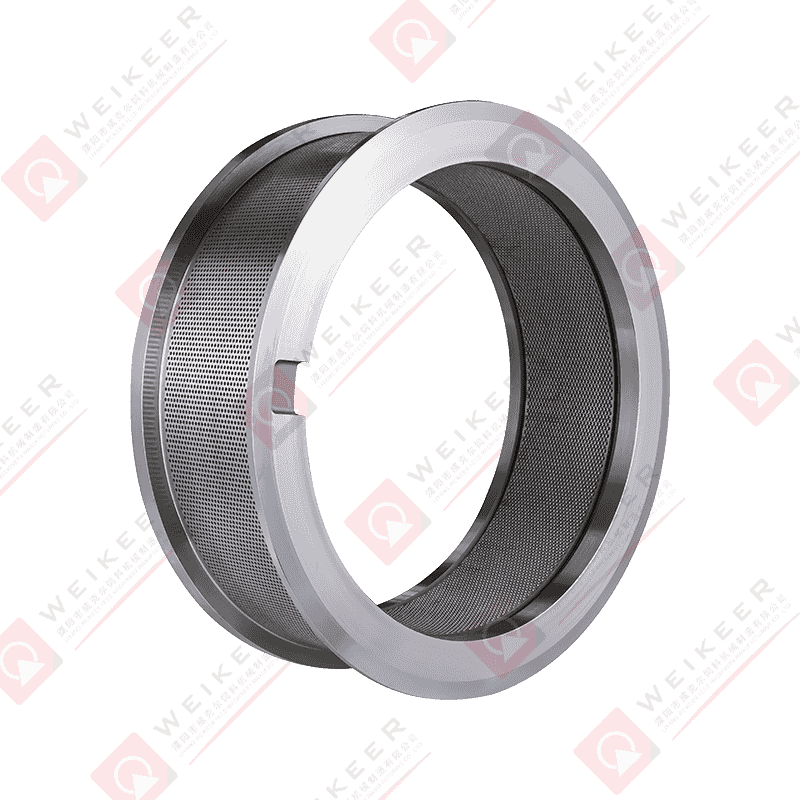

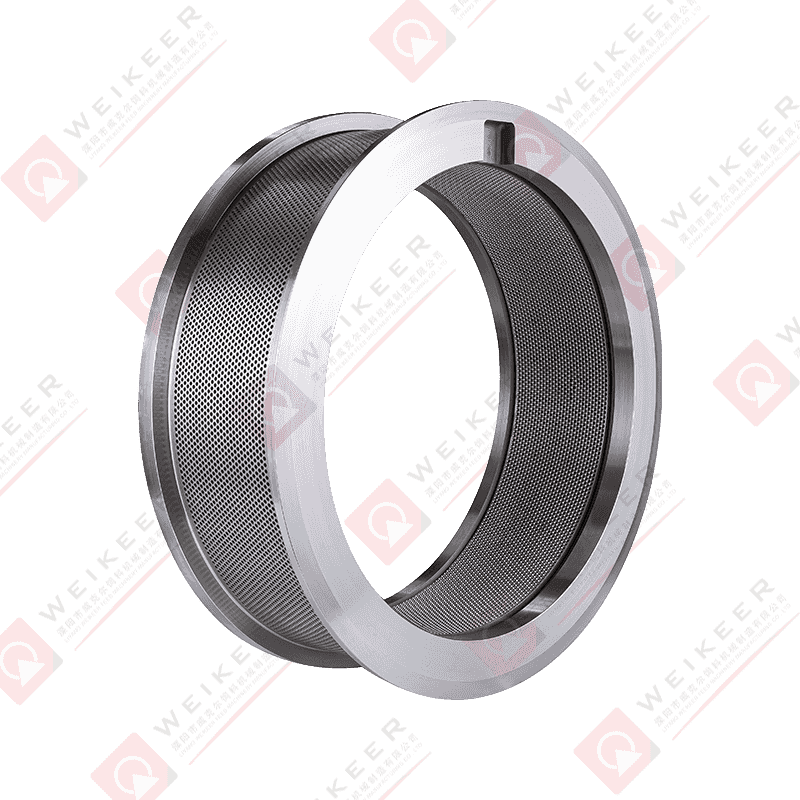

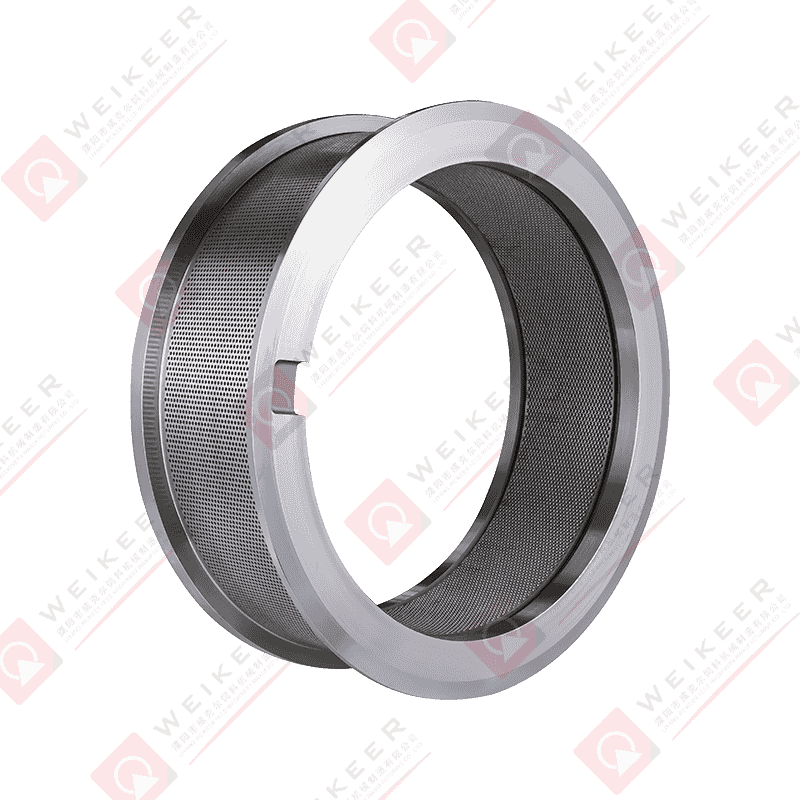

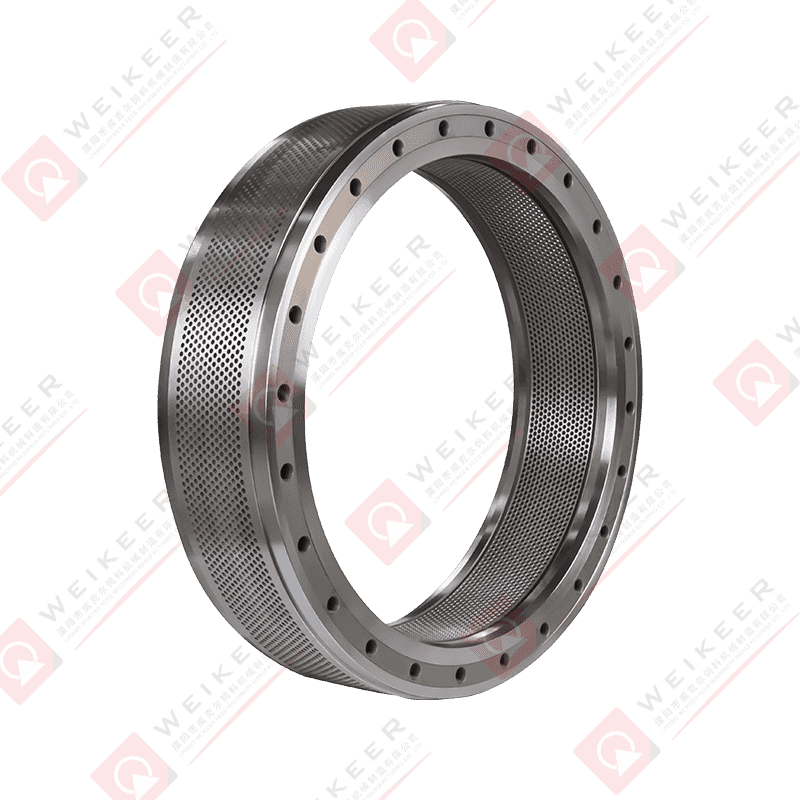

In the feed, wood pellet, biomass energy and chemical industries, the demand for pellet products is growing. As the core equipment of the pellet production line, the performance of the pellet machine directly determines the quality and production efficiency of the pellet products. In the pellet machine, the ring die (Ring Die) is a key component of molding, and its material and process level are particularly important.

