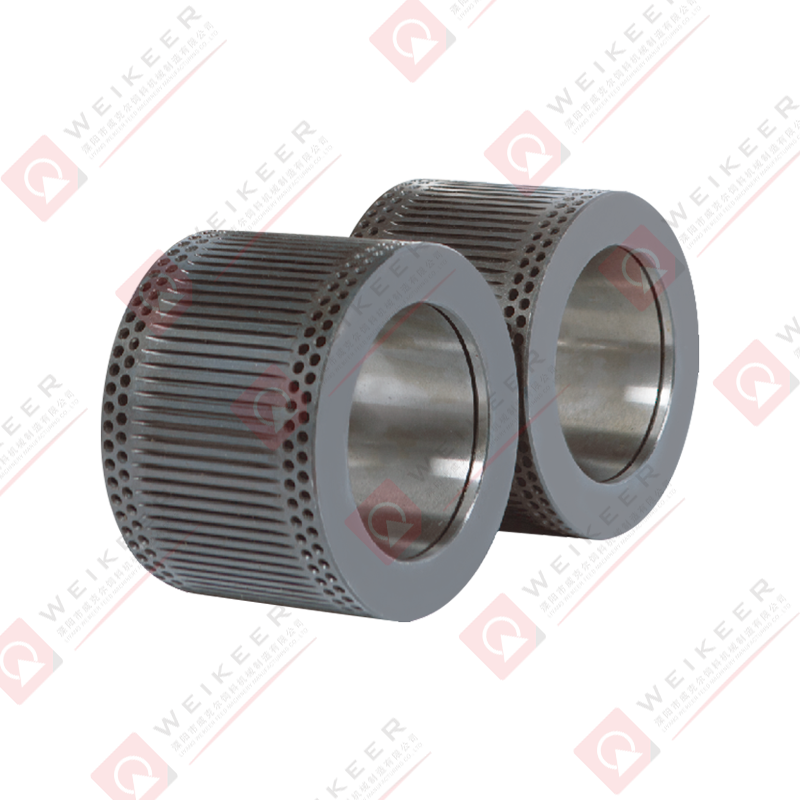

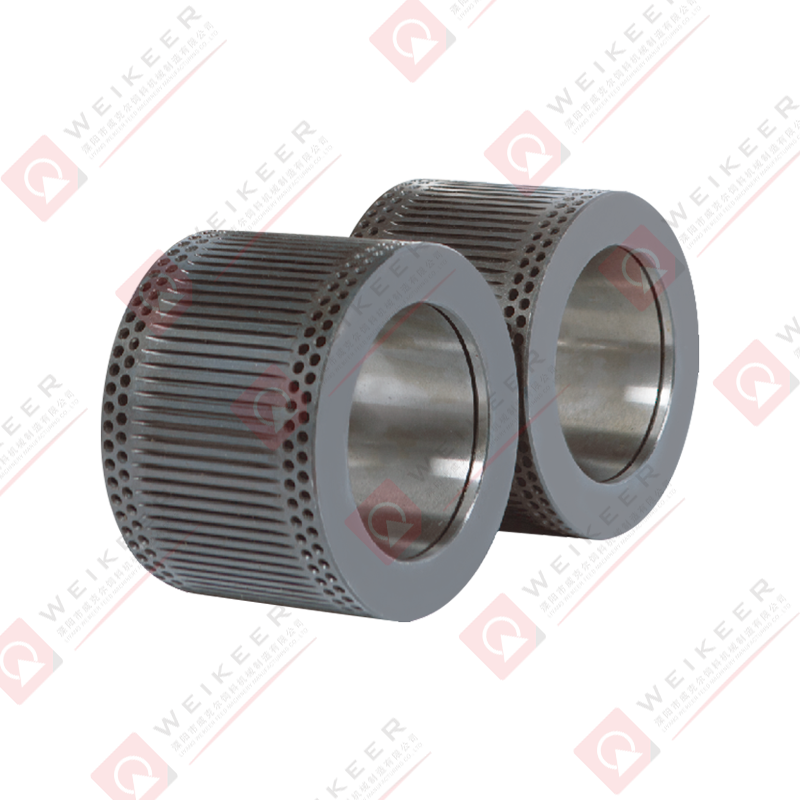

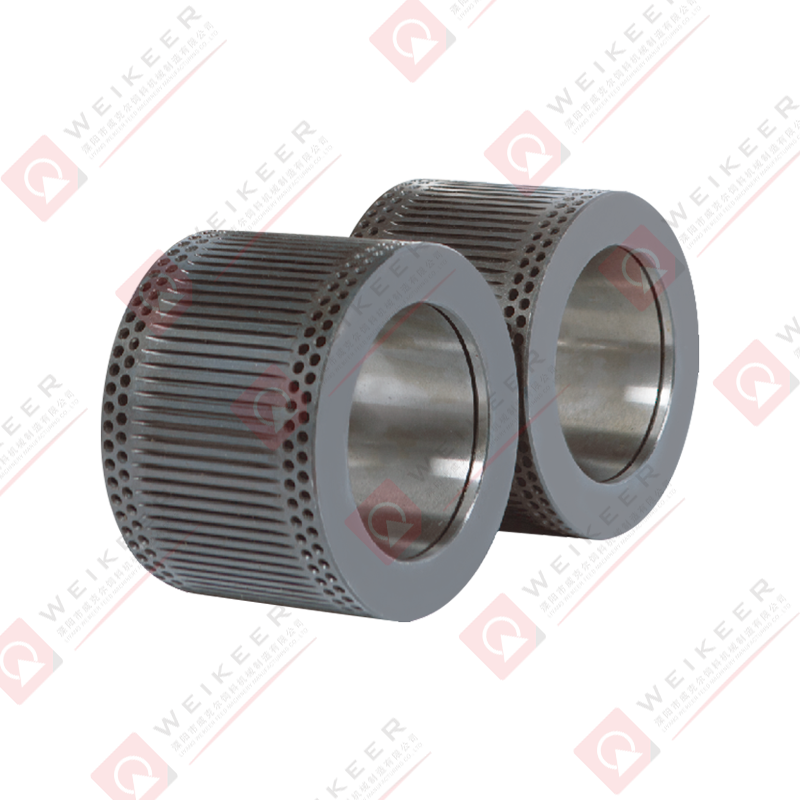

Introduction to Bearing Steel Pellet Mill Rollers and Shells

Bearing steel pellet mill rollers and shells are critical components in modern feed production. These precision-engineered parts, often paired with screw-type stainless steel ring dies, are designed to handle high pressures and maintain consistent performance in pellet mills. By providing optimal durability and wear resistance, these components directly impact the efficiency, quality, and longevity of the feed production process.

