In the feed and biomass pellet industry, efficiency, durability, and precision are critical. One of the most vital components that directly affects output and quality is the screw type stainless steel ring die used in pellet mills. But what exactly is a screw type stainless steel ring die? How does it work, and why is it preferred over other materials or designs? This article provides an in-depth exploration of its features, benefits, applications, and maintenance tips.

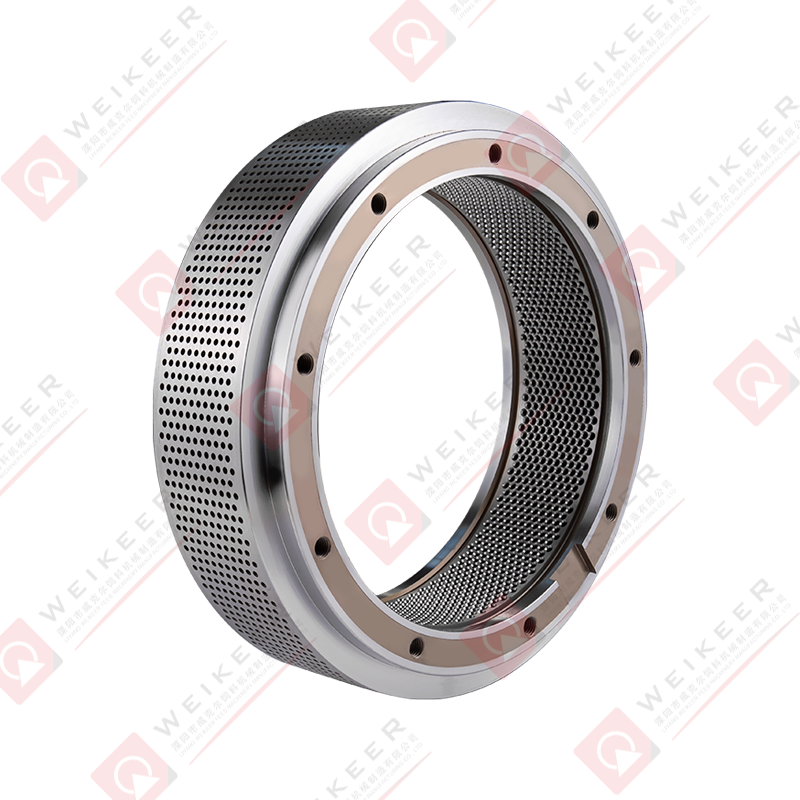

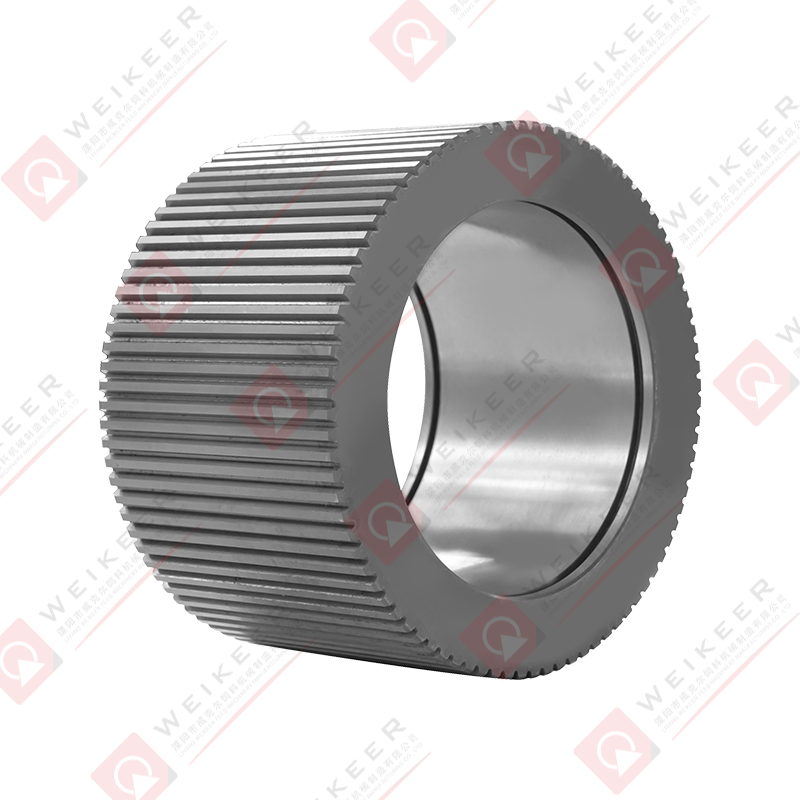

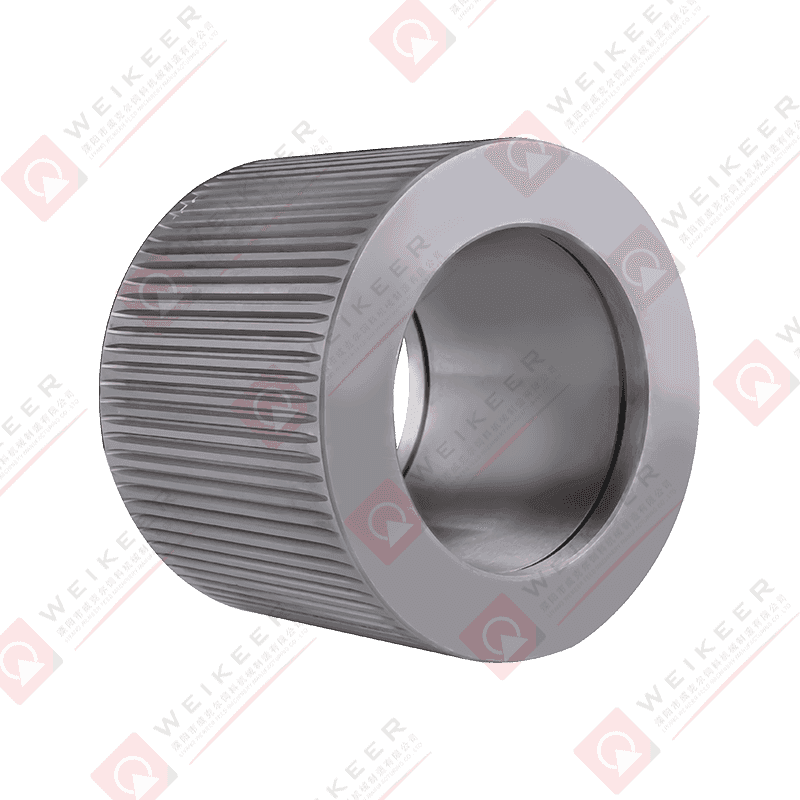

1. What Is a Screw Type Stainless Steel Ring Die?

A screw type stainless steel ring die is a crucial component of a pellet mill, responsible for shaping raw materials into uniform pellets. The ring die has a circular structure with precisely engineered holes through which the feedstock is forced by the screw shaft. Stainless steel construction ensures high strength, corrosion resistance, and durability, which are essential for high-volume production and abrasive materials.

This combination of screw extrusion and ring die technology allows for efficient compression and uniform pellet formation, reducing waste and ensuring consistent quality.

2. How Does a Screw Type Ring Die Work in a Pellet Mill?

- Material Feeding – Raw materials, such as animal feed ingredients, biomass, or wood powder, are fed into the pellet mill chamber.

- Screw Extrusion – The screw pushes the material toward the ring die, generating pressure and shear force.

