Biomass pellets are a sustainable fuel source widely used for energy generation, heating, and even as animal feed. The quality and density of these pellets are critical parameters that affect combustion efficiency, transport, storage, and overall performance. In a biomass pellet mill, one of the most crucial components determining pellet quality is the ring die. The design, material, and configuration of the ring die have a profound impact on pellet formation, durability, density, and production efficiency.

This article explores the key ways in which ring die design influences pellet quality and density, along with factors that optimize pellet production in biomass processing.

1. Understanding the Role of a Ring Die in a Biomass Pellet Mill

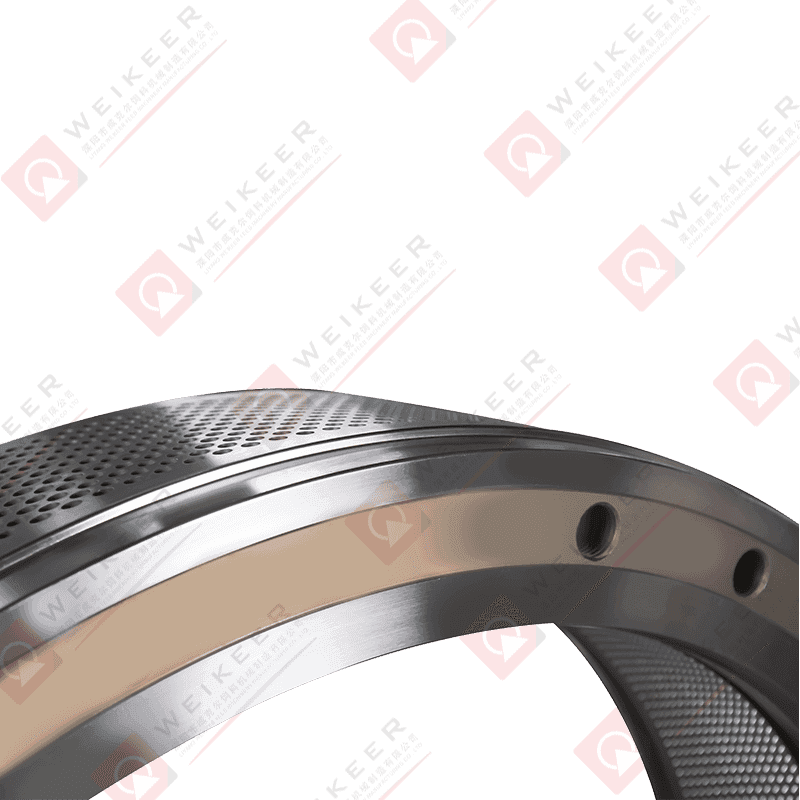

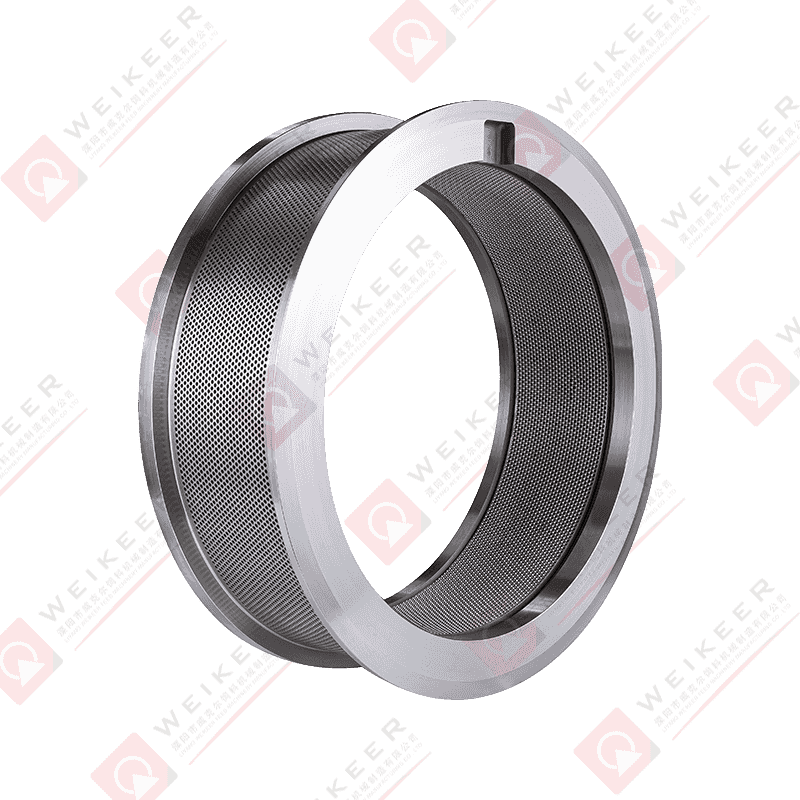

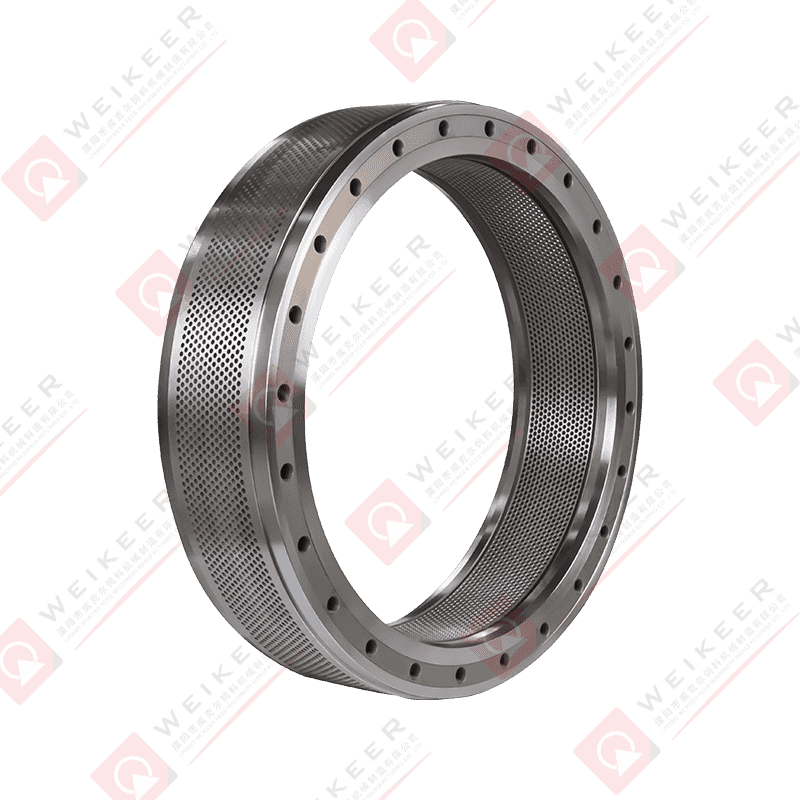

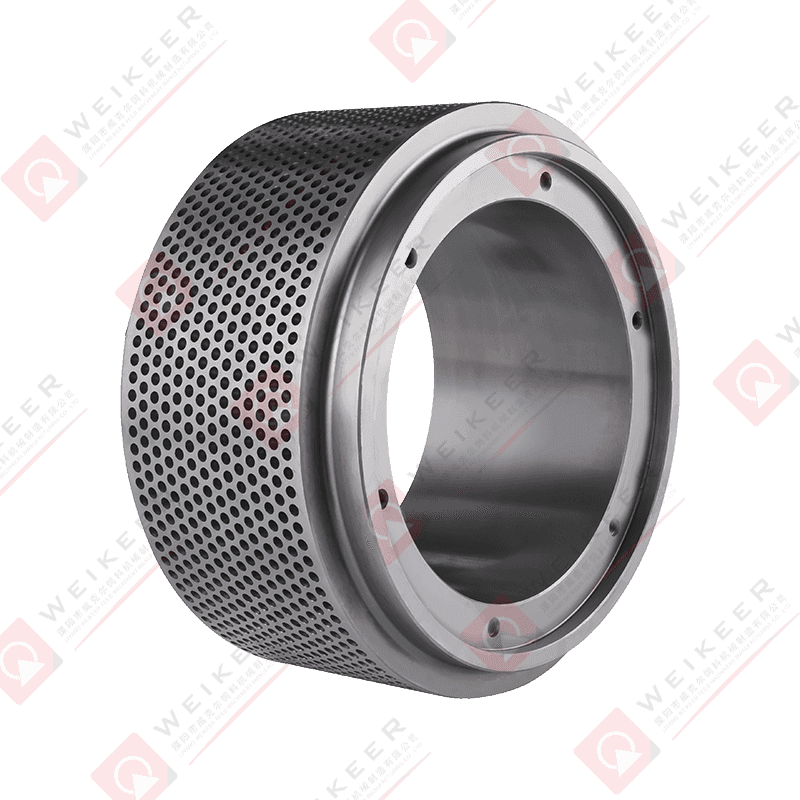

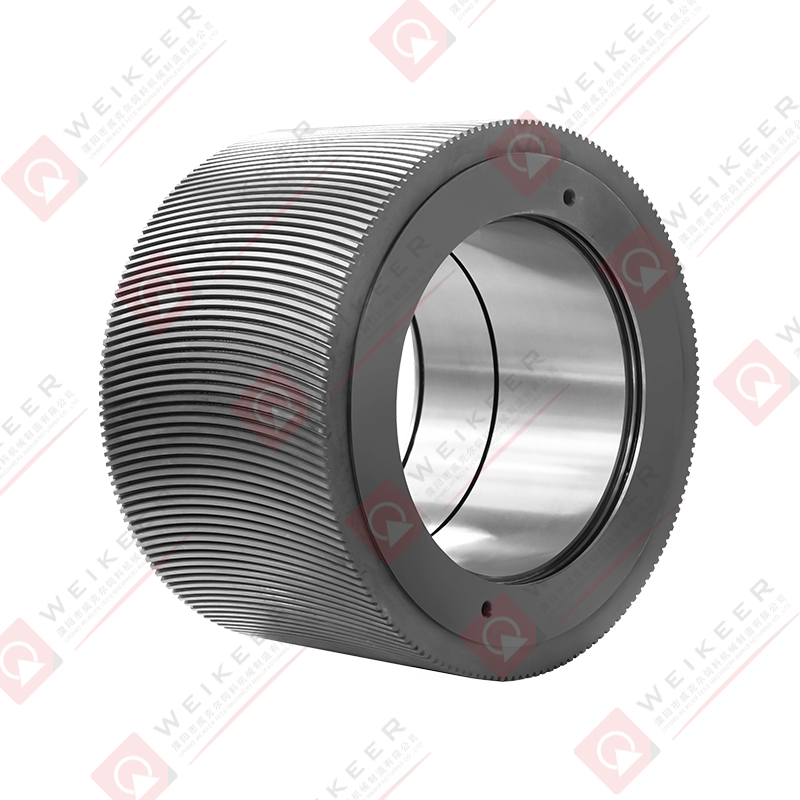

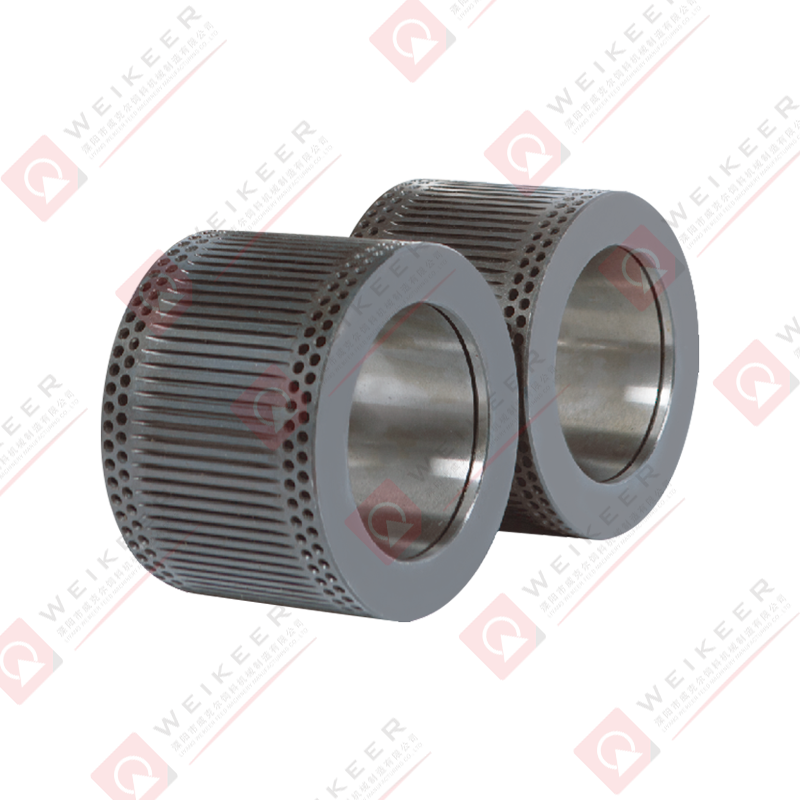

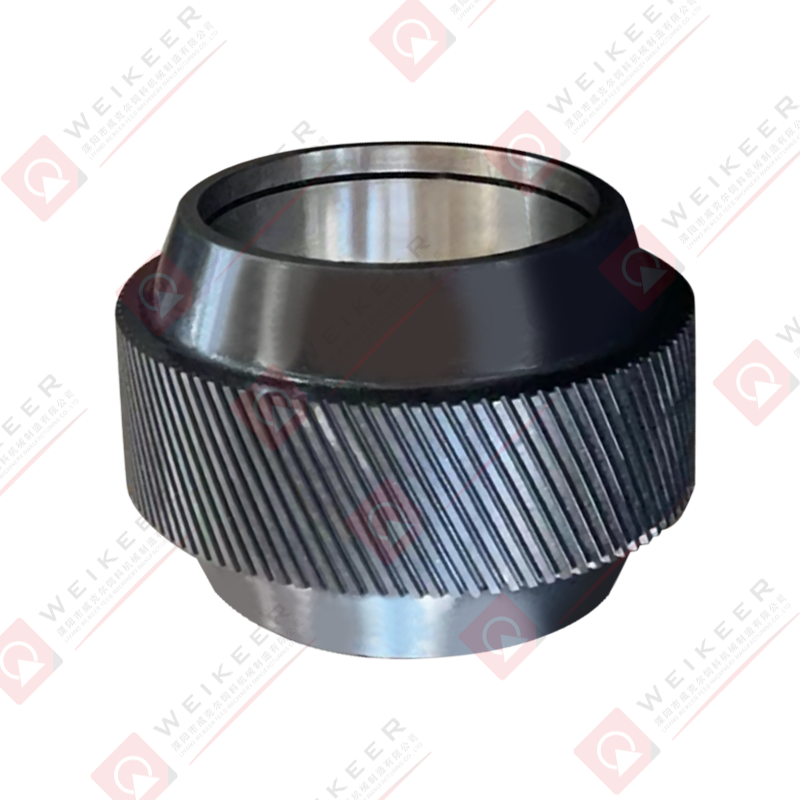

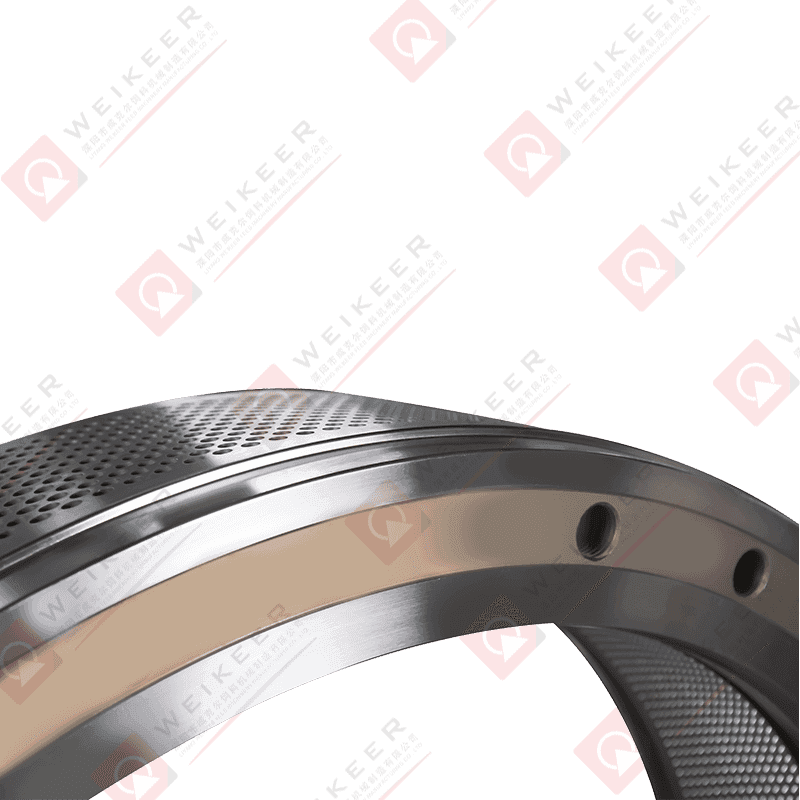

A ring die pellet mill uses a hollow cylindrical die with radial holes to compress biomass into pellets. The main components involved in the pelletizing process include:

