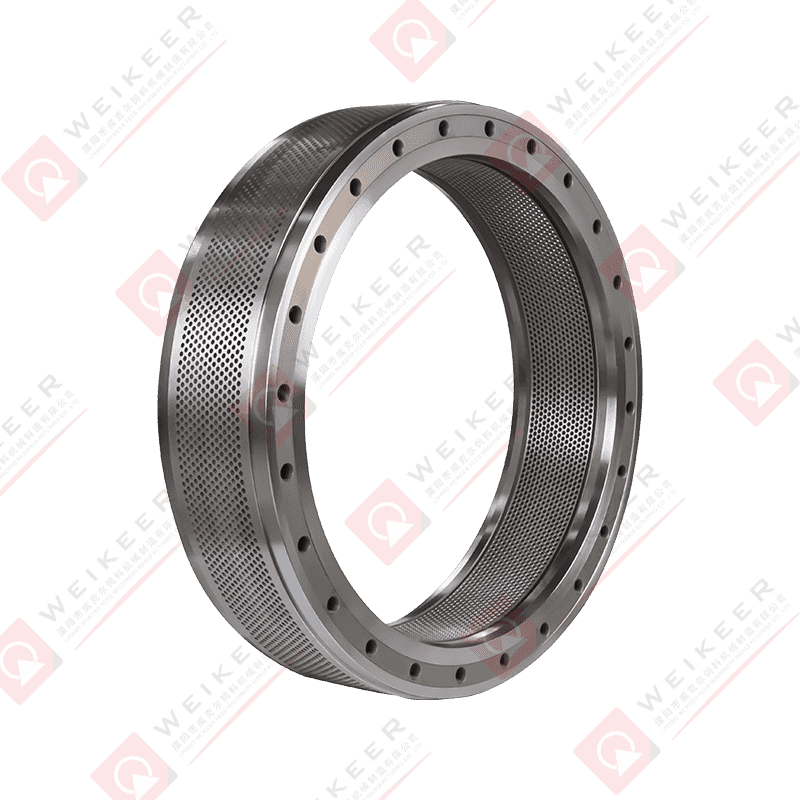

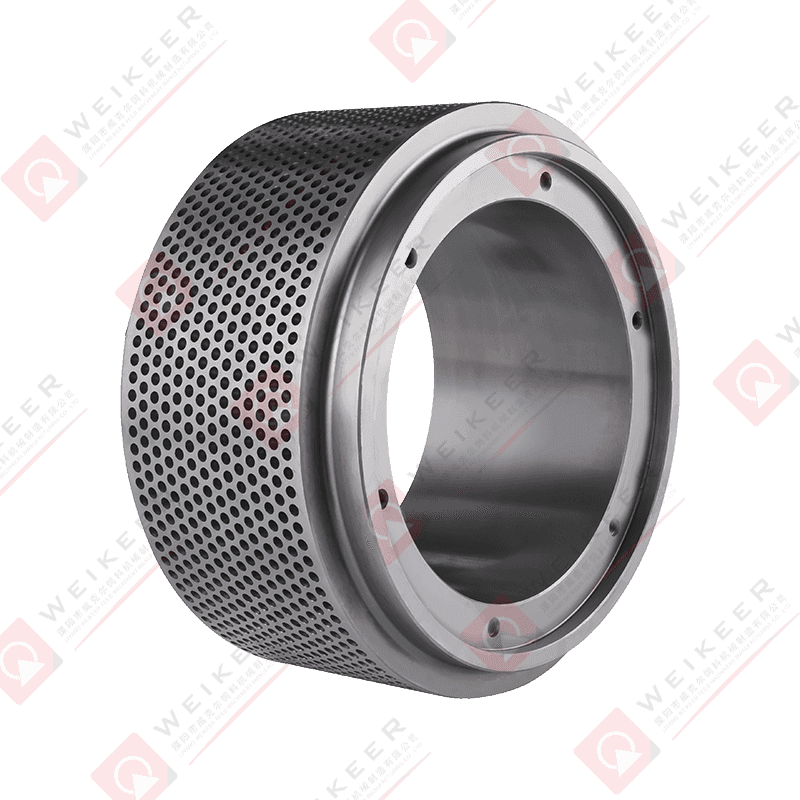

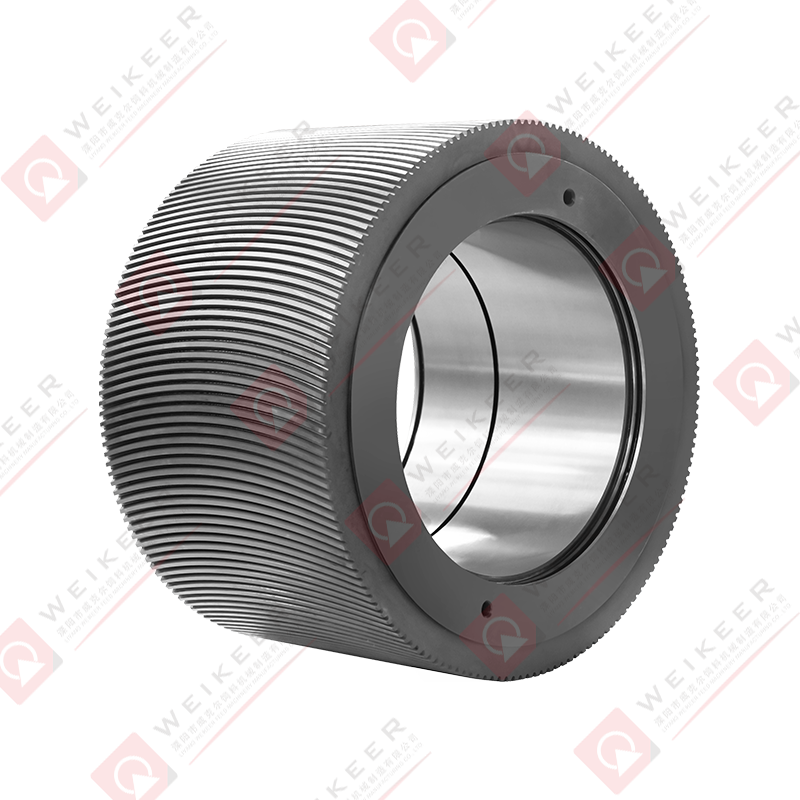

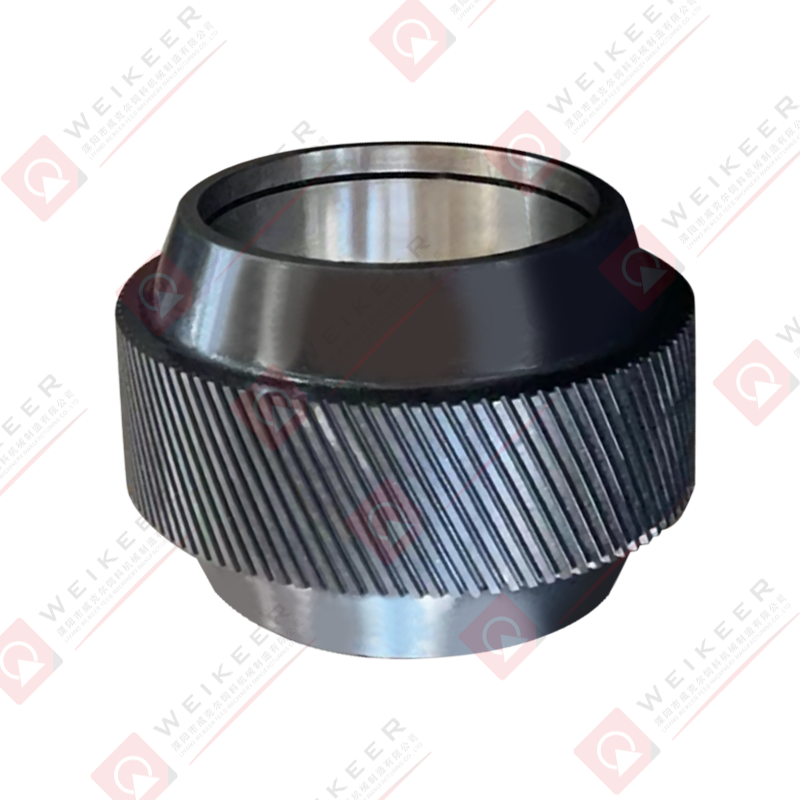

Pellet mills rely heavily on the quality, durability, and precision of their ring dies to achieve efficient and consistent pelletizing performance. Among the various types of ring dies on the market, Anchorear stainless steel ring dies have gained wide recognition for their superior mechanical strength, advanced machining accuracy, and exceptional corrosion resistance. These characteristics make them ideal for applications such as biomass fuel production, livestock feed processing, aquafeed manufacturing, and industrial pelletizing lines. Because the ring die directly affects pellet density, surface finish, throughput, and energy consumption, choosing a high-performance stainless steel die is crucial for ensuring stable, long-term mill operation.