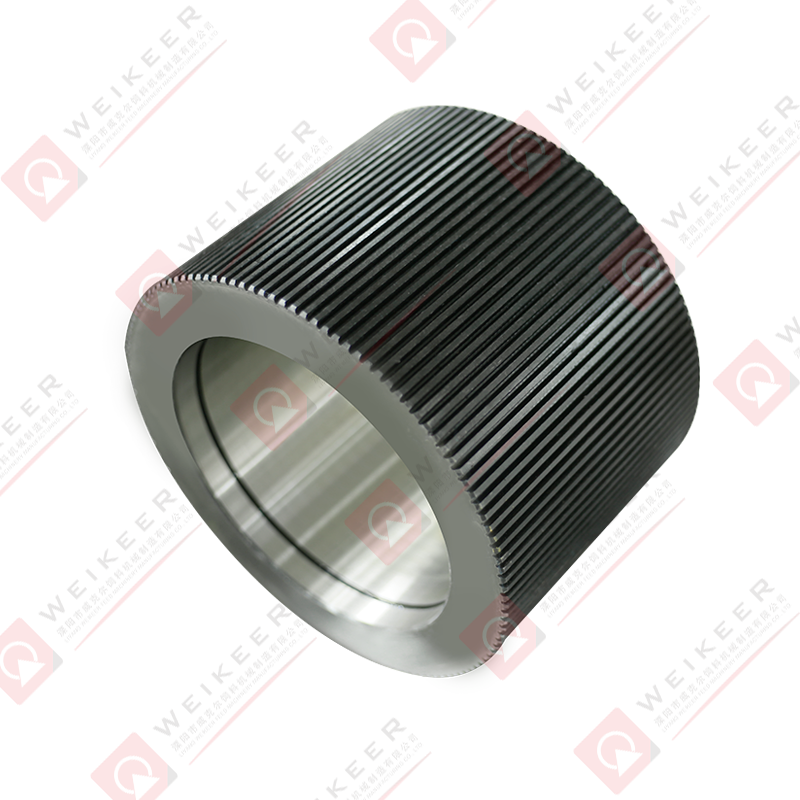

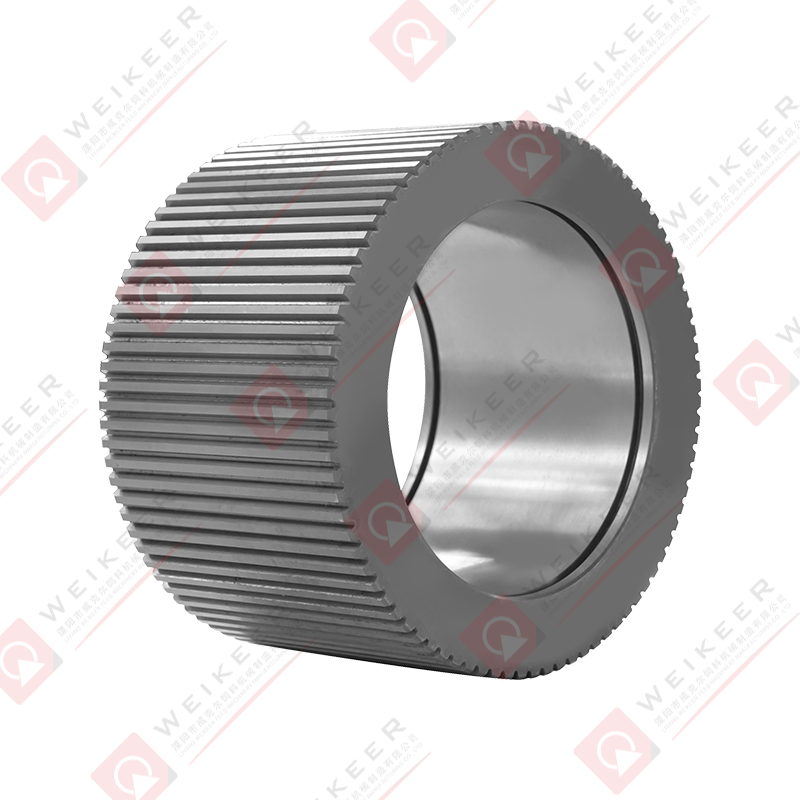

Enhanced Durability and Wear Resistance

One of the main advantages of using bearing steel for pellet mill rollers and shells is the material’s exceptional durability. Bearing steel is engineered to resist wear, corrosion, and mechanical stress. In the context of feed production, this means that:

- The rollers maintain their shape and precision even under continuous operation.

- The shells resist deformation and abrasion caused by high-speed compression of feed material.

- Maintenance frequency is reduced, leading to lower operational downtime.