- Ring Die: A rotating cylinder with holes through which raw material is pressed.

- Rollers: Press the biomass through the die holes, forming dense pellets.

- Feeding System: Ensures consistent raw material supply to the die.

- Conditioning System: Prepares raw material with moisture and heat to facilitate pelletizing.

The ring die acts as the shaping and compression component, determining pellet diameter, surface smoothness, hardness, and density. Its design and specifications significantly influence the final product.

2. Key Design Parameters of a Ring Die

Several design parameters of a ring die impact pellet quality and density:

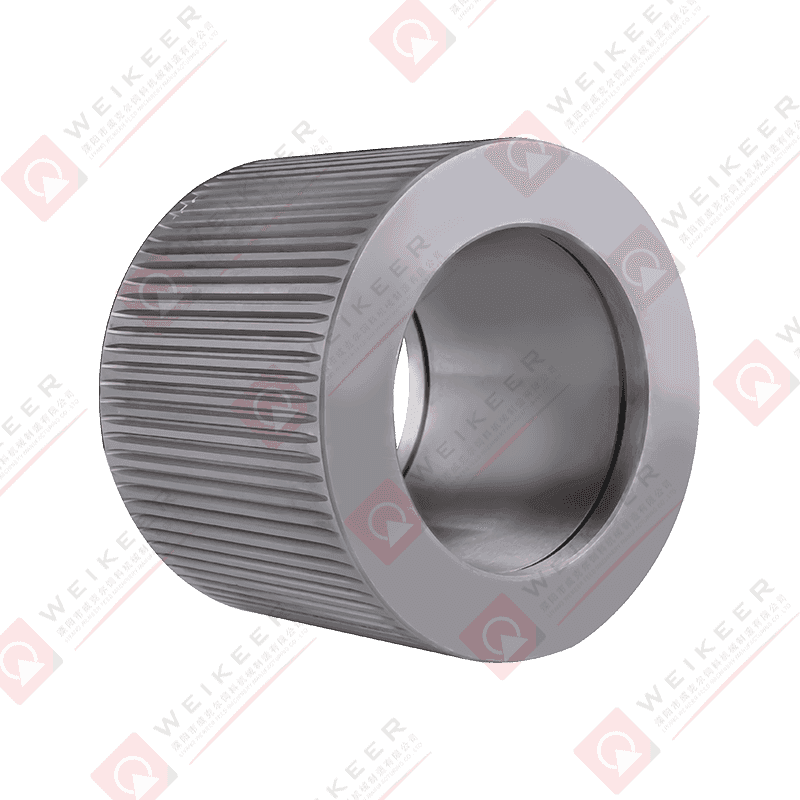

a. Die Thickness

- Impact on Pellet Density: Thicker dies provide longer compression paths, allowing more compaction and higher pellet density.

- Effect on Production Efficiency: Thicker dies may require more power, increasing energy consumption, but can improve pellet durability.

- Optimization: Die thickness should balance compression length, material flow, and power requirements.

b. Hole Diameter

- Influence on Pellet Size: The hole diameter directly determines pellet diameter. Smaller holes generally produce denser and harder pellets.

- Effect on Feeding: Larger holes allow easier material flow and higher throughput but may reduce pellet density.

- Material Consideration: Fine, fibrous biomass may require smaller holes to form cohesive pellets.

c. Hole Length-to-Diameter Ratio (L/D Ratio)

- Definition: Ratio of die hole length to diameter.

- Impact on Pellet Formation: Higher L/D ratios result in longer compression paths, increasing material compaction and pellet density.

