Biomass pellet mills are widely used in the production of renewable fuel pellets made from agricultural residues, sawdust, wood chips, and other biomass materials. A critical component of any pellet mill is the ring die, which shapes the raw material into uniform pellets under high pressure and temperature. While the technology has advanced significantly, pellet mill ring dies are still prone to certain operational problems that can reduce productivity, compromise pellet quality, and increase maintenance costs.

This article explores the common problems encountered with biomass pellet mill ring dies, their causes, and practical solutions to ensure optimal performance and extended service life. Understanding these issues is essential for plant operators, maintenance personnel, and engineers working in biomass pellet production.

1. Introduction to Pellet Mill Ring Dies

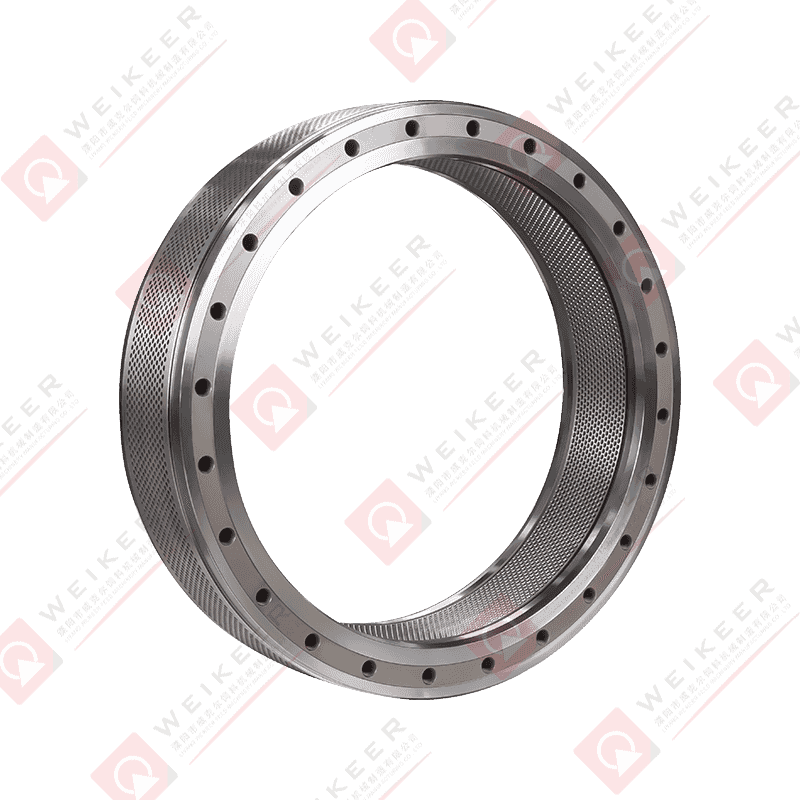

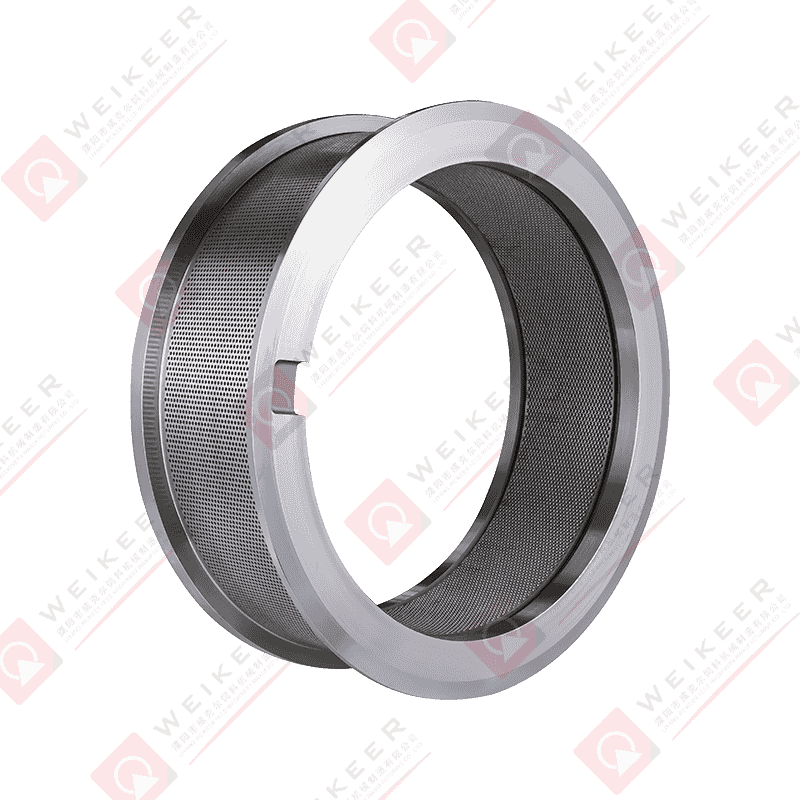

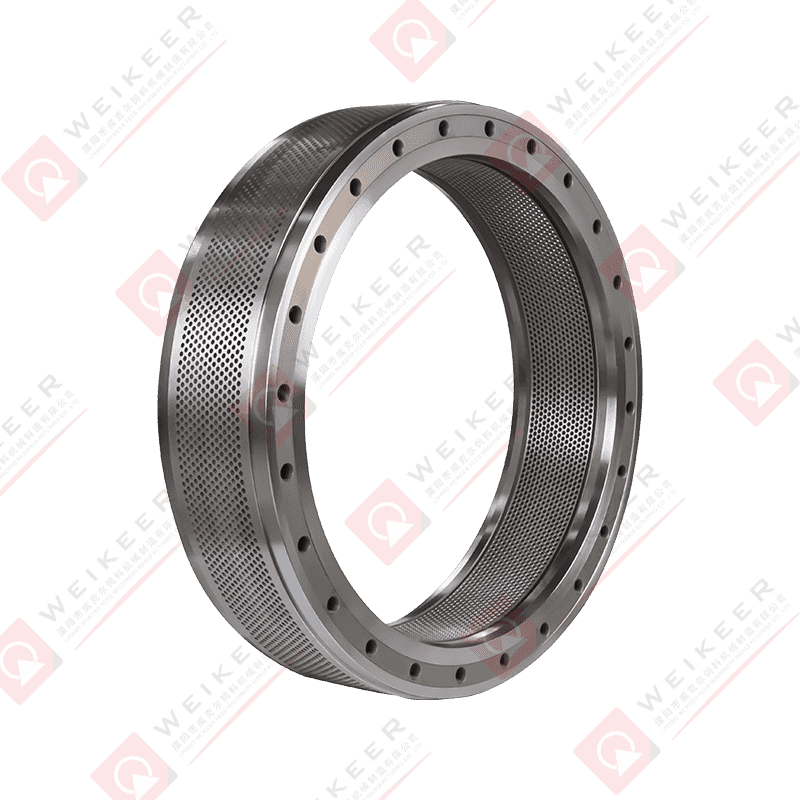

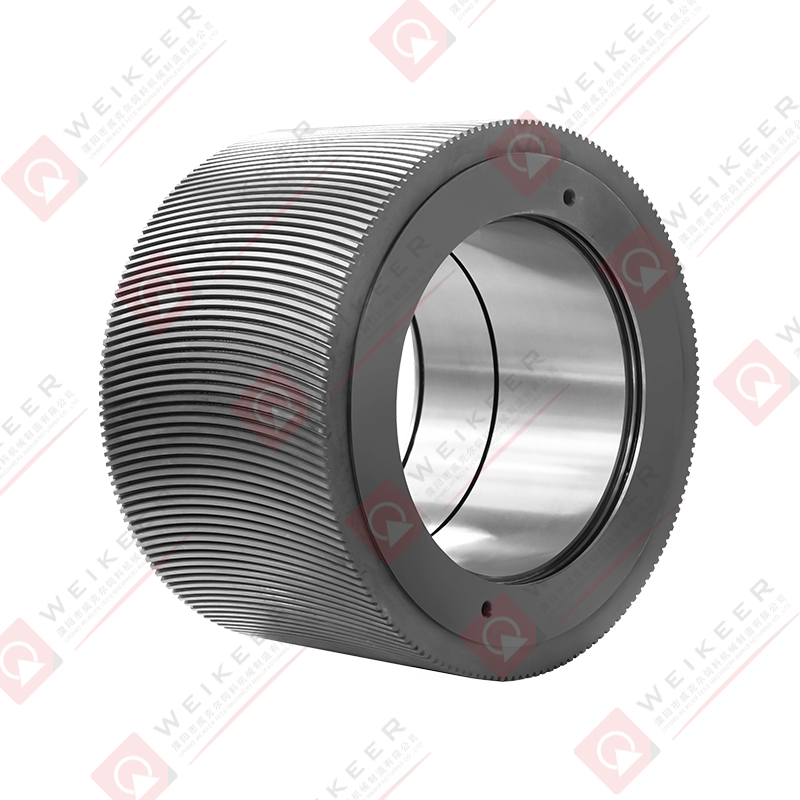

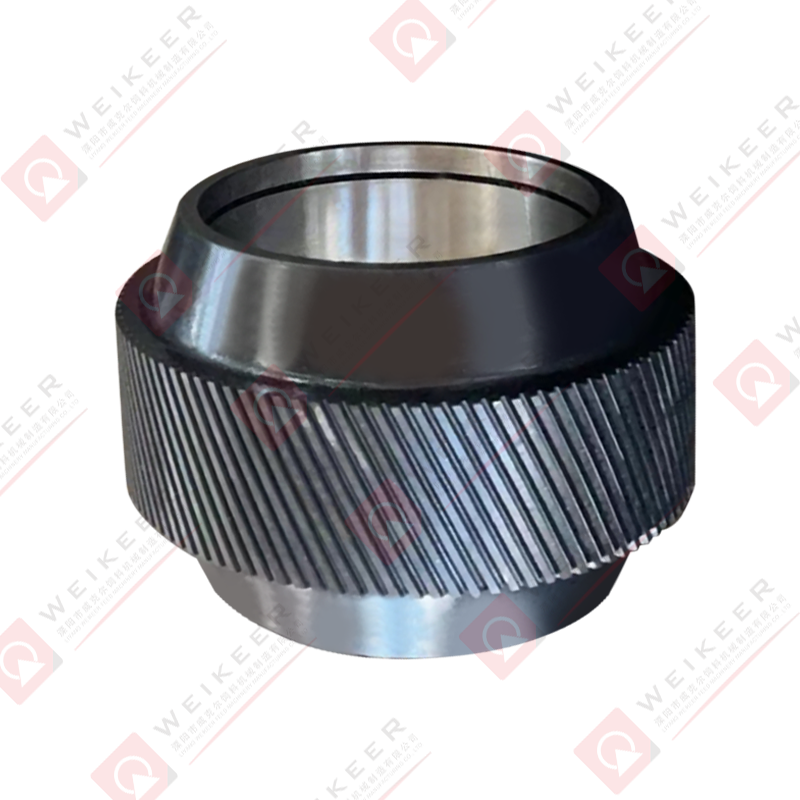

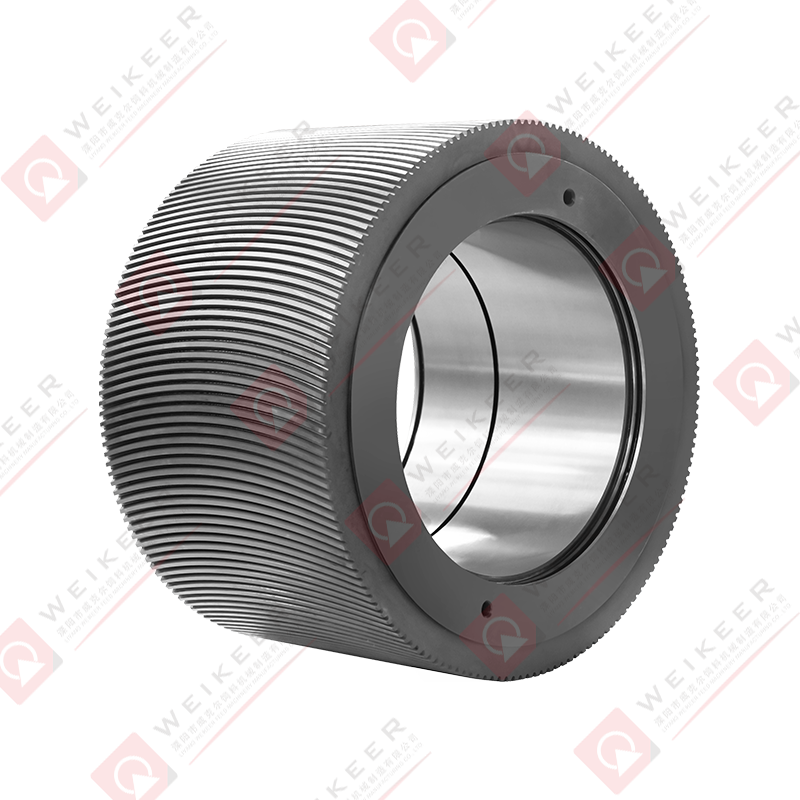

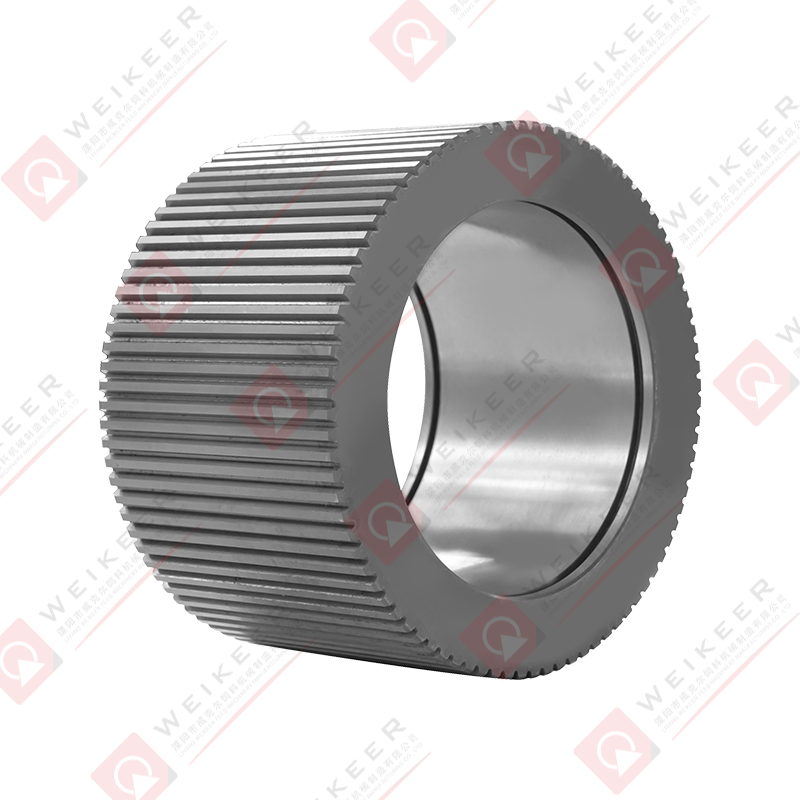

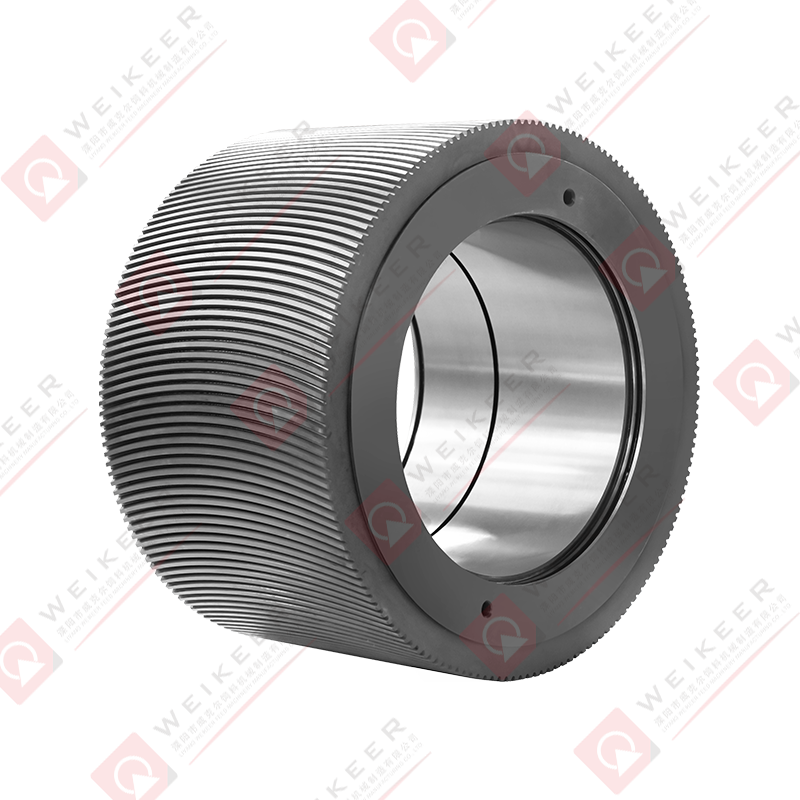

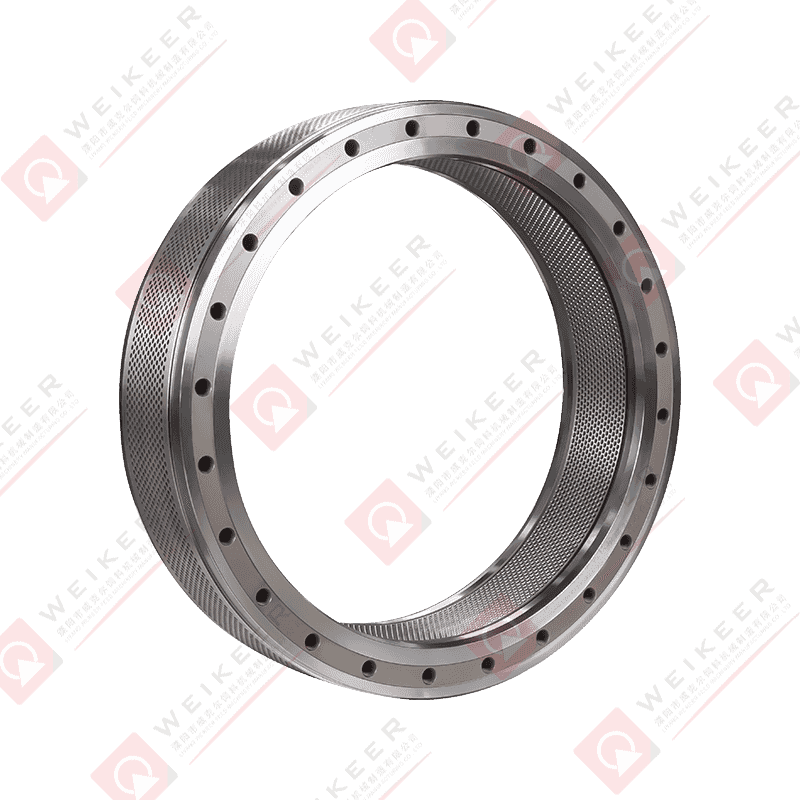

A pellet mill ring die is a cylindrical steel component with numerous holes through which biomass material is forced by rollers. The friction and compression generate