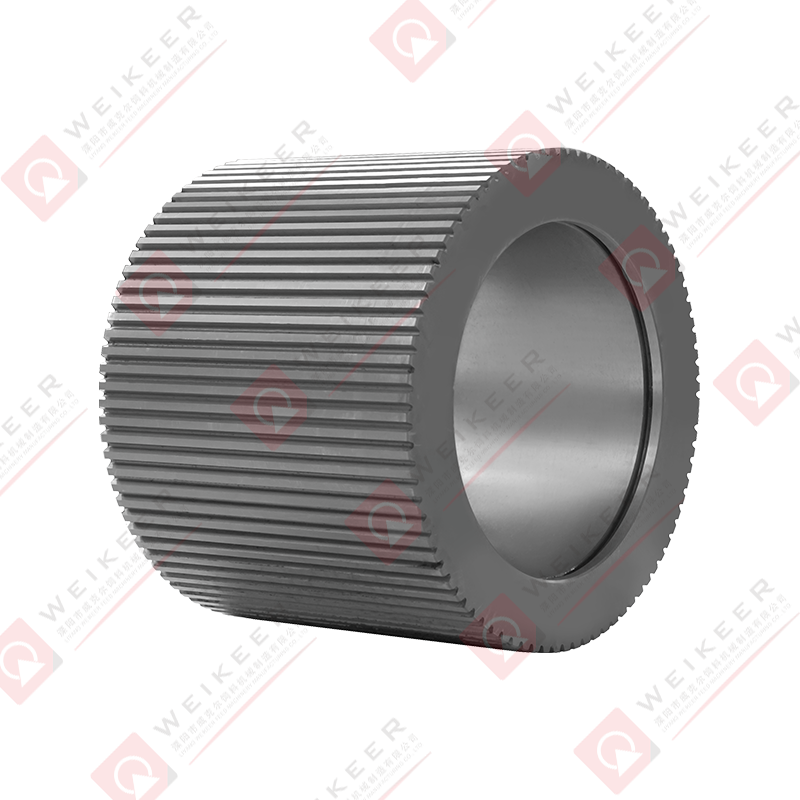

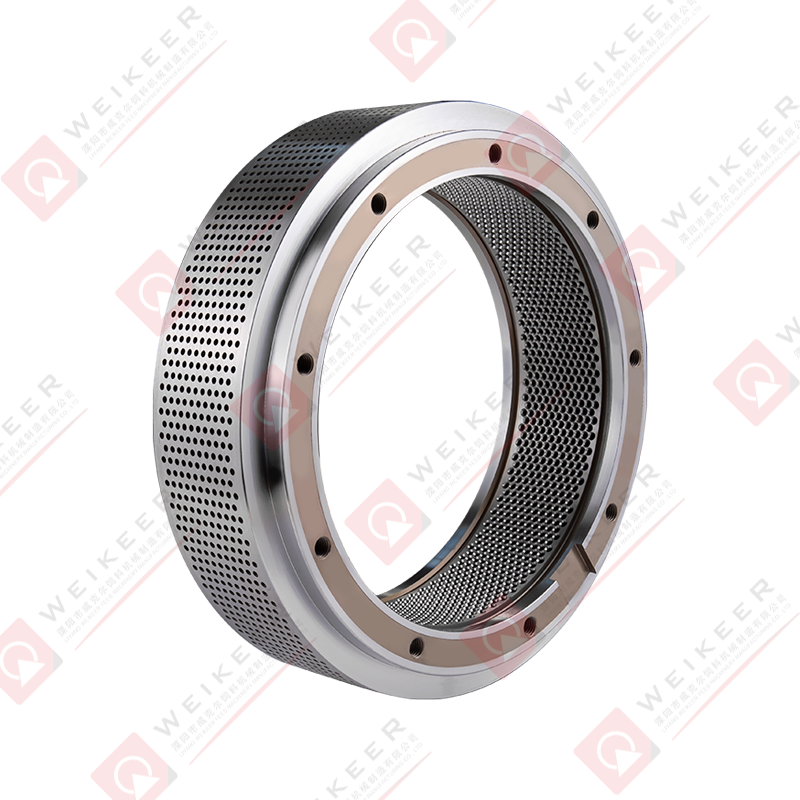

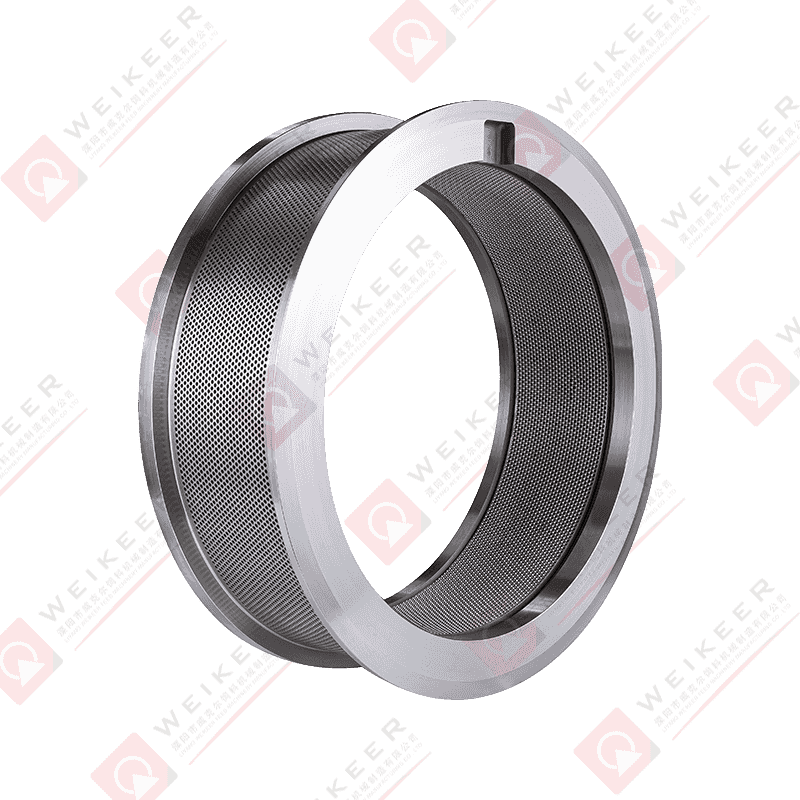

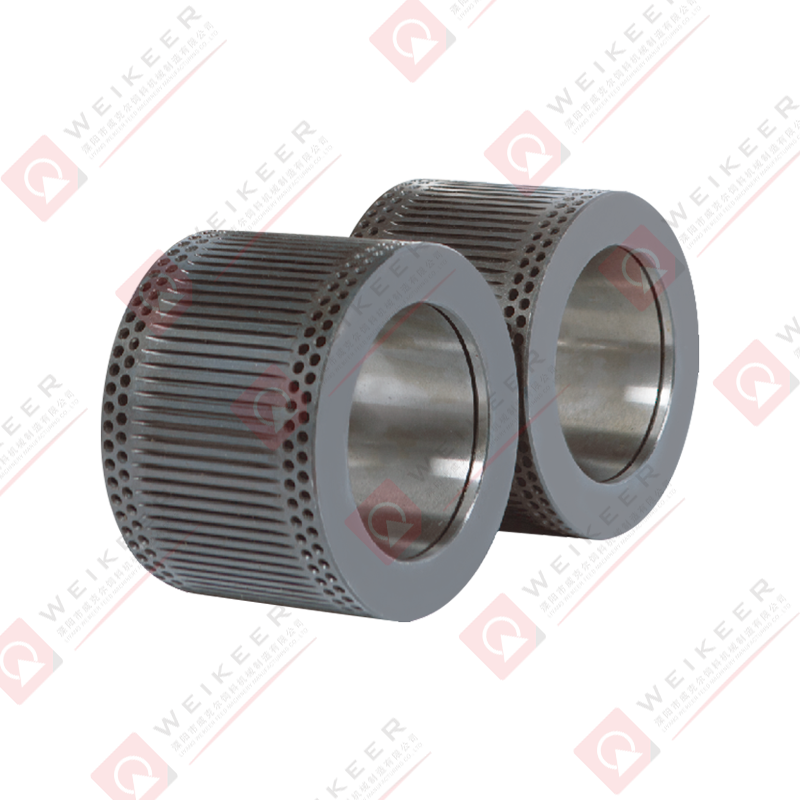

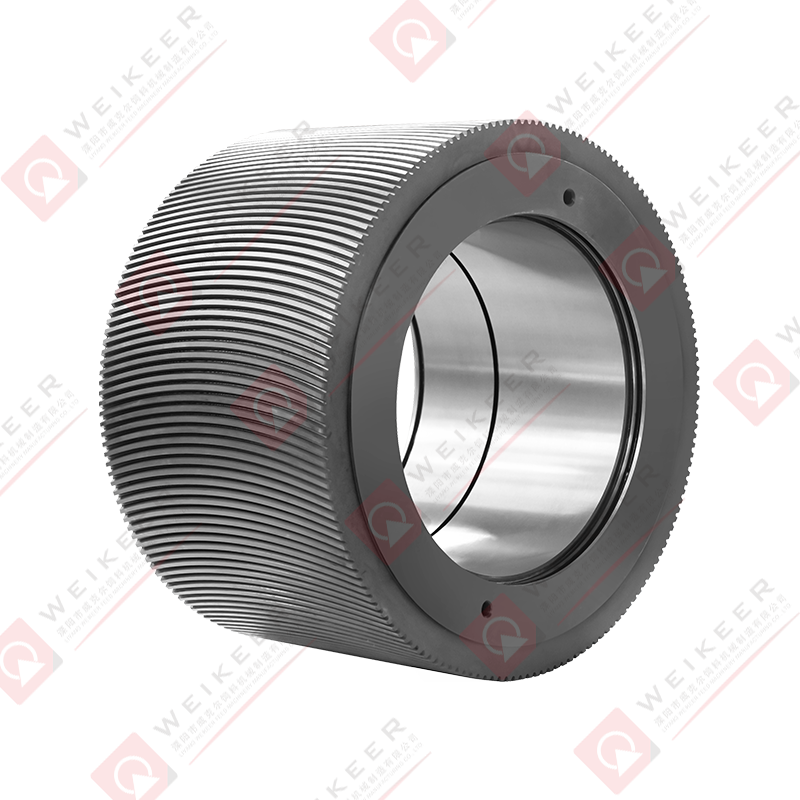

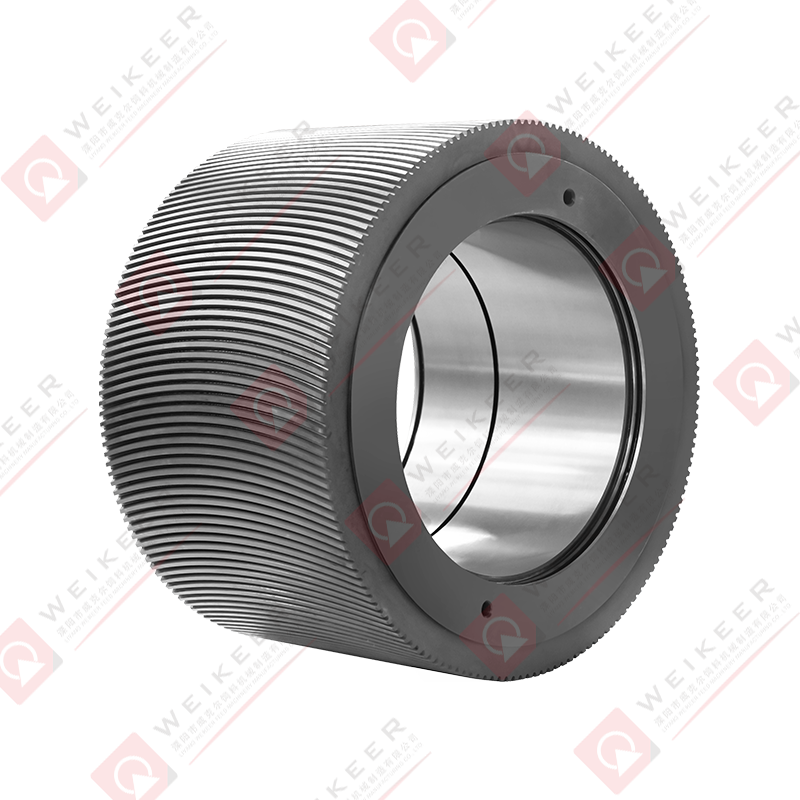

Pellet mills play a crucial role in industries such as animal feed, biomass energy, and chemical production. One of the core components of a pellet mill is the roller shell, which works together with the die to compress raw materials into uniform pellets. Since rollers are constantly subjected to high pressure, abrasion, and fatigue during operation, the choice of material directly affects efficiency, durability, and maintenance costs. Among the various materials used for roller shells, Bearing Steel GCr15 has emerged as a leading choice due