Screw-type ring dies are critical wear parts in pellet mills. Proper maintenance and cleaning not only preserve pellet quality but also significantly extend die service life and reduce operating costs. This article delivers a hands-on, practical procedure for routine inspection, cleaning, preventive maintenance, troubleshooting, and reconditioning of screw-type ring dies. It focuses on techniques you can implement in an industrial environment with standard shop tools and safety practices.

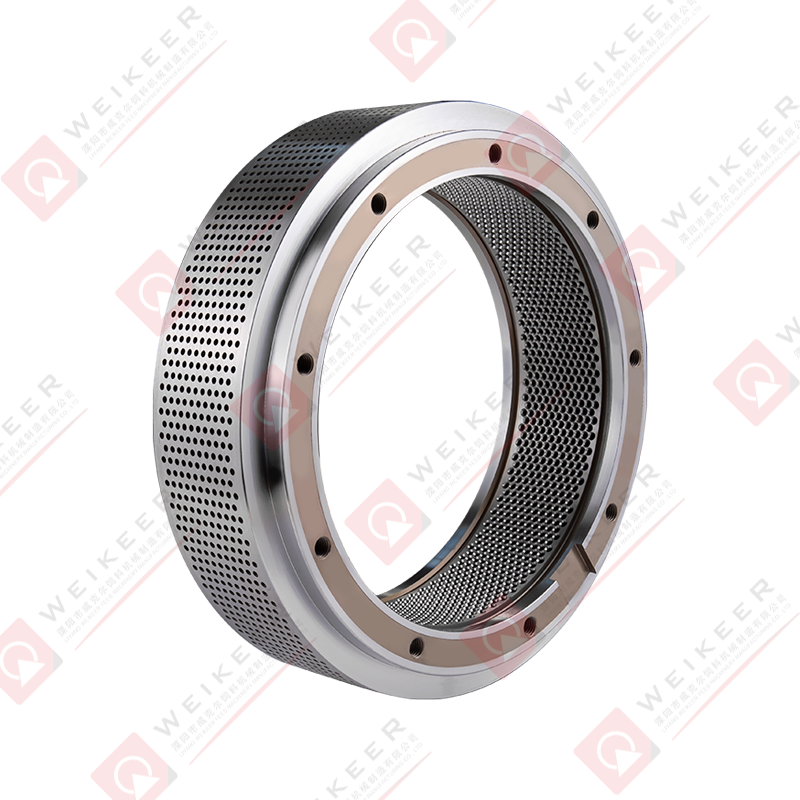

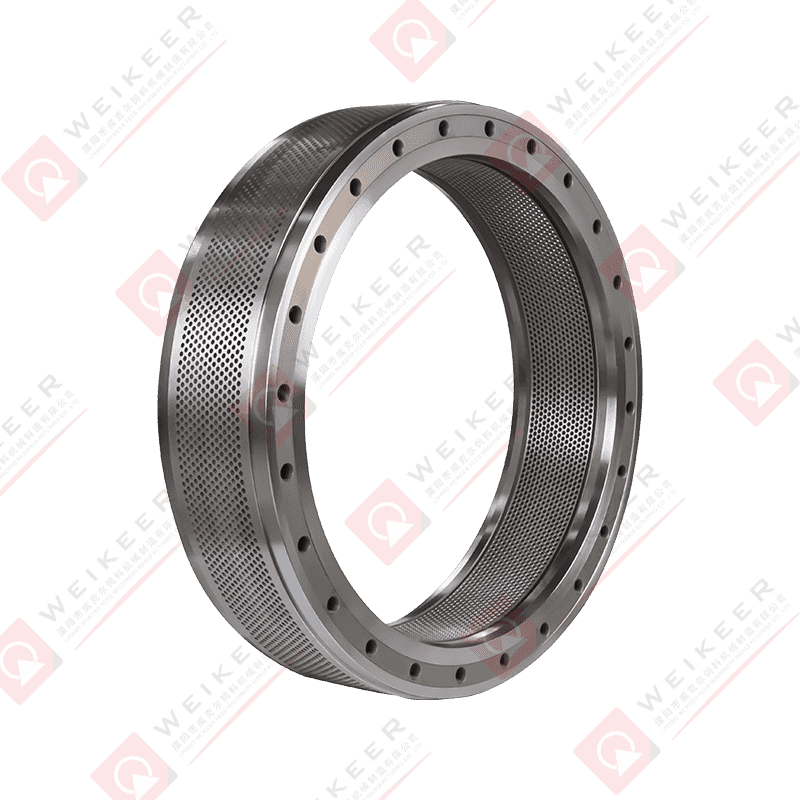

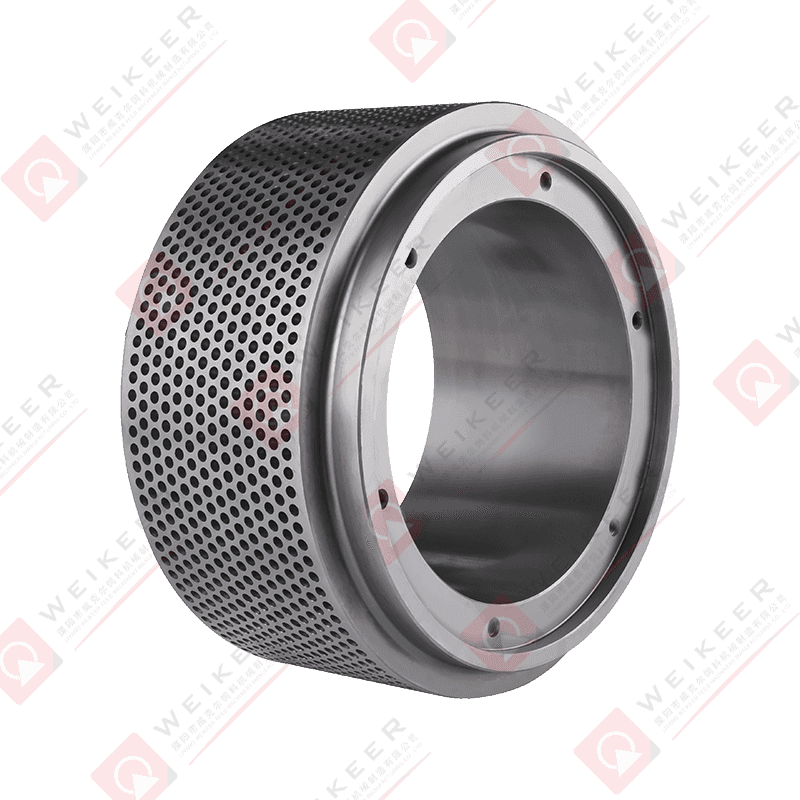

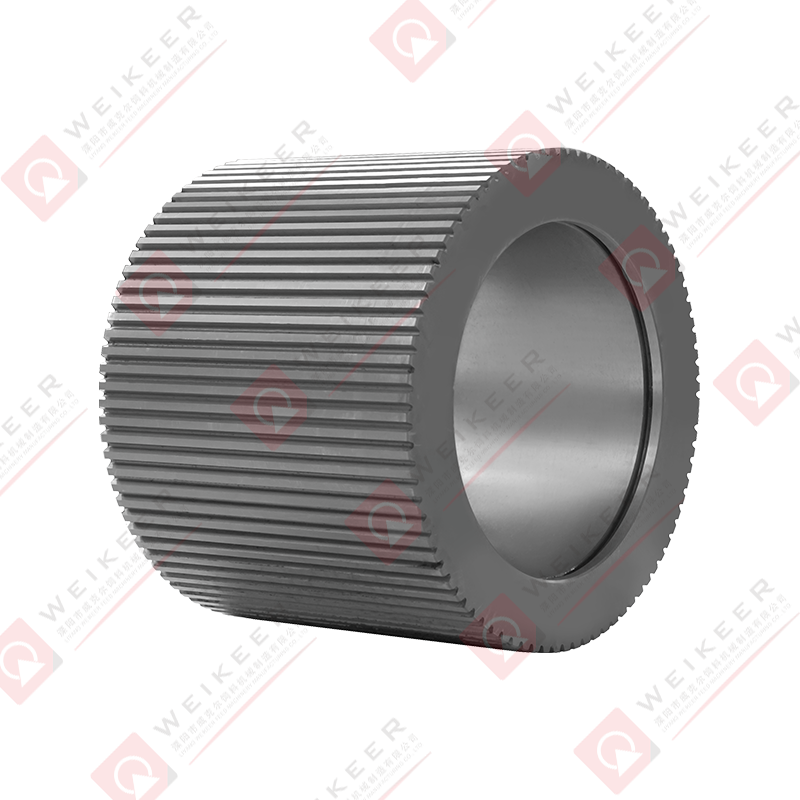

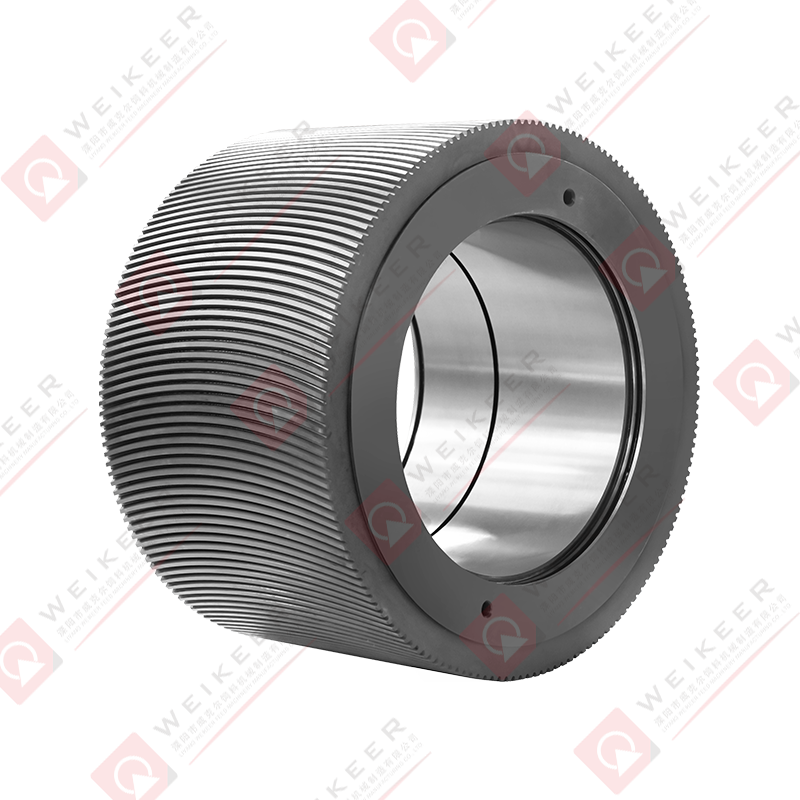

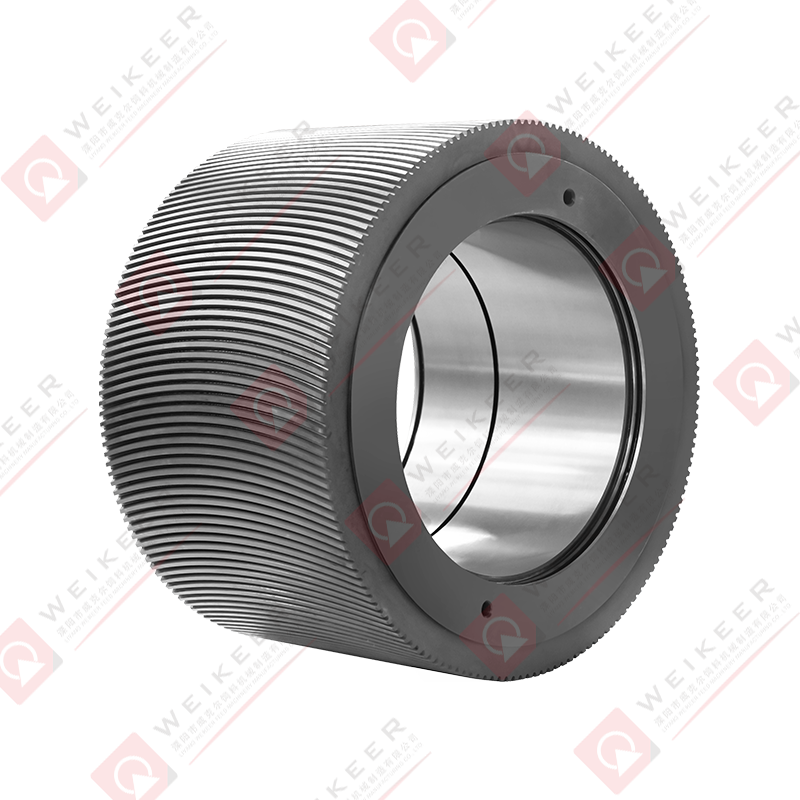

Understand the Screw-Type Ring Die: Failure Modes and Wear Patterns