Anchorear, known for its material engineering and advanced CNC drilling technology, produces stainless steel ring dies designed to withstand intense mechanical stress and continuous wear. Unlike carbon steel dies that tend to wear faster or deform under high loads, stainless steel models offer balanced hardness, toughness, and corrosion resistance. These advantages reduce downtime, prevent premature failures, and maintain consistent pellet quality across extended production cycles.

How Does Stainless Steel Improve Ring Die Performance in Pellet Mills?

Stainless steel is favored in pellet mill ring die manufacturing because it offers a combination of high durability, chemical resistance, and stable metallurgical structure. When pelletizing biomass, high-protein feed, or abrasive raw materials, the die experiences constant friction and heat. Inferior materials can expand, crack, or experience uneven wear, resulting in low pelletization rates or inconsistent pellet shape. Stainless steel—especially alloys used by Anchorear—is engineered to maintain mechanical integrity during high-temperature and high-pressure operations.

Another advantage of stainless steel is its resistance to corrosion caused by moisture-rich feed formulas or aggressive biomass fibers. While carbon steel dies require more maintenance to prevent rust, stainless steel provides a significantly longer operational window. This reduces the frequency of shutdowns and improves the overall cost-efficiency of pellet plants. In addition, stainless steel supports finer and more precise hole drilling, leading to improved pellet uniformity and smoother pellet surface quality.

Core Material Benefits

- High resistance to wear, reducing uneven friction over time.

- Superior corrosion protection for feed formulas containing moisture or acids.

- Excellent machinability for precise compression ratio control.

- Stable thermal performance, minimizing expansion and deformation.

- Longer service lifespan compared to traditional carbon steel dies.

What Manufacturing Techniques Elevate Anchorear Ring Die Quality?

