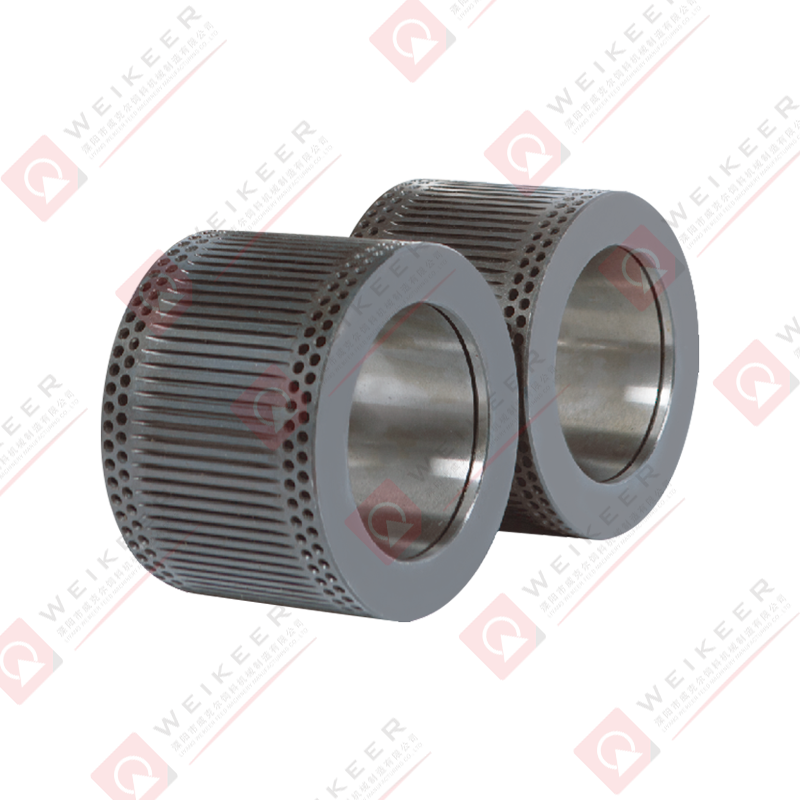

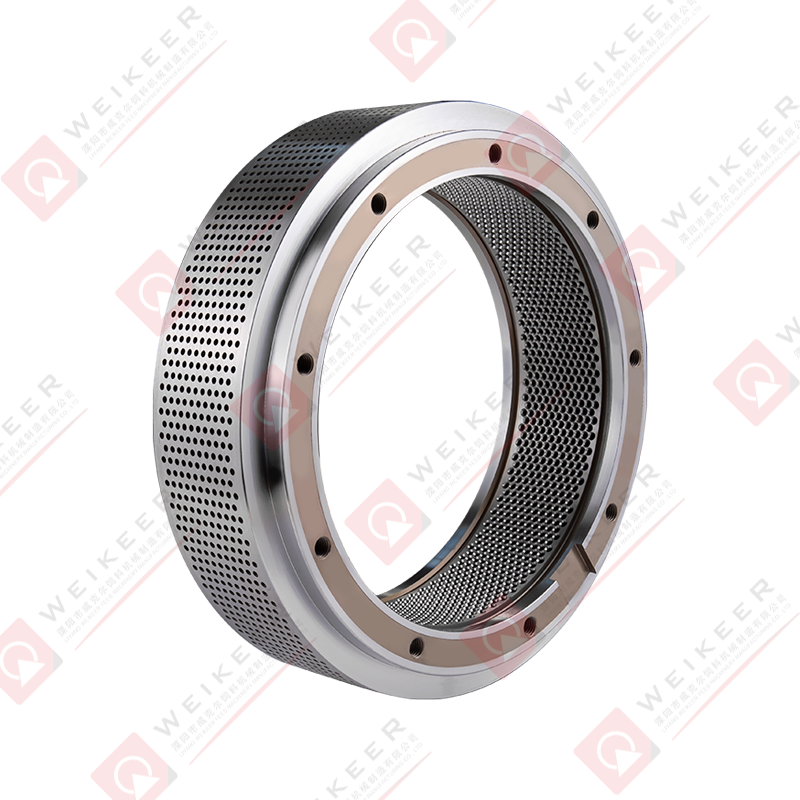

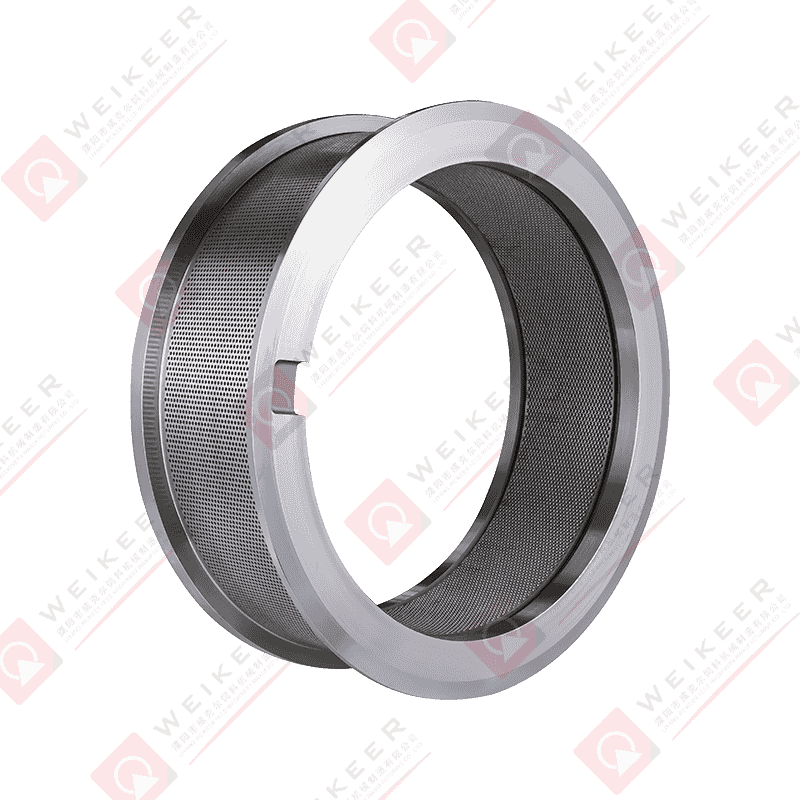

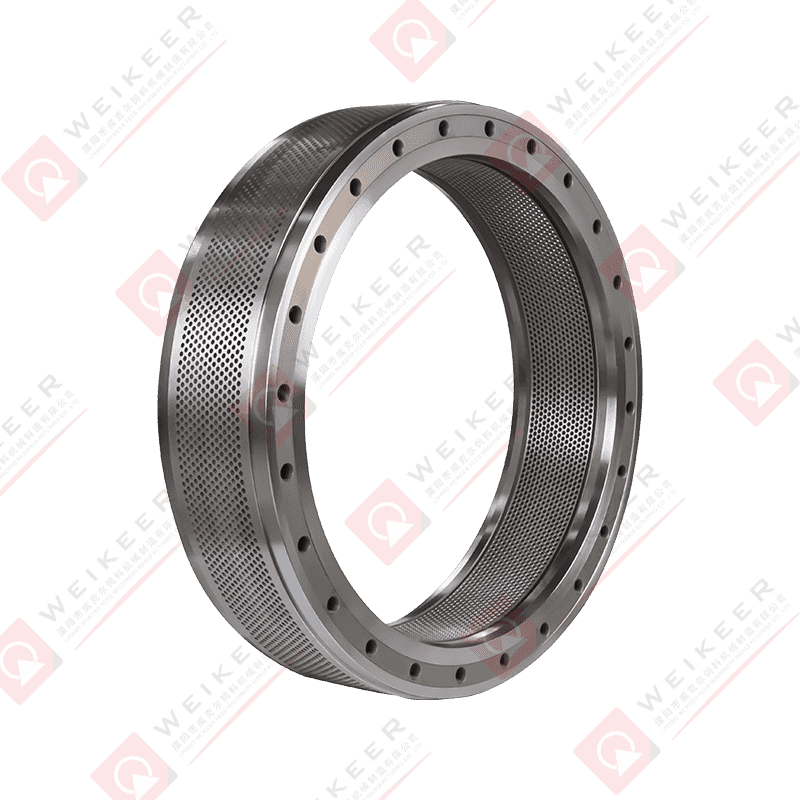

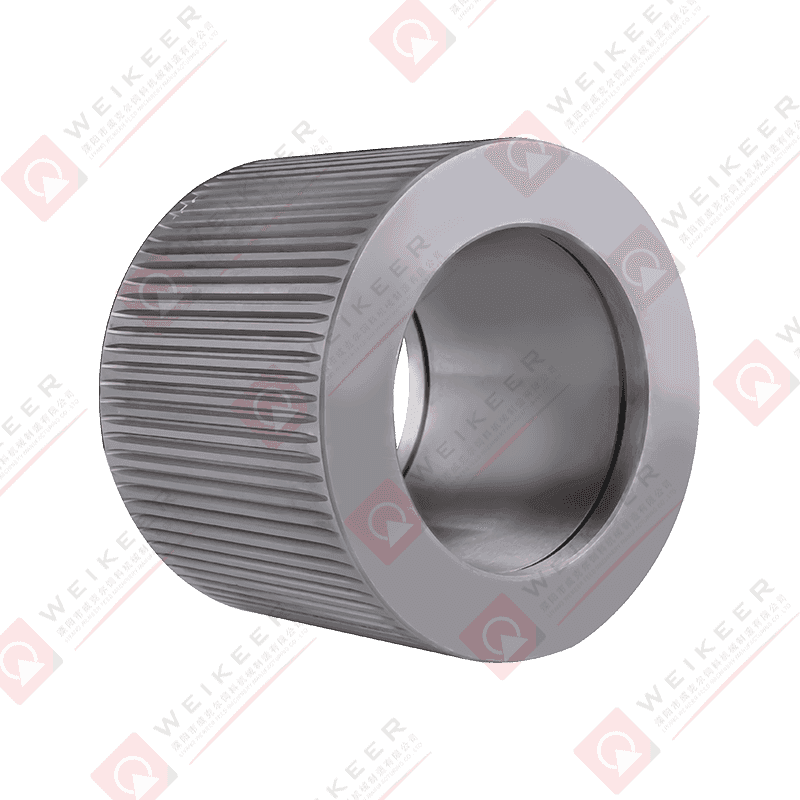

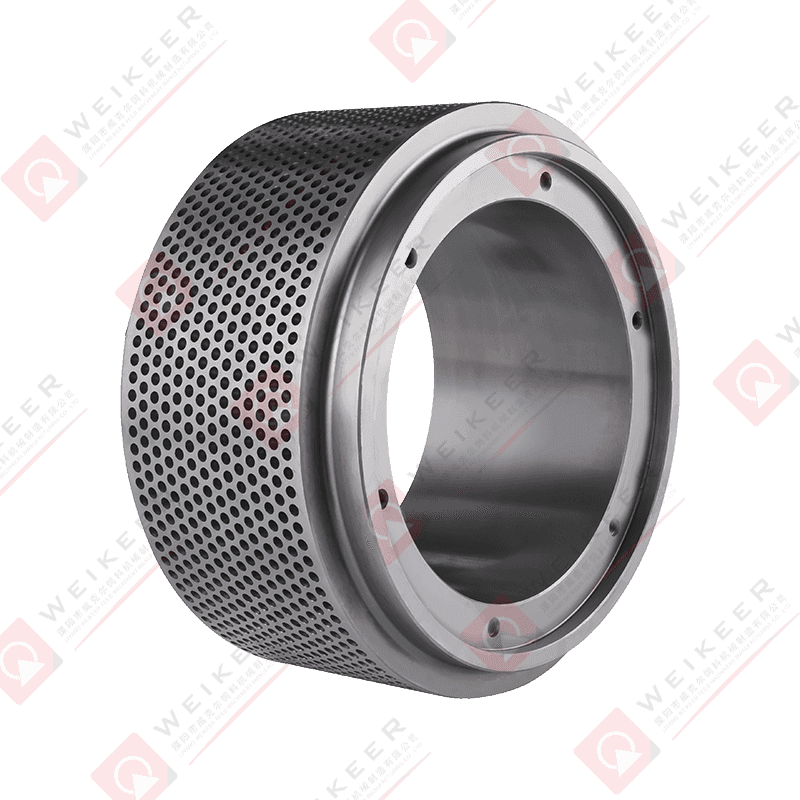

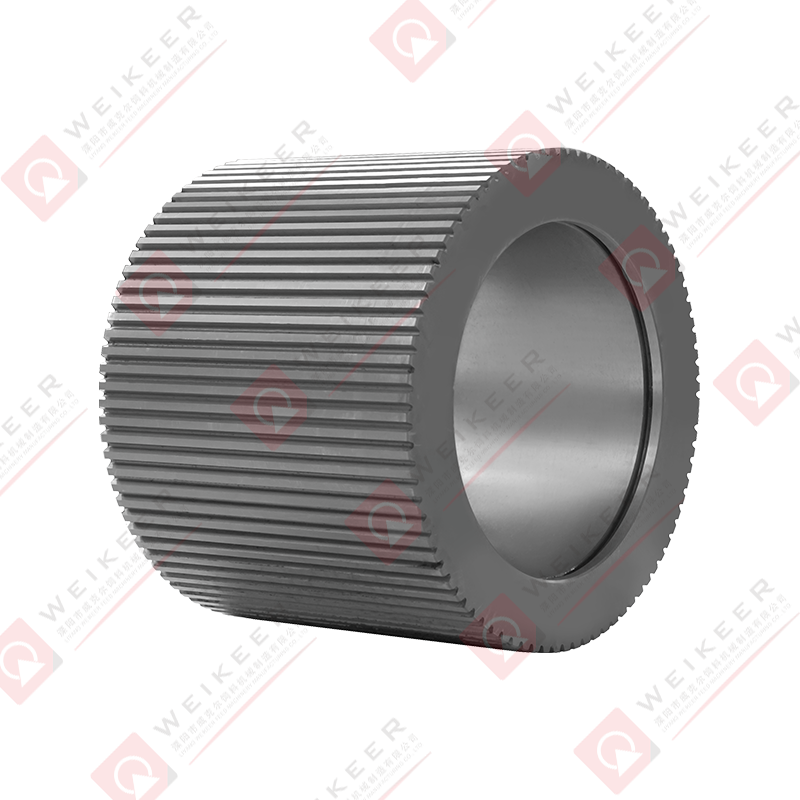

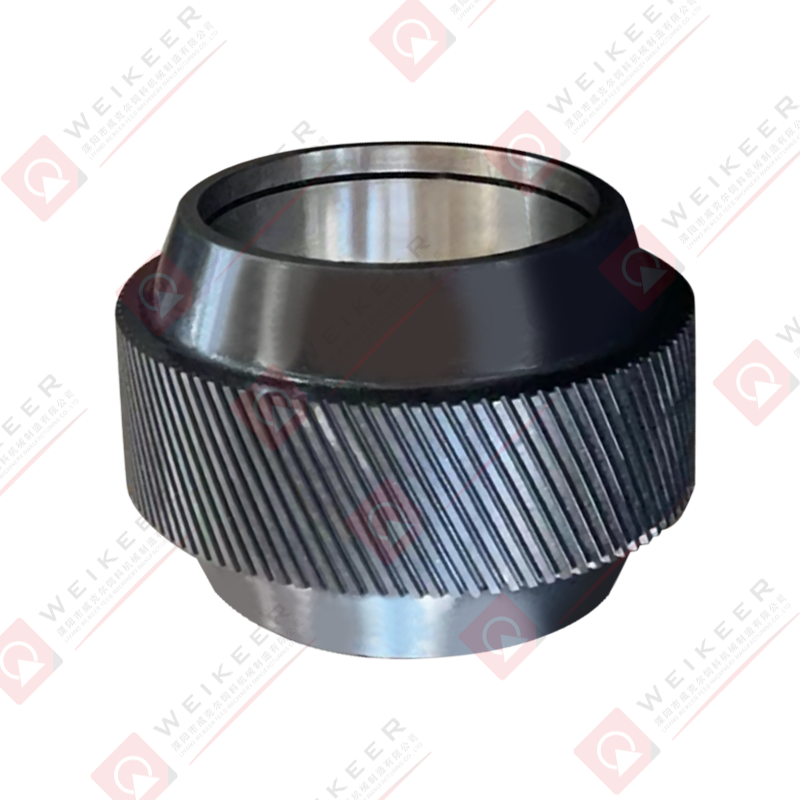

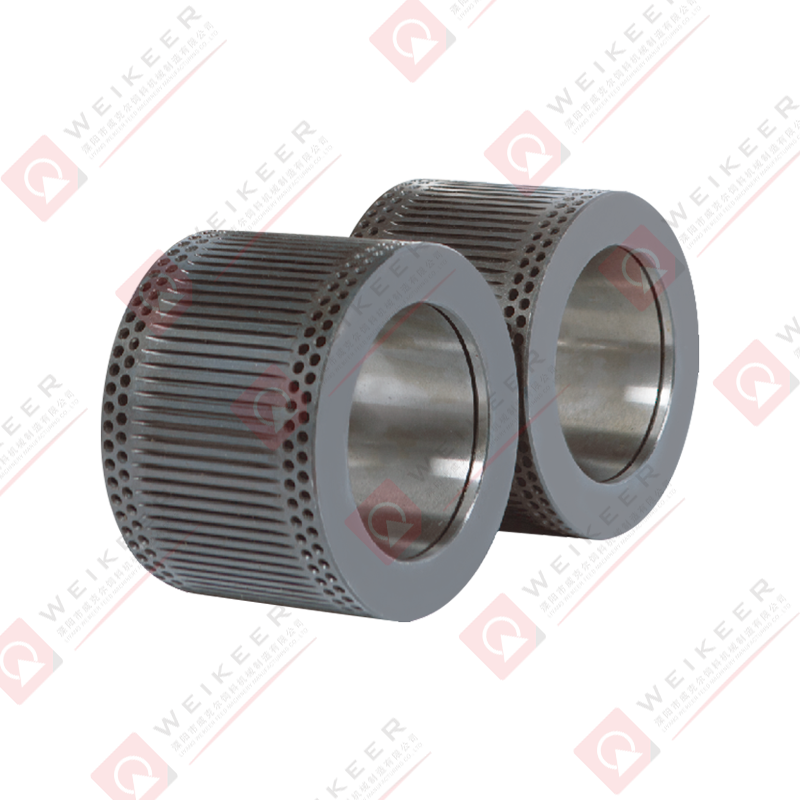

GCr15 pellet mill rollers and shells are critical components in feed and biomass pellet production. Manufactured from high-carbon chromium bearing steel, GCr15 provides exceptional hardness, wear resistance, and durability. These properties make the rollers and shells ideal for heavy-duty operations, but without proper maintenance, even the most robust components can wear prematurely. Understanding their structure and function is the first step in extending their lifespan.

Common Causes of Wear and Damage

Pellet mill rollers and shells face extreme pressure, friction, and high-speed rotation during operation. Common causes of wear include:

- Insufficient lubrication, leading to metal-to-metal contact.

- Material impurities in raw feed causing abrasion.

- Incorrect roller gap settings that increase stress.

- High operational temperature causing surface softening.

- Lack of regular inspection, leading to unnoticed micro-cracks or deformation.

Routine Inspection and Monitoring

Regular inspection is essential for prolonging roller and shell lifespan. Techniques include:

- Visual inspection for cracks, scoring, and uneven wear.

- Measuring roller and shell diameter to ensure they remain within tolerance.

- Monitoring vibration and noise levels during operation to detect imbalance or misalignment.

- Checking lubrication systems to confirm proper oil or grease distribution.

Proper Lubrication Practices

Lubrication is critical to reduce friction and prevent overheating. Best practices include:

- Use high-quality grease or oil recommended for GCr15 steel and pellet mill operations.

- Establish a lubrication schedule based on operational hours and load conditions.

- Ensure even application of lubricant across the roller surface to avoid dry spots.

- Monitor lubricant temperature and replace when contaminated or degraded.

Maintaining Optimal Roller Gap and Alignment

The roller gap directly affects pellet quality and roller wear. Key steps for maintaining optimal settings:

- Measure roller gap frequently and adjust according to feed material type and moisture content.

- Ensure parallel alignment of rollers to prevent uneven pressure distribution.

- Use precision tools for gap measurement to maintain tight tolerances.

- Regularly recalibrate machinery to compensate for thermal expansion and mechanical wear.

Temperature Control and Cooling

Excessive heat softens GCr15 steel and accelerates wear. Temperature management tips include:

- Install temperature sensors on rollers and shells to monitor heat levels.

- Use cooling systems, such as water jackets or forced air, to maintain optimal operating temperatures.