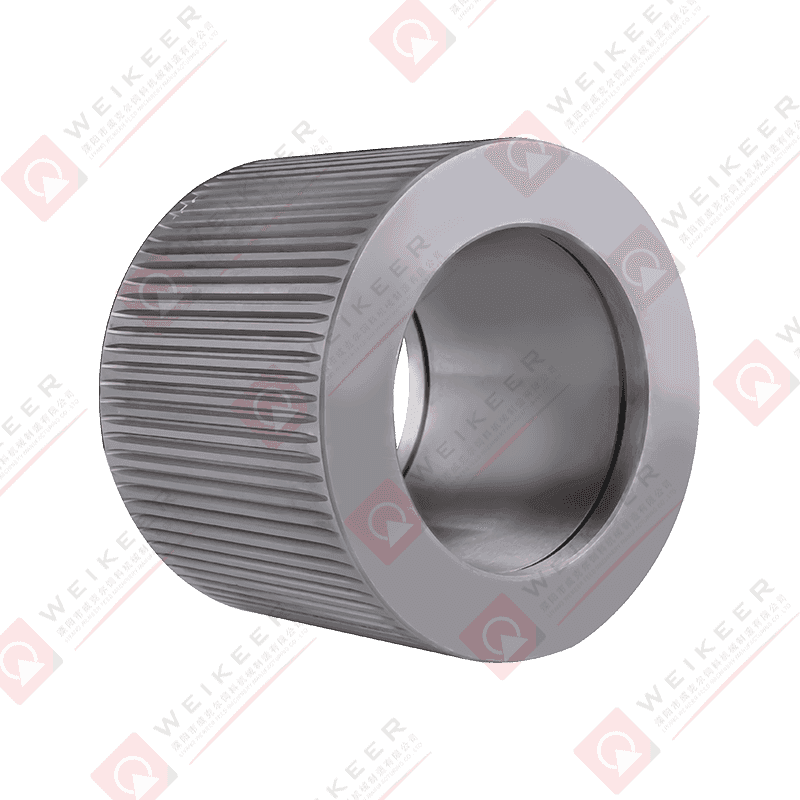

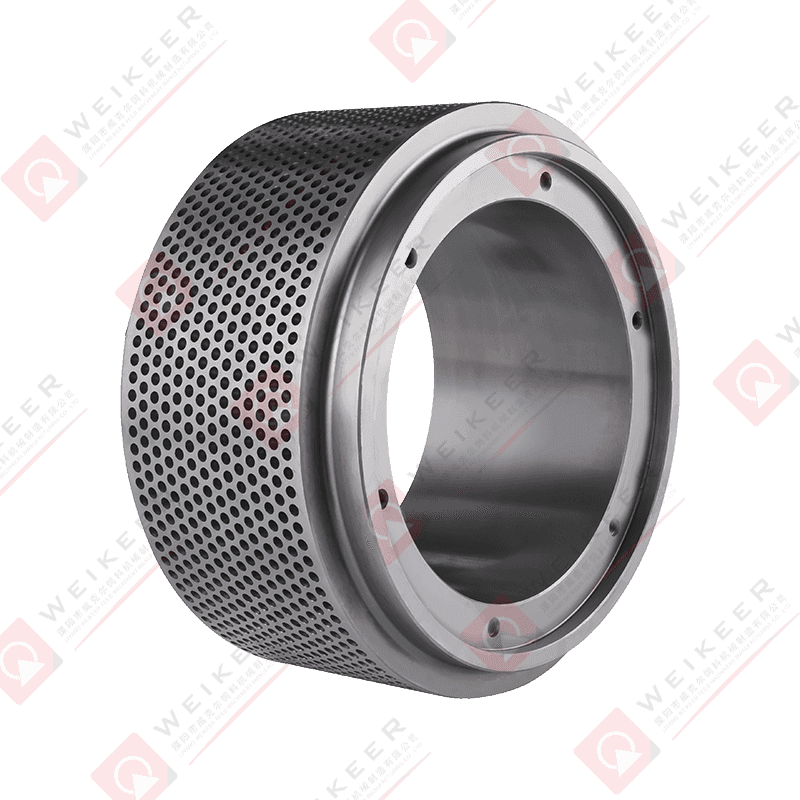

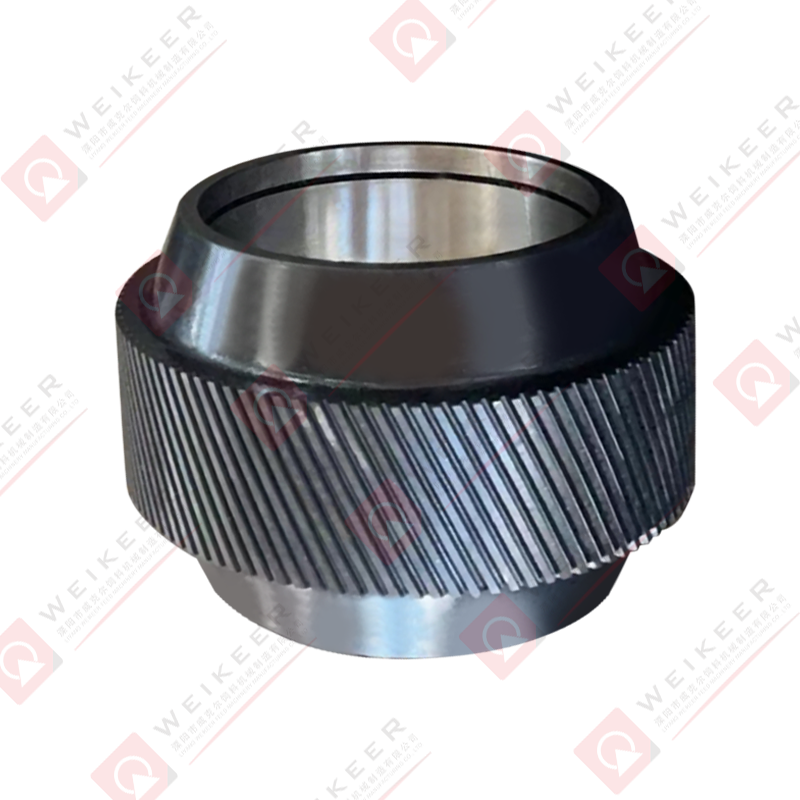

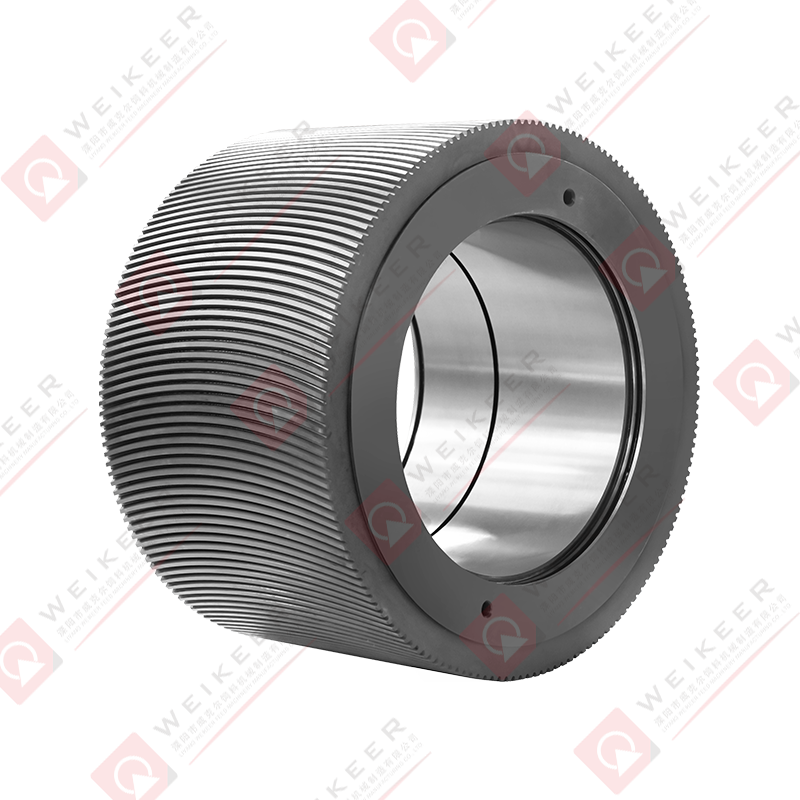

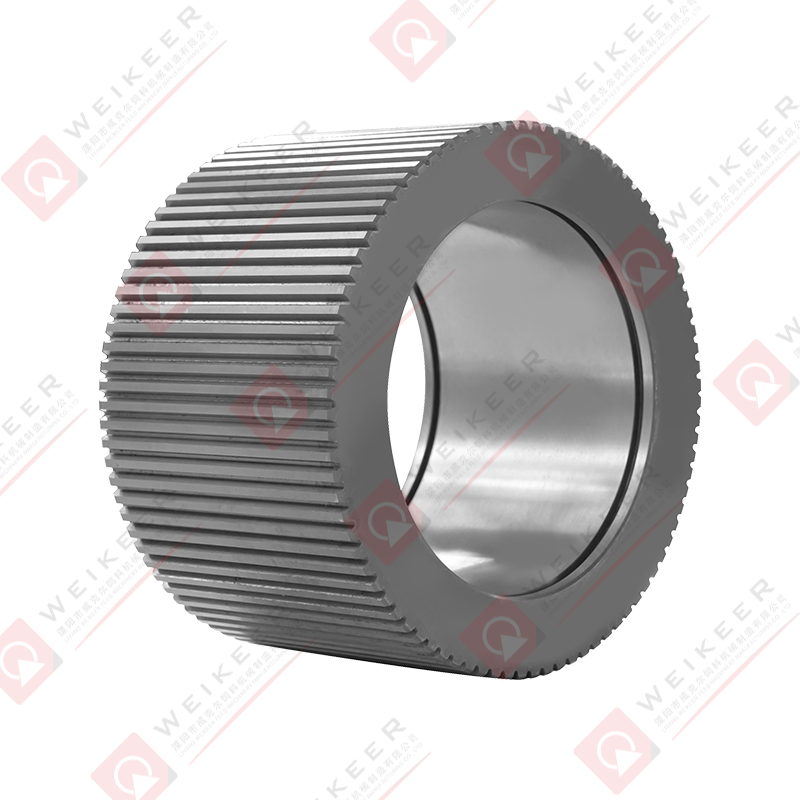

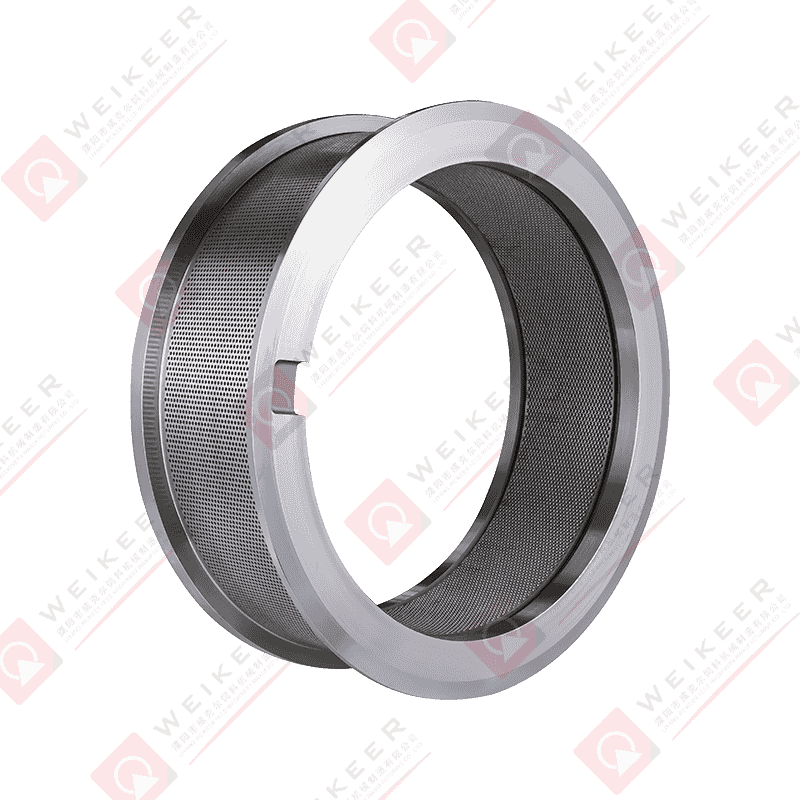

Main features of Anchorear stainless steel ring die

High wear resistance

Anchorear stainless steel ring die is made of high-strength stainless steel material, and is vacuum heat treated and precision machined. It has high hardness, smooth hole wall and long wear resistance. Compared with ordinary carbon steel ring die, the service life can be increased by 30%-50%.

Excellent corrosion resistance

Stainless steel material has strong resistance to acid, alkali, moisture and corrosive substances. It is suitable for pelleting different types of materials such as biomass fuel, animal feed, aquatic feed, especially high moisture or high oil materials.

High-precision processing technology

Anchorear ring die adopts CNC drilling technology and polishing to ensure uniform die holes, high particle density, good molding effect, and reduce material blockage and energy consumption.