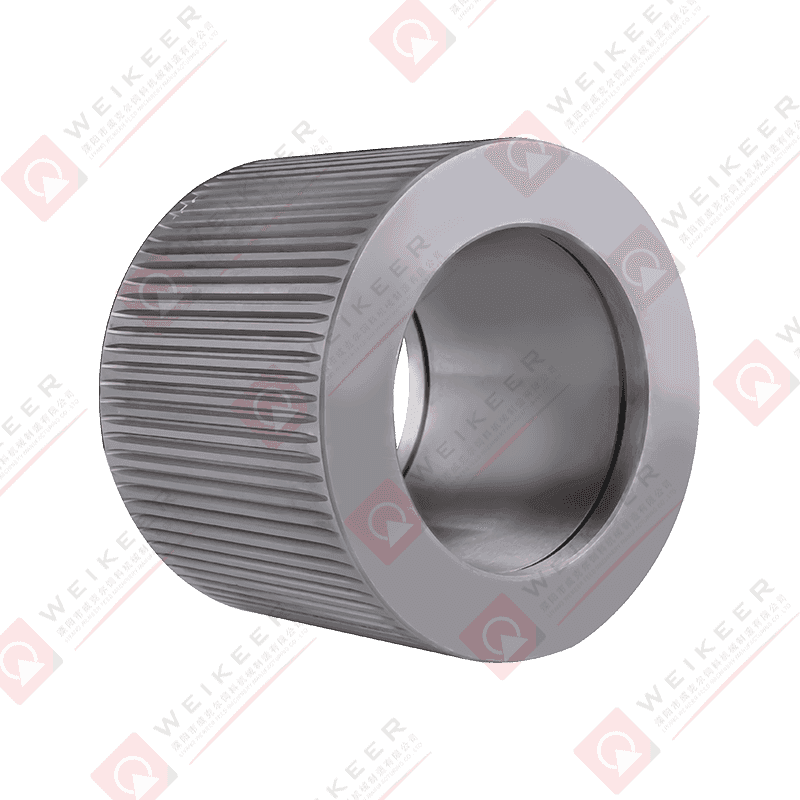

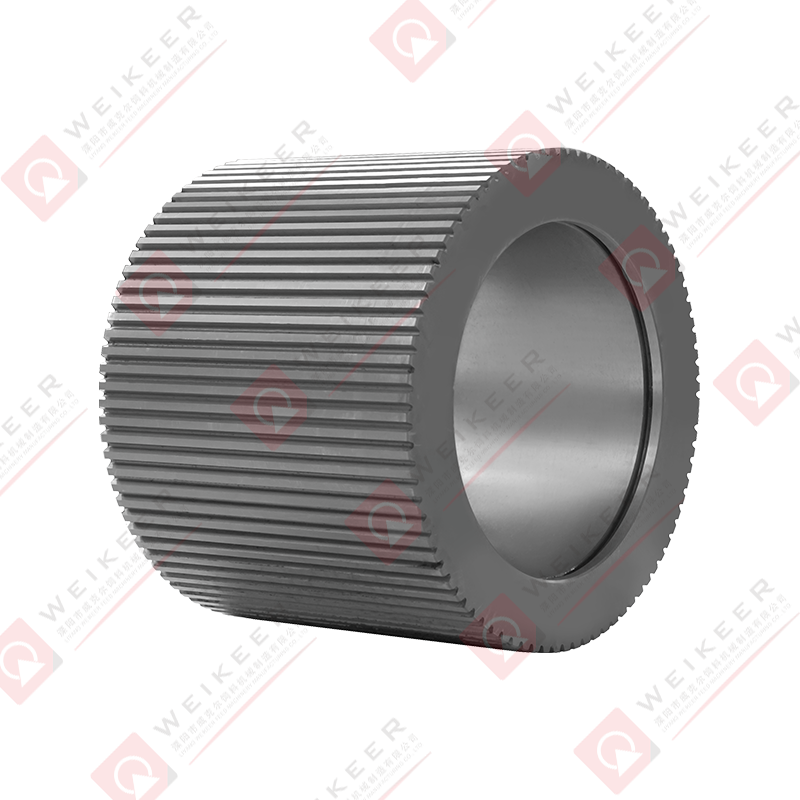

The performance of a ring die is influenced not only by its material but also by the precision of its manufacturing process. Anchorear adopts advanced production technologies such as CNC gun-drilling, vacuum heat treatment, and mirror-polishing to ensure high dimensional accuracy and consistent compression ratios across thousands of die holes. These precision-focused processes help optimize pellet mill output while maintaining uniform pellet size and density.

Gun-drilling, in particular, is essential for producing smooth and accurate die holes. Poorly drilled holes with rough internal surfaces can cause pellet jamming, excess friction, or rapid die wear. Anchorear’s techniques create micro-smooth holes, improving material flow and reducing energy consumption. Additionally, controlled heat treatment enhances die hardness and uniformity, ensuring consistent performance throughout the die’s lifespan.

Key Manufacturing Features

| Technology |

Function |

Impact on Performance |

| CNC Gun Drilling |

Creates smooth, precise holes with exact diameter. |

Improves pellet uniformity and reduces friction. |

| Vacuum Heat Treatment |

Enhances wear resistance and structural stability. |

Extends lifespan and prevents cracking. |

| Mirror Polishing |

Reduces surface roughness on hole walls. |

Boosts throughput and decreases energy use. |

How Do Anchorear Ring Dies Improve Pellet Quality?

