In modern pellet production, whether for biomass, animal feed, or wood fuel, the performance and longevity of roller shells play a decisive role in the overall efficiency of the pellet mill. Among the various materials used, bearing steel has become a preferred choice due to its excellent hardness, wear resistance, and fatigue strength. However, even the most durable bearing steel roller shells require proper maintenance and operational management to achieve optimal performance and service life. This article explores the key strategies to maintain and extend the life of bearing steel roller shells in pellet production lines.

1. Understanding the Role of Bearing Steel Roller Shells

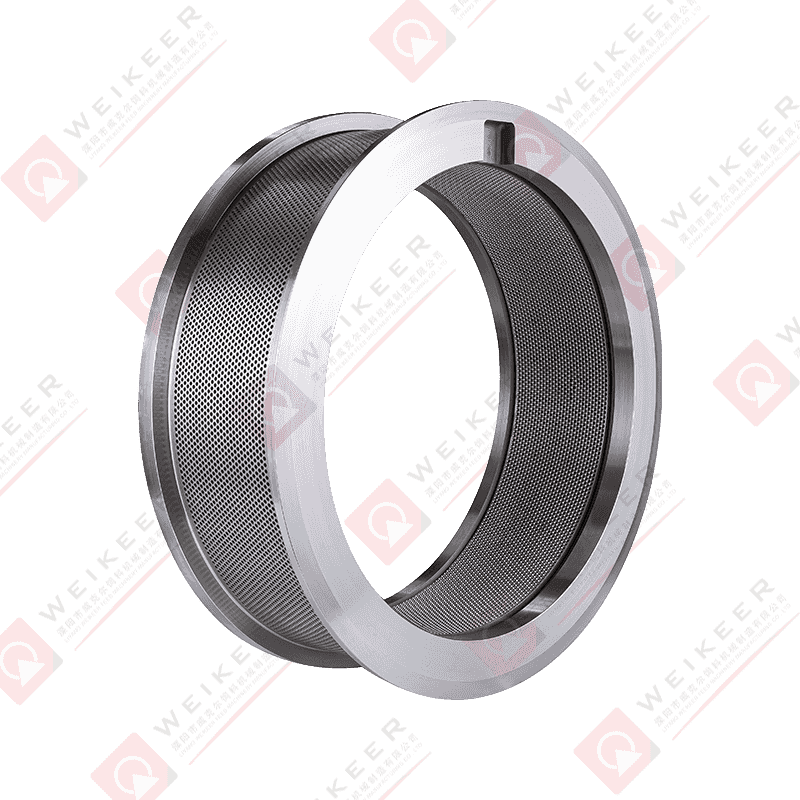

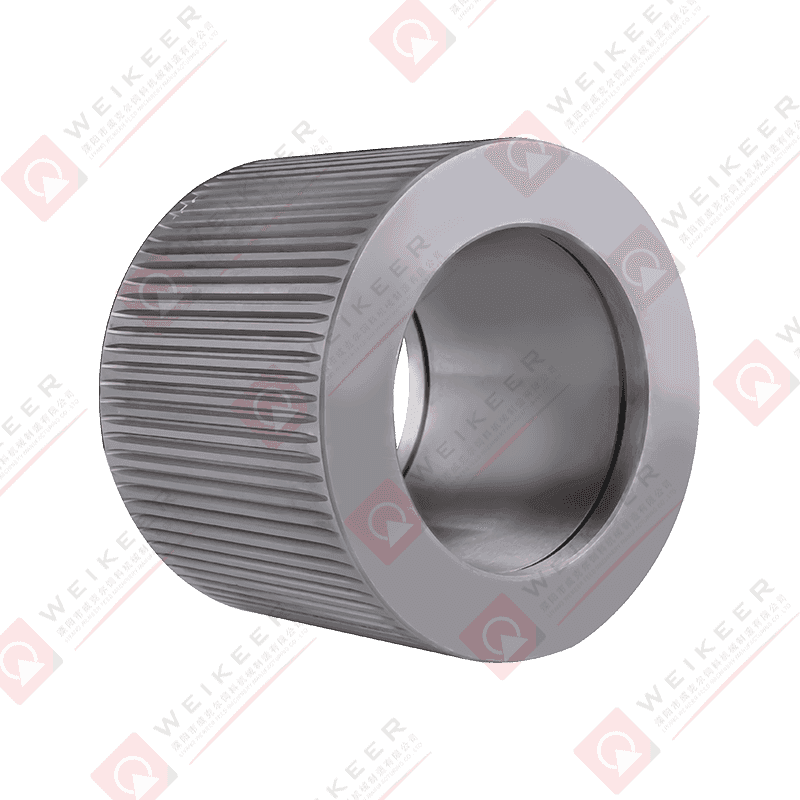

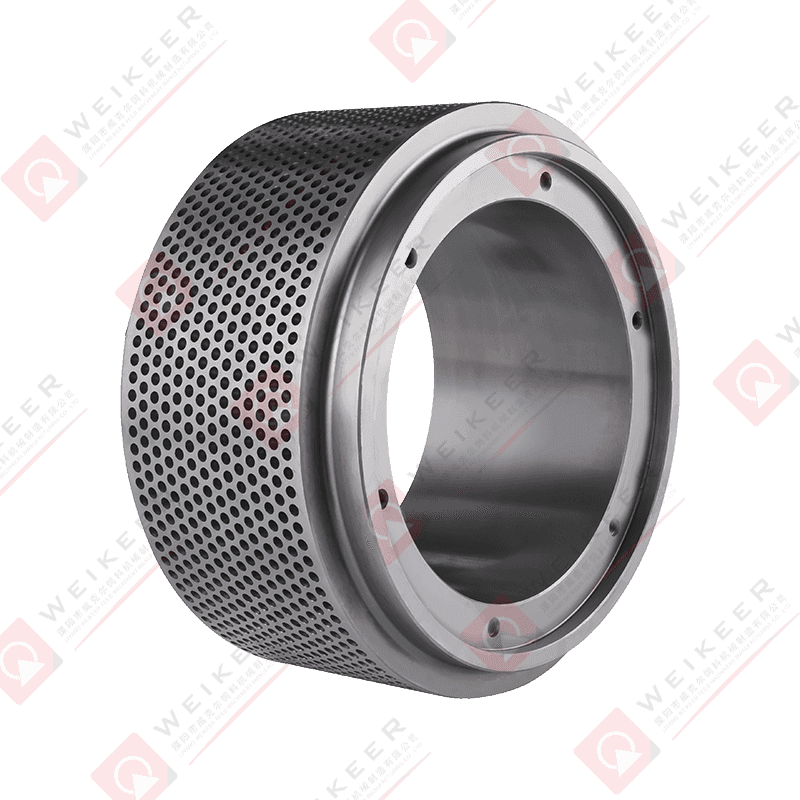

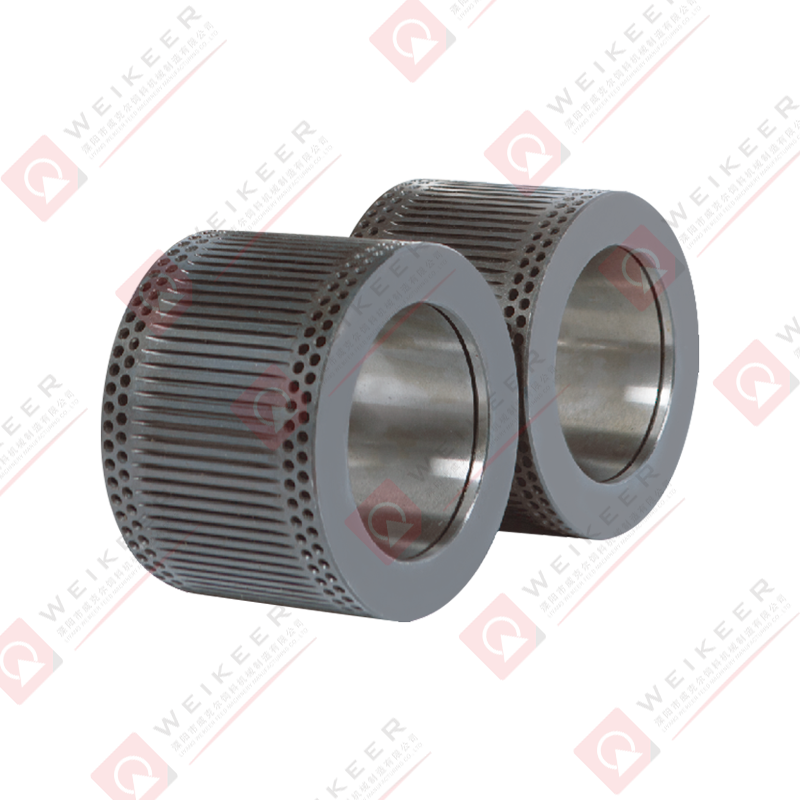

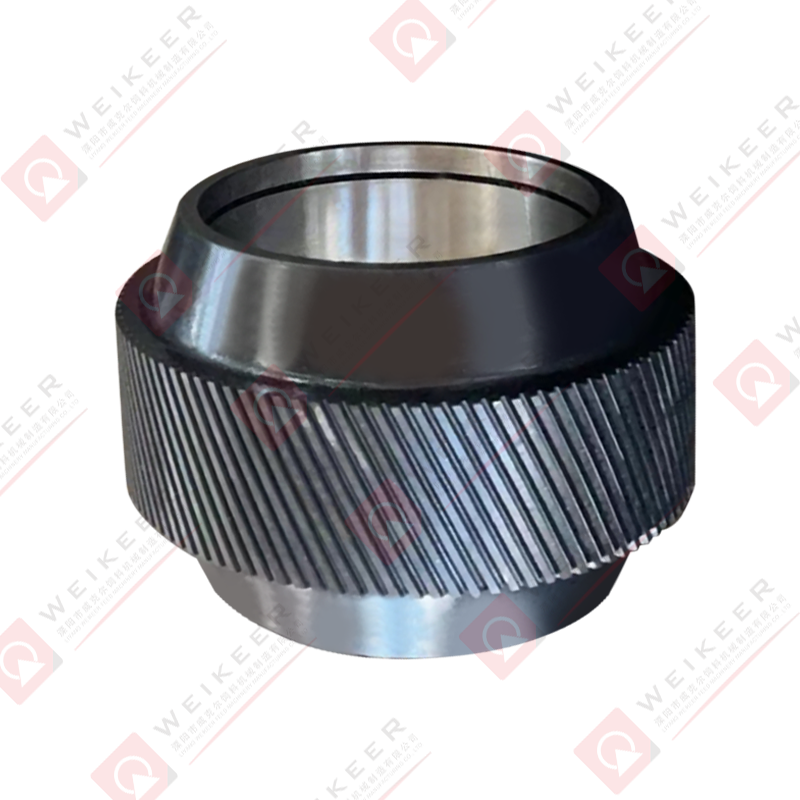

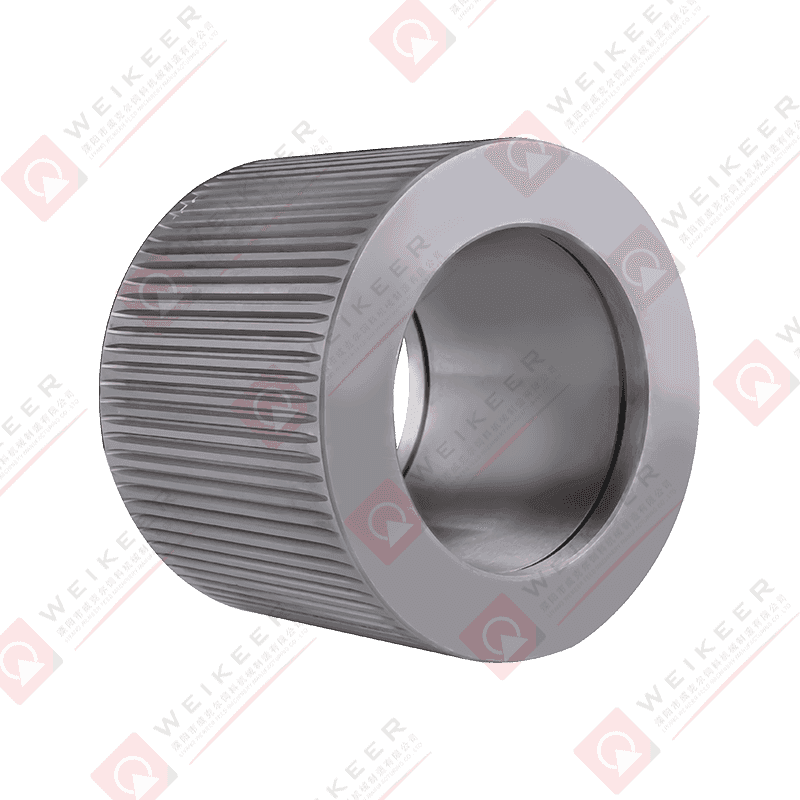