- Limitations: Excessively high L/D ratios can increase friction, heat, and energy consumption, possibly causing die wear.

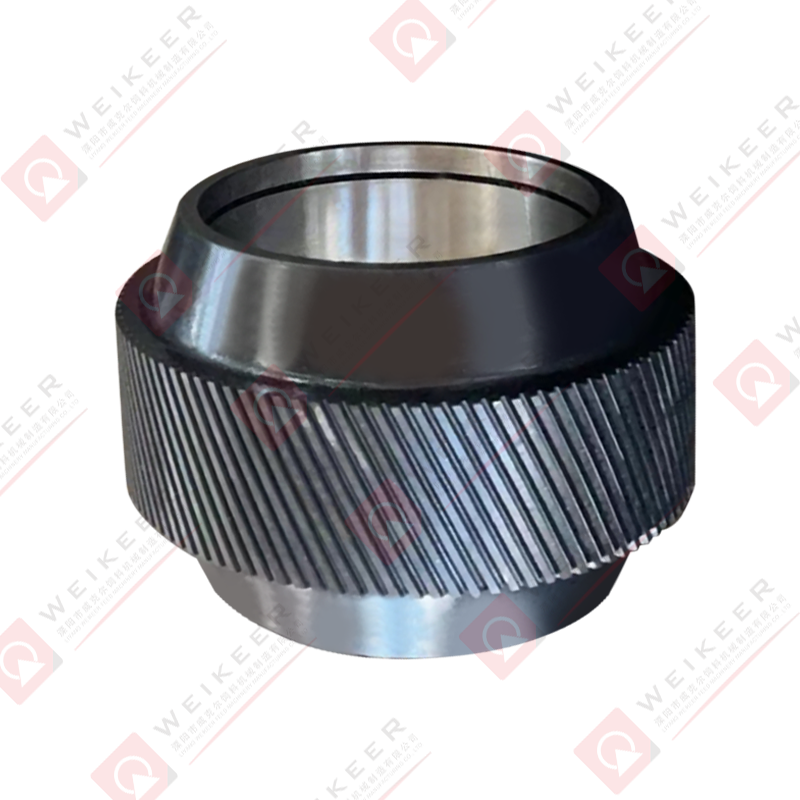

d. Hole Shape and Angle

- Straight vs. Tapered Holes: Straight holes provide uniform compression, while tapered holes assist pellet release.

- Impact on Pellet Surface: Proper tapering reduces friction during ejection, preventing pellet cracking or deformation.

- Effect on Wear: Tapered or conical holes distribute stress, extending die life.

e. Die Material

- Common Materials: High-strength alloy steel, manganese steel, or specialized wear-resistant steel.

- Impact on Quality: Hard, durable materials maintain hole precision over time, ensuring consistent pellet density.

- Corrosion Resistance: In biomass with high moisture or acidic content, corrosion-resistant materials prevent die degradation and uneven compression.

f. Die Rotation Speed

- Indirect Influence: Although technically part of the mill setup, the die rotation speed affects material compaction within the die holes.

- Optimal Speed: Adequate rotational speed ensures proper feeding, compression, and heat generation for pellet binding.

3. How Ring Die Design Influences Pellet Quality

a. Pellet Density

- Compression Path: Longer hole length (high L/D ratio) allows biomass to compress more, increasing pellet density.

- Hole Diameter: Smaller holes produce more compact pellets.

- Roller Pressure: Optimized die design allows consistent pressure application, reducing voids and ensuring uniform density.

- Result: Dense pellets burn longer, transport efficiently, and resist breakage.

b. Pellet Durability

- Surface Finish: Smooth, tapered holes reduce friction and prevent cracks during ejection.

- Consistent Material Flow: Uniform hole distribution in the die ensures balanced compression, minimizing weak spots.

- Wear Resistance: Durable die materials maintain hole shape over time, preserving pellet consistency.

c. Pellet Length and Shape

- Impact of Hole Design: Longer holes produce slightly elongated pellets; taper angle influences pellet ejection and rounding.

- Quality Aspect: Uniform pellet length facilitates mechanical handling, packaging, and combustion efficiency.

d. Moisture Content and Heat

- Interaction with Die Design: Ring dies with optimal hole configuration create adequate frictional heat during compression, aiding in lignin activation (natural binder in biomass).

- Effect on Pellet Quality: Proper heat and moisture ensure strong pellet binding, reducing fines and improving hardness.

4. Factors Affecting Density and Quality Beyond the Die

While ring die design is critical, other parameters also interact with die performance:

a. Raw Material Properties

- Particle Size: Smaller, uniform particles compact better through die holes, producing denser pellets.

- Moisture Content: Ideal moisture (8–12% for wood, varies by biomass) ensures proper binding and compaction.

- Lignin Content: Natural binders aid in pellet formation and density.

b. Roller Configuration

- Pressure Distribution: Rollers must evenly press material into die holes to maintain consistent density.

- Wear and Alignment: Proper roller alignment prevents uneven compaction and pellet variation.

c. Operating Conditions

- Feed Rate: Consistent feed avoids material overloading or insufficient compression.

- Temperature: Frictional heat within the die aids binding; extreme temperatures can damage die or biomass.

- Lubrication and Maintenance: Regular die maintenance ensures hole precision and prevents density inconsistency.

5. Differences Between Ring Die and Flat Die Designs

While the article focuses on ring dies, understanding the distinction helps in evaluating pellet quality:

- Ring Die: Material moves through a rotating cylindrical die; suitable for large-scale production, higher density, and better durability.

- Flat Die: Material pressed through holes in a flat plate; simpler, lower throughput, less dense pellets.

Impact on Pellet Quality: Ring die designs generally produce harder, denser, and more uniform pellets compared to flat die mills due to longer compression paths and better material flow.

6. Maintenance and Longevity of Ring Dies

Ring die design also affects maintenance frequency and service life, indirectly influencing pellet quality:

- Wear Patterns: High L/D ratio and small holes increase die stress; high-quality materials mitigate wear.

- Regular Inspection: Check for hole deformation or cracks; worn holes reduce pellet density and produce fines.

- Cleaning: Remove buildup to maintain smooth compression and prevent pellet defects.

- Replacement Schedule: Timely replacement ensures consistent pellet quality and avoids downtime.

7. Optimization Strategies for High-Quality Pellets

To maximize pellet quality and density:

- Select Appropriate Die Material: High-strength, wear-resistant steel ensures consistent compression.

- Optimize Hole Diameter and L/D Ratio: Balance compression for density without excessive wear.

- Maintain Uniform Feed and Moisture Content: Consistent raw material improves compaction.

- Monitor Die and Roller Wear: Regular maintenance preserves hole geometry and uniform density.

- Adjust Operating Parameters: Feed rate, temperature, and roller pressure must complement die design.

- Use Lubrication or Conditioning: Prevent material sticking and reduce friction damage.

8. Industrial Applications and Benefits

Ring die pellet mills are widely used in:

- Energy Production: Wood, straw, and agricultural residues for biomass boilers and power plants.

- Animal Feed: Pellets for livestock or aquaculture feed.

- Waste Management: Converting agricultural and forestry residues into compact pellets.

Benefits of Optimized Ring Die Design:

- Higher pellet density reduces storage and transport volume.

- Durable pellets resist breakage and fines during handling.

- Consistent quality improves combustion efficiency or feed performance.

- Increased production efficiency with reduced downtime.

9. Conclusion

The ring die is the heart of a biomass pellet mill, directly affecting pellet quality, density, durability, and production efficiency. Key design factors include:

- Die thickness: Longer compression paths for denser pellets.

- Hole diameter and L/D ratio: Balance between material flow, compression, and energy consumption.

- Hole shape and taper: Ensures smooth ejection, reduces surface defects, and prevents cracking.

- Die material: High-strength, wear-resistant alloys maintain hole precision over time.

By carefully selecting and maintaining the ring die, operators can produce uniform, dense, and durable pellets, optimize energy consumption, and reduce maintenance costs. Proper integration with raw material preparation, roller configuration, and operating conditions ensures the highest pellet quality for industrial applications.

Ultimately, understanding the interaction between ring die design, material properties, and operating parameters is essential for maximizing the efficiency and output of a biomass pellet mill, making it a cornerstone of sustainable biomass energy production.

русский

русский Español

Español عربى

عربى 中文简体

中文简体