Pellet mills are essential machines widely used in feed production, biomass fuel processing, and other industries to compress raw materials into pellets. Among the core components of a pellet mill, the ring die plays a crucial role in determining pellet quality, production efficiency, and machine longevity. The screw type stainless steel ring die is an advanced variation designed to improve pelletizing performance and durability.

1. What Is a Pellet Mill Ring Die?

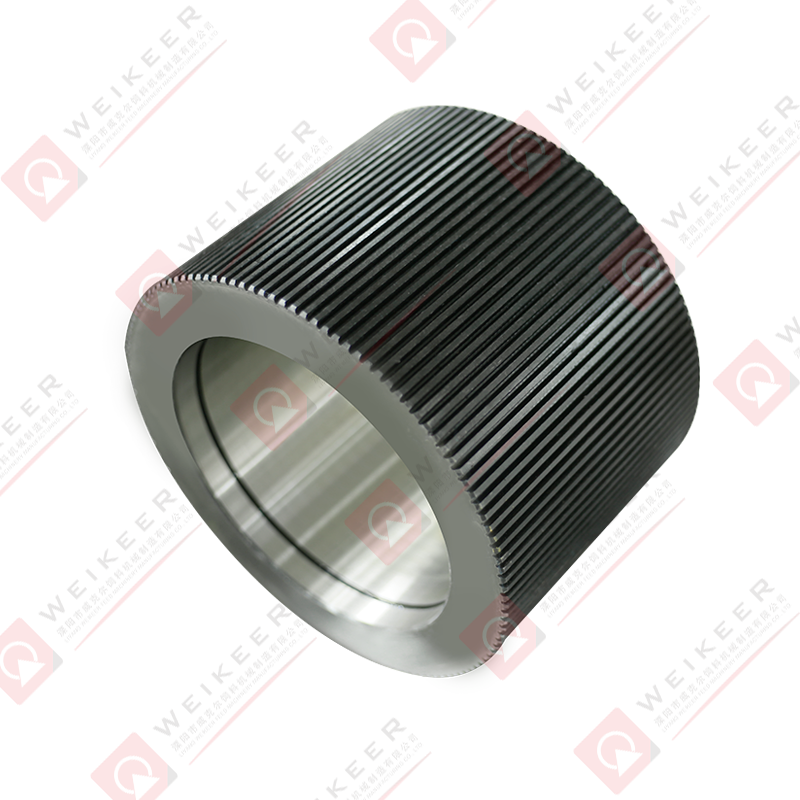

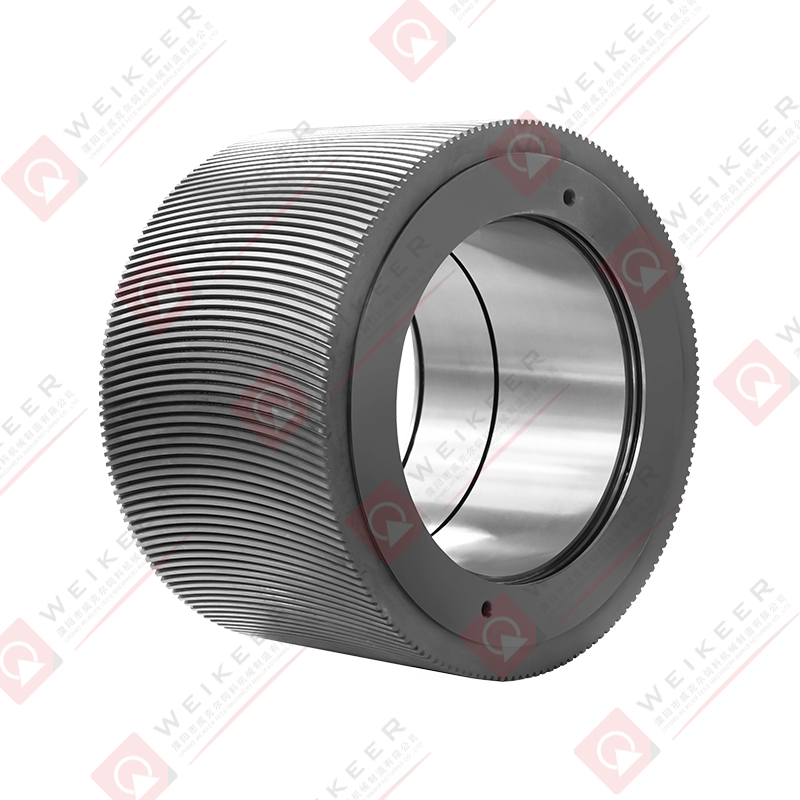