This durability ensures that the pellet mill can operate at peak efficiency for extended periods without the need for frequent part replacement, directly improving overall production efficiency.

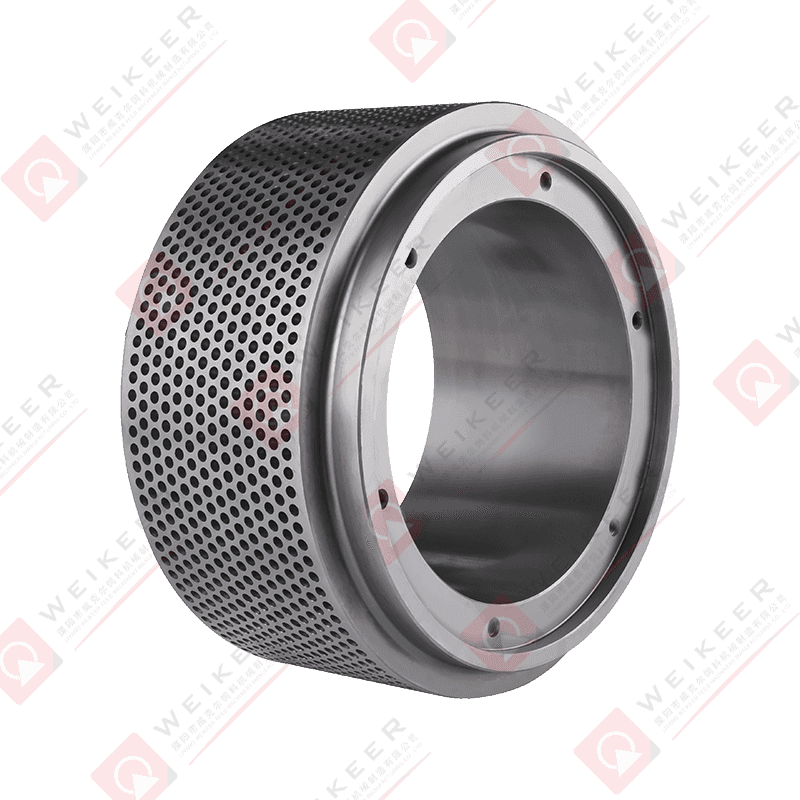

Precision Performance and Pellet Quality

Precision is critical in feed production, as uneven compression or misalignment can lead to inconsistent pellet size, density, and durability. Bearing steel rollers and shells provide the necessary rigidity and dimensional stability to ensure consistent performance. Key benefits include:

- Uniform compression throughout the feed material.

