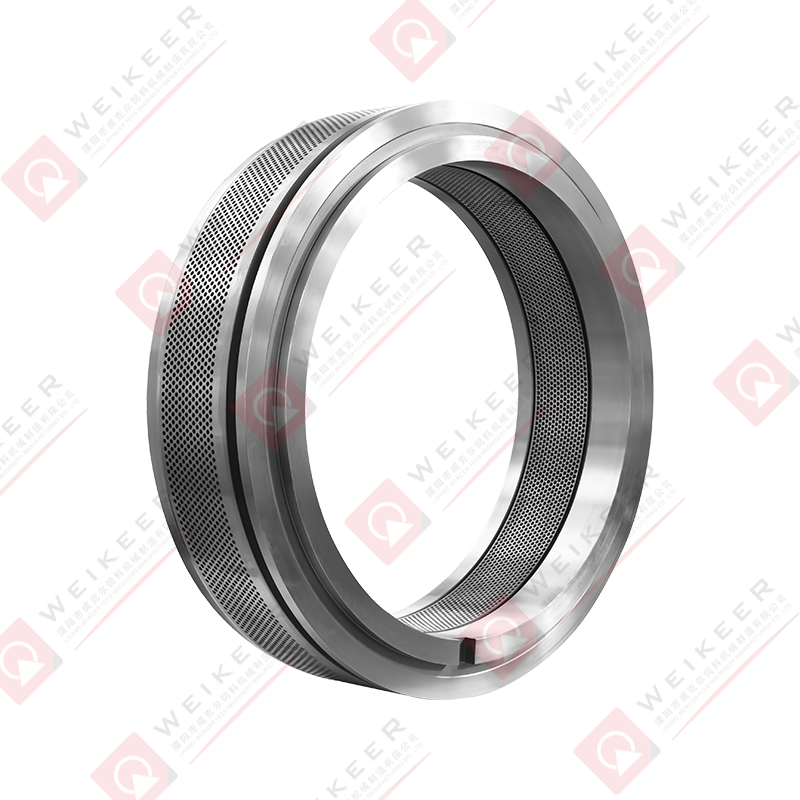

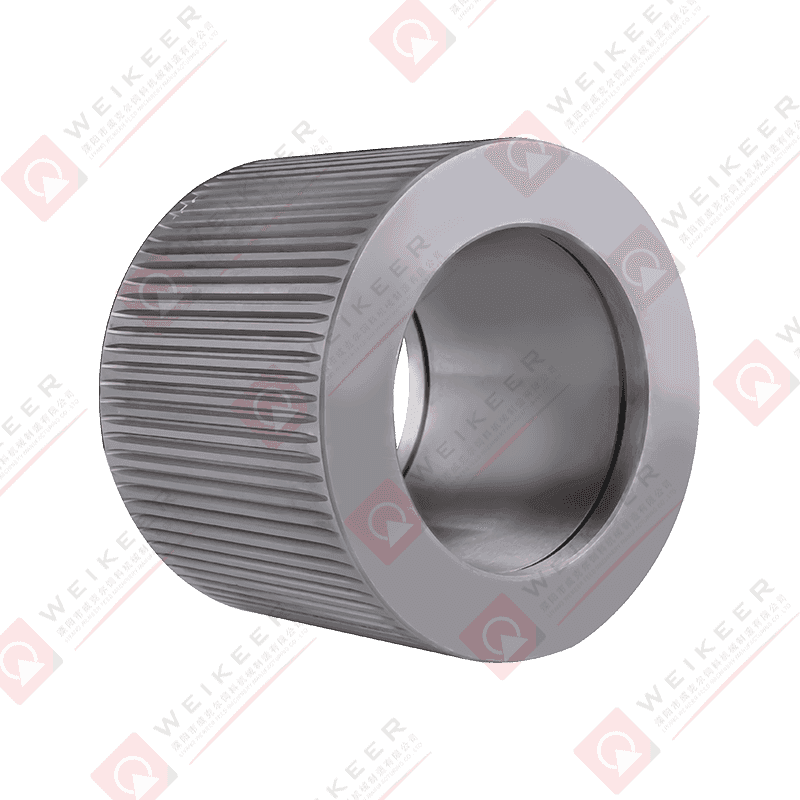

Understanding Ring Die Basics in Pellet Production

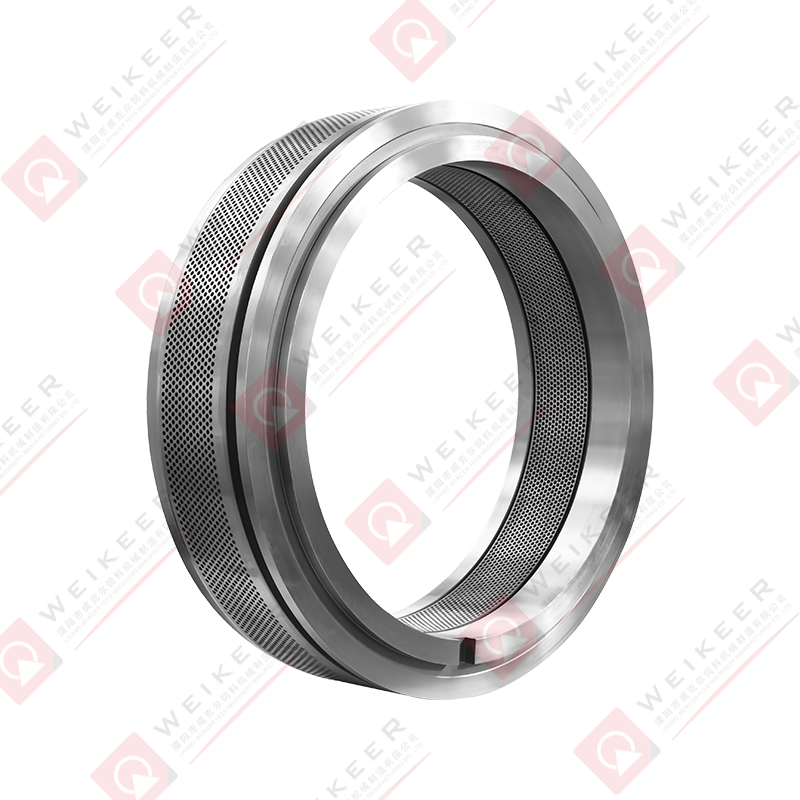

The ring die is the heart of any pellet mill, serving as the critical component that shapes raw materials into uniform pellets. In aqua feed production, selecting the appropriate ring die directly impacts pellet quality, production efficiency, and overall operational costs. The ring die works by forcing material through precisely drilled holes under high pressure, creating cylindrical pellets that are then cut to the desired length. Understanding the fundamental principles of ring die operation helps manufacturers make informed decisions when selecting equipment for their specific production needs.

The performance of your pellet machine heavily depends on the compatibility between the ring die and your feed formulation. Different aquaculture species require varying pellet sizes, densities, and nutritional compositions, which means the ring die must be carefully matched to these specifications. Factors such as hole diameter, hole depth, compression ratio, and material composition all play crucial roles in determining whether a ring die will perform optimally for your specific application. Making the wrong choice can lead to poor pellet quality, increased energy consumption, excessive wear, and frequent production interruptions.

Critical Specifications for Ring Die Selection

Hole Diameter and Pellet Size

The hole diameter of your ring die determines the final pellet diameter, which must align with the feeding requirements of your target aquatic species. Smaller fish and shrimp typically require pellets ranging from 0.8mm to 2.0mm, while larger fish species may need pellets between 3.0mm and 8.0mm or even larger. When selecting hole diameter, consider not only the current size of your stock but also their growth stages, as you may need multiple ring dies to accommodate different life cycle phases. The hole diameter also affects production capacity, with larger holes generally allowing higher throughput but requiring more power to operate efficiently.