to its superior mechanical properties and performance. This article explores the unique advantages of GCr15 bearing steel in pellet mill roller shells compared to alternative materials.

Understanding Bearing Steel GCr15

GCr15 is a high-carbon chromium bearing steel widely recognized for its excellent hardness, wear resistance, and fatigue strength. It is considered the Chinese equivalent of AISI 52100 or DIN 100Cr6, which are globally used bearing steels. The typical chemical composition of GCr15 includes around 1% carbon, 1.5% chromium, and trace amounts of manganese and silicon. This balanced composition provides a high degree of hardness after heat treatment while retaining adequate toughness for demanding mechanical applications.

The material was initially developed for rolling element bearings, which endure heavy loads and rotational stresses. Over time, its exceptional properties have made it a popular choice for manufacturing roller shells in pellet mills, where similar mechanical challenges exist.

Key Advantages of GCr15 Bearing Steel in Pellet Mill Rollers

1. Superior Wear Resistance

Pellet mill rollers are in constant contact with abrasive feedstocks such as wood, straw, biomass residues, and grain mixtures. Materials like mild steel or alloy steels wear out quickly, leading to reduced pellet quality and higher maintenance frequency.

GCr15 bearing steel, when properly heat-treated, achieves a hardness range of 58–65 HRC, which significantly enhances its resistance to wear. This means the roller shell can maintain its surface integrity longer, ensuring consistent pellet dimensions and reduced downtime.

Comparison:

- Mild steel: lower hardness, prone to rapid surface wear.

- Alloy steel (general): moderate wear resistance but lower hardness stability under high loads.

- GCr15: excellent wear resistance with long-lasting performance.

2. High Fatigue Strength

During the pelletizing process, rollers experience repetitive stress as they rotate and press material through the die holes. If the material lacks fatigue strength, micro-cracks develop over time, leading to roller shell failure.

GCr15’s microstructure, after heat treatment, offers high compressive strength and fatigue resistance, making it ideal for long-term cyclic loading. This reduces the risk of premature roller failure and extends the overall service life of the machine.