- Pellet Formation – Material is forced through the holes of the stainless steel ring die, forming cylindrical pellets.

- Cutting and Cooling – A knife trims the pellets to the desired length, which are then cooled and stored for use.

The screw type mechanism ensures continuous feeding, uniform pressure, and minimal energy loss, making it ideal for both small and large-scale production.

3. Key Features and Advantages

| Feature |

Description |

Benefit |

| Stainless Steel Construction |

High-grade stainless steel resistant to corrosion and wear |

Longer service life, lower maintenance costs |

| Screw Type Feeding |

Screw shaft pushes material uniformly through the ring die |

Ensures consistent pellet density and size |

| Precision Engineering |

Accurate hole diameter and spacing |

Produces uniform pellets, reduces waste |

| High Efficiency |

Optimized design reduces friction and energy loss |

Lower operating costs and higher throughput |

| Wide Material Compatibility |

Can process biomass, wood, feed, and agro-industrial materials |

Versatile for various industries |

| Replaceable Components |

Ring dies and screws can be replaced individually |

Simplifies maintenance and reduces downtime |

| Corrosion and Abrasion Resistance |

Stainless steel withstands moisture and abrasive particles |

Maintains efficiency even in harsh conditions |

4. Applications of Screw Type Stainless Steel Ring Die Pellet Mills

- Animal Feed Production – Produces feed pellets for poultry, livestock, aquaculture, and pets.

- Biomass Energy – Converts wood chips, sawdust, straw, and other biomass into fuel pellets.