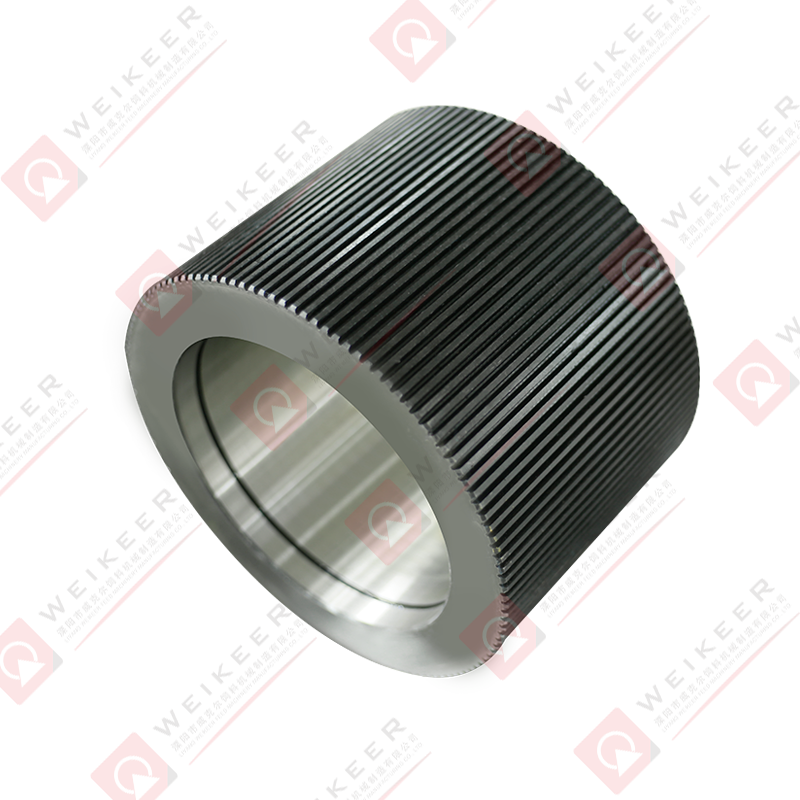

Compression Ratio Considerations

The compression ratio, defined as the relationship between the effective length of the die hole and its diameter, significantly influences pellet density and durability. For aqua feed applications, compression ratios typically range from 1:6 to 1:13, depending on the formulation characteristics. High-protein, low-fiber formulations generally require lower compression ratios (1:6 to 1:8), while formulations with higher fiber content need increased compression (1:10 to 1:13) to achieve proper binding. Selecting the wrong compression ratio can result in soft, crumbly pellets that dissolve too quickly in water or overly dense pellets that fish cannot easily consume.

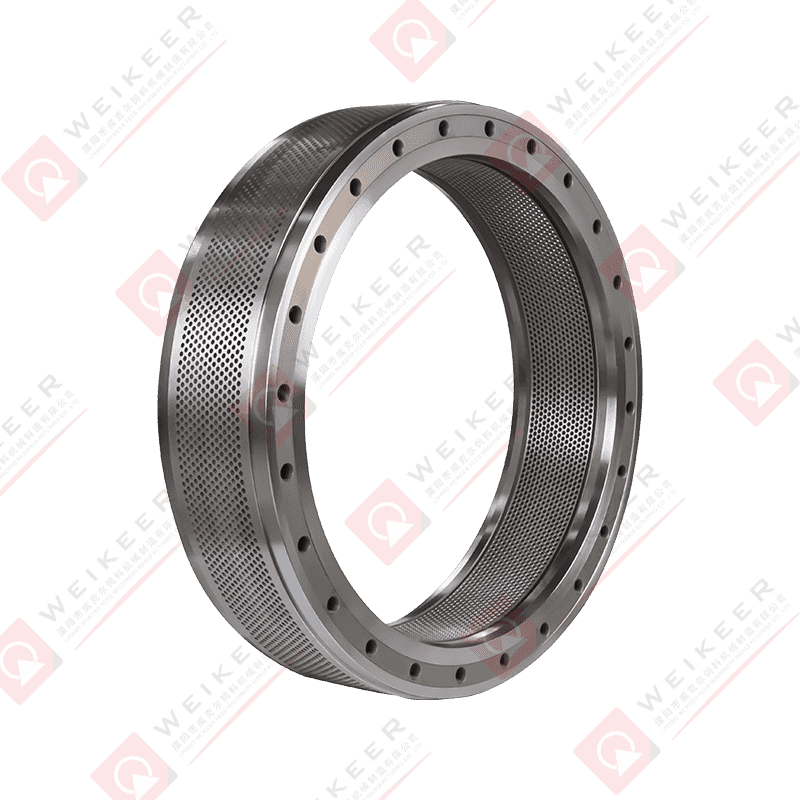

Effective Working Area

The effective working area refers to the portion of the ring die that actively produces pellets during operation. This specification directly correlates with production capacity and should match your throughput requirements. A ring die with insufficient effective area will limit production output regardless of motor power, while an oversized die may operate inefficiently at lower capacities. Calculate your required production volume and select a ring die with an effective area that allows operation at 75-85% of maximum capacity for optimal efficiency and longevity.