Roller shells are the main components responsible for compressing raw materials through the die holes in a pellet mill. Made from high-quality bearing steel (commonly GCr15 or equivalent), they endure extreme pressure, friction, and temperature during continuous operation. Bearing steel’s high carbon and chromium content provides superior surface hardness (typically 60–65 HRC) and excellent fatigue resistance, enabling it to withstand long-term stress and abrasive wear.

However, the working environment of a pellet mill — involving constant contact with fibrous, sometimes corrosive, or hard particles — means that even the strongest roller shells will degrade over time. The rate of wear depends heavily on maintenance, lubrication, operating conditions, and raw material quality.

2. Proper Installation and Alignment

The foundation of long service life begins with correct installation. Misalignment between the roller shells and the die can cause uneven pressure distribution, resulting in premature wear or cracking.

- Ensure parallel alignment: The roller and die must be perfectly parallel to distribute the load evenly.

- Check for concentricity: Misalignment can create vibration and excessive localized stress.

- Use precision tools: Laser alignment or dial indicators are recommended for accurate setup.

Improper alignment may cause the roller shells to wear unevenly on one side, reducing pellet quality and potentially damaging the pellet mill spindle or bearings.

3. Optimal Lubrication Practices

Lubrication is one of the most critical factors influencing the longevity of bearing steel roller shells. Friction and heat generation can lead to micro-cracks, pitting, and surface fatigue if lubrication is insufficient or contaminated.

- Use high-temperature-resistant lubricants: Synthetic greases with anti-wear and anti-oxidation additives are recommended.

- Maintain a clean lubrication system: Contaminants such as dust or raw material particles can mix with the grease and create abrasive paste.

- Establish a consistent lubrication schedule: Automatic or centralized systems ensure steady and uniform grease distribution.

- Avoid over-lubrication: Excess grease can trap heat, degrade seals, and attract dust, accelerating wear.

A well-maintained lubrication system minimizes friction, prevents overheating, and preserves the surface integrity of the roller shell.

4. Controlling Raw Material Quality

The nature of the raw material directly affects roller shell wear. Contaminants such as sand, metal fragments, or stones act as abrasives that rapidly erode the working surface.

- Screen and clean materials: Use magnetic separators and sieves to remove ferrous and non-ferrous impurities before pelleting.

