In the growing world of biomass energy and animal feed production, pellet mills have emerged as vital machinery. At the heart of every highperformance pellet mill lies a crucial component: the ring die. Among various ring die configurations, the screw type stainless steel ring die is gaining increasing attention due to its exceptional durability, uniformity, and efficiency.

This article explores the importance, advantages, and applications of screw type stainless steel ring dies in pellet mills, providing valuable insight for manufacturers, processors, and investors in the biomass and feed industries. If you’re looking to boost production, improve pellet quality, or reduce downtime, understanding this component is essential.

What Is a Screw Type Stainless Steel Ring Die?

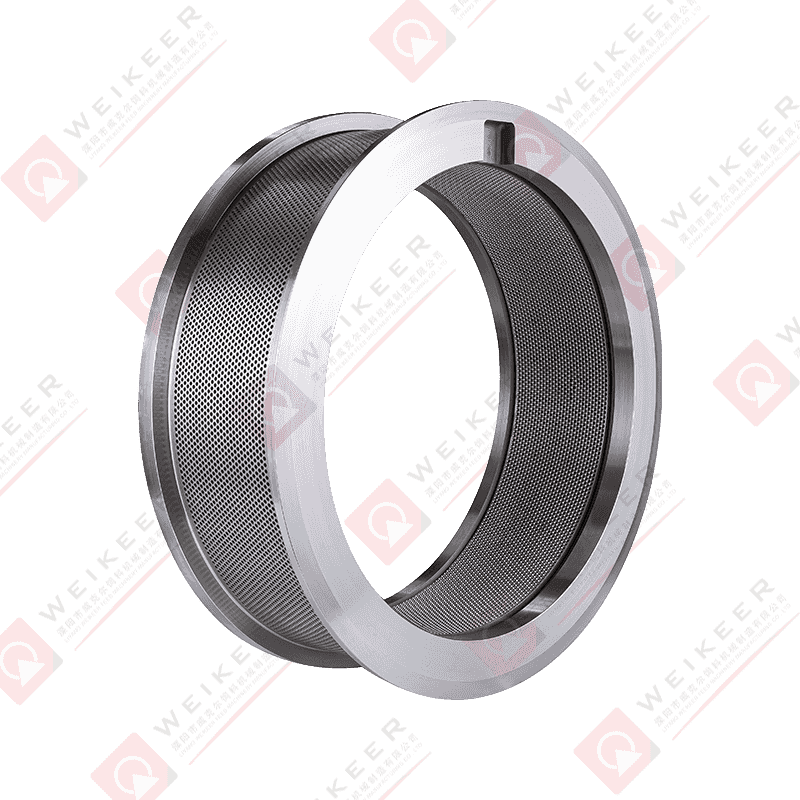

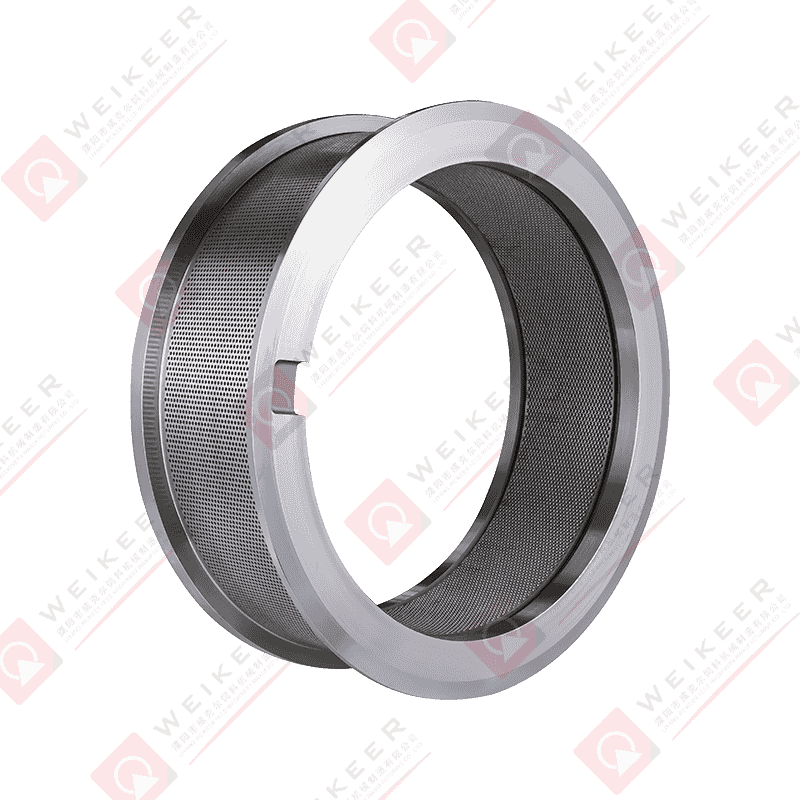

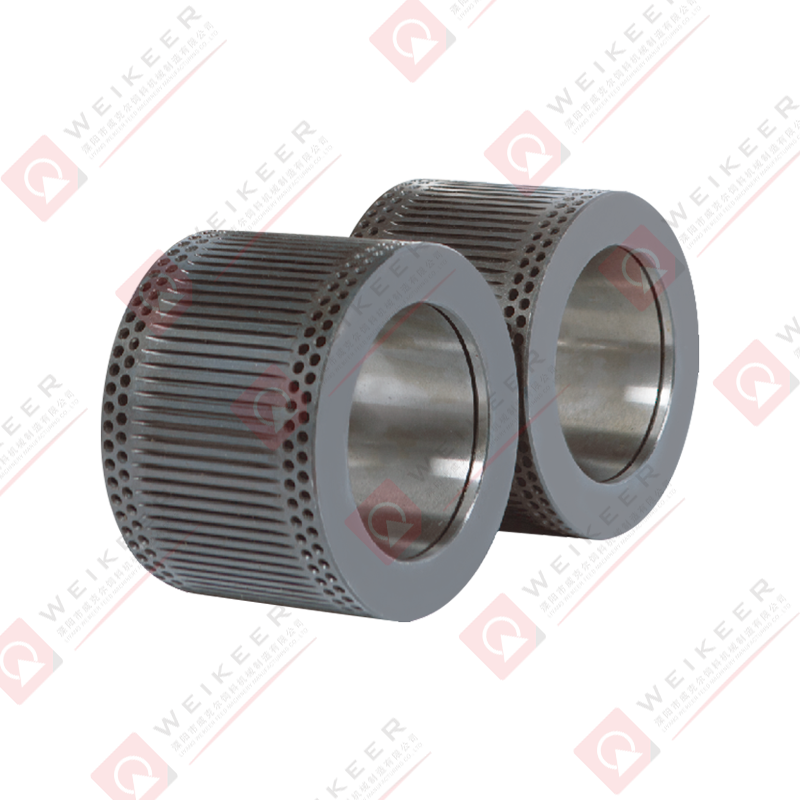

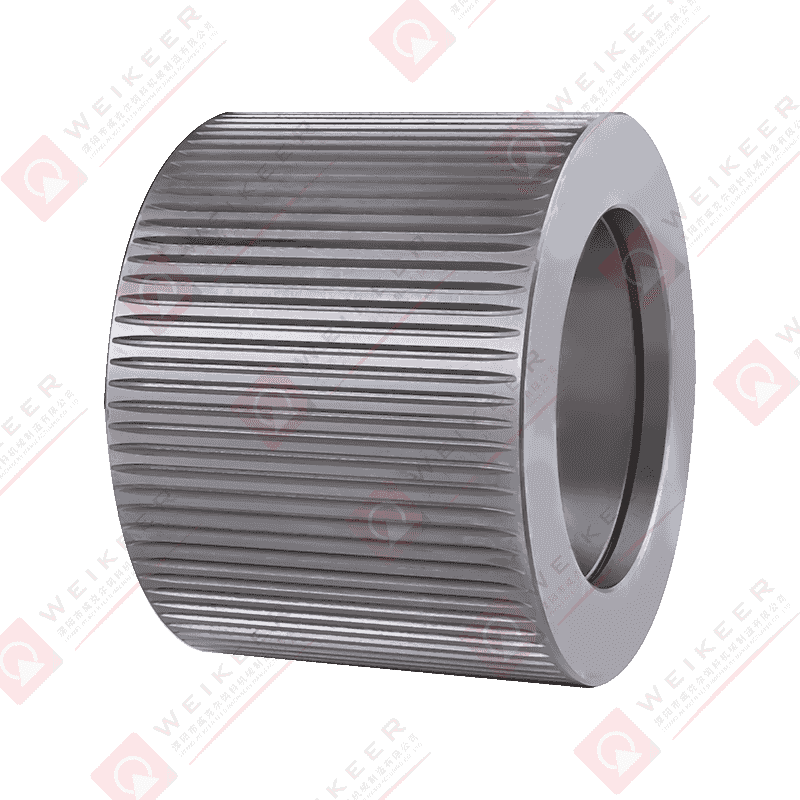

A ring die is a cylindrical steel component with radial holes through which powdered material is compressed to form pellets. It rotates within the pellet mill, working together with rollers to apply pressure and force the material through the die holes, producing dense, uniform pellets.

The screw type ring die refers to how the die is secured into the pellet mill—using a screwfastening mechanism rather than traditional locking systems. This setup offers greater stability, easier maintenance, and better alignment during operation.