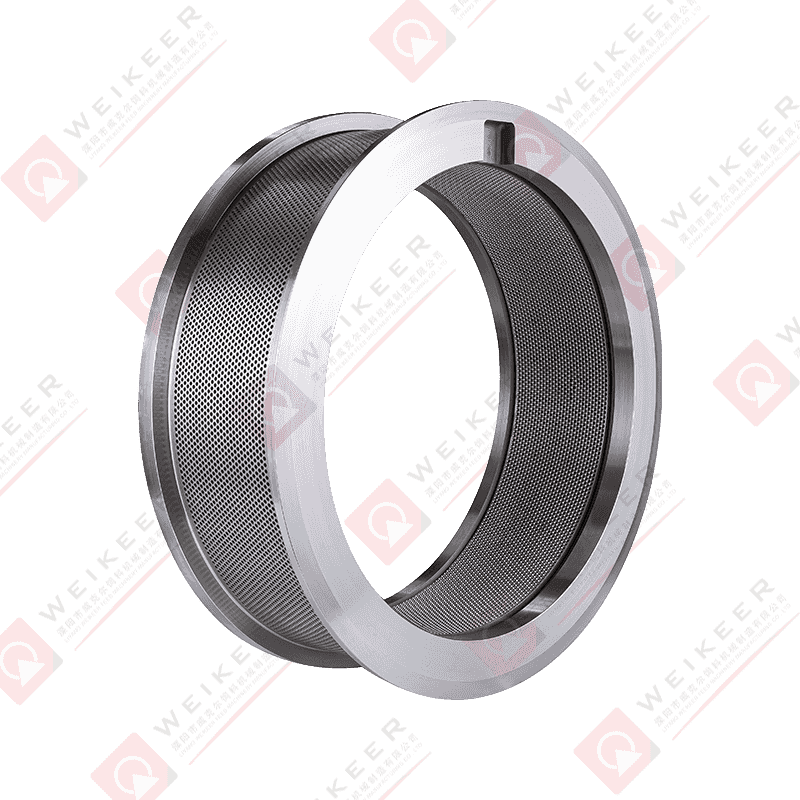

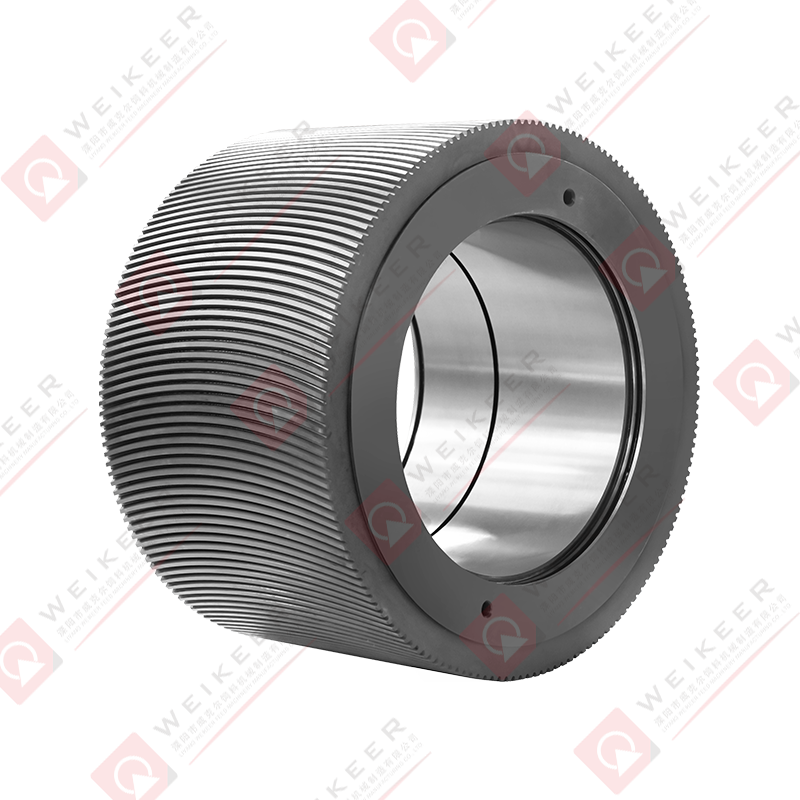

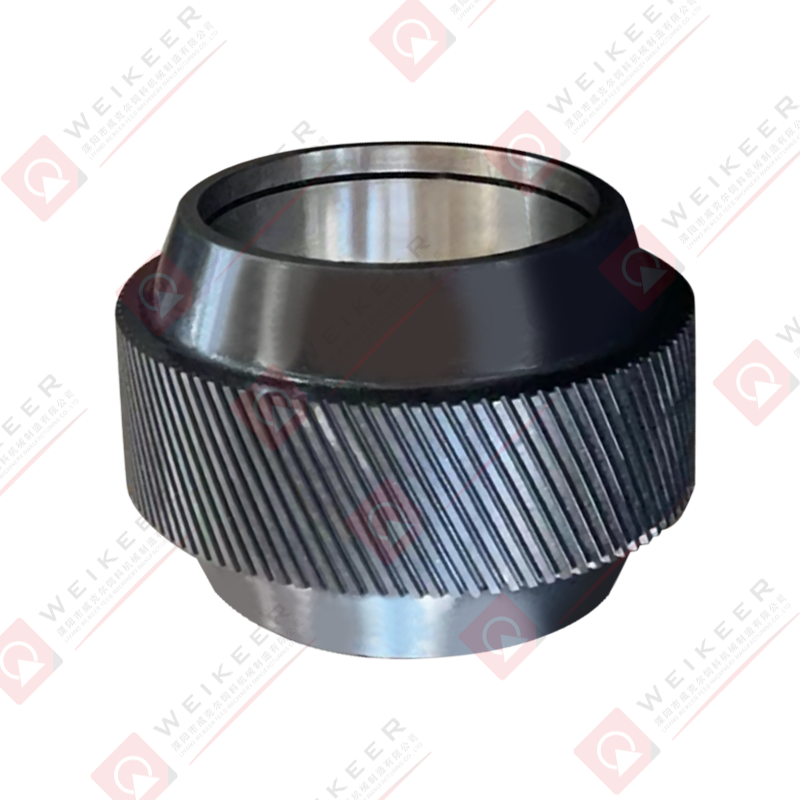

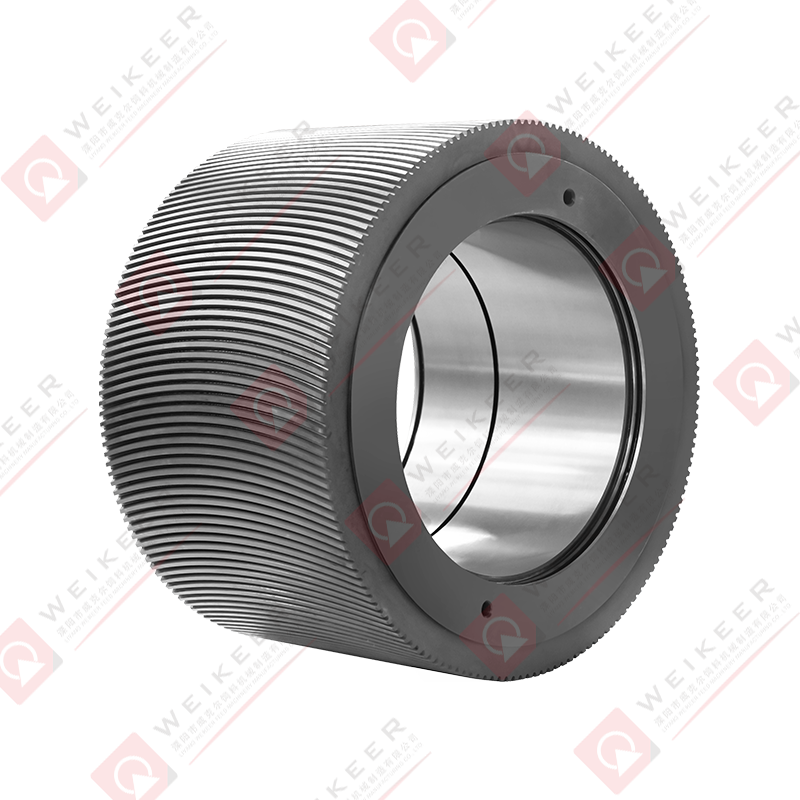

Ring Die Material Quality and Durability

The material composition of your ring die determines its lifespan, resistance to wear, and ability to maintain dimensional accuracy over time. High-quality ring dies are typically manufactured from alloy steel with specific heat treatment processes to achieve optimal hardness and toughness. The most common materials include stainless steel grades like X46Cr13, 20CrMnTi, and specialized alloys with chrome content ranging from 12% to 18%. For aqua feed production, where formulations often contain salt and moisture, corrosion-resistant materials become particularly important to prevent premature degradation and contamination of the final product.

Surface hardening treatments such as vacuum heat treatment, carburizing, or nitriding can significantly extend ring die life. Premium ring dies undergo precision drilling using CNC machinery, ensuring consistent hole dimensions throughout the die surface. The drilling quality directly affects pellet uniformity and production stability. When evaluating ring die options, inquire about the manufacturing process, heat treatment specifications, and expected lifespan under your specific operating conditions. While higher-quality dies command premium prices, their extended service life and superior performance often result in lower total cost of ownership.