Pellet quality—defined by hardness, durability, density, and uniformity—is primarily determined by the design and condition of the ring die. Anchorear stainless steel ring dies are engineered with optimized compression ratios, smooth bore finishes, and consistent hole sizes. These elements help produce pellets with high structural integrity and minimal fines. Whether processing wood biomass, poultry feed, ruminant feed, aquaculture pellets, or organic fertilizer, the ring die’s geometry directly influences pellet performance.

A well-designed ring die helps maintain feed nutrition integrity during pelletization, prevents overheating, and enhances pellet water stability in aquafeed production. The uniform compression ensures pellets retain the desired diameter and density, improving storage stability and reducing crumbling. For biomass fuel producers, higher pellet density translates into better calorific value and more stable combustion.

Pellet Quality Benefits

- Increased pellet hardness and durability index.

- Reduced fines, resulting in cleaner storage and transport.

- Stable pellet diameter and density for different feed formulas.

- Improved thermal efficiency for biomass pellets.

- Minimized nutrient loss for animal feed pellets.

Where Are Anchorear Stainless Steel Ring Dies Used?

Ring dies play a crucial role in multiple industries where pelletizing is essential. Anchorear stainless steel ring dies are compatible with a wide range of pellet mill brands, making them versatile across different production lines. They are used not only in agricultural feed production but also in energy, environmental, and industrial sectors. Their durability and precision support high-demand operations where consistent output is required.

Typical Application Sectors

- Biomass fuel pellet production using wood, straw, or agricultural residues.

- Poultry, cattle, and swine feed pellet manufacturing plants.

- Aquafeed production requiring high water durability pellets.

- Industrial pelletizing of organic fertilizers or chemical powders.

- Recycling-based pellet systems such as plastic or rubber processing.

How to Select the Right Anchorear Stainless Steel Ring Die?

Selecting the appropriate ring die requires a careful evaluation of pellet mill specifications, feedstock characteristics, and production targets. Factors such as compression ratio, hole diameter, working thickness, and alloy grade must align with the intended pelletizing application. Anchorear offers customization options tailored to biomass, livestock feed, aquafeed, or industrial pellets, ensuring optimal performance for each process.

Selection Considerations

- Match hole size and compression ratio to the feed formula characteristics.

- Confirm compatibility with the pellet mill model and roller specifications.

- Evaluate stainless steel grade for abrasive or corrosive materials.

- Choose thickness and hardness based on production volume and operating pressure.

- Consult performance history and wear rate data for improved accuracy.

How to Maintain Anchorear Stainless Steel Ring Dies for Longer Service Life?

Proper maintenance can significantly extend the life of any ring die, but it is especially effective for stainless steel dies due to their superior wear resistance. Regular monitoring of die condition, feed formulation changes, and roller adjustments helps maintain stable pelletizing conditions. Neglecting maintenance not only shortens die lifespan but also affects pellet quality and increases energy usage.

Anchorear ring dies benefit from smooth hole surfaces, but lubrication, feed conditioning, and mill alignment remain critical. By implementing preventive maintenance strategies, production plants can reduce downtime, improve operational efficiency, and maximize return on investment.

Maintenance Recommendations

- Ensure proper steam conditioning to avoid excessive die stress.

- Inspect hole wear patterns and rotate the die when needed.

- Maintain correct roller-die clearance to prevent overheating.

- Clean blocked die holes regularly to maintain throughput.

- Record production data to identify abnormal performance trends.

Conclusion: Why Anchorear Stainless Steel Ring Dies Are a Reliable Choice

Anchorear stainless steel ring dies stand out in the pellet mill industry due to their robust material strength, advanced manufacturing precision, and impressive operational longevity. These ring dies offer significant advantages in pellet quality, mechanical stability, and cost efficiency. Whether used in biomass production, livestock feed manufacturing, or industrial pelletizing processes, Anchorear dies provide reliable and consistent results across thousands of operational hours. By selecting the appropriate die design and implementing proper maintenance practices, pellet mill operators can achieve improved performance and long-term productivity.

русский

русский Español

Español عربى

عربى 中文简体

中文简体