Using stainless steel adds another layer of benefit—enhancing the die’s resistance to wear, corrosion, and high pressure. It’s the perfect combination of strength and precision for processing wood, biomass, feed, or fertilizer.

Key Advantages of Screw Type Stainless Steel Ring Die

1. Exceptional Durability and Wear Resistance

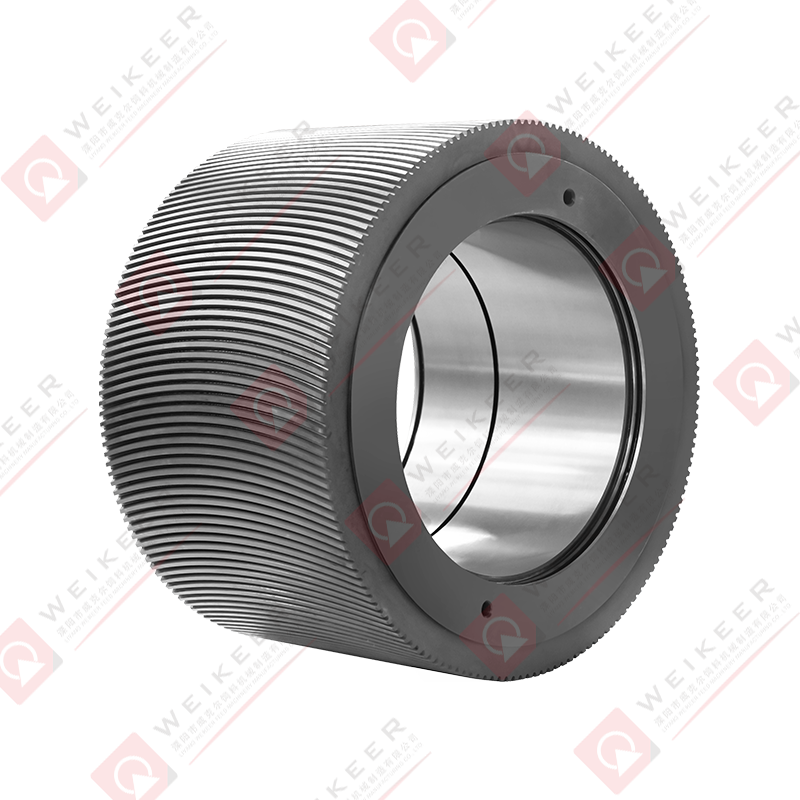

Stainless steel ring dies offer superior hardness and longevity. They resist deformation, cracking, and abrasion—even under highpressure continuous production. This extends the die’s service life, reducing replacement frequency and improving costefficiency.