heat, softening the material and compacting it into pellets. Ring dies are typically made from high-strength alloy steel or hardened carbon steel to withstand wear, corrosion, and high operational stress.

Functions of the Ring Die:

- Determines pellet diameter and density

- Controls output and feed rate

- Contributes to energy efficiency of the pellet mill

- Influences pellet quality and durability

Despite their robust design, several operational problems can arise due to material properties, improper maintenance, or machine settings.

2. Common Problems with Biomass Pellet Mill Ring Dies

a. Die Wear and Abrasion

Problem:

Over time, the inner surface of the die holes can wear down due to friction with raw materials. This wear may result in:

- Inconsistent pellet diameter

- Poor pellet density and strength

- Reduced output

Causes:

- High silica content or abrasive impurities in biomass

- Improper lubrication of rollers and bearings

- Continuous operation at high speed without maintenance

Solutions:

- Use high-quality, hardened steel dies designed for abrasive materials

- Pre-screen and clean raw biomass to remove sand, grit, or foreign materials

- Implement regular die inspections and timely replacement when wear reaches critical limits

- Optimize roller pressure and feed rate to minimize excessive friction

b. Clogging or Die Blockage

Problem:

Pellet die holes can become blocked, resulting in reduced pellet output and uneven material flow. Severe clogging may halt production entirely.

Causes:

- High moisture content in raw biomass

- Sticky or resinous materials

- Insufficient die rotation or uneven roller pressure

Solutions:

- Ensure raw material moisture content is within the recommended range (usually 10–15%)

- Mix in additives such as sawdust or dry biomass to reduce stickiness

- Regularly clean die holes using specialized brushes or air blowers

- Adjust roller pressure and die speed to prevent material accumulation

c. Cracking or Fracture of the Ring Die

Problem:

Cracks or fractures in the ring die can lead to catastrophic machine failure, posing safety risks and costly downtime.