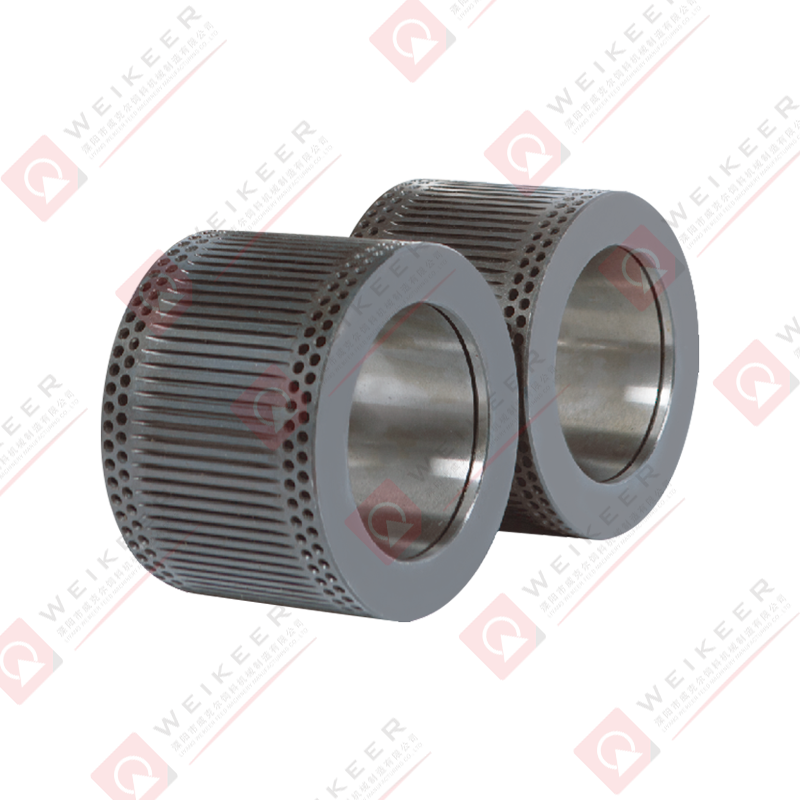

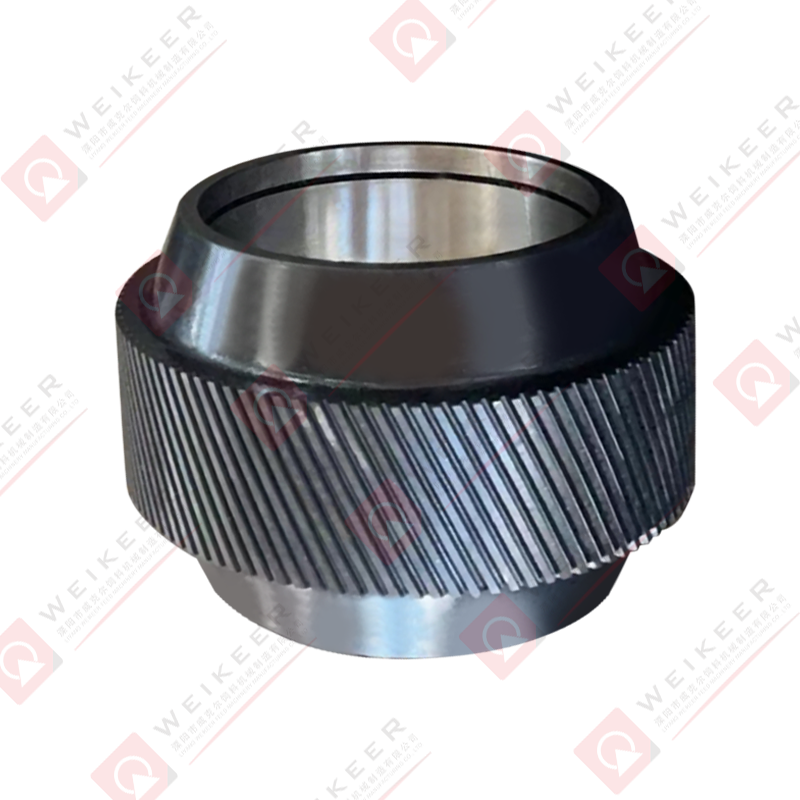

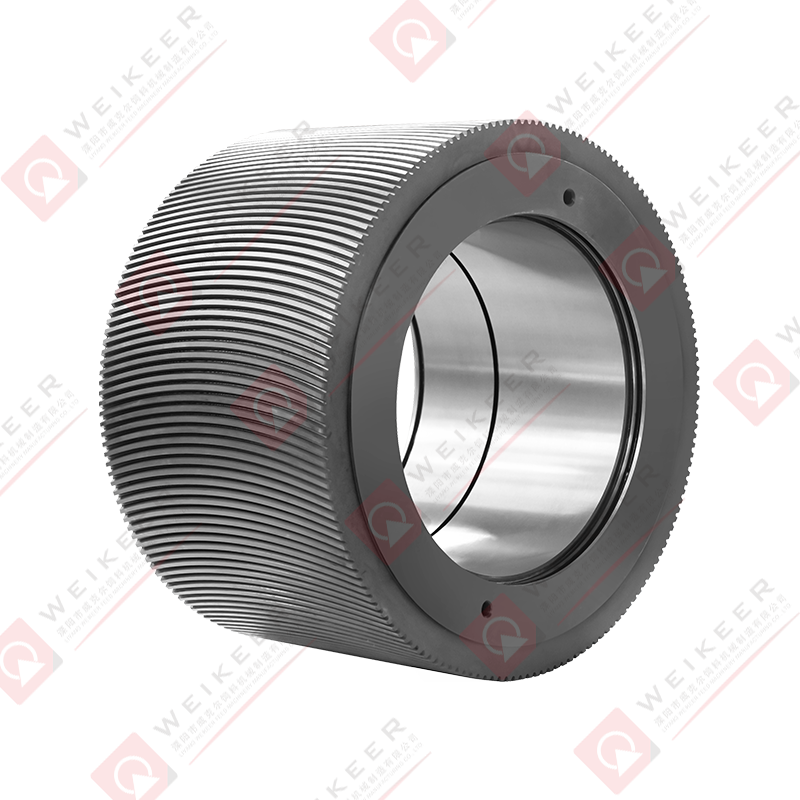

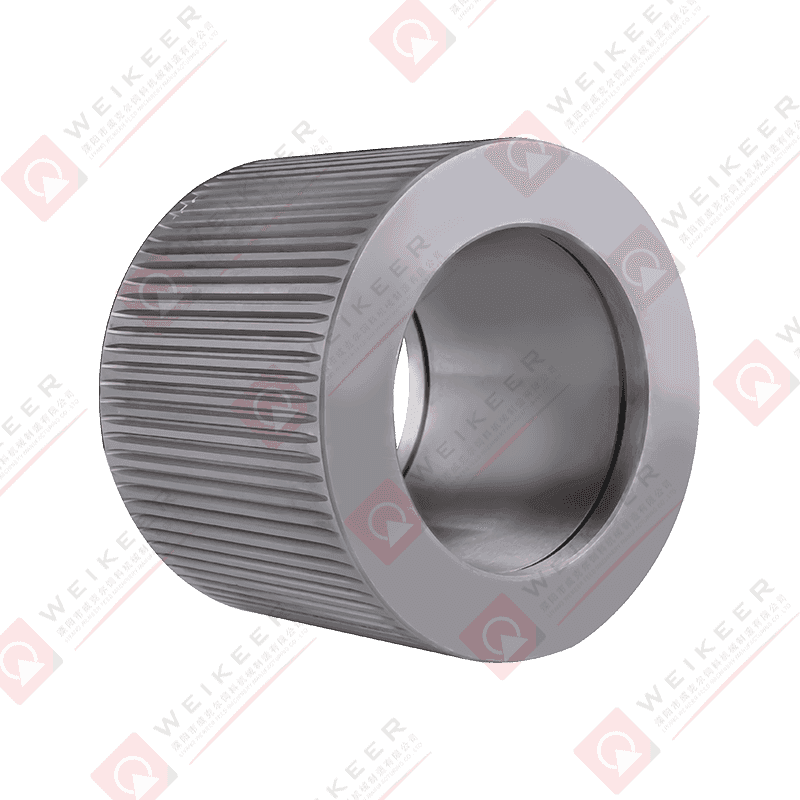

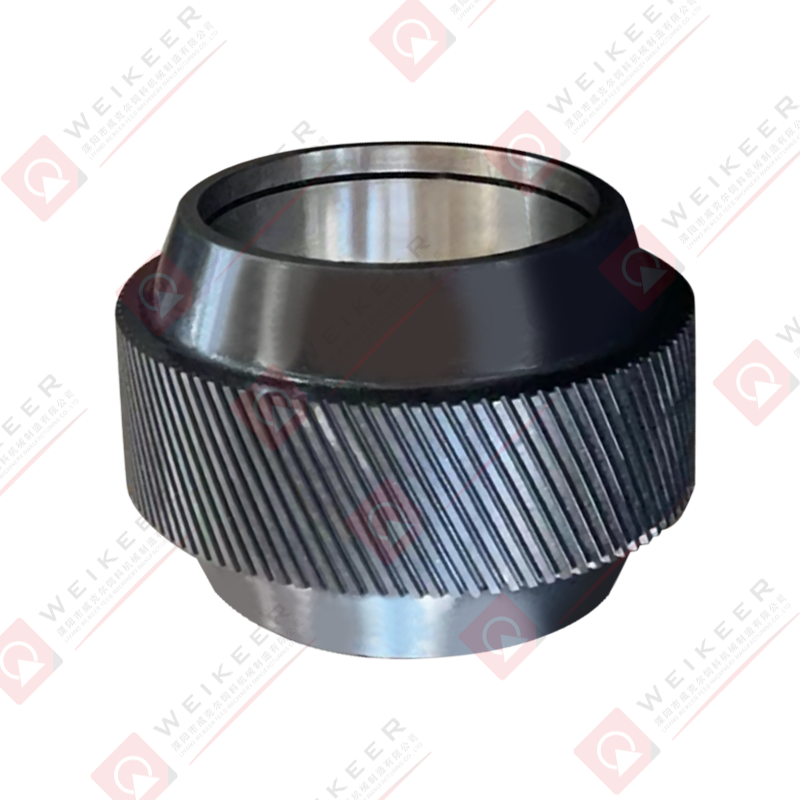

A ring die is a cylindrical, perforated metal ring that serves as the die in ring die pellet mills. It contains multiple holes or perforations through which raw materials are forced to form pellets of a specific size and shape. The die's surface and hole dimensions directly affect pellet density, size uniformity, and overall quality.