- Consistent pellet size and density, reducing waste and improving feed quality.

- Enhanced compatibility with stainless steel ring dies, ensuring smooth material flow.

High-quality bearing steel components reduce the risk of irregular wear, which can compromise pellet quality and decrease mill efficiency over time.

Reduced Maintenance and Operational Downtime

Maintenance is a significant cost factor in feed production. Bearing steel rollers and shells, due to their hardness and resistance to wear, extend the operational life of pellet mills. This provides several operational advantages:

- Longer intervals between component replacements.

- Reduced labor costs for maintenance and repairs.

- Minimized downtime, allowing continuous high-volume feed production.

By lowering the frequency of maintenance, bearing steel rollers and shells help producers maintain consistent throughput and maximize mill utilization.

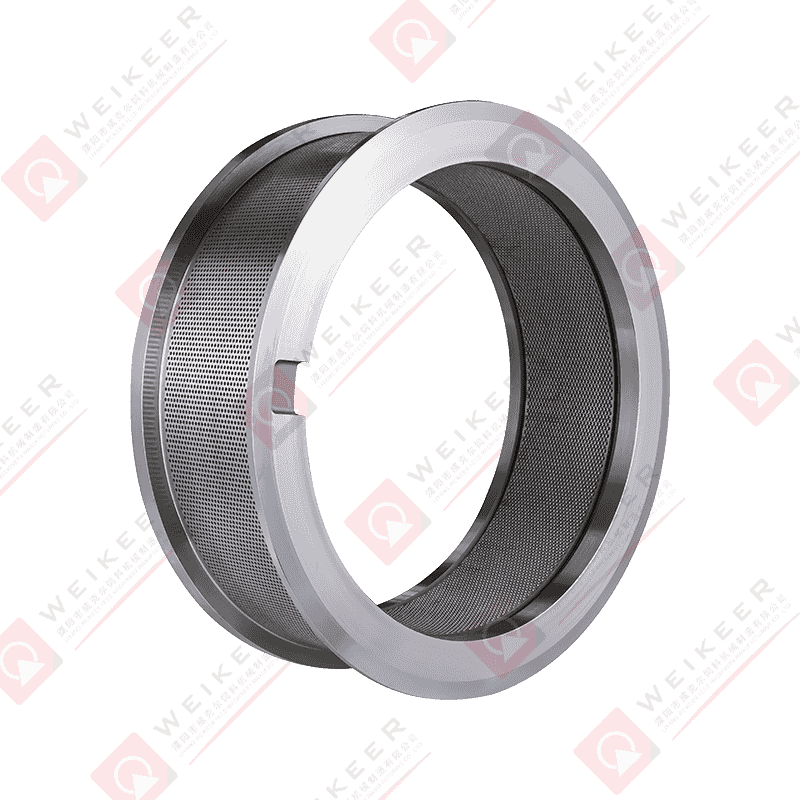

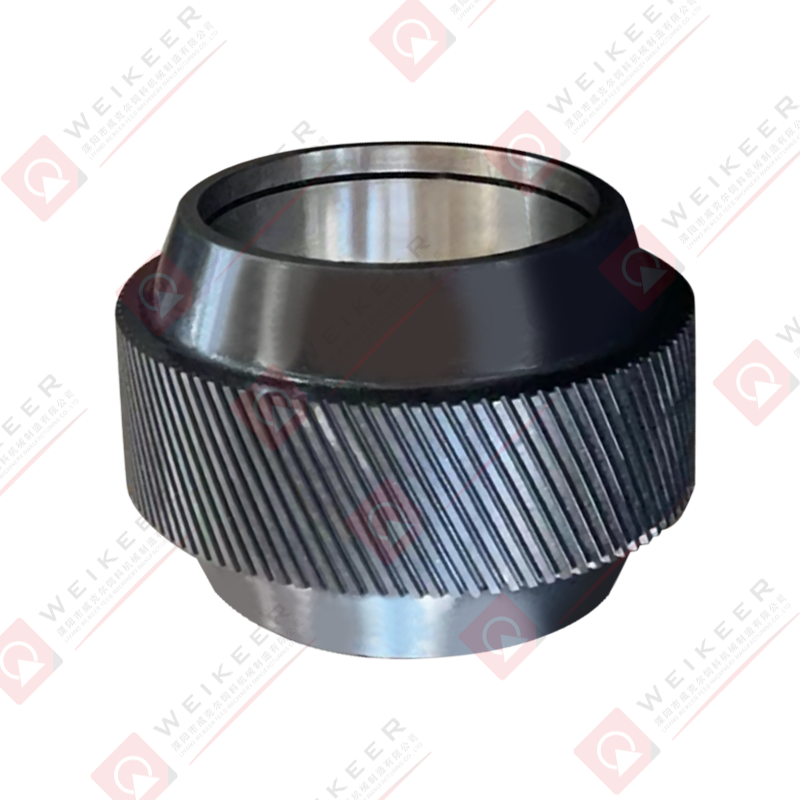

Compatibility with Screw-Type Stainless Steel Ring Dies

Screw-type stainless steel ring dies are often paired with bearing steel rollers for efficient feed pellet production. The combination ensures:

- Optimal material compression due to precise alignment between roller and die surfaces.

- Improved energy efficiency, as less power is wasted overcoming friction or misalignment.

- Extended die life by reducing localized stress and wear.

This synergy between high-quality rollers and ring dies significantly enhances feed production efficiency while maintaining consistent pellet quality.

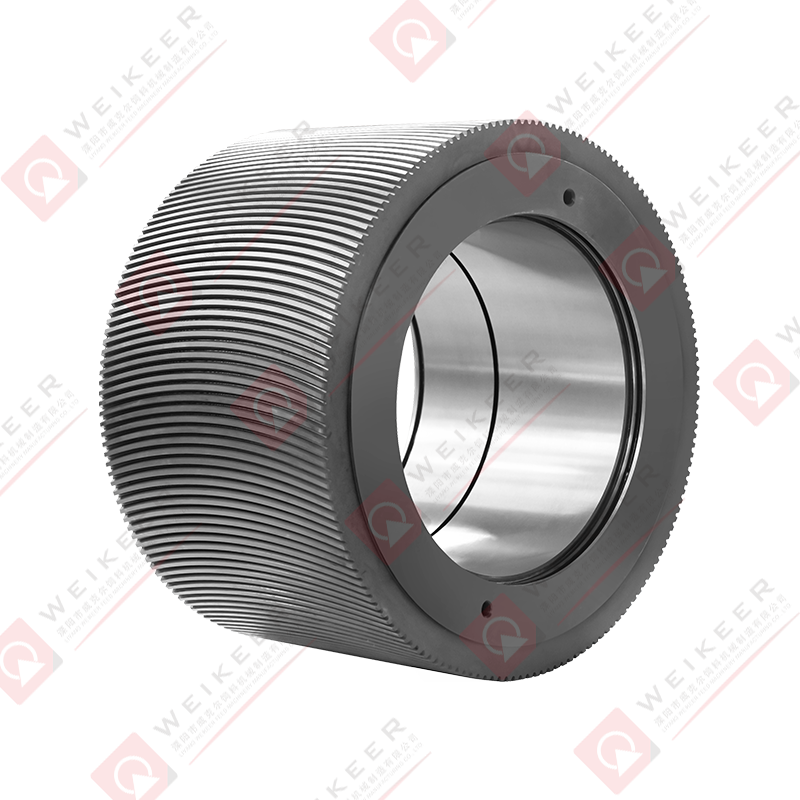

Energy Efficiency and Cost Reduction