Matching Ring Die to Feed Formulation

Different feed formulations exhibit varying pelleting characteristics based on their ingredient composition, moisture content, and physical properties. Understanding your formulation's behavior is essential for selecting the appropriate ring die configuration. High-starch formulations typically pellet more easily due to the natural binding properties of gelatinized starch, allowing for lower compression ratios and wider processing windows. Conversely, high-protein formulations with limited starch content require more aggressive compression and may benefit from specialized die configurations with relief holes or counterbores to reduce back pressure and prevent die choking.

| Feed Type |

Recommended Compression Ratio |

Typical Hole Diameter |

Material Hardness |

| Shrimp Feed |

1:8 to 1:10 |

0.8-2.5mm |

HRC 55-60 |

| Fish Fry Feed |

1:7 to 1:9 |

1.0-3.0mm |

HRC 54-58 |

| Grower Fish Feed |

1:9 to 1:11 |

3.0-6.0mm |

HRC 56-60 |

| High-Fiber Feed |

1:10 to 1:13 |

4.0-8.0mm |

HRC 58-62 |

The moisture content of your feed mixture before pelleting also influences ring die selection. Most aqua feed formulations require conditioning to 15-18% moisture content for optimal pelleting. Formulations at the lower end of this range may benefit from dies with slightly higher compression ratios to ensure adequate pellet binding, while those with higher moisture content can use lower compression ratios. Additionally, the inclusion of binders, oils, and other additives affects the flow characteristics and required compression, necessitating careful consideration during die selection.

Evaluating Ring Die Manufacturers and Quality Standards

Not all ring die manufacturers maintain the same quality standards, and selecting a reputable supplier is as important as choosing the correct specifications. Established manufacturers typically offer comprehensive technical support, including formulation analysis and die specification recommendations based on your specific requirements. Look for manufacturers with proven experience in aqua feed applications, as the unique demands of water-stable pellets require specialized expertise. Request sample dies or trial periods when possible, allowing you to verify performance under actual production conditions before committing to large purchases.

Quality certifications and manufacturing standards provide valuable indicators of ring die reliability. ISO 9001 certification demonstrates a manufacturer's commitment to quality management systems, while specific material certifications verify the alloy composition and heat treatment processes. Request detailed specifications including material composition certificates, hardness testing results, and dimensional tolerance data. Premium manufacturers often provide die mapping services, documenting the specific configuration and performance characteristics of each die for future reference and reordering.