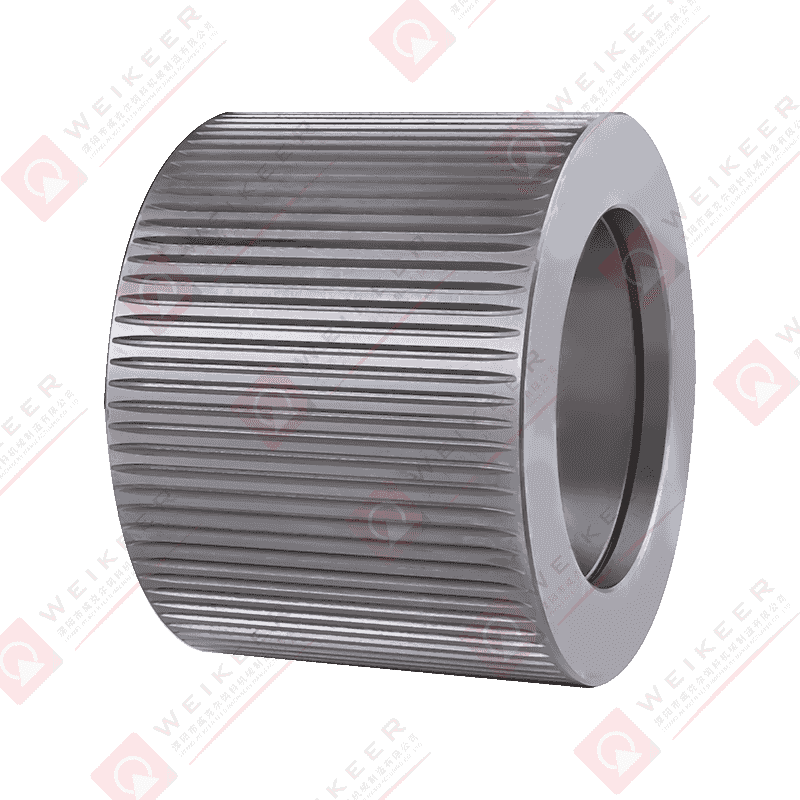

3. Dimensional Stability After Heat Treatment

Heat treatment is essential for enhancing the hardness and wear resistance of roller shells. However, some steels undergo significant deformation during quenching and tempering, which can cause manufacturing challenges and affect roller precision.

GCr15 bearing steel is known for its dimensional stability, allowing precise machining and heat treatment without significant distortion. This ensures that roller shells maintain their designed geometry, improving pelletizing efficiency and reducing reworking costs.

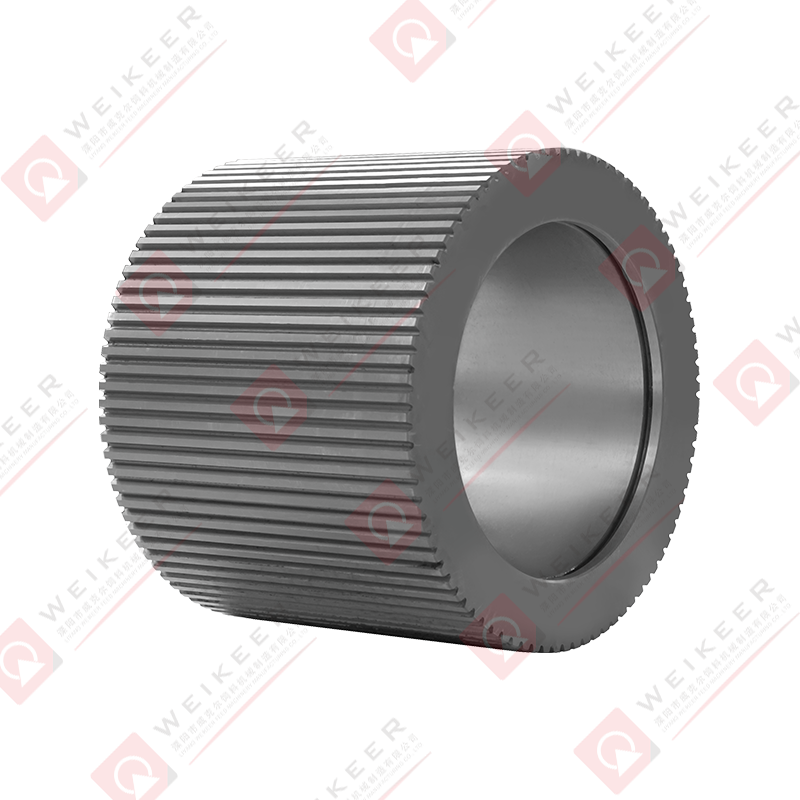

4. High Load-Bearing Capacity

The pelletizing process requires rollers to withstand extreme pressure while pushing raw material through the die. GCr15’s high load-bearing capacity stems from its combination of hardness and toughness. This makes it more capable of handling heavy workloads without cracking, compared to softer steels or lower-grade alloys.

