The production of cat litter pellets has become a rapidly growing industry, driven by rising pet ownership and the increasing demand for eco-friendly, high-quality litter products. At the heart of the pelletizing process is the Anchorear ring die, a precision-engineered component in cat litter pellet mills that determines pellet size, shape, density, and overall quality. Because the ring die operates under high pressure, friction, and temperature, it is subject to wear and tear that can directly impact production efficiency and product consistency. Proper maintenance and usage practices are crucial to extend the lifespan of an Anchorear ring die and reduce operational costs.

This article explores the key methods, best practices, and maintenance strategies that can help maximize the performance and durability of a ring die used in cat litter pellet mills.

1. Understanding the Function of an Anchorear Ring Die

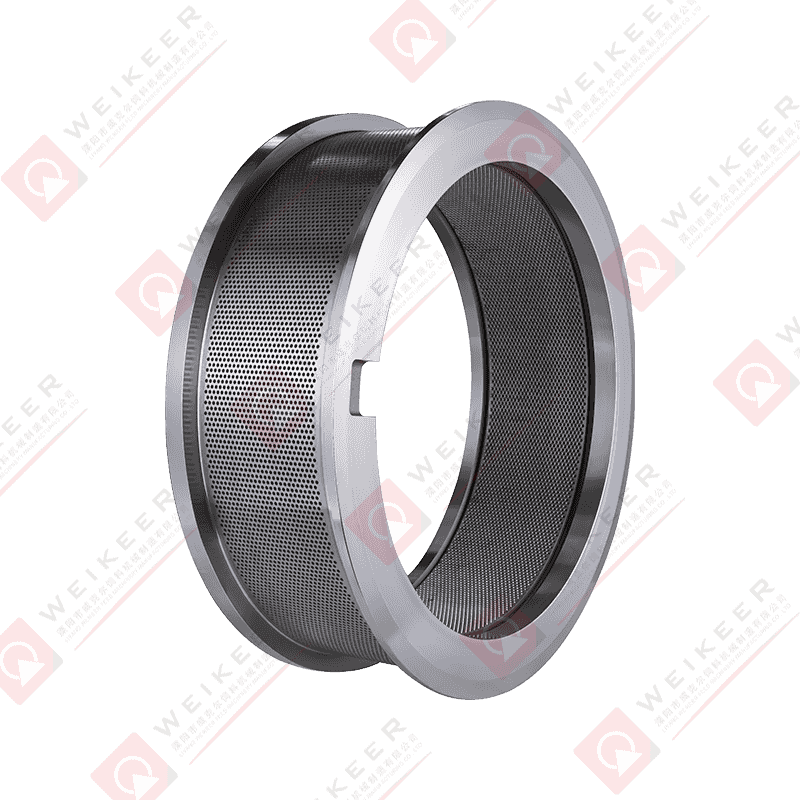

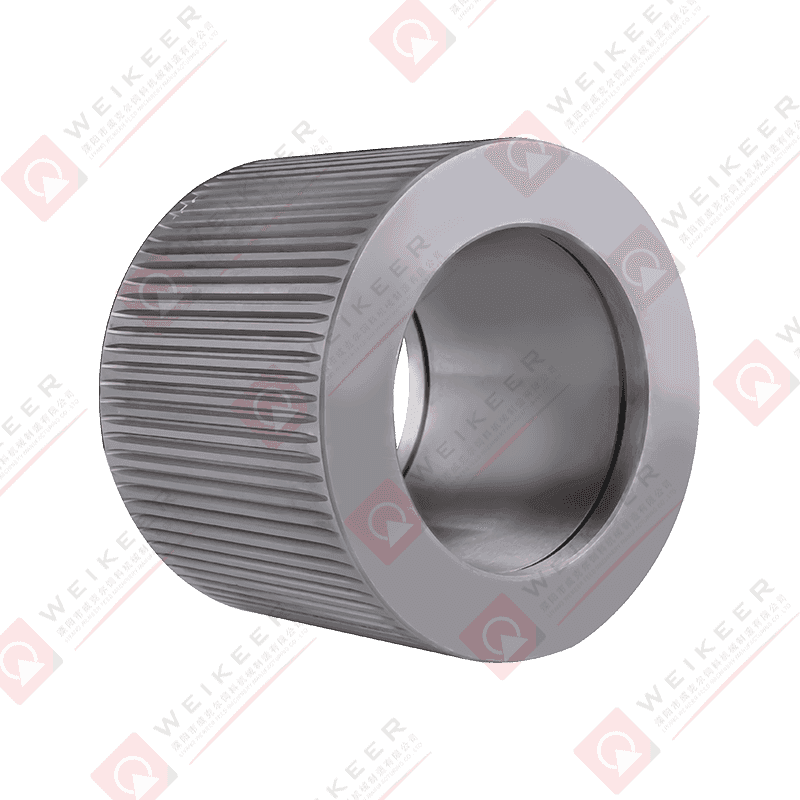

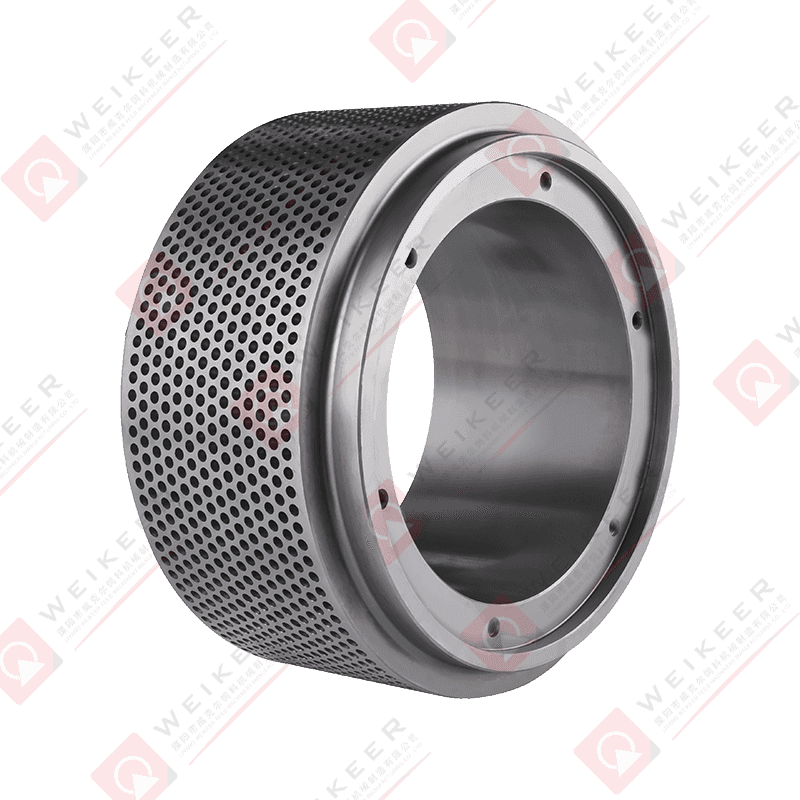

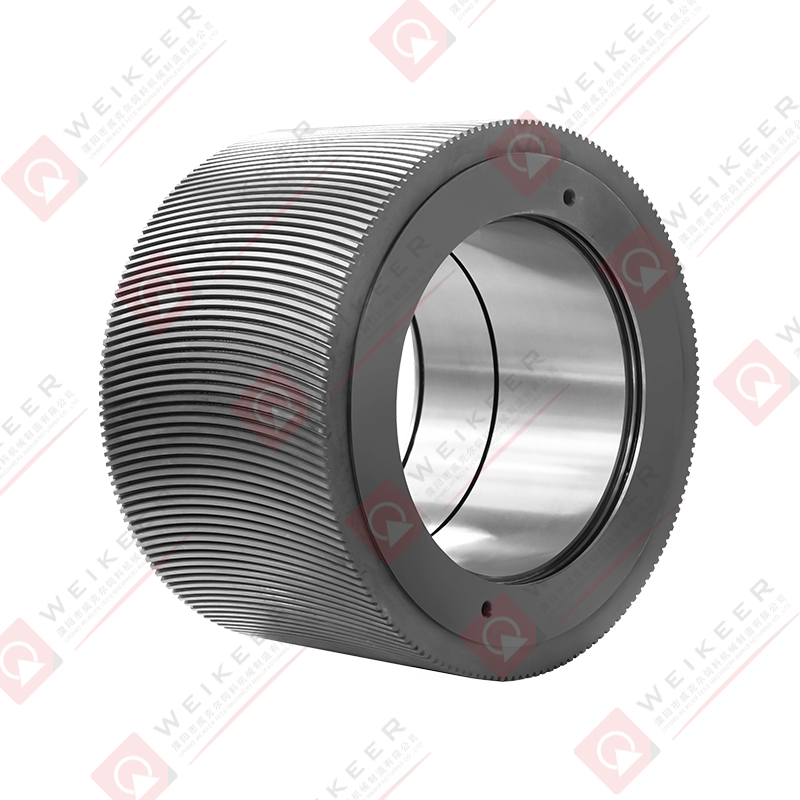

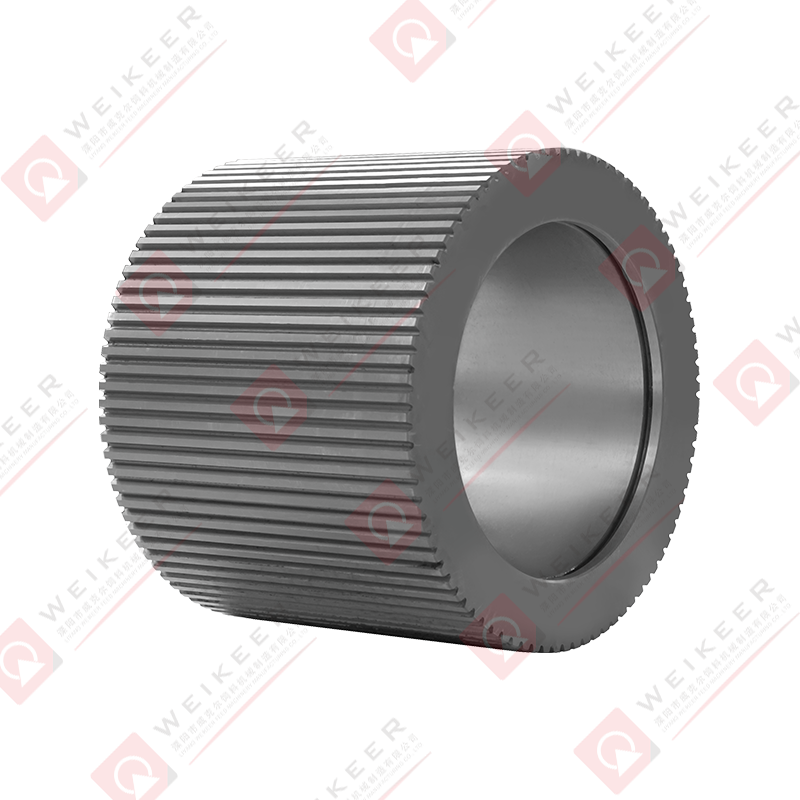

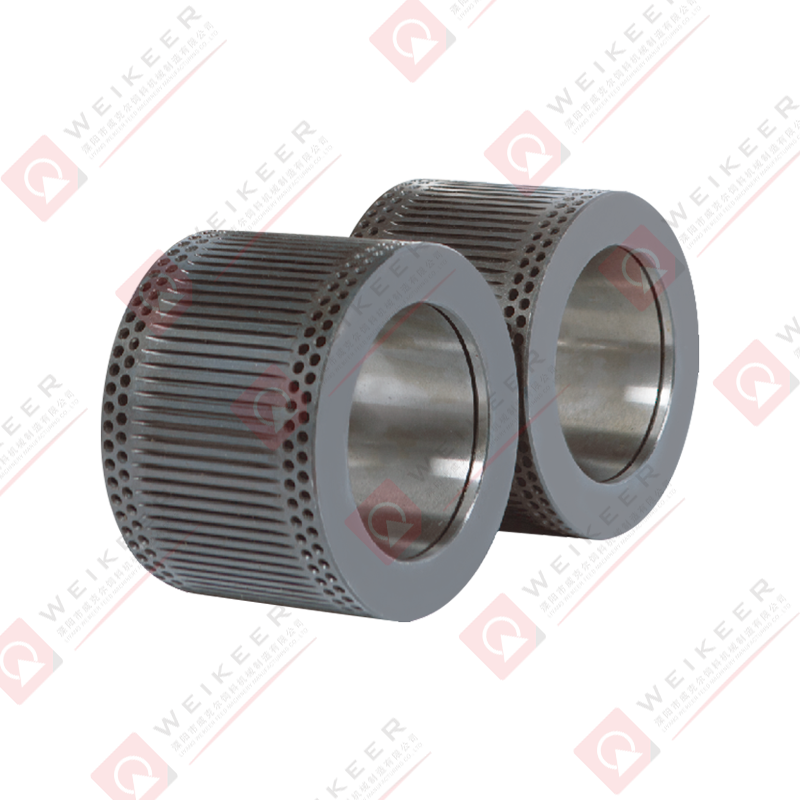

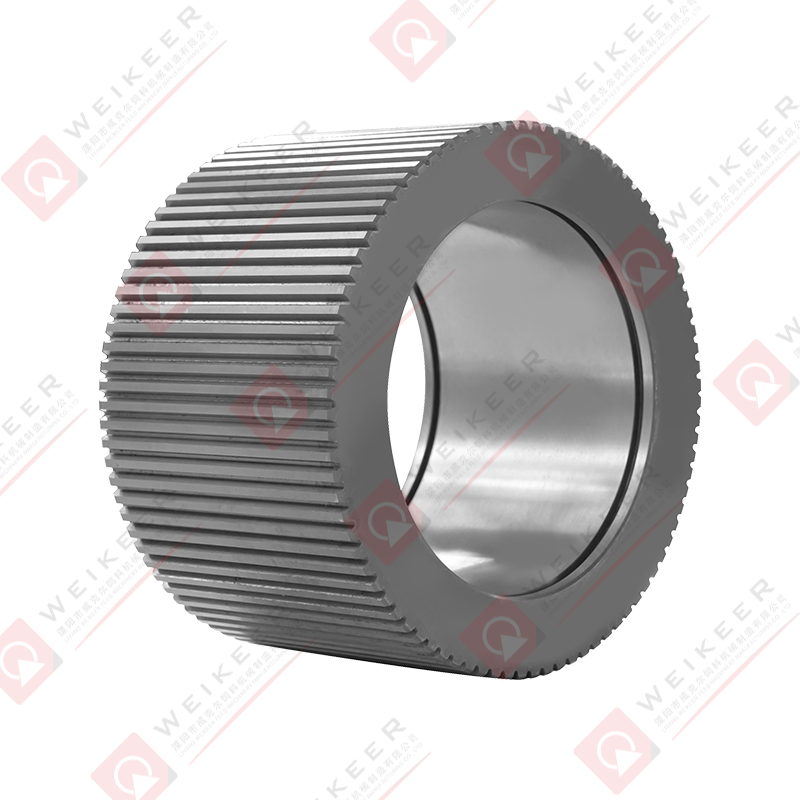

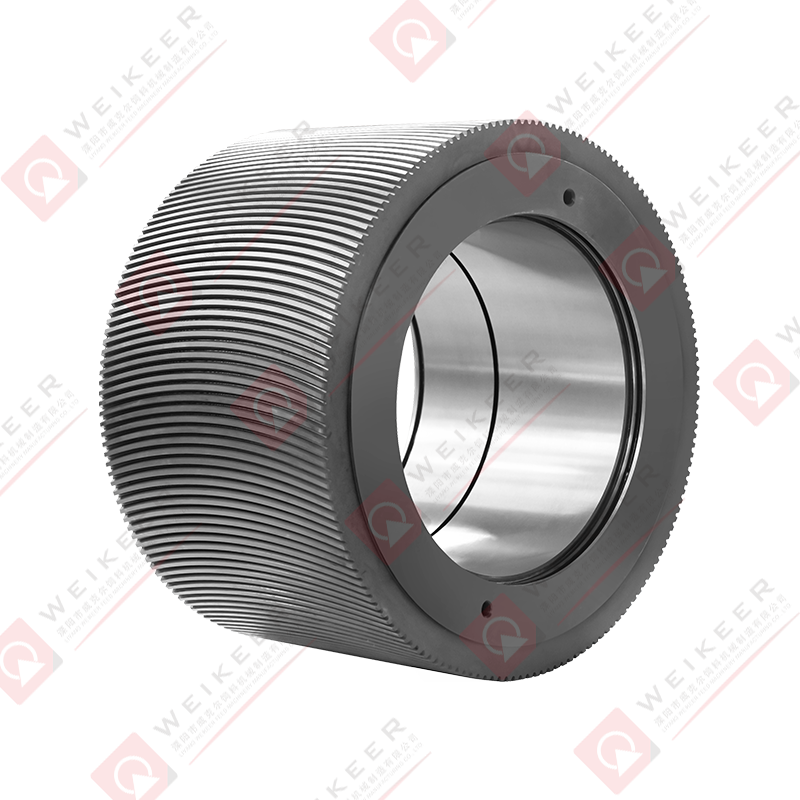

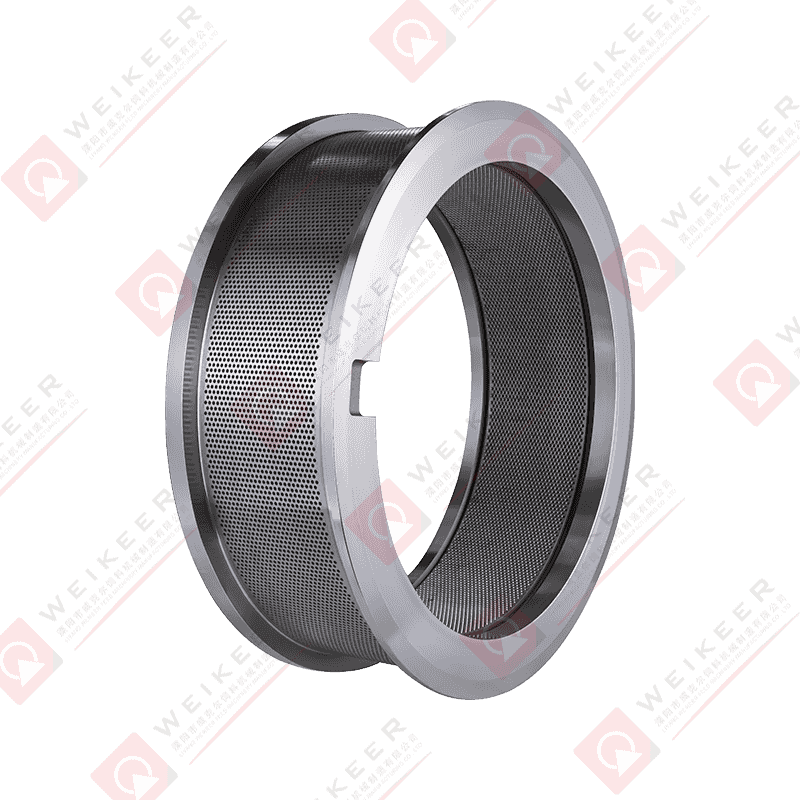

