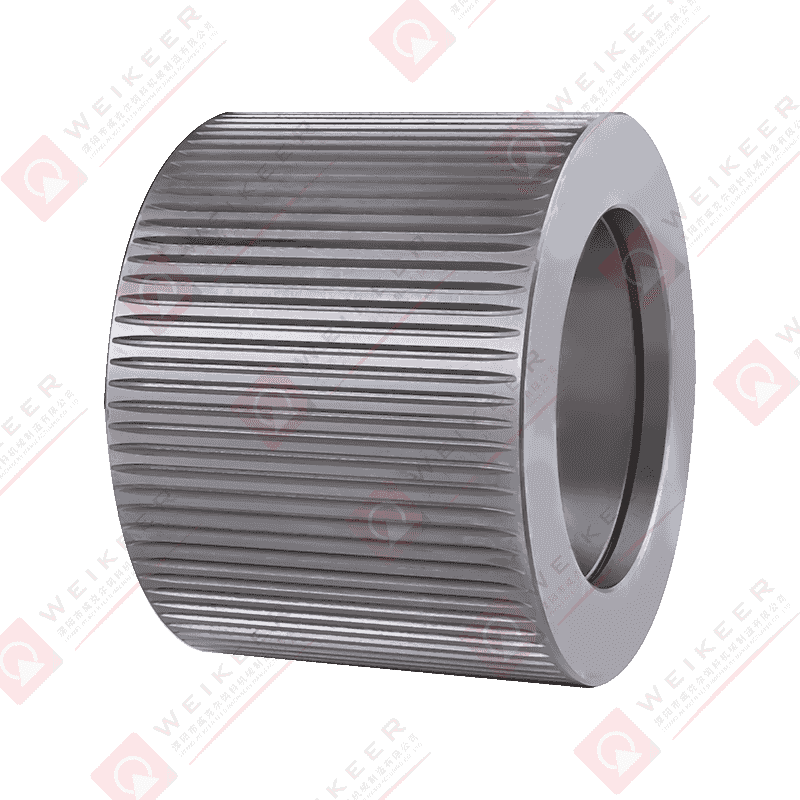

Ring dies are cylindrical components with multiple holes through which raw material is forced by rollers in a pellet mill. The die determines the pellet size, density, and shape, and its material significantly affects production efficiency.

Key functions of a ring die include:

- Shaping raw material into uniform pellets

- Withstanding high pressure and friction during the pelleting process

- Ensuring consistent output by maintaining hole dimensions under heavy load

Because the die directly interacts with both the raw material and the rollers, its strength, wear resistance, and heat tolerance are crucial for the machine’s overall performance.

2. Advantages of Stainless Steel Material

Stainless steel offers several advantages over traditional steel or alloy dies used in pellet mills. These advantages are particularly evident in demanding production environments where wear, corrosion, and high temperature are concerns.

2.1 Corrosion Resistance

- Stainless steel contains chromium, which forms a protective oxide layer on the surface, preventing rust and corrosion.

- Pellet mills often process moist, acidic, or chemically treated materials, which can corrode conventional dies quickly.

- Stainless steel ring dies maintain structural integrity even in humid or chemically aggressive environments, reducing downtime and replacement frequency.

2.2 High Wear Resistance

- The hardness and tensile strength of stainless steel make it highly resistant to abrasion caused by constant contact with raw material and rollers.

- This reduces pitting, cracking, and hole deformation, ensuring pellets maintain consistent shape and density.

- Industrial mills with stainless steel dies can operate longer without maintenance, significantly lowering operational costs.

2.3 Heat Tolerance

- During the pelleting process, friction between raw material, rollers, and the die generates considerable heat.

- Stainless steel can withstand high temperatures without losing strength or warping, ensuring stable performance even in continuous production runs.

- Heat resistance also minimizes die expansion, preserving precise hole dimensions and maintaining pellet quality.

2.4 Hygiene and Food Safety

- Stainless steel is non-porous and easy to clean, making it ideal for feed and food pellet production.

- It prevents bacterial growth and contamination, complying with food safety standards.

- This property is particularly critical in animal feed, aquaculture feed, and pet food industries, where hygiene is paramount.

3. Performance Benefits in Pellet Production

Using stainless steel ring dies enhances the overall efficiency and output quality of pellet mills.