Efficient energy use is a critical concern in industrial feed production. Bearing steel rollers and shells contribute to energy efficiency in several ways:

- Reduced friction between rollers and dies lowers motor load and electricity consumption.

- Consistent pellet formation prevents jams or overloads that can disrupt production.

- Durable components reduce the need for frequent part replacement, minimizing material costs.

Over time, these improvements in energy efficiency and reduced operational costs lead to significant savings for feed manufacturers.

Optimized Feed Throughput

The ultimate measure of efficiency in a pellet mill is throughput. Bearing steel rollers and shells, when used with screw-type stainless steel ring dies, optimize feed throughput by:

- Ensuring consistent feed material compression and flow.

- Minimizing downtime caused by component wear or alignment issues.

- Allowing higher-speed operation without compromising pellet quality.

This combination maximizes production capacity while maintaining high-quality output, making the investment in bearing steel components worthwhile for feed producers.

Conclusion

Bearing steel pellet mill rollers and shells play a crucial role in enhancing feed production efficiency. Their superior durability, precision performance, and compatibility with screw-type stainless steel ring dies improve pellet quality, reduce maintenance, optimize energy consumption, and maximize throughput. For feed manufacturers looking to maintain consistent output, reduce operational costs, and ensure long-term reliability, investing in high-quality bearing steel components is essential.

русский

русский Español

Español عربى

عربى 中文简体

中文简体