- Control moisture content: Ideal moisture (usually 10–15%) ensures smoother compression and prevents excessive friction.

- Uniform particle size: Consistent granularity reduces roller vibration and uneven load.

Clean, consistent, and properly conditioned feedstock not only improves pellet quality but also significantly extends the life of the roller shell.

5. Monitoring Operating Conditions

Pellet mills operate under high mechanical loads. Excessive pressure, speed, or feed rate can accelerate roller shell degradation.

- Avoid overloading: Overfeeding the mill increases pressure on the rollers, leading to surface fatigue and metal fatigue.

- Maintain optimal speed: Too high a speed increases friction and temperature, while too low a speed can cause slippage and uneven wear.

- Monitor temperature: Bearing steel loses hardness when exposed to prolonged high temperatures. Use thermal sensors to detect overheating early.

- Adjust roller-die gap: The gap should be precisely set based on material type; a smaller gap produces denser pellets but increases stress on the rollers.

Regular monitoring of these parameters helps operators maintain stable production and reduce mechanical stress on the roller shells.

6. Regular Inspection and Preventive Maintenance

Routine inspections can detect early signs of wear or failure, allowing timely intervention before costly downtime occurs.

- Visual inspection: Check for surface cracks, grooves, or uneven wear.

- Measure hardness: Over time, the working surface may soften due to heat; re-hardening or replacement may be required.

- Monitor bearing conditions: Damaged bearings cause misalignment, vibrations, and additional wear on roller shells.

- Scheduled replacement: Even with perfect maintenance, roller shells have a finite lifespan. Establish a preventive replacement schedule based on operating hours and production volume.

Implementing a digital maintenance log or predictive monitoring system can further optimize maintenance intervals.

7. Correct Handling and Storage

Bearing steel roller shells should be treated as precision components. Improper handling or storage can lead to corrosion, deformation, or surface damage even before installation.

- Store in a dry, temperature-controlled environment: Moisture can cause corrosion on the polished steel surface.

- Apply protective oil coating: This prevents oxidation during long-term storage.

- Avoid impact: Dropping or striking the roller shell can cause micro-fractures invisible to the naked eye but detrimental during operation.

Proper handling ensures that roller shells retain their mechanical integrity until they are ready for use.

8. Surface Reconditioning and Reuse

In some cases, worn bearing steel roller shells can be reconditioned through machining and heat treatment processes.

- Regrinding the surface: Removes worn layers and restores the correct profile.

- Re-hardening: Induction or case hardening can restore surface hardness to near-original levels.

- Re-coating: Applying wear-resistant coatings like tungsten carbide can improve durability in abrasive environments.

Reconditioning offers an economical alternative to replacement while maintaining satisfactory performance, provided the structural integrity remains intact.9. Importance of Operator Training

Even the most advanced equipment and materials can fail prematurely if operators are not properly trained. Operators should understand the mechanical principles of roller and die interaction, lubrication procedures, and troubleshooting techniques.

- Train staff on maintenance schedules and inspection routines.

- Provide guidelines for adjusting feed rates and pressure settings.

- Promote awareness of early warning signs of roller wear.

A skilled and attentive operator is the best insurance against unexpected breakdowns.

10. Conclusion

The service life of bearing steel roller shells in pellet mills depends not only on material quality but also on how the equipment is operated and maintained. From installation and lubrication to raw material control and periodic inspection, every detail contributes to performance stability and cost efficiency.

By following proper maintenance strategies — ensuring alignment, using clean and well-lubricated systems, maintaining optimal operating parameters, and training personnel — pellet manufacturers can significantly extend roller shell lifespan, improve pellet quality, and reduce overall production costs.

Ultimately, proactive maintenance and attention to operational detail transform bearing steel roller shells from consumable components into long-lasting assets within the pellet production process.

русский

русский Español

Español عربى

عربى 中文简体

中文简体