3.1 Consistent Pellet Size and Density

- Stainless steel dies maintain uniform hole dimensions despite heavy use, producing pellets with consistent size and density.

- Consistency ensures better feed quality, more uniform combustion in biomass pellets, and improved customer satisfaction.

3.2 Higher Production Capacity

- Reduced wear and smooth surface of stainless steel ring dies reduce friction between rollers and die.

- Lower friction results in less power consumption and higher throughput, enabling mills to produce more pellets per hour.

3.3 Reduced Downtime and Maintenance

- Traditional steel dies may require frequent resurfacing, replacement, or adjustments due to wear and corrosion.

- Stainless steel dies last longer, requiring less maintenance, reducing production interruptions, and lowering overall operational costs.

3.4 Energy Efficiency

- Smooth, hard surfaces reduce resistance during pellet extrusion, which decreases motor load and energy consumption.

- Energy savings can be significant, particularly in large-scale industrial operations, enhancing overall cost-effectiveness.

4. Applications Across Industries

Stainless steel ring dies are versatile and can be used in multiple industries where pellet mills are employed:

4.1 Biomass Pellet Industry

- Materials: Sawdust, wood shavings, straw, agricultural residues

- Benefits: Corrosion resistance ensures durability when processing moist or chemically treated biomass; heat tolerance maintains high throughput during continuous operation.

4.2 Animal Feed Production

- Materials: Corn, soybean meal, wheat bran, fish meal

- Benefits: Hygiene and smooth surfaces prevent bacterial contamination; consistent pellet size ensures nutritional uniformity and easier consumption for animals.

4.3 Aquaculture Feed

- Materials: Fish meal, soybean protein, algae

- Benefits: Stainless steel prevents corrosion caused by high moisture and salt content; precision hole design allows floating or sinking pellet shapes as required.

4.4 Industrial and Specialty Applications

- Materials: Biomass for energy, wood chips, and other organic materials

- Benefits: Stainless steel dies handle high abrasion and continuous production in power plants or large-scale pellet factories efficiently.

5. Longevity and Cost-Effectiveness

While stainless steel ring dies may have a higher upfront cost than traditional dies, their long-term benefits outweigh the initial investment:

- Extended lifespan reduces replacement frequency and costs.

- Lower maintenance requirements save labor and downtime expenses.

- Energy efficiency reduces operational costs per ton of pellet produced.

- Improved product quality increases market competitiveness and customer satisfaction.

In large-scale operations, these advantages translate into significant savings and improved ROI over time.

6. Maintenance Tips for Stainless Steel Ring Dies

Even though stainless steel is durable, proper maintenance ensures optimal performance and longevity:

- Regular cleaning: Remove residual material from holes to prevent clogging and uneven pellet extrusion.

- Lubrication: Apply suitable lubrication to rollers and die surfaces to reduce wear and friction.

- Temperature monitoring: Avoid prolonged overheating; monitor motor load and operational temperature.

- Inspection: Periodically check for wear or damage, especially if processing abrasive materials.

- Proper storage: Store dies in a dry environment when not in use to prevent surface oxidation.

Routine care ensures that stainless steel ring dies maintain efficiency and quality for years.

7. Conclusion

Stainless steel ring dies have become a preferred choice for modern pellet mills due to their combination of durability, corrosion resistance, and performance benefits. The key advantages include:

- Corrosion resistance for handling moist, acidic, or chemically treated materials

- High wear resistance, reducing abrasion and maintaining hole integrity

- Heat tolerance, ensuring consistent performance during continuous production

- Hygienic properties, essential for animal feed and food pellet applications

- Consistent pellet quality, improving density, size uniformity, and appearance

- Reduced downtime and maintenance, enhancing operational efficiency

- Energy efficiency, lowering power consumption during production

These benefits make stainless steel ring dies ideal for biomass, animal feed, aquaculture feed, and specialty pellet production. While the initial investment may be higher than traditional steel dies, the long-term operational savings, improved product quality, and extended service life make them a cost-effective and reliable solution for pellet mill operations.

By choosing stainless steel ring dies, operators can achieve higher productivity, lower maintenance costs, and superior pellet quality, ensuring that their pellet mill operates efficiently and economically in the long term.

русский

русский Español

Español عربى

عربى 中文简体

中文简体