- Avoid overfeeding, which increases friction and heat generation.

- Allow the mill to cool down after prolonged operation before maintenance or cleaning.

Surface Treatment and Hardening

Surface treatment can significantly extend the operational life of GCr15 rollers and shells:

- Induction or nitriding hardening increases wear resistance and fatigue strength.

- Regular polishing and minor grinding remove micro-abrasions and restore smooth surfaces.

- Consider specialized coatings to reduce friction and corrosion.

- Replace severely worn rollers or shells instead of attempting repairs that may compromise safety.

Cleaning and Contamination Prevention

Keeping rollers and shells clean reduces abrasive wear and maintains pellet quality:

- Remove feed residues after each production cycle.

- Inspect for foreign particles that can scratch or damage surfaces.

- Use non-abrasive cleaning tools and solvents compatible with GCr15 steel.

- Implement protective storage methods when rollers are not in use.

Scheduled Replacement and Lifecycle Management

Even with excellent maintenance, rollers and shells eventually reach the end of their useful life. Lifecycle management strategies:

- Track operational hours and wear rates to schedule timely replacement.

- Maintain an inventory of spare rollers and shells to minimize downtime.

- Document maintenance history for each component to analyze wear trends.

- Consult manufacturers’ guidelines for maximum service life and replacement intervals.

Conclusion

Proper maintenance of GCr15 pellet mill rollers and shells is critical for maximizing durability, improving pellet quality, and reducing operational costs. By combining routine inspection, optimal lubrication, precise alignment, temperature control, surface treatment, and scheduled replacement, manufacturers can significantly extend component lifespan and ensure consistent, high-performance pellet production.

русский

русский Español

Español عربى

عربى 中文简体

中文简体