Before you start any maintenance program, know how screw-type holes wear and fail. Typical failure modes include abrasive wear that enlarges and changes screw threads, thermal/creep deformation at high temperatures, galling from metal-to-metal contact, and edge chipping from tramp metal. Recognizing the wear pattern—uniform wall thinning, eccentric wear, star-shaped hole deformation, or surface cracking—helps you choose the correct cleaning and reconditioning approach.

Common indicators of die degradation

Reduced throughput, higher motor torque, poor pellet density, increased fines, and inconsistent pellet length all point to die wear or clogged screw channels. Track these process metrics and combine them with visual inspection to decide when to service the die.

Safety and Preparation

Always apply lockout-tagout (LOTO) to the pellet mill and associated drive equipment before removing the die. Wear appropriate PPE: heavy gloves, safety glasses, face shield, hearing protection, and steel-toe footwear. Work on a clean, stable bench with good lighting and use lifting aids for heavy dies. Review chemical safety data sheets (SDS) for any cleaners or solvents you plan to use.

Routine Inspection and Measurement

Make visual inspection and basic measurements a routine activity—daily quick checks at startup and more thorough examinations monthly or at planned shutdowns. Key items to inspect include die hole profile, entry/exit edge sharpness, surface finish inside screw grooves, bolt hole integrity, run-out on the die face, and any signs of overheating or discoloration.

Measurement tools and tolerance checks

Use calipers and plug gauges to check hole diameters and compare to original specifications. Use a dial indicator to measure axial run-out across the die face—accept no more than manufacturer-recommended tolerances (commonly 0.05–0.1 mm depending on die size). Record measurements in a maintenance log to detect gradual wear trends.

Cleaning Methods: Tools and Step-by-Step Procedures

Cleaning removes compacted feed, binder residues, and scale that reduce throughput and cause overheating. Choose non-abrasive mechanical cleaning first and reserve chemical cleaning for stubborn organic residues. Avoid media that will change die surface hardness or damage protective coatings.