Good heat dissipation performance

Stainless steel ring die has better heat dissipation performance, can maintain a low temperature rise under high-intensity continuous working environment, and extend the overall service life of the equipment.

Application field

Anchorear stainless steel ring die pellet machine is suitable for the production of a variety of pellet products:

Feed industry: used for the production of feed pellets for pigs, cattle, poultry, aquatic products, etc.

Biomass energy: suitable for biomass pellet fuel made from raw materials such as sawdust, rice husks, and corn stalks.

Chemical industry: used for granular finished products made of chemical powder.

Organic fertilizer, compound fertilizer: used for pellet molding operations in the fertilizer industry.

Advantages of Anchorear ring die pellet machine

High efficiency and energy saving

The die hole design is optimized to reduce the pressing resistance, improve the pressing efficiency, reduce the unit power consumption, and effectively save production costs.

Stable pellet quality

The pellets are dense, smooth, water-resistant and wear-resistant, with a high qualified rate of finished products, which is particularly suitable for high-end feed and biomass fuel production.

Low maintenance cost

Long service life and low wear rate reduce the frequency of ring die replacement, maintenance cost and downtime.

Support customized services

Anchorear can design and customize parameters such as die hole diameter and compression ratio according to different material characteristics and process requirements to meet personalized production needs.

Development trend and prospects

With the strengthening of environmental protection policies and the expansion of market demand for clean energy and efficient feed, Anchorear stainless steel ring die pellet machine shows development trends in the following aspects:

Intelligence and automation: In the future, more functions such as intelligent monitoring, remote diagnosis and automatic lubrication will be integrated to improve the level of equipment management.

Application of new materials: Develop ultra-wear-resistant and ultra-corrosion-resistant alloy stainless steel materials to further improve the performance of ring dies.

Green energy saving: Optimize power transmission and die hole design, continuously improve energy efficiency, and help energy conservation and emission reduction.

Anchorear stainless steel ring die pellet machine occupies an important position in the fields of feed, biomass, chemical industry, etc. with its high-quality ring die components and excellent overall performance. Choosing high-quality ring die can not only improve the quality of pellet products, but also reduce production and maintenance costs. It is a wise choice for modern pellet production companies to enhance their competitiveness. In the future, Anchorear will continue to promote the development of pellet machine equipment towards a more efficient, environmentally friendly and intelligent direction through technological innovation.

русский

русский Español

Español عربى

عربى 中文简体

中文简体