5. Cost-Effectiveness in the Long Run

While the initial manufacturing cost of GCr15 roller shells may be slightly higher than those made from mild steel or standard alloy steel, the extended service life and reduced maintenance costs offer long-term economic benefits. Pellet mill operators benefit from fewer replacements, less downtime, and consistent pellet quality, which ultimately improves production efficiency and profitability.

6. Consistency in Pellet Quality

Pellet quality depends heavily on the roller’s surface condition. If rollers wear unevenly, pellets can vary in size, density, and smoothness. GCr15 steel roller shells maintain a uniform surface texture even after prolonged use, resulting in stable pellet output that meets industry standards for size and density.

7. Resistance to Corrosion with Proper Surface Treatment

Although GCr15 is not inherently stainless, it responds well to protective treatments such as surface hardening, coating, or nitriding. These treatments enhance resistance to corrosion from moisture-laden feedstock or biomass materials. In contrast, many low-grade steels corrode quickly, which accelerates wear and reduces efficiency.

Comparison with Other Common Materials

To better highlight the advantages of GCr15, it is useful to compare it with other materials used in pellet mill rollers:

Mild Steel

- Pros: Low cost, easy to machine.

- Cons: Poor wear resistance, short lifespan, frequent replacement required.

- Comparison: GCr15 lasts significantly longer under abrasive and high-pressure conditions.

Standard Alloy Steel (e.g., 42CrMo)

- Pros: Good toughness and moderate wear resistance, lower cost than bearing steel.

- Cons: Not as hard or wear-resistant as GCr15, prone to fatigue over time.

- Comparison: GCr15 offers higher hardness and fatigue strength, better suited for continuous industrial operation.

Stainless Steel

- Pros: Excellent corrosion resistance, suitable for moist or chemical-rich feedstocks.

- Cons: Lower hardness compared to GCr15, higher cost, reduced wear resistance.

- Comparison: While stainless is better against corrosion, GCr15 outperforms in wear resistance and load capacity.

Carbide-Coated Steels

- Pros: Exceptional wear resistance, very long service life.

- Cons: Very high cost, difficult to manufacture, brittle under shock loads.

- Comparison: GCr15 provides a balance between performance and cost, making it a more practical choice for most pellet mills.

Practical Applications and Performance Feedback

Manufacturers and operators of pellet mills frequently report that GCr15 roller shells deliver 30–50% longer service life compared to standard alloy steel rollers. In high-capacity biomass pellet production lines, this durability translates to fewer stoppages and more consistent output. Additionally, feed producers highlight that rollers made from GCr15 maintain pellet uniformity, reducing fines and improving pellet durability index (PDI), a critical metric for feed quality.

Maintenance and Care of GCr15 Roller Shells

To maximize the advantages of GCr15, proper care and maintenance are essential:

- Regular Lubrication: Prevents excessive heat build-up and reduces friction.

- Timely Replacement of Worn Dies: Prevents uneven wear on the rollers.

- Surface Treatments: Applying hard coatings or nitriding can further extend roller life.

- Inspection for Micro-Cracks: Even though GCr15 has high fatigue strength, early detection prevents catastrophic failure.

With these practices, GCr15 rollers can achieve optimal service life and consistent performance.

Conclusion

Bearing Steel GCr15 stands out as one of the most reliable materials for pellet mill roller shells. Its superior wear resistance, fatigue strength, dimensional stability, and load-bearing capacity provide significant advantages over mild steel, standard alloy steels, and even stainless steels. While it may carry a slightly higher upfront cost, its long service life and consistent performance make it highly cost-effective for industrial pelletizing operations.

For operators seeking efficiency, reduced downtime, and consistent pellet quality, GCr15 bearing steel is a proven material choice that balances durability, performance, and economic value. In comparison with other materials, it provides the best overall combination of strength, wear resistance, and cost-effectiveness, ensuring smooth and reliable operation in the demanding environment of pellet production.

русский

русский Español

Español عربى

عربى 中文简体

中文简体