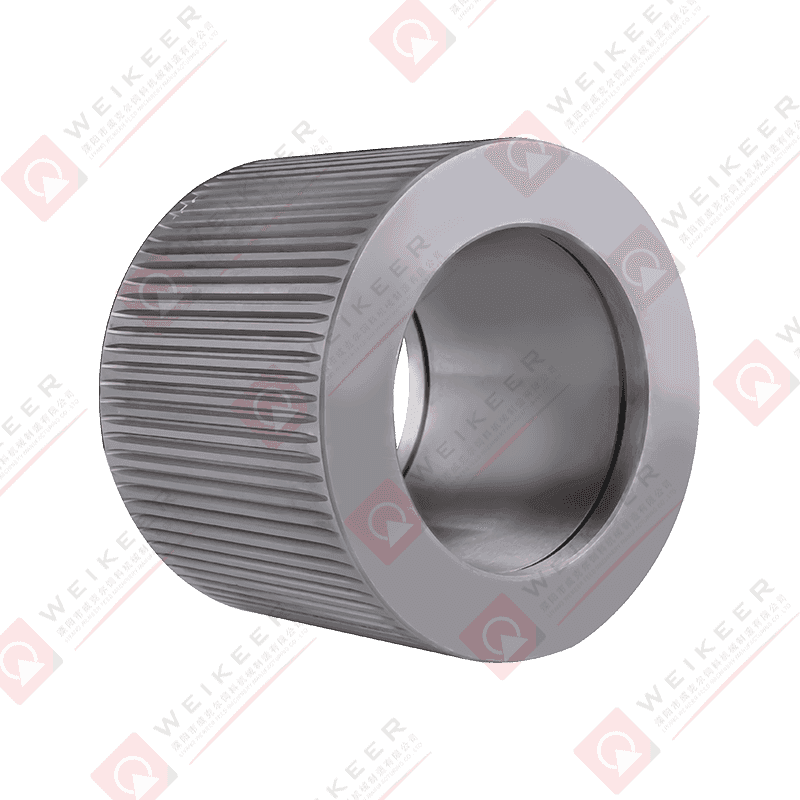

Mechanical cleaning

Start with compressed air and soft-bristle brushes to remove loose fines. For screw-type holes, use flexible stainless-steel brush cables sized to the screw diameter and rotate slowly to avoid enlarging the profile. For compacted residues use a brass or nylon brush first; only use carbide or steel burrs sparingly and under experienced hands to avoid removing base material unintentionally.

Ultrasonic and media blasting options

Ultrasonic cleaning with a compatible aqueous detergent is excellent for removing organic binders without mechanical abrasion—ensure the tank fits the die and that fixtures support safe immersion. Low-pressure media blasting with glass beads or walnut shells can remove stuck material while being gentler than sand; test on a scrap die first.

Chemical cleaning

Use mild alkaline detergents or solvent blends recommended by the die manufacturer to dissolve oils and binders. Limit exposure time and rinse thoroughly with deionized water to prevent chemical attack or residue. Never use strong acids or chlorinated solvents unless explicitly approved—these can strip heat treatments and embrittle the die.

Reconditioning and Repair Techniques

When wear exceeds acceptable limits, reconditioning restores geometry and prolongs service life. Options include shot peening to relieve surface stress, hard-facing weld repair for localized gouging, re-machining or re-reaming screw-type holes to nominal diameter, and re-hardening/coating. Re-machining must follow original thread profile and helix angle to preserve pellet compression behavior.

When to replace vs. recondition

Replace the die if wall thickness falls below manufacturer minimums, if cracks extend through the die, or if repeated rework cannot restore hole geometry economically. Recondition when wear is moderate and material removal for re-machining will not compromise structural integrity.

Operational Best Practices to Minimize Wear

You can substantially extend die life by addressing upstream process control and feed preparation. Keep tramp metal out with magnets and screens; control moisture to recommended ranges; maintain consistent feed particle size through proper grinding and screening; avoid overfeeding and ensure uniform feed distribution across the die face. Monitor roller-press settings and knife clearance—incorrect settings accelerate die wear.

- Install magnetic traps and coarse screens ahead of the mill.

- Control moisture within ±1–2% of the target to prevent plugging or excessive slip.

- Use consistent hammer-mill settings to maintain feed gradation.

- Balance rollers and maintain proper nip pressure to reduce eccentric loading.

Maintenance Schedule and Checklist

Adopt a scheduled maintenance program with daily, weekly, monthly, and annual tasks. Consistent logs help correlate die condition with operating variables so you can refine maintenance intervals.

| Interval |

Key Tasks |

Purpose |

| Daily |

Visual check, record motor load, pellet quality |

Catch early clogs or feed issues |

| Weekly |

Inspect die face, brush screw holes, check knife clearance |

Remove buildup and ensure cutting efficiency |

| Monthly |

Measure hole diameters, run-out, and log values |

Track wear trends for planned reconditioning |

| Annual |

Full teardown, ultrasonic/deep clean, specialist rework if needed |

Restore geometry or replace before catastrophic wear |

Troubleshooting: Common Problems and Fixes

If you see excessive fines, inconsistent pellet size, or rapid increases in motor current, follow a structured troubleshooting path: check feed gradation and moisture first, inspect die for plugged or worn screw holes, check roller condition and knife sharpness, examine bearings and drive alignment, then escalate to die reconditioning if basic fixes do not restore performance.

Conclusion

A disciplined maintenance and cleaning program for screw-type ring dies pays dividends in pellet quality, throughput, and total cost of ownership. Combine daily monitoring, appropriate cleaning methods, careful reconditioning, upstream process control, and a documented schedule to maximize die life. When in doubt, consult die manufacturers or qualified reconditioning shops to avoid irreversible damage during repairs.

русский

русский Español

Español عربى

عربى 中文简体

中文简体