- Agricultural Waste Management – Recycles crop residues and byproducts into high-value pellets.

- Industrial Applications – Pelletizing chemical powders or other granular materials for industrial use.

- Renewable Energy Projects – Provides consistent and uniform biomass pellets for boilers, stoves, and power plants.

5. How to Choose the Right Screw Type Stainless Steel Ring Die

-

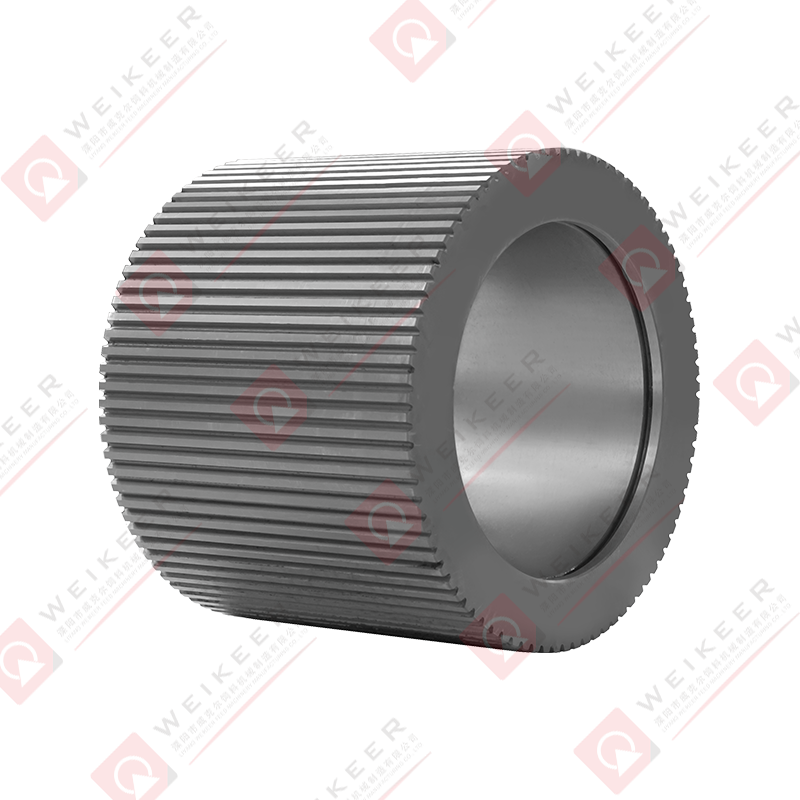

Material Hardness

- Stainless steel grade and surface treatment affect durability, especially when processing abrasive materials.

-

Hole Diameter and Density

- Determines pellet size, density, and production capacity. For example, 2–12 mm hole diameters are common in feed and biomass pellet mills.

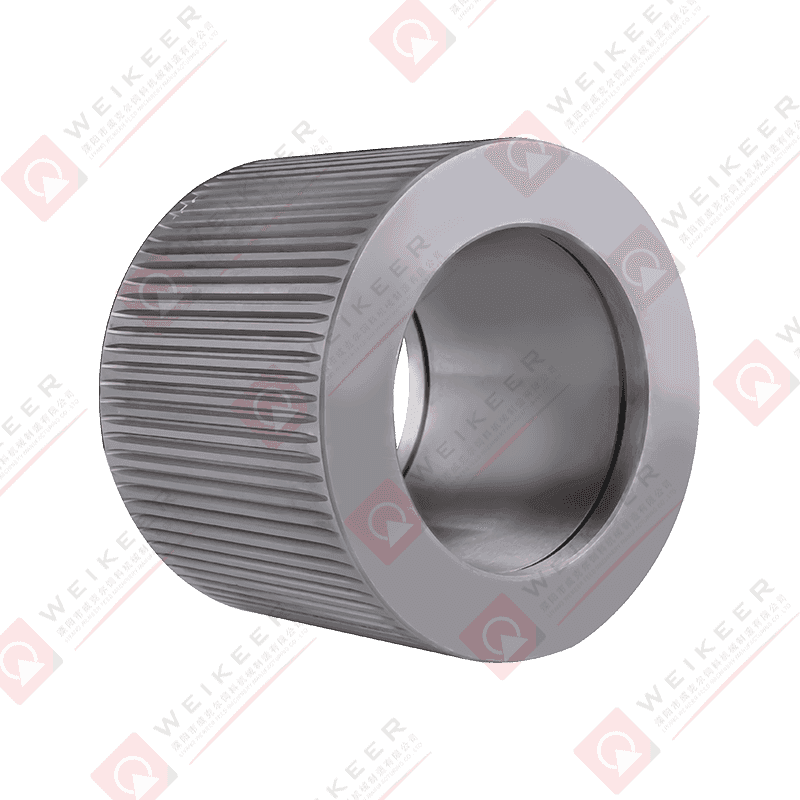

-

Ring Die Thickness

- Thicker dies withstand high pressure and prolonged operation but may require stronger motors.