Traditionally, ring dies are made of various steel alloys, but stainless steel ring dies offer superior corrosion resistance, wear resistance, and mechanical strength, which is critical for handling abrasive or corrosive raw materials.

2. What Does “Screw Type” Mean in This Context?

The term screw type refers to the design of the internal grooves or channels on the ring die or the way the material is conveyed inside the pellet mill. In some designs, the die or the rollers include screw-like features that enhance material flow and pressure distribution.

Screw type ring dies incorporate a helical or spiral groove pattern inside or near the die holes, helping:

Evenly distribute raw material around the die circumference.

Improve material feeding and reduce clogging.

Enhance compression uniformity for consistent pellet quality.

Reduce friction and wear on die and rollers.

3. Structure of a Pellet Mill Screw Type Stainless Steel Ring Die

Key Components:

Stainless Steel Body: The main cylindrical body made from high-grade stainless steel for corrosion resistance and mechanical strength.

Perforated Ring: A series of holes drilled or punched in a precise pattern and size, usually with a helical or screw-type groove pattern.

Inner Spiral Grooves: Internal screw-type channels designed to facilitate smooth material movement and efficient pellet formation.

Mounting Holes: For securing the die onto the pellet mill.

The precision in manufacturing ensures consistent hole size, smooth surface finish, and balanced mechanical properties.

4. How Does It Work?

Step-by-Step Operation:

Raw Material Feeding: The raw material (e.g., wood flour, animal feed ingredients, biomass) is fed into the pellet mill’s hopper.

Compression Between Rollers and Ring Die: The material is pressed by rollers against the rotating ring die.

Forcing Through Die Holes: Due to the high pressure, raw material is forced through the ring die holes.

Pellet Formation: As the material passes through these perforations, it is compressed and heated by friction, causing the material’s natural binders to activate, solidifying the pellet shape.

Pellet Discharge: The formed pellets exit the outer surface of the ring die and are cut to length by a knife.

The screw-type grooves inside or near the die help distribute material evenly, reduce pressure fluctuations, and minimize wear on the die and rollers, which results in smoother operation and longer service life.

5. Advantages of Screw Type Stainless Steel Ring Dies

5.1 Enhanced Durability

Stainless steel resists corrosion from moisture and acidic raw materials, extending the die’s lifespan compared to carbon steel.

5.2 Improved Pellet Quality

The screw-type design promotes uniform compression, resulting in consistent pellet density and size, improving feed quality or fuel performance.

5.3 Increased Efficiency

Better material flow reduces downtime caused by clogging or jamming, increasing throughput and reducing energy consumption.

5.4 Lower Maintenance Costs

The combination of durable materials and improved design means less frequent die replacement and maintenance.

5.5 Versatility

Suitable for a wide range of materials including biomass, feed, fertilizer, and chemical powders.

6. Typical Applications

Animal Feed Production: Pellets for poultry, cattle, fish, and pets.

Biomass Fuel: Wood pellets, sawdust, straw pellets for heating and power generation.

Fertilizer Pelletizing: Organic and inorganic fertilizers.

Chemical Industry: Pelletizing powdered chemicals or additives.

7. Maintenance Tips for Screw Type Stainless Steel Ring Dies

Regular Cleaning: Prevent material buildup in die holes and grooves.

Lubrication: Properly lubricate rollers and related moving parts.

Routine Inspection: Check for wear, cracks, or corrosion.

Proper Operation: Avoid overloading and maintain consistent feed rates.

Timely Replacement: Replace dies before excessive wear affects pellet quality.

The pellet mill screw type stainless steel ring die is a vital component for efficient pellet production. Its specialized screw-type design enhances material flow and pressure distribution, while stainless steel construction ensures durability and corrosion resistance. By improving pellet quality, operational efficiency, and equipment longevity, this advanced ring die design supports diverse industries from animal feed to renewable energy.

русский

русский Español

Español عربى

عربى 中文简体

中文简体