2. Corrosion Resistance for Wet or Acidic Material

Pellet mills often process materials with high moisture content or acidic properties. Stainless steel resists corrosion far better than carbon steel, making it ideal for wood pellets, palm fiber, alfalfa, and aquatic feed production.

3. Precision Machining for High Pellet Quality

Screw type ring dies are manufactured with CNC precision machining, ensuring uniform hole size and smooth surfaces. This results in consistent pellet dimensions, fewer fines, and enhanced bulk density. Higher pellet quality means better combustion in energy applications and better digestibility in feed production.

4. Improved Pellet Mill Performance

The screw type installation allows for tighter and more secure fastening, reducing vibration and improving alignment. This enhances the machine’s efficiency, leading to higher output rates and less energy consumption.

5. Faster and Easier Maintenance

Thanks to the screwtype fastening system, installation and replacement of the ring die becomes much faster and safer. This is particularly beneficial in highvolume factories where downtime needs to be minimized. Technicians can swap dies with minimal tools and effort, keeping production lines moving smoothly.

6. Customization for Various Materials

Whether you’re producing hardwood pellets, poultry feed, or fertilizer, screw type stainless steel ring dies can be customdrilled in terms of hole diameter, compression ratio, and hardness—ensuring optimized performance for your specific raw materials.

Common Applications

Screw type stainless steel ring dies are used in various industries, especially where reliability and longterm performance are critical:

Biomass Pellet Production

Including sawdust, wood chips, straw, rice husk, and other agricultural waste.

Animal Feed Manufacturing

Used for poultry feed, cattle feed, pig feed, and aquatic feed formulations.

Fertilizer Pelletizing

Helps compress organic or compound fertilizer powder into manageable pellet forms.

Recycling and WastetoEnergy Processing

Converts waste plastics or biomass into energy pellets.

Why Stainless Steel Ring Dies Outperform Standard Steel

While carbon steel dies are more affordable upfront, stainless steel ring dies offer significant longterm value. They retain their structural integrity under higher loads, last longer under abrasive conditions, and resist rust even in humid environments. This makes stainless steel an ideal choice for professional pellet producers seeking high throughput and minimal maintenance.

Moreover, stainless steel is easier to clean and doesn’t react chemically with the materials being processed, ensuring product purity—especially important in feed and foodrelated applications.

Factors to Consider When Choosing a Screw Type Ring Die

If you're upgrading or replacing a ring die, here are critical aspects to evaluate:

1. Material Grade – Choose highquality stainless steel (typically SUS304 or SUS316) for optimal resistance and longevity.

2. Hole Compression Ratio – This affects the density and hardness of the pellet. Materials like softwood need different ratios than alfalfa or corn stalks.

3. Die Thickness – Thicker dies last longer but may require more power to operate.

4. Cooling and Lubrication – Check if the die supports cooling channels or if the pellet mill requires additional lubrication systems.

5. Machine Compatibility – Ensure the screwtype die matches your specific pellet mill brand and model.

Boosting Productivity and Profit with the Right Ring Die

A poorly performing ring die can cause:

Pellet jamming

Uneven pellet sizes

Frequent downtime

Increased energy consumption

Lower product yield

By contrast, a highperformance screw type stainless steel ring die maximizes machine efficiency, enhances pellet quality, and cuts down maintenance time. This ultimately contributes to greater profitability and smoother operations.

Whether you're a smallscale feed producer or running a large biomass pellet plant, investing in quality components pays off.

Final Thoughts

The screw type stainless steel ring die is more than just a part—it’s the engine that drives efficiency in your pelletizing operations. Combining robust structure, precision engineering, and easy installation, this ring die type has become the preferred solution for modern pellet mill manufacturers and processors.

русский

русский Español

Español عربى

عربى 中文简体

中文简体