Installation and Break-In Procedures

Proper installation and break-in procedures are essential for maximizing ring die performance and longevity. New ring dies require a gradual break-in period to achieve optimal operating conditions. Begin with formulations that pellet easily and gradually introduce your standard production formulas. During the initial 4-8 hours of operation, monitor die temperature, power consumption, and pellet quality closely. Properly broken-in dies develop a polished surface inside the holes that reduces friction and improves pellet flow, enhancing both capacity and efficiency.

Before installing a new ring die, ensure all mounting surfaces are clean and free from debris or damage. Verify that the die is properly aligned and securely fastened according to manufacturer specifications. Improper installation can lead to uneven wear, vibration, and premature failure. During the break-in period, expect slightly lower production rates and higher power consumption than steady-state operation. This temporary reduction is normal and necessary for developing the optimal working surface within the die holes.

Maintenance and Service Life Optimization

Regular maintenance significantly extends ring die service life and maintains consistent pellet quality. Implement a routine inspection schedule to monitor die condition, checking for signs of wear, damage, or hole enlargement. Common wear patterns include hole bell-mouthing on the inlet side and polishing on the outlet side. Measure hole diameters periodically using precision gauges to track wear progression and plan replacement before quality issues arise. Most aqua feed ring dies can produce between 2,000 and 5,000 tons of pellets before requiring replacement, though actual life varies based on formulation abrasiveness and operating conditions.

Proper cleaning procedures prevent buildup and corrosion that can shorten die life. After production runs, purge the die with an oil-based flushing agent or specially formulated die cleaner to prevent material from hardening inside the holes. For extended shutdowns, coat the die with food-grade oil to prevent rust and corrosion. Store unused dies in a dry, temperature-controlled environment to preserve their condition. Some manufacturers offer reconditioning services that can restore worn dies to near-original specifications at a fraction of the cost of replacement, providing a cost-effective option for extending equipment investment.

Cost Considerations and ROI Analysis

While initial purchase price is an important consideration, total cost of ownership provides a more accurate basis for ring die selection. A premium ring die that costs 30-50% more than a budget alternative but lasts twice as long and produces higher quality pellets delivers superior value. Calculate the cost per ton of finished product, factoring in die purchase price, expected service life, production capacity, energy consumption, and pellet quality improvements. Higher-quality dies often enable increased production speeds and reduced downtime, contributing to improved overall profitability.

Consider maintaining an inventory of ring dies with different specifications to accommodate various production requirements and provide backup capacity. Having spare dies on hand minimizes downtime when changes are needed or unexpected wear occurs. For operations with multiple formulations or species requirements, investing in a range of dies optimized for specific applications yields better results than attempting to use a single compromise configuration. Track performance metrics for each die including production volume, pellet quality parameters, energy consumption, and maintenance requirements to inform future purchasing decisions and optimize your die inventory.

Common Problems and Troubleshooting Solutions

Understanding common ring die problems helps you identify issues quickly and implement appropriate solutions. Die choking, where material blocks the holes and prevents pellet flow, typically indicates excessive compression ratio, insufficient conditioning, or formulation problems. Reduce compression ratio or improve conditioning to resolve this issue. Poor pellet quality with excessive fines or soft pellets suggests insufficient compression, inadequate conditioning temperature, or worn die holes. Verify die specifications match your formulation and check conditioning system performance.

- Uneven wear patterns indicate alignment problems, roller issues, or material flow imbalances requiring equipment inspection and adjustment

- Excessive power consumption may result from oversized die holes, incorrect compression ratio, or insufficient conditioning moisture

- Pellet length variation suggests knife adjustment needs, inconsistent material flow, or die hole enlargement from wear

- Hot spots or smoking during operation indicate inadequate lubrication, excessive friction, or incorrect die specification for the formulation

- Rapid die wear points to abrasive formulation ingredients, insufficient die hardness, or contamination with foreign materials

Selecting the right ring die for your pellet machine requires careful consideration of multiple factors including feed formulation characteristics, production requirements, quality standards, and operational conditions. By understanding the technical specifications, material quality indicators, and performance criteria outlined in this guide, you can make informed decisions that optimize your aqua feed production efficiency, pellet quality, and equipment longevity. Regular monitoring, proper maintenance, and partnership with reputable suppliers ensure your ring die investment delivers maximum value throughout its service life.

русский

русский Español

Español عربى

عربى 中文简体

中文简体