Causes:

- Overloading the pellet mill

- Thermal stress due to high frictional heat

- Poor-quality steel or improper heat treatment during manufacturing

- Excessive roller pressure or misalignment

Solutions:

- Select dies made from high-quality alloy steel with proper heat treatment

- Monitor operating parameters and avoid overloading the mill

- Ensure even roller pressure and proper alignment

- Conduct regular thermal inspections to identify early signs of cracks

d. Uneven Pellet Formation

Problem:

Pellets may vary in size, shape, or density, affecting quality, storage, and combustion efficiency.

Causes:

- Uneven die hole diameter due to wear

- Inconsistent raw material particle size

- Irregular roller pressure or misaligned die and rollers

Solutions:

- Grind raw biomass to uniform particle size before feeding into the mill

- Inspect die regularly for uniformity and replace if necessary

- Adjust roller pressure and machine alignment to ensure consistent material flow

- Maintain consistent feed rate to the pellet mill

e. Overheating and Thermal Deformation

Problem:

Excessive heat generated during operation can cause die deformation, softening of steel, and reduced lifespan.

Causes:

- High friction due to worn die or excessive roller pressure

- High ambient temperature in the production area

- Poor lubrication of moving components

Solutions:

- Implement proper lubrication for roller bearings and die surfaces

- Operate at recommended speeds and pressure settings

- Use dies with heat-resistant alloy steel designed for high-temperature operation

- Monitor temperature using sensors and allow cooling periods if necessary

f. Corrosion and Rust

Problem:

Ring dies exposed to moisture, acids, or corrosive chemicals can suffer from rust or surface degradation, reducing efficiency and lifespan.

Causes:

- Improper storage in humid environments

- Residual moisture in biomass

- Use of corrosive chemicals during production or cleaning

Solutions:

- Store dies in dry, temperature-controlled areas

- Clean and dry dies after use, especially when producing wet biomass pellets

- Apply corrosion-resistant coatings or select stainless steel dies for harsh chemical environments

g. Roller and Die Misalignment

Problem:

Misalignment between the rollers and the ring die can lead to uneven wear, increased friction, and poor pellet quality.

Causes:

- Improper installation or adjustments

- Machine foundation settling or vibrations

- Worn bearings or shafts

Solutions:

- Perform precise alignment during installation

- Conduct routine maintenance checks for alignment and bearing condition

- Replace worn components promptly to prevent uneven wear

3. Preventive Maintenance Strategies

Effective preventive maintenance can significantly extend the life of biomass pellet mill ring dies:

- Regular Inspection: Check for wear, cracks, corrosion, and alignment issues at scheduled intervals.

- Lubrication: Ensure proper lubrication of rollers, bearings, and other moving parts to reduce friction and heat.

- Raw Material Preparation: Control moisture content, particle size, and remove abrasive impurities.

- Operational Monitoring: Monitor machine load, pressure, speed, and temperature to maintain optimal operating conditions.

- Cleaning Procedures: Regularly clean die holes and surrounding surfaces to prevent clogging and material buildup.

- Replacement Planning: Maintain a schedule for die replacement based on wear indicators rather than waiting for complete failure.

4. Innovations to Reduce Ring Die Problems

Modern pellet mills incorporate several innovations to reduce die-related problems:

- Advanced Alloy Dies: Using tungsten carbide coatings or high-strength alloys to resist wear and corrosion.

- Cooling Systems: Integrating air or water cooling to maintain optimal die temperature.

- Automatic Lubrication: Ensuring consistent lubrication reduces friction and overheating.

- Vibration Monitoring: Sensors detect misalignment or imbalance to prevent damage.

- Optimized Die Design: CAD-based die geometries improve material flow and reduce clogging.

5. Conclusion

The biomass pellet mill ring die is a vital component in ensuring efficient and consistent pellet production. However, it is subject to several common problems, including:

- Wear and abrasion

- Clogging or blockage

- Cracking or fracture

- Uneven pellet formation

- Overheating and thermal deformation

- Corrosion and rust

- Roller and die misalignment

Understanding the causes and implementing practical solutions—such as proper material selection, routine maintenance, careful raw material preparation, and monitoring operational parameters—can greatly enhance the performance, lifespan, and safety of ring dies.

By proactively addressing these issues, pellet mill operators can maximize output, maintain high pellet quality, reduce downtime, and extend the service life of ring dies, ultimately improving the overall efficiency and profitability of biomass pellet production operations.

русский

русский Español

Español عربى

عربى 中文简体

中文简体