-

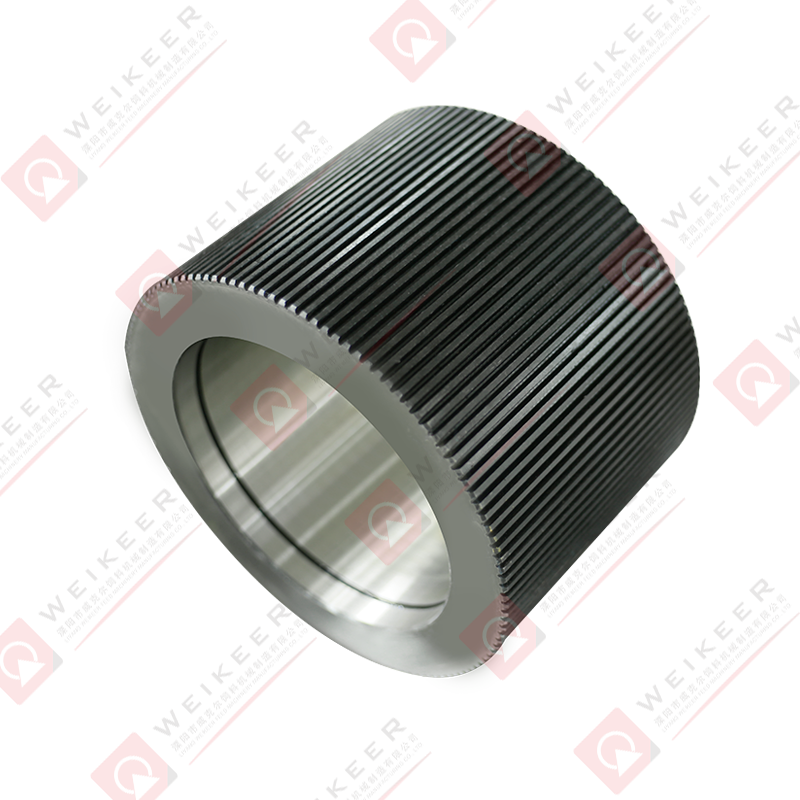

Screw Type Design

- Single-screw or double-screw configurations affect feeding uniformity and production efficiency.

-

Compatibility with Pellet Mill

- Ensure the die’s dimensions match the mill’s specifications to maintain performance and safety.

6. Maintenance Tips for Stainless Steel Ring Dies

- Regular Cleaning – Remove residual material after each production cycle to prevent blockage and corrosion.

- Lubrication – Apply appropriate lubrication to moving parts to reduce friction and wear.

- Check Alignment – Ensure screws and dies are properly aligned to prevent uneven wear.

- Inspect for Wear – Monitor hole edges and surface for signs of abrasion or corrosion.

- Timely Replacement – Replace worn dies or screws before they affect pellet quality or damage the mill.

7. Benefits of Using Stainless Steel Ring Dies

- Longer Lifespan – Stainless steel resists corrosion, rust, and wear, extending die life compared to cast iron or mild steel.

- Consistent Pellet Quality – Uniform hole design ensures even pellet density and size.

- Reduced Maintenance – Corrosion and wear resistance lower downtime and repair costs.

- High Production Efficiency – Optimized screw feeding and die design improve output and reduce energy consumption.

- Versatility – Suitable for a wide range of feedstock materials, from soft grains to hard biomass.

8. Conclusion

The screw type stainless steel ring die is a vital component in pellet mills, directly impacting production efficiency, pellet quality, and equipment longevity. Its precision engineering, durable material, and versatile design make it indispensable for animal feed manufacturers, biomass energy producers, and industrial pellet applications.

By selecting the right die based on material, hole size, thickness, and compatibility, and following proper maintenance practices, manufacturers can achieve consistent output, high-quality pellets, and reduced operational costs.

For anyone involved in pellet production, investing in high-quality stainless steel screw type ring dies is a smart decision that ensures reliability, efficiency, and long-term value.

русский

русский Español

Español عربى

عربى 中文简体

中文简体