Before delving into maintenance strategies, it is important to understand the role of the ring die. The ring die is a cylindrical steel component with precision-drilled holes, through which raw material (such as sawdust, corn cob, paper pulp, or clay used in cat litter) is pressed by rollers to form pellets.

Key responsibilities of the ring die include:

- Shaping pellets: The diameter and compression ratio of the die holes determine pellet size and density.

- Ensuring uniformity: A well-designed ring die ensures consistent pellets for better absorbency and clumping in cat litter.

- Influencing productivity: The wear condition of the die affects throughput, energy consumption, and pellet quality.

Because the ring die is in constant contact with abrasive raw materials and experiences continuous mechanical pressure, it naturally wears over time. Extending its lifespan depends on reducing unnecessary stress, preventing blockages, and implementing a strong maintenance program.

2. Common Causes of Ring Die Wear and Failure

Several factors contribute to premature damage or wear of an Anchorear ring die:

- Abrasive Raw Materials: Cat litter often contains materials like bentonite clay or silica, which are highly abrasive and accelerate wear.

- Improper Moisture Content: If raw materials are too dry or too wet, they cause uneven pressure on the die, leading to cracks or surface damage.

- Incorrect Compression Ratio: Using the wrong die specifications can overstrain the equipment and reduce die life.

- Poor Conditioning of Raw Material: Inadequate grinding or uneven particle size distribution increases stress on die holes.

- Improper Machine Operation: Running the mill at excessively high loads or with poor roller alignment damages both rollers and the die.

- Lack of Cleaning: Material residues can harden in die holes, leading to blockages, reduced output, and localized stress fractures.

Understanding these causes provides the foundation for implementing effective maintenance strategies.

3. Best Practices for Maintaining an Anchorear Ring Die

a) Proper Conditioning of Raw Materials

The raw material must be uniform in size and moisture content before entering the pellet mill. For cat litter:

- Moisture should typically be 10–15%, depending on material type.

- Grinding should ensure particles are fine enough to reduce pressure on die holes.

- Mixing additives or binding agents evenly prevents uneven wear.

Well-conditioned material reduces friction, lowers energy use, and extends die life.

b) Regular Cleaning of the Ring Die

- After each production run, run oily material (like rice bran or corn flour with oil) through the die to clean and lubricate it.

- Remove any hardened material deposits to prevent hole blockage.

- Avoid leaving the die idle with material inside, as it may harden and damage the die during restart.

c) Proper Machine Alignment and Operation

- Ensure that rollers and die are correctly aligned to avoid uneven wear.

- Avoid running the mill at maximum load for prolonged periods, as this accelerates die fatigue.

- Monitor machine vibration, as misalignment can cause uneven pressure and premature damage.

d) Lubrication and Cooling

- Maintain proper lubrication of bearings and rollers, as this reduces excess heat and stress on the die.

- Ensure effective cooling systems to keep operating temperatures stable, preventing thermal cracks in the die.

e) Use of Correct Die Specifications

- Choose the right compression ratio and hole diameter suitable for cat litter production.

- Using a die designed specifically for abrasive materials (like a hardened steel die) will improve resistance to wear.

4. Preventive Maintenance Strategies

Preventive maintenance is the key to maximizing ring die lifespan. Some effective strategies include:

-

Scheduled Inspections

- Regularly inspect the die surface for cracks, burrs, or deformation.

- Check die holes for blockages and wear patterns.

- Replace rollers when they show signs of uneven wear to avoid damaging the die.

-

Die Rotation

- Rotate the die periodically to ensure even wear on all sides.

- This simple practice prevents localized thinning and extends usable life.

-

Proper Storage

- Store spare dies in a dry, clean environment to avoid rusting.

- Apply a thin layer of oil to the die surface when in storage.

-

Operator Training

- Skilled operators who understand the relationship between raw material, machine settings, and die condition can prevent many common problems.

-

Monitoring Performance Data

- Keep track of pellet output, energy consumption, and pellet quality. Sudden changes may indicate die wear or blockages.

5. Repair and Reconditioning of Ring Dies

In some cases, worn dies can be reconditioned instead of being replaced:

- Re-drilling and polishing die holes restores smooth surfaces and reduces friction.

- Surface hardening treatments can improve wear resistance.

- Laser or plasma treatment may be used to enhance durability.

However, reconditioning should only be done by professional service providers to avoid altering the die specifications and compromising pellet quality.

6. Benefits of Extending Ring Die Lifespan

Implementing effective maintenance not only reduces replacement costs but also provides several long-term benefits:

- Lower operational costs: Fewer die replacements reduce capital expenses.

- Consistent pellet quality: Properly maintained dies ensure uniform size, absorbency, and clumping properties in cat litter pellets.

- Improved machine efficiency: Reduced friction and fewer blockages lower energy consumption.

- Reduced downtime: Preventive maintenance minimizes unplanned stoppages, improving productivity.

7. Future Trends in Ring Die Technology

As demand for high-quality cat litter grows, ring die technology continues to evolve:

- Advanced alloys and coatings: New materials improve hardness and wear resistance.

- Precision drilling: Laser and CNC machining provide smoother die holes for better pellet quality.

- Self-cleaning dies: Innovative designs may reduce the need for manual cleaning.

Adopting these advancements can further extend die life and increase production efficiency.

Conclusion

The Anchorear ring die is one of the most critical components in cat litter pellet mills, directly affecting pellet quality, machine efficiency, and production costs. Its lifespan depends on careful attention to raw material conditioning, proper operation, regular cleaning, and preventive maintenance. By adopting best practices—such as scheduled inspections, correct machine alignment, lubrication, and storage—manufacturers can significantly extend the usability of their ring dies.

In addition, operator training, performance monitoring, and the use of advanced die materials and treatments play a vital role in ensuring long-term durability. With proactive maintenance and attention to detail, businesses can maximize the value of their investment in ring dies, reduce downtime, and maintain consistent production of high-quality cat litter pellets.

русский

русский Español

Español عربى

